Abstract

Although solid Au is usually most stable as a face-centered cubic (fcc) structure, pure hexagonal close-packed (hcp) Au has been successfully fabricated recently. However, the phase stability and mechanical property of this new material are unclear, which may restrict its further applications. Here we present the evidence that hcp → fcc phase transformation can proceed easily in Au by first-principles calculations. The extremely low generalized-stacking-fault (GSF) energy in the basal slip system implies a great tendency to form basal stacking faults, which opens the door to phase transformation from hcp to fcc. Moreover, the Au lattice extends slightly within the superficial layers due to the self-assembly of alkanethiolate species on hcp Au (0001) surface, which may also contribute to the hcp → fcc phase transformation. Compared with hcp Mg, the GSF energies for non-basal slip systems and the twin-boundary (TB) energies for  and

and  twins are larger in hcp Au, which indicates the more difficulty in generating non-basal stacking faults and twins. The findings provide new insights for understanding the nature of the hcp → fcc phase transformation and guide the experiments of fabricating and developing materials with new structures.

twins are larger in hcp Au, which indicates the more difficulty in generating non-basal stacking faults and twins. The findings provide new insights for understanding the nature of the hcp → fcc phase transformation and guide the experiments of fabricating and developing materials with new structures.

Similar content being viewed by others

Introduction

In recent years, many new materials of nanoparticles have been synthesized and applied in potential domains. Note that there is often phase transformation among face-centered cubic (fcc), body-centered cubic (bcc) and hexagonal closed-packed (hcp) systems in mono-component nanocrystal superlattices, especially for the noble metal nanostructures1,2,3,4,5,6,7,8,9. This can be attributed to the diffusion of guest molecules (e.g. dodecanethiol)3, surface stress4,5, specific stacking processes depending on evaporation kinetics6 and high pressure7,8 etc. Solid Au is usually most stable as an fcc structure. Surprisingly, Huang et al.1 have reported the first in situ synthesis of pure hcp Au square sheets on graphene oxide, which possess an edge length of 200–500 nm and a thickness of ~2.4 nm (~16 Au atomic layers). The exclusive hcp phase, which is stable under ambient conditions, provides a significant basis for fabricating novel Au architectures with unique chemical and physical properties10. Recently, it is observed that a large value of initial residual stress drives the fcc/hcp phase transformation in [100]/{100} Au nanowires during the energy minimization process, as conducted by molecular dynamics simulation5. Moreover, Stoeva et al.11 reported that Au particles obtained by the solvated metal atom dispersion method predominantly organized into hcp nanocrystal superlattices with long-range translational ordering.

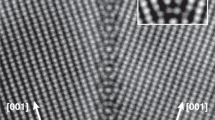

Note that structural defects such as point defects, stacking faults, dislocations, twins and grain boundaries can be observed in nanocrystal superlattices12, which are similar to the phenomena shown in classical crystals. In hcp Au nanocrystal, the stacking faults and twin defects were both indicated by transmission electron microscope (TEM)1. With the appearance of faulted stacking in hcp structures, the ideal hcp packing sequence (…ABABAB…) would exhibit partial fcc feature, e.g. the ABC sequence in I2 (…ABABCACA…) and T2 (…ABABCBABA…) stacking faults. Therefore, the stacking faults in one system can be actually regarded as the presence of a segment of the other2. Moreover, the mixed stacking of hcp and fcc planes was confirmed in Au plates, suggesting that the pure hcp phase will become less stable when the Au sheets grow thicker1. Since the close relationship between the stacking faults and phase transformation, it is necessary to investigate the defect properties of hcp Au, so as to evaluate the structural stability and growth mechanism of this new material.

Furthermore, the first synthesis of hcp Au stimulates us to explore its novel mechanical properties and to make comparisons with common hcp structures, e.g. Mg, in anticipation of developing new materials which are distinct from those natural crystals for wider application. On the atomic level, the plastic formability of hcp crystals is closely related to the ease of the formation of dislocations and twins. Note that the GSF energy, which quantifies the ability of the dislocation in a crystal to glide onto an intersecting slip plane, affects the nucleation and mobility of dislocations13 as well as the propensities to form twins14. Meanwhile, the TB energy is intimately connected with the mobility of twinning dislocations15, without referring to the atomic shuffling during the nucleation of twins in hcp crystals. Therefore, the TB energies mainly depict the stability of twin structures without involving the formation dynamics.

Though these defect parameters are significant in reflecting the mechanical properties of hcp Au, they are difficult to be investigated experimentally due to the structural instability. Moreover, a universal fcc to hcp phase transformation is possible only when the dimension of Au nanostructure decreases to a critical value, which also increases the difficulty in detecting the hcp Au phase by experiments. Alternatively, the first-principles method based on density functional theory (DFT)16 has emerged as a key technology in determining the properties of material, which enables the calculation of defect energies at a reasonable computational cost. Therefore, the main purpose of this paper is to study the energies of stacking faults and twin boundaries in hcp Au using first-principles method. For the calculation of GSF energy, the basal slip system ( and

and  ), prismatic slip system (

), prismatic slip system ( ) and pyramidal slip system (

) and pyramidal slip system ( and

and  ) are considered respectively, as illustrated in Fig. 1. Meanwhile, the

) are considered respectively, as illustrated in Fig. 1. Meanwhile, the  mirror reflection, the

mirror reflection, the  mirror glide as well as the

mirror glide as well as the  mirror reflection and the

mirror reflection and the  mirror glide twin boundaries are taken into account when calculating the TB energy. In addition, the elastic properties of hcp Au, which are associated with the brittleness and ductility of materials17, are also calculated for the systematic study of hcp Au. For comparison, the corresponding physical parameters for fcc Au and hcp Mg are listed as well, in order to estimate the structural stability and application of hcp Au. Note that a lot of surfactant molecules adsorb on the surface of Au nanostructure during the synthesis processes1,2,3. Therefore, the effect of the thiol surfactant to the crystal lattice of hcp Au is also investigated. The intrinsic parameters in this calculation contribute to completing the theoretical database of hcp Au and act as a guide to experiments of fabricating and developing materials with new structure.

