Abstract

In this paper we report the performances of a lithium-ion sulfur battery characterized by a polymer configuration. The cell, based on a sulfur-carbon cathode, a Li-Sn-C nanostructured anode and a PEO-based, polysulfide-added electrolyte, shows very good electrochemical performances in terms of stability and delivered capacity. The remarkable cell performances are ascribed to the mitigation of the cathode dissolution process due to the buffer action ensured by the polysulfide added to the polymer electrolyte. This electrolyte configuration allows the achievement of a stable capacity ranging from 500 to 1500 mAh gS-1, depending on the cycling rate. The use of a polymer electrolyte and the replacement of the lithium metal with a Li-Sn-C nanostructured alloy are expected to guarantee high safety content, thus suggesting the battery here studied as advanced energy storage system.

Similar content being viewed by others

Introduction

Elemental sulfur is a very attractive cathode material for lithium batteries due to its non-toxicity, low cost, eco-sustainability and high theoretical energy density, i.e. 2600 Wh kg−1, that largely exceeds the value associated to conventional cathode materials1,2,3,4. However, the use of the sulfur electrode in liquid electrolyte is still limited by the formation of soluble polysulfide Li2Sx (1 ≤ x ≤ 8) at the cathode and its contemporary migration in the solution, thus leading to shuttle reaction and precipitation of Li2S2 and Li2S at the anode, with consequent loss of active material and capacity fading5,6,7. These issues have been recently mitigated by moving from bulk-electrodes to sulfur-carbon composites, in which the elemental sulfur is efficiently trapped within protecting carbon matrixes of various configurations8,9,10,11,12,13,14. The change of the electrolyte configuration by the addition of Li-film forming salts, e.g. LiNO3 and lithium polysulfides, have been recently revealed as efficient solutions to promote the formation of a stable SEI film layer at the lithium surface, thus reducing the polysulfide shuttle effect and the cathode dissolution15,16. Moreover, the addition of a dissolved polysulfide (i.e. Li2Sx) to liquid electrolytes, such as DOL-DME-LiTFSI and TEGDME-LiCF3SO3, has shown the most promising results in increasing the lithium-sulfur cell stability and efficiency17,18,19,20. However, the use of lithium metal in liquid electrolytes may lead to safety hazard associated with possible dendrite formation, cell short-circuit, heat evolution and, in presence of flammable electrolyte, to firing21. Hence, alternative, not flammable electrolytes, such as inorganic glass-type lithium conducting materials22,23,24 or polymer membranes25,26, characterized by wide electrochemical stability window and favorable SEI film formation, are required in order to match the safety targets in batteries using lithium-metal as high capacity anode. Furthermore, the replacement of lithium metal with alternative, high performance anodes, such as lithium alloy materials, e.g. Li-Sn and Li-Si, is considered the most suitable solution to increase the safety content of the cell27,28. Polymer electrolytes, such as those based on PEO, still suffer from low ionic conductivity and high interphase resistance at temperature lower than 70°C29. Recent work demonstrated that PEO-based electrolytes operating at lower temperature level may be achieved by the use of various plasticizers, such as organic carbonates30 or glymes31,32. This class of “gel-type” polymer electrolytes requires, however, a proper optimization, in particular in terms of cycling stability, in order to be efficiently used in lithium sulfur cell.

In this work we report a rechargeable lithium-ion polymer battery based on the combination of high capacity sulfur-carbon cathode, nanostructured LixSn-C anode and polysulfide-added PEO-based gel membrane. The polymer membranes have been added by polysulfide of various composition in order to prevent the electrode dissolution and plasticized by a EC:DMC carbonate-based additive to make them suitable for application at room temperature. We demonstrated that the lithium-ion cell can deliver, at room temperature, a stable capacity of 1500 mAh gs−1 at C/20 and of 500 mAh gs−1 at C/5, with an average voltage of 1.7 V and a theoretical energy density in respect to the sulfur weight calculated to range from 2500 Wh kg−1 at the lower C-rate to 800 Wh kg−1 at the higher one, that is expected to reflect in high practical energy density and remarkable safety content, i.e. promising characteristics of a system proposed for high energy storage application.

Results and discussions

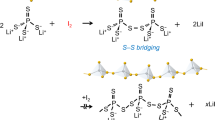

The polymer membranes studied in this work are characterized by the following composition: PEO20LiCF3SO3 + 10% w:w ZrO2. A polysulfide, Li2Sx, (1 ≤ x ≤ 8), was added to the membranes during the synthesis with the aim to reduce the cathode dissolution during lithium-sulfur cell operation, see methods section for membranes preparation. Figure 1, reporting the Arrhenius conductivity plots of the membranes and, in inset, the photographic images, evidence that the polysulfide-free membrane (indicate as PEO) is characterized by a white color; while the membranes containing Li2S (indicate as PEO-Li2S) and Li2S8 (indicate as PEO- Li2S8) appear yellow and red, respectively17,30. The Arrhenius plots reveal the typical behavior of a PEO-based solid electrolyte, characterized by a high ionic conductivity, i.e. of the order of 10−3–10−4 S cm−1, at temperature higher than 70°C and a rapid decay to a value of about 10−7 S cm−1 below 70°C, due to the amorphous-crystalline phase change of the PEO33,34. Furthermore, the plots of Fig. 1 show only minor difference between the various membranes, including polysulfide-free one, thus excluding relevant role of the selected polysulfide in the ion conduction. Instead, recent works demonstrated the effective role of the polysulfide addition, in particular of Li2S8, in improving the lithium-sulfur cell behavior17,18,19,20.

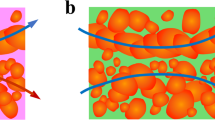

With the aim to improve the room-temperature ionic conductivity of the polymer electrolyte we plasticized the Li2S8-added membrane, that is expected to efficiently buffer the cathode dissolution, by using EC:DMC-based solution. The impedance spectra and corresponding time evolution of the ionic conductivity at 25°C reported in Figure 2a and b, respectively, indicate a cell resistance of about 10Ω, slightly decreasing during the storage time most likely due to a solvent-polymer cross-linking process and a conductivity value as high as 10−3 S cm−1. This membrane, reported in inset of Fig. 2b and following indicated with the acronym GPS-Li2S8, has been selected as suitable electrolyte for an efficient application in RT-lithium sulfur polymer battery. Further tests on membranes obtained by plasticizing the polysulfide-free and the Li2S-added polymer electrolytes, reported in the Supplementary Information section, Figure S1, show very similar conductivity trend, with a value of about 10−3 S cm−1.