mirror glide twin boundaries are taken into account when calculating the TB energy. In addition, the elastic properties of hcp Au, which are associated with the brittleness and ductility of materials17, are also calculated for the systematic study of hcp Au. For comparison, the corresponding physical parameters for fcc Au and hcp Mg are listed as well, in order to estimate the structural stability and application of hcp Au. Note that a lot of surfactant molecules adsorb on the surface of Au nanostructure during the synthesis processes1,2,3. Therefore, the effect of the thiol surfactant to the crystal lattice of hcp Au is also investigated. The intrinsic parameters in this calculation contribute to completing the theoretical database of hcp Au and act as a guide to experiments of fabricating and developing materials with new structure.

Results and discussion

Structural parameters

The calculated equilibrium lattice constants and cohesive energy for fcc Au, hcp Au and Mg are listed in Table 1. For hcp Au, the structural parameters (a = 2.952 Å, c = 4.885 Å) in our work are in acceptable tolerance with the values of the experiment (a = 2.96 Å, c = 4.84 Å)1 and other simulation (a = 2.927 Å, c = 4.903 Å)18. The c/a ratio of hcp Au (1.655) is larger than that of Mg (1.608), implying larger anisotropy in lattice parameters for hcp Au. Note that the lattice constant for primitive cell of fcc Au ( Å) is very close to that of hcp Au (2.952 Å), which reveals the intrinsic link between the fcc and hcp phase. Moreover, the cohesive energy (

Å) is very close to that of hcp Au (2.952 Å), which reveals the intrinsic link between the fcc and hcp phase. Moreover, the cohesive energy ( ) of hcp Au (−3.2045 eV) is negative, indicating that the existence of this new phase is energetically favorable. According to the energetic results, the stability of crystal is sequenced as: fcc Au >hcp Au.

) of hcp Au (−3.2045 eV) is negative, indicating that the existence of this new phase is energetically favorable. According to the energetic results, the stability of crystal is sequenced as: fcc Au >hcp Au.

Surfactant effect

In hcp Au nanostructure, a lot of surfactant molecules adsorbed on its surface1,2. In view of the molecule-surface interactions, the effect of the surfactant, e.g. thiols, to the lattice constant of hcp Au is investigated. Spontaneous formation of an ordered molecular over-layer on the gold surfaces has been found for the thiols, namely molecular self-assembly. A series of experiments has revealed the Au (111) surface releases gold adatoms that become incorporated into the monolayer19,20,21,22. This configuration is further confirmed by the Au top-site adsorption of alkanethiolate in experiments23,24.

For hcp Au (0001) surface, the Au-adtom-induced self assembly of alkanethiolate species is presented analogy to the fcc Au (111) surface. Accordingly, a 4 × 2 slab (along the  and

and  direction) with 9 layers was constructed, separated by a 12 Å vacuum. Upon relaxation, the Au adatom locates at the twofold bridge site and the headgroup-S atom of CH3S occupies the Au top-site as shown in Fig. 2a,b. The distribution of Au adatom and alkanethiolate species on hcp Au (0001) surface is similar to that on fcc Au (111). This originates from the same in-plane atomic coordination on the two close packed planes. Meanwhile, the S atom is attached to both the Au adatom (Aua in Fig. 2a) and the underlying lattice atom (Aul in Fig. 2a) with r(S-Aua) = 2.344 Å and r(S-Aul) = 2.523 Å respectively. These values are very close to the 2.33 Å and 2.49 Å in the case of adoption of alkanethiolate on fcc Au (111)19. The binding energy of the CH3S- species and the Au substrate is 2.08 eV, which is smaller than the value of cohesive energy for hcp Au, i.e. 3.2045 eV (Table 1).

direction) with 9 layers was constructed, separated by a 12 Å vacuum. Upon relaxation, the Au adatom locates at the twofold bridge site and the headgroup-S atom of CH3S occupies the Au top-site as shown in Fig. 2a,b. The distribution of Au adatom and alkanethiolate species on hcp Au (0001) surface is similar to that on fcc Au (111). This originates from the same in-plane atomic coordination on the two close packed planes. Meanwhile, the S atom is attached to both the Au adatom (Aua in Fig. 2a) and the underlying lattice atom (Aul in Fig. 2a) with r(S-Aua) = 2.344 Å and r(S-Aul) = 2.523 Å respectively. These values are very close to the 2.33 Å and 2.49 Å in the case of adoption of alkanethiolate on fcc Au (111)19. The binding energy of the CH3S- species and the Au substrate is 2.08 eV, which is smaller than the value of cohesive energy for hcp Au, i.e. 3.2045 eV (Table 1).

Note that the formation of bare hcp Au (0001) surface is accompanied by charge transfer from the dangling bonds into the in-plane bonds, which increases the attraction between the surface atoms. The adoption of S with strong electronegativity leads to a charge redistribution into the surface-molecule bonds, which weakens the attraction between surface Au atoms and increases the superficial lattice constant. For the adoption of alkanethiolate on hcp Au (0001) surface, the average in-plane distance between Aul and surrounding Au atoms ( ) is increased from 2.952 Å to 2.997 Å. Such adsorbate-induced surface stress has also been confirmed in alkanethiolate-Au (111) self-assembled monolayers25. Moreover, the adsorption of alkanethiolate surfactant results in increased tensile stress when the S-C bond is normal to the surface and therefore gives rise to a significant expansion of the Au lattice (

) is increased from 2.952 Å to 2.997 Å. Such adsorbate-induced surface stress has also been confirmed in alkanethiolate-Au (111) self-assembled monolayers25. Moreover, the adsorption of alkanethiolate surfactant results in increased tensile stress when the S-C bond is normal to the surface and therefore gives rise to a significant expansion of the Au lattice ( : 3.049 Å). This situation is remedied to some extent by the tilting of the S-C bond (

: 3.049 Å). This situation is remedied to some extent by the tilting of the S-C bond ( : 2.997 Å). The resulting directionality of the S-C bond leads to a preferred value of the C-S-Aul bond angle of 106.5°.