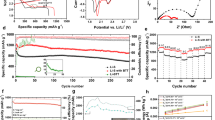

MCMB-S composite cathode17,24 and a nanostructured Sn-C anode28,35 have been selected as high performance materials for application in the polymer lithium ion battery. Prior to use in full cell, the Sn-C anode has been pre-lithiated (following indicated by LixSn-C, x ≤ 4.4) as already reported in previous paper using lithium-alloying anodes36, this with the aim to make it a suitable lithium-source for battery using discharged cathodes, such as sulfur, see also methods section. Fig. 3a, reporting the cycling behavior of the Li/GPS-Li2S8/S-C half-cell performed at 84 mA gs−1 (C/20) and 25°C, evidences a very stable capacity of the order of 1600 mAh gs−1 that is of about 96% of sulfur theoretical capacity, with no signs of decay upon cycling, thus confirming the suitability of the selected polymer electrolyte and its effective role in buffering the sulfur electrode dissolution. The voltage profile of the Li-S cell reported in Fig 3b shows an average discharge volage of 2 V and a charge characterized by a multiple plateau extending up to 4 V. The sloping trend and the charge over-voltage, not expected for the typical lithium-sulfur cell, are most likely due to the gelled nature of the electrolyte, including carbonate species that may increase the cell polarization at the room temperature, thus affecting Li-S reaction kinetics30. This issue may be most likely addressed by optimizing the cathode/electrolyte interphase properties. The relatively low Coulombic efficiency, i.e. of about 95%, indicates some electrolyte decomposition at the higher voltage levels (about 4 V) rather than to eventual shuttle effect that, however, cannot be completely excluded. In order to avoid excessive electrolyte decomposition and SEI film formation, that may decrease the cell performances, the charge has been limited to the theoretical value of the sulfur electrode (1675 mAh gS−1, corresponding to 20 h of charge). Furthermore, the sharp voltage profile observed during the 1st charge of the Li/GPS-Li2S8/S-C cell may be most likely attributed to a partial activation of the Li2S formed during cell discharge, as already demonstrated by previous work30. The specific capacity is calculated considering only the sulfur mass loaded in the electrode material, this in view of the minor contribution of the polysulfide dissolved into the electrolyte. This consideration is supported by figure S2 in Supplementary Information section, reporting the galvanostatic cycling test performed using a sulfur-free, carbon working electrode, the GPS-Li2S8 electrolyte and lithium foil anode. Indeed, the figure S2 shows negligible performances, thus excluding the carbon and polysulfide contribution to the overall lithium-sulfur cell capacity. The carbon and the dissolved polysulfide act as buffer matrix limiting eventual cathode dissolution and assuring remarkable cell performance and high specific capacity approaching the theoretical value.

(a) Discharge capacity vs. cycle number and (b) 1st and 30th cycle voltage profile of the Li/GPS-Li2S8/S-C half cell using a current of 84 mA g−1S, 1 V as discharge limit and 20 hours as charge limit. (c) Cycling behavior and (d) 1st, 10th and 30th cycle voltage profile of the Li/GPS-Li2S8/LixSn-C half cell using a current of 100 mA g−1Sn-c and a voltage ranging between 1.5 V and 0.01 V. Measurements performed at 25°C. For membrane composition see manuscript test.

The lithiated Sn-C anode has been cycled in lithium half cell using the GPS-Li2S8 electrolyte at a current of 100 mA g−1 (about C/4), see cycling response and voltage profile in Fig. 3c and d. The figure reveals a first cycle with a capacity limited to about 200 mAh g−1 that following increases to about 380 mAh g−1, i.e. 95% of the theoretical value of the Sn-C electrode. This trend is most likely associated to a progressive wetting process of the Sn-C electrode by the GPS-Li2S8 electrolyte. After the first few cycles, Fig. 3d shows a stable capacity of about 380 mAh g−1, with an average working voltage (Fig. 3c) of about 0.5 V and a Coulombic efficiency around 98%.

Figure 4 shows the performances of the full cell combining the LixSn-C anode, the Sulfur-Carbon cathode and the GPS-Li2S8 electrolyte membrane at 25°C. Fig 4a, reporting the impedance spectroscopy response of the full-cell, shows an overall resistance limited to about 55Ω, thus suggesting the suitability of the electrodes/electrolyte configuration for battery application. Figures 4b and c show the voltage profiles of the cycling tests performed at C/20 and C/5 rates, respectively, using the LixSn-C/GPS-Li2S8/S-C cell. The voltage profile of Fig. 4b evidences a first cycle characterized by a low capacity, of about 500 mAh gs−1 (black curve highlighted by dots) and a progressive increase to about 1500 mAh gs−1 by the ongoing of the test, as most likely associated with the anode/electrolyte wetting process already mentioned in figure 3c,d discussion. At the steady state condition, the cell voltage profile reflects the combination of the Li-Sn alloying and the Li-S electrochemical process, with the overall reaction:

(a) Impedance response of a LixSn-C/GPS-Li2S8/S-C full cell before cycling. (b) Voltage profile during the 1st, 2nd, 4th, 6th, 8th and 10th cycle of the LixSn-C/GPS-Li2S8/S-C full-cell cycled at 25°C using a current rate of 84 mAh gS−1 (corresponding to C/20, 1C = 1675 mAh gs−1), a discharge voltage limit of 0.4V and 20 hours as charge time limit. (c) Voltage profile during the following 12th, 15th, 20th, 25th and 30th cycles of the LixSn-C/GPS-Li2S8/S-C full cell cycled at 25°C using a current rate of 335 mAh gS−1 (corresponding to C/5, 1C = 1675 mAh gs−1) and a voltage ranging between 0.2 V and 3.8 V.