: 2.997 Å). The resulting directionality of the S-C bond leads to a preferred value of the C-S-Aul bond angle of 106.5°.

The covalent character of the S-Au bond also expands the inter-planar spacing between the superficial hcp Au (0001) planes slightly. The average distance between the A1 and A2 layers (see Fig. 2a,  ) is 4.895 Å for the adsorption of alkanethiolate species, which is 4.890 Å on the bare hcp Au (0001) surface. Note that the titling of the S-C bond also alleviates the expansion of inter-planar spacing, i.e. the value of

) is 4.895 Å for the adsorption of alkanethiolate species, which is 4.890 Å on the bare hcp Au (0001) surface. Note that the titling of the S-C bond also alleviates the expansion of inter-planar spacing, i.e. the value of  is 4.912 Å if the S-C bond is normal to the surface. The lattice parameters in the underlying layers (a = 2.952 Å, c = 4.887 Å) are similar to those of hcp Au bulk (a = 2.952 Å, c = 4.885 Å).

is 4.912 Å if the S-C bond is normal to the surface. The lattice parameters in the underlying layers (a = 2.952 Å, c = 4.887 Å) are similar to those of hcp Au bulk (a = 2.952 Å, c = 4.885 Å).

The adsorption of alkanethiolate molecules on hcp Au (0001) surface enlarges the gold lattice in the superficial layers (e.g. the three outer layers), while it has slight effect in the underlying layers. The extension of surface lattice constants may facilitate the hcp Æ fcc phase transformation, as the lattice parameter a of hcp Au (2.952 Å) is smaller than that for the primitive cell of fcc Au ( Å). Moreover, the fcc Æhcp transformation of Au is proven to involve the compression of lattice along the

Å). Moreover, the fcc Æhcp transformation of Au is proven to involve the compression of lattice along the  direction22 and it in turn is predicted to be an expansion process for the hcp → fcc transformation. However, more experimental evidences are in expectation.

direction22 and it in turn is predicted to be an expansion process for the hcp → fcc transformation. However, more experimental evidences are in expectation.

GSF energy

To calculate the GSF energies of hcp Au, which reflects its bulk property, a 16-layer slab (32-atom) is constructed based on the optimized unit cell (a = 2.952 Å, c = 4.885 Å). Five slip systems for both hcp Au and Mg are taken into account, as shown in Fig. 1. Specifically, the three < a > -type slip systems ( ,

,  and

and  ) are considered. Moreover, the second pyramidal slip system (

) are considered. Moreover, the second pyramidal slip system ( ), which is responsible for accommodating the strains of c- and a-axis simultaneously, is also calculated. Meanwhile, the basal slip system (

), which is responsible for accommodating the strains of c- and a-axis simultaneously, is also calculated. Meanwhile, the basal slip system ( ) is considered, as the dissociation of perfect dislocations into partial dislocations is energetically favorable26:

) is considered, as the dissociation of perfect dislocations into partial dislocations is energetically favorable26:

For fcc Au, the GSF energies are calculated in the primary slip system ( ).

).

The GSF energy curves ( -curve), which express the initiation of one whole stacking fault, were plotted against the applied shift vector for fcc Au, hcp Au and Mg in Fig. 3a–f. Hereinto, the maximum energy on the

-curve), which express the initiation of one whole stacking fault, were plotted against the applied shift vector for fcc Au, hcp Au and Mg in Fig. 3a–f. Hereinto, the maximum energy on the  -curve is the unstable SFE

-curve is the unstable SFE  , which denotes the lowest energy barrier for dislocation nucleation27, while the local minimum indicates the intrinsic SFE

, which denotes the lowest energy barrier for dislocation nucleation27, while the local minimum indicates the intrinsic SFE  28. The computed

28. The computed  and

and  values are marked on the

values are marked on the  curves and summarized in Table 2, together with those obtained by other first-principles predictions29,30,31,32,33,34. Note that the GSF energies for Mg32 in different slip systems accord with the results calculated by others29,30,31,32,33,34, which proves the accuracy of our calculations.

curves and summarized in Table 2, together with those obtained by other first-principles predictions29,30,31,32,33,34. Note that the GSF energies for Mg32 in different slip systems accord with the results calculated by others29,30,31,32,33,34, which proves the accuracy of our calculations.

) and the intrinsic stacking fault energy (

) and the intrinsic stacking fault energy ( ) for hcp Au, Mg and fcc Au in different slip systems.

) for hcp Au, Mg and fcc Au in different slip systems.In slip systems  (Fig. 3a),

(Fig. 3a),  (Fig. 3b) and

(Fig. 3b) and  (Fig. 3f), the

(Fig. 3f), the  curves keep saddle-shaped, in which the local maximum and minimum values both exist. However, there is no local minimum on the GSF energy curves of the

curves keep saddle-shaped, in which the local maximum and minimum values both exist. However, there is no local minimum on the GSF energy curves of the  (Fig. 3c),

(Fig. 3c),  (Fig. 3d) and

(Fig. 3d) and  (Fig. 3e) system.

(Fig. 3e) system.

In  system of fcc Au, the

system of fcc Au, the  (83.6 mJ/m2) and

(83.6 mJ/m2) and  (24.3 mJ/m2) values for the intrinsic I stacking fault are close to the results (94 and 27 mJ/m2) of Wu et al32. For some common fcc metals, the energy barrier (

(24.3 mJ/m2) values for the intrinsic I stacking fault are close to the results (94 and 27 mJ/m2) of Wu et al32. For some common fcc metals, the energy barrier ( ) for the initiation of the I structure is: 169 mJ/m2 (Al)35, 180 mJ/m2 (Cu)35, 305 mJ/m2 (Ni)36, 111 mJ/m2 (Ag)32, 311 mJ/m2 (Pt)32 and 215 mJ/m2 (Pd)32. By comparison, the relatively low GSF energy for fcc Au indicates the ease of slip and thus, good plasticity.

) for the initiation of the I structure is: 169 mJ/m2 (Al)35, 180 mJ/m2 (Cu)35, 305 mJ/m2 (Ni)36, 111 mJ/m2 (Ag)32, 311 mJ/m2 (Pt)32 and 215 mJ/m2 (Pd)32. By comparison, the relatively low GSF energy for fcc Au indicates the ease of slip and thus, good plasticity.

In hcp Au and Mg, the  curves for different slip systems show similar trends in variation, e.g. the existence of

curves for different slip systems show similar trends in variation, e.g. the existence of  and

and  corresponding to approximately the same fault vector (abnormal:

corresponding to approximately the same fault vector (abnormal:  in

in  system). The GSF energies of hcp Au for five slip systems are sequenced as:

system). The GSF energies of hcp Au for five slip systems are sequenced as:  <

<  <

<  <

<  <

<  .

.

In the basal  slip system, the

slip system, the  and

and  values are apparently lower for hcp Au than those for hcp Mg and are even lower than those for fcc Au. Specially, the

values are apparently lower for hcp Au than those for hcp Mg and are even lower than those for fcc Au. Specially, the  values for the intrinsic (I2) and twin-like (T2) faults are even negative, implying that the I2 (…ABABABCACACA…) and T2 (…ABABABCBABAB…) can form extremely easily. In the basal

values for the intrinsic (I2) and twin-like (T2) faults are even negative, implying that the I2 (…ABABABCACACA…) and T2 (…ABABABCBABAB…) can form extremely easily. In the basal  slip system, the

slip system, the  value of hcp Au is 12.3% lower than that of hcp Mg. This also indicates that the basal stacking faults can form more easily in hcp Au than in hcp Mg. Once the basal stacking faults generate, the segment of fcc crystal will appear, which is regarded as the beginning of hcp → fcc phase transformation. Accordingly, the hcp Au is predicted to be unstable. Moreover, the experimental evidence has been validated that hcp → fcc phase transformation of Au can proceed easily, e.g. when the Au sheet is exposed to an electron beam or grows thicker1.

value of hcp Au is 12.3% lower than that of hcp Mg. This also indicates that the basal stacking faults can form more easily in hcp Au than in hcp Mg. Once the basal stacking faults generate, the segment of fcc crystal will appear, which is regarded as the beginning of hcp → fcc phase transformation. Accordingly, the hcp Au is predicted to be unstable. Moreover, the experimental evidence has been validated that hcp → fcc phase transformation of Au can proceed easily, e.g. when the Au sheet is exposed to an electron beam or grows thicker1.

In the prismatic  as well as pyramidal

as well as pyramidal  and

and  slip systems, the

slip systems, the  values of hcp Au are larger than those of hcp Mg by about 15.0%, 22.0% and 42.4% respectively. Therefore, the difficulties are increased in generating non-basal stacking faults for hcp Au compared with Mg.

values of hcp Au are larger than those of hcp Mg by about 15.0%, 22.0% and 42.4% respectively. Therefore, the difficulties are increased in generating non-basal stacking faults for hcp Au compared with Mg.

TB energy

The  mirror reflection,

mirror reflection,  mirror glide,

mirror glide,  mirror reflection and

mirror reflection and  mirror glide twin boundaries were constructed following Wang et al.’s work34, as illustrated in Fig. 4a–d respectively. The grey and gold balls in supercells represent the two kinds of stacking planes along the

mirror glide twin boundaries were constructed following Wang et al.’s work34, as illustrated in Fig. 4a–d respectively. The grey and gold balls in supercells represent the two kinds of stacking planes along the  in hcp Au. The rotation angle between the hcp matrix and the twin is 87.4° and 124.8° for

in hcp Au. The rotation angle between the hcp matrix and the twin is 87.4° and 124.8° for  and

and  twins, respectively.

twins, respectively.

The TB energies for hcp Au and Mg are summarized in Table 3 and the results of Mg are shown to agree with the data reported by Wang et al.34. Considering the  and

and  twin boundaries separately, the corresponding TB energies are close in values for mirror reflection and mirror glide-type twins. Therefore, it is predicted that the glide of the interfacial crystal planes have minor effects on the TB energies. Similar results have also been obtained in Wang et al.’s work34. Moreover, the twin structures with 15 and 17 layers are adopted here to investigate the effects of supercell sizes on the TB energies. For

twin boundaries separately, the corresponding TB energies are close in values for mirror reflection and mirror glide-type twins. Therefore, it is predicted that the glide of the interfacial crystal planes have minor effects on the TB energies. Similar results have also been obtained in Wang et al.’s work34. Moreover, the twin structures with 15 and 17 layers are adopted here to investigate the effects of supercell sizes on the TB energies. For  mirror reflection twin boundaries, increasing the supercell size by up to 34 atoms can only decrease the TB energies of hcp Au by about 7.8%. For

mirror reflection twin boundaries, increasing the supercell size by up to 34 atoms can only decrease the TB energies of hcp Au by about 7.8%. For  mirror glide,

mirror glide,  mirror reflection and mirror glide twin boundaries, the TB energies of Au34 (17 layers) are slightly larger than those of Au30 (15 layers) by less than 3.7%. Accordingly, the calculated TB energies show weak dependence on the adopted supercell size.

mirror reflection and mirror glide twin boundaries, the TB energies of Au34 (17 layers) are slightly larger than those of Au30 (15 layers) by less than 3.7%. Accordingly, the calculated TB energies show weak dependence on the adopted supercell size.