Furthermore, Fig. 4b reveals a relatively low Coulombic efficiency (about 90%) due to partial electrolyte decomposition at the higher voltage levels (see also figure 3b). This process may be mitigated both by limiting the charge capacity to the theoretical value of the sulfur electrode or by increasing the cycling rate, as demonstrated by the plot in Fig. 4c, reporting the cycling behavior at C/5. The figure shows, in fact, increased cell efficiency (to about 99%) by increasing the c-rate; however the higher c-rate leads to a contemporary increase of the cell polarization with consequent reduction of the delivered capacity to about 600 mAh gs−1 and, progressively, to 500 mAh gs−1 during cycling.

Conclusion

The LixSn-C/GPS-Li2S8/S-C lithium ion sulfur cell here proposed is characterized by high safety level, due to the polymer configuration and the absence of lithium metal anode and expected low cost. At the lower c-rate the cell may stably deliver a capacity of about 1500 mAh gs−1 at an average voltage of 1.8 V, while at the higher c-rate the cell delivers a still relevant capacity of about 500 mAh gs−1 at an average voltage of 1.5 V, hence with a theoretical energy density ranging from 2700 to 750 Wh kgs−1, respectively, that is expected to reflect in a relatively high practical energy density. The polysulfide addition to the polymer electrolyte allowed an enhancement of the cell stability and a reduction of the polysulfide dissolution from the cathode side, as suggested by the cycling tests. The cell here characterized may be suggested as suitable energy storage system for application requiring high energy and safety levels, such as electric vehicles motion. However, longer cycle life and further characterizations are certainly required to match the severe targets of the lithium battery community.

Methods

The Sulfur-carbon cathode material was prepared by melting sulfur (Aldrich, 99.9%) and mixing it with meso porous carbon micro beads powder (MCMB, Osaka gas) in a 1:1 weight ratio at 130°C. The powder was refined at room temperature using a high-energy mechanical milling system (Retsch Mill MM400) for 2 hours (30 min of milling and 15 min of rest) at frequency of 15 Hz. The electrode was then prepared as a thin film by plating on Al support a slurry formed by dispersing the active material, 10% of Super P carbon (conducting agent, Timcal) and 10% PVdf (binder, Solef, 6020) in N-methyl pirrolidone (NMP, Aldrich). The resulting slurry, approximately 40 µm thick, was dried at 50°C under vacuum to remove the residual solvent, previous to lithium cell assembly; the final sulfur loading was about 1.0 mg cm−2. The Sn-C powder was prepared according to previous papers28,35, with a final loading of 4.8 mg cm−2; prior to use, the Sn-C electrode was fully lithiated by direct contact with a lithium foil wet by a LP30 solution, for 8 hr under 1 kg cm−2 of pressure33. The pristine PEO20LiCF3SO3 + 10% wt ZrO2 electrolyte (PEO in Fig. 1 inset) was prepared by a solvent-free procedure involving mixing under argon atmosphere PEO (MW 600000 Da, Aldrich) and lithium triflate (LiCF3SO3, Aldrich), in a 20:1 molar ratio, with 10% w:w of ZrO2 (Aldrich). The mixture was glass-ball milled using a rotating system under argon for 24 hours and hot-pressed at 90°C for 1 hour at 4 tons that is a procedure assuring the dissolution of the salts in the polymer matrix, including the polysulfide29,30.

The Li2S-added membrane (PEO-Li2S in Fig. 1 inset) was prepared following the procedure above described, by loading, during the first stage, 5% w:w Li2S (Aldrich) into-the pristine (PEO20LiCF