The TB energies mainly reflect the stability of twin structures without referring to the nucleation course of twins. By comparison, the TB energies are larger in hcp Au than in hcp Mg for the four twin types, implying less stability of twin structures in the former case. Moreover, the  TB energies in hcp Au are lower than

TB energies in hcp Au are lower than  TB energies, which is the same as the situation in Mg.

TB energies, which is the same as the situation in Mg.

Elastic property

For a hexagonal solid, there are five independent elastic constants, namely, C11, C12, C13, C33 and C55. For a cubic crystal, there are only three independent elastic constants, namely, C11, C12 and C44. The elastic constants for hcp Au, Mg and fcc Au are calculated and listed in Table 4. Note that our calculated Cij values agree well with the results of Shang et al.37,38, in which the stability of pure elements was successfully discussed in terms of the elasticity. The acceptable tolerance between our results and other simulation37,38 indicates the accuracy of our work.

Based on the predicted Cij’s, the mechanical stability for a given structure can be judged according to Born’s criteria39,40:  ,

,  and

and  for hexagonal system; and

for hexagonal system; and  ,

,  and

and  for cubic system.

for cubic system.

Note that hcp Mg and fcc Au, which have stable structures at room temperature, satisfy the above Born criteria for mechanical stability. Meanwhile, the new material hcp Au also accords with the Born’s criteria, implying the mechanically metastable. The results of elastic constants confirm the possibility of fabricating pure and stable hcp Au under ambient conditions1. Although the elastic property demonstrates that hcp Au is metastable, the phase transformation from hcp to fcc is still predicted to proceed easily according to the GSF energies and the surfactant effect, which is also in good agreement with the experimental observation1.

Starting from Cij’s, the polycrystalline aggregate properties such as bulk modulus (B), shear modulus (G) and Young’s modulus (E) are calculated according to the Voigt41 (Bv and Gv), Reuss42 (Br and Gr) and Hill43 approximations and indicated in Table 4. Surprisingly, the G of hcp Au (19.5 GPa) is comparable to that of hcp Mg (21.5 GPa) and fcc Au (26.8 GPa). Moreover, the values of B are similar between hcp Au (140.2 GPa) and fcc Au (137.6 GPa) and are far larger than that for hcp Mg (36.4 GPa). Therefore, hcp Au possesses potential application prospect and it is of great significance to in situ synthesize the pure hcp Au in experiment1. Meanwhile, more methods are still in urgent need involving hindering the hcp → fcc phase transformation and stabilizing hcp Au structure.

In summary, we perform systematic first-principles calculations to predict the structural parameters, GSF energies, TB energies and surfactant effect to hcp Au, in anticipation of evaluating the structural stability and mechanical properties of this new material. Originating from the self-assembly of alkanethiolate species on hcp Au (0001), a slight extension of surface lattice is found, which may be related to the ease of the hcp → fcc phase transformation. Furthermore, the comparisons are made among hcp Au, fcc Au and hcp Mg. In the basal  and

and  slip systems, the GSF energies (

slip systems, the GSF energies ( ) are apparently lower for hcp Au than those for hcp Mg and even for fcc Au. Accordingly, the basal stacking faults with partial fcc feature may generate more frequently in hcp Au, which facilities the transformation to an fcc phase. In the prismatic

) are apparently lower for hcp Au than those for hcp Mg and even for fcc Au. Accordingly, the basal stacking faults with partial fcc feature may generate more frequently in hcp Au, which facilities the transformation to an fcc phase. In the prismatic  as well as pyramidal

as well as pyramidal  and

and  slip systems, the larger

slip systems, the larger  values for hcp Au than for hcp Mg indicate the increased difficulties in generating non-basal stacking faults in the former case. Moreover, the TB energies of

values for hcp Au than for hcp Mg indicate the increased difficulties in generating non-basal stacking faults in the former case. Moreover, the TB energies of  and

and  twins are larger in hcp Au than in hcp Mg, implying less stability of twin boundaries in hcp Au. The mechanically metastable of hcp Au is proved in terms of Born’s criteria, which verifies the existence of this new phase, however it still shows great tendency to transform to the fcc phase because of the easy operation of basal stacking faults and the surfactant effect. The calculated values can serve as the input for the future simulation of the growth process of these planar defects and contribute to guiding the experiments of fabricating and developing materials with new structure.

twins are larger in hcp Au than in hcp Mg, implying less stability of twin boundaries in hcp Au. The mechanically metastable of hcp Au is proved in terms of Born’s criteria, which verifies the existence of this new phase, however it still shows great tendency to transform to the fcc phase because of the easy operation of basal stacking faults and the surfactant effect. The calculated values can serve as the input for the future simulation of the growth process of these planar defects and contribute to guiding the experiments of fabricating and developing materials with new structure.

Methods

Methods and parameters for calculation

The calculation of total energy in this work was performed by the Cambridge Sequential Total Energy Package code (CASTEP)44 based on density-functional theory (DFT), in which the Perdew Wang’s45 (PW91) version of the generalized gradient approximation (GGA) was employed as exchange correlation functional. The plane-wave cutoff was set to 400 eV. The optimization was performed through the Broyden-Fletcher-Goldfarb-Shanno (BFGS) technique with the convergence tolerances: the energy change less than 5 × 10−6 eV/atom, the Hellmann–Feynman force within 0.01 eV/Å and the maximum displacement less than 5 × 10−4 Å. The Brillouin zone integration was sampled using dense Monkhorst-Pack46 k-point meshes.

The structural properties (equilibrium lattice constants, cohesive energy) of hcp Au, Mg and fcc Au were evaluated by full optimization on both equilibrium volume and atomic positions. The k-point meshes were samples as: 18 × 18 × 12 for hcp Mg and hcp Au and 12 × 12 × 12 for fcc Au. The cohesive energy ( ) of the pure elements was computed according to Formula (2):

) of the pure elements was computed according to Formula (2):

where  is the total energy of the elements in their ground-state crystal structures,

is the total energy of the elements in their ground-state crystal structures,  is the energy of isolate atom and n is the number of atoms in the crystal.

is the energy of isolate atom and n is the number of atoms in the crystal.

To evaluate the surfactant effect to the lattice constants of hcp Au, a 4 × 2 slab (along the  and

and  direction) with 9 layers was constructed, separated by a 12 Å vacuum. The plane-wave basis cutoff energy was 400 eV. The 2 × 2 × 1 k-point was utilized according to the Monkhorst-Pack scheme.

direction) with 9 layers was constructed, separated by a 12 Å vacuum. The plane-wave basis cutoff energy was 400 eV. The 2 × 2 × 1 k-point was utilized according to the Monkhorst-Pack scheme.

Calculation of the GSF energy

The GSF energy can be obtained by incrementally shifting the upper half crystal along the slip direction and calculating the energy differences per unit area47, as shown in Formula (3).

where  is the total energy of the supercell with the fault vector u,

is the total energy of the supercell with the fault vector u,  stands for the energy of the perfect lattice and A represents the area of the fault planes. The stacking-fault vector u varies from 0.0b to 1.0b with a step of 0.1b for each slip system; hereinto b is the corresponding Burgers vector. During geometry optimization, all atoms in supercells were allowed to be relaxed along z-axis, i.e. the direction normal to the slip planes. For the calculation of the GSF energy, the k-point meshes in different systems are listed in Table 2.

stands for the energy of the perfect lattice and A represents the area of the fault planes. The stacking-fault vector u varies from 0.0b to 1.0b with a step of 0.1b for each slip system; hereinto b is the corresponding Burgers vector. During geometry optimization, all atoms in supercells were allowed to be relaxed along z-axis, i.e. the direction normal to the slip planes. For the calculation of the GSF energy, the k-point meshes in different systems are listed in Table 2.

A 32-atom hcp Au supercell containing 16 layers was constructed to calculate the GSF profiles, as illustrated by Huang et al.1. Meanwhile, a large vacuum width of 15 Å was added to accommodate the out-of-plane relaxations and to improve the calculation efficiency. The supercells with the same size were also employed for Mg. In the  slip system, the intrinsic I2 (…ABABABCACACA…) stacking fault is generated from the perfect hcp structure (…ABABABABABAB…) and the twin fault T2 (…ABABABCBABAB…) can be obtained by the further shear of I2.

slip system, the intrinsic I2 (…ABABABCACACA…) stacking fault is generated from the perfect hcp structure (…ABABABABABAB…) and the twin fault T2 (…ABABABCBABAB…) can be obtained by the further shear of I2.

Moreover, the fcc Au slabs consisting of 13 (111) planes were also constructed to calculate the GSF energy in  slip system. The intrinsic I (…ABCABCBCABCA…) stacking fault can be generated from the perfect fcc structure (…ABCABCABCABC…) and the two-layer twin fault T (…ABCABCBABCAB…) is formed basing on the further shear of I.

slip system. The intrinsic I (…ABCABCBCABCA…) stacking fault can be generated from the perfect fcc structure (…ABCABCABCABC…) and the two-layer twin fault T (…ABCABCBABCAB…) is formed basing on the further shear of I.

Calculation of the TB energy

The TB energy is depicted as the energy difference between the supercell containing twin boundary and the equivalent in bulk material34, as expressed in Formula (4).

where  and

and  correspond to the total energy of the supercells with and without twin boundaries and

correspond to the total energy of the supercells with and without twin boundaries and  represents the area of twin boundary. Note that full periodic boundary conditions were applied in our DFT calculations for both the twins and therefore, two twin boundaries exist in each supercell: one is in the middle of supercell and the other is on its top/bottom edge. Accordingly, the

represents the area of twin boundary. Note that full periodic boundary conditions were applied in our DFT calculations for both the twins and therefore, two twin boundaries exist in each supercell: one is in the middle of supercell and the other is on its top/bottom edge. Accordingly, the  is divided by 2 in Formula (4). The effect of the supercell sizes on the calculated TB energies was studied. The built supercells with different sizes are listed in Table 3, as well as the corresponding k-point meshes.

is divided by 2 in Formula (4). The effect of the supercell sizes on the calculated TB energies was studied. The built supercells with different sizes are listed in Table 3, as well as the corresponding k-point meshes.

Calculation of the elastic constants

The calculation of the elastic constants was performed by the CASTEP code. The Perdew Wang’s45 (PW91) version of the generalized gradient approximation (GGA) was employed as exchange correlation functional. The plane-wave cutoff was set to 400 eV. The Brillouin zone was sampled on 18 × 18 × 12 k-point mesh for hcp Mg and hcp Au and 12 × 12 × 12 for fcc Au based on the Monkhorst-Pack scheme46. The criteria for the convergence of optimization on atomic internal freedoms were selected as: the energy difference within 1 × 10−6 eV/atom, the maximum force within 0.002 eV/Å and the maximum displacement within 1 × 10−4 Å.

The elastic stiffness coefficients were determined from a linear fit of the calculated stress as a function of strain48. The ground-state structure was strained according to symmetry-dependent strain patterns with varying amplitudes. Subsequently, the stress tensor was computed after a re-optimization of the internal structure parameters, i.e. a geometry optimization with fixed cell parameters. The elastic stiffness coefficients are then the proportionality coefficients relating the applied stress to the computed strain. Two positive and two negative amplitudes were used for each strain component with the value of 0.001 and 0.003 respectively.

The B and G are calculated using the Voigt-Reuss-Hill approximations43 for averaging the elastic constants of the single crystal.

For hexagonal system, the Voigt values are expressed as follows41:

And the Reuss values are calculated according to Formula (7) and (8)42:

The Hill mean values are obtained by43:

For cubic system, the elastic properties (B, G, E) are calculated as follows43:

Additional Information

How to cite this article: Wang, C. et al. Generalized-stacking-fault energy and twin-boundary energy of hexagonal close-packed Au: A first-principles calculation. Sci. Rep. 5, 10213; doi: 10.1038/srep10213 (2015).

References

Huang, X. et al. Synthesis of hexagonal close-packed gold nanostructures. Nat. Commun. 2, 292–297 (2011).

Huang, X. et al. Synthesis of gold square-like plates from ultrathin gold square sheets: the evolution of structure phase and shape. Angew. Chem. Int. Ed. 50, 12245–12248 (2011).

Goubet, N. & Pileni, M. P. Negative supracrystals inducing a FCC–BCC transition in gold nanocrystal superlattices. Nano Res. 7, 171–179 (2014).

Diao, J., Gall, K. & Dunn, M. L. Surface-stress-induced phase transformation in metal nanowires. Nat. Mater. 2, 656–660 (2003).

Sutrakar, V. K. & Mahapatra, D. R. Universal stability and temperature dependent phase transformation in group VIIIB–IB transition metal FCC nanowires. J. Phys. Chem. C. 115, 10394–10398 (2011).

Pileni, M. P. Supra- and nanocrystallinities: a new scientific adventure. J. Phys. Condens. Matter 23, 503102–503110 (2011).

Ahuja, R., Rekhi, S. & Johansson, B. Theoretical prediction of a phase transition in gold. Phys. Rev. B. 63, 2121011–2121013 (2001).

Dubrovinsky, L. et al. Noblest of all metals is structurally unstable at high pressure. Phys. Rev. Lett. 98, 0455031–0455034 (2007).

Huang, X. et al. Graphene oxide-templated synthesis of ultrathin or tadpole-shaped Au nanowires with alternating hcp and fcc domains. Adv. Mater. 24, 979–983 (2012).

Caroff, P. et al. Controlled polytypic and twin-plane superlattices in III–V nanowires. Nat. Nanotechnol. 4, 50–55 (2009).

Stoeva, S. I. et al. Face-centered cubic and hexagonal closed-packed nanocrystal superlattices of gold nanoparticles prepared by different methods. J. Phys. Chem. B. 107, 7441–7448 (2003).

Bodnarchuk, M. I., Shevchenko, E. V. & Talapin, D. V. Structural defects in periodic and quasicrystalline binary nanocrystal superlattices. J. Am. Chem. Soc. 133, 20837–20849 (2011).

Sandlöbes, S. et al. The relation between ductility and stacking fault energies in Mg and Mg–Y alloys. Acta Mater. 60, 3011–3021 (2012).

Xu, B., Capolungo, L. & Rodney D. On the importance of prismatic/basal interfaces in the growth of twins in hexagonal close packed crystals. Scripta Mater. 68, 901–904 (2013).

Lane, N. J. et al. First-principles study of dislocations in hcp metals through the investigation of the twin boundary. Phys. Rev. B. 84, 1841011–1841017 (2011).

Kohn, W. & Sham, L. J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 140, A1133–A1138 (1965).

Pugh, S. F. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos. Mag. 45, 823–843 (1954).

Wang, Y. et al. Ab initio lattice stability in comparison with CALPHAD lattice stability. Calphad 28, 79–90 (2004).

Maksymovych, P., Sorescu, D. C. & Yates Jr., J. T. Gold-adatom-mediated bonding in self-assembled short-chain alkanethiolate species on the Au (111) surface. Phys. Rev. Lett. 97, 1461031–1461034 (2006).

Cossaro, A. et al. X-ray diffraction and computation yield the structure of alkanethiols on gold (111). Science 321, 943–946 (2008).

Häkkinen, H. The gold–sulfur interface at the nanoscale. Nat. Chem. 4, 443–455 (2012).

Maksymovych, P., Voznyy, O., Dougherty, D. B., Sorescu, D. C. & Yates Jr., J. T. Gold adatom as a key structural component in self-assembled monolayers of organosulfur molecules on Au (111). Prog. Surf. Sci. 85, 206–240 (2010).

Kondoh, H. et al. Adsorption of thiolates to singly coordinated sites on Au (111) evidenced by photoelectron diffraction. Phys. Rev. Lett. 90, 0661021–0661024 (2003).

Roper, M. G. et al. Atop adsorption site of sulphur head groups in gold-thiolate self-assembled monolayers. Chem. Phys. Lett. 389, 87–91 (2004).

Srinivasan, V., Cicero, G. & Grossman J. C. Adsorption-induced surface stresses in alkanethiolate-Au self-assembled monolayers. Phys. Rev. Lett. 101, 1855041–1855044 (2008).

Shang, S. L. et al. Generalized stacking fault energy, ideal strength and twinnability of dilute Mg-based alloys: A first-principles study of shear deformation. Acta Mater. 67, 168–180 (2014).

Yan, J. A., Wang, C. Y. & Wang, S.Y. Generalized-stacking-fault energy and dislocation properties in bcc Fe: A first-principles study. Phys. Rev. B. 70, 1741051–1741055 (2004).

Datta, A., Waghmare, U. V. & Ramamurty, U. Structure and stacking faults in layered Mg–Zn–Y alloys: A first-principles study. Acta Mater. 56, 2531–2539 (2008).

Jette, E. R. & Foote, F. Precision Determination of Lattice Constants. J. Chem. Phys. 3, 605–616 (1935).

Han, J., Su, X. M., Jin, Z. H. & Zhu, Y. T. Basal-plane stacking-fault energies of Mg: A first-principles study of Li- and Al-alloying effects. Scripta Mater. 64, 693–696 (2011).

Nogaret, T., Curtin, W. A., Yasi, J. A., Hector Jr., L. G. & Trinkle, D. R. Atomistic study of edge and screw <c+a> dislocations in magnesium. Acta Mater. 58, 4332–4343 (2010).

Wu, X. Z., Wang, R., Wang, S. F. & Wei, Q. Y. Ab initio calculations of generalized-stacking-fault energy surfaces and surface energies for FCC metals. Appl. Surf. Sci. 256, 6345–6349 (2010).

Pei, Z. et al. Ab initio and atomistic study of generalized stacking fault energies in Mg and Mg–Y alloys. New J. Phys. 15, 0430201–04302019 (2013).

Wang, Y., Chen, L. Q., Liu, Z. K. & Mathaudhu, S. N. First-principles calculations of twin-boundary and stacking-fault energies in magnesium. Scripta Mater. 62, 646–649 (2010).

Jahnátek, M., Hafner, J. & Krajčí, M. Shear deformation, ideal strength and stacking fault formation of fcc metals: A density-functional study of Al and Cu. Phys. Rev. B. 79, 2241031–22410317 (2009).

Datta, A., Waghmare, U. V. & Ramamurty, U. Density functional theory study on stacking faults and twinning in Ni nanofilms. Scripta Mater. 60, 124–127 (2009).

Ganeshan, S., Shang, S. L., Wang, Y. & Liu, Z. K. Effect of alloying elements on the elastic properties of Mg from first-principles calculations. Acta Mater. 57, 3876–3884 (2009).

Shang, S. L. et al. First-principles calculations of pure elements: Equations of state and elastic stiffness constants. Comput. Mater. Sci. 48, 813–826 (2010).

Born, M. & Huang, K. in Dynamical theory of crystal lattices 1st edn, Ch. 3, 142 Clarendon Press 1954).

Nye, J. F. in Physical properties of crystals: their representation by tensors and matrices 1st edn, Ch. 8, 142 (Clarendon Press, 1985).

G. Simmons, H. Wang . Single crystal elastic constants and calculated aggregate properties MIT Press 1971).

Reuss, A. Calculation of low limit of mixed crystals. Z. Angew. Math. Mech. 9, 49 (1929).

Hill, R. The elastic behavior of a crystalline aggregate. Proc. Phys. Soc. London, Sect. A 65, 349–354 (1952).

Segall, M. D. et al. First-principles simulation: ideas, illustrations and the CASTEP code. J. Phys. Condens. Matter 14, 2717–2744 (2002).

Perdew, J. P. & Wang, Y. Accurate and simple analytic representation of the electron-gas correlation energy. Phys. Rev. B. 45, 13244–13249 (1992).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B. 13, 5188–5192 (1976).

Vitek, V. Intrinsic stacking faults in body-centred cubic crystals. Philos. Mag. 18, 773–786 (1968).

Shang, S. L., Wang, Y. & Liu, Z. K. First-principles elastic constants of a- and θ- Al2O3 . Appl. Phys. Lett. 90, 1019091–1019093 (2007).

Walker, G. B. & Marezio, M. Lattice parameters and zone overlap in solid solutions of lead in magnesium. Acta Metall. 7, 769–773 (1959).

Hector Jr., L. G., Herbst, J. F., Wolf, W., Saxe, P. & Kresse, G. Ab initio thermodynamic and elastic properties of alkaline-earth metals and their hydrides. Phys. Rev. B. 76, 0141211–01412118 (2007).

Acknowledgements

Financial supports from The Natural Science Foundation of China (Nos. 51271086 and 51474111) and Doctoral Fund of Ministry of Education of China (20120061110031) are greatly acknowledged. Partial financial supports come from The Fundamental Research Funds for Jilin University (JCKY-QKJC02) and The Foundation of Jilin University for Distinguished Young Scholars.

Author information

Authors and Affiliations

Contributions

C.W. and H.Y.W. conceived and designed the experiments. C.W., F.Q. and T.L.H. performed the model construction and energetic calculations. C.W., H.Y.W. and X.N.X. performed the data analysis. C.W., H.Y.W. and Q.C.J. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Wang, C., Wang, H., Huang, T. et al. Generalized-stacking-fault energy and twin-boundary energy of hexagonal close-packed Au: A first-principles calculation. Sci Rep 5, 10213 (2015). https://doi.org/10.1038/srep10213

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep10213

This article is cited by

-

Stacking fault energy of basal plane for hexagonal closed-packed medium entropy alloy ZrHfTi: Ab initio prediction

Applied Physics A (2021)

-

Investigation on mechanical behaviors of Cu-Ni binary alloy nanopillars: a molecular dynamics study

Journal of Molecular Modeling (2020)

-

The influence of dilute aluminum and molybdenum on stacking fault and twin formation in FeNiCoCr-based high entropy alloys based on density functional theory

Scientific Reports (2019)

-

First-Principles Studies on Twinnability of Magnesium Alloys: Effects of Yttrium and Lithium on \(\left( {10\bar{1}1} \right)\left[ {\bar{1}012} \right]\) 10 1 ¯ 1 1 ¯ 012 Compression Twinning Deformation Processes

Metals and Materials International (2018)

-

Controlled growth of hexagonal gold nanostructures during thermally induced self-assembling on Ge(001) surface

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

,

,  and

and  slip systems; (b)

slip systems; (b)  and

and  slip systems.

slip systems.

slip system; for hcp Au and Mg in (b)

slip system; for hcp Au and Mg in (b)  , (c)

, (c)  , (d)

, (d)  , (e)

, (e)  and (f)

and (f)  slip systems.

slip systems.

mirror reflection, (b)

mirror reflection, (b)  mirror glide, (c)

mirror glide, (c)  mirror reflection and (d)

mirror reflection and (d)  mirror glide. The grey and gold balls represent the two atomic layers along the

mirror glide. The grey and gold balls represent the two atomic layers along the  direction conventionally used for the hcp structure.

direction conventionally used for the hcp structure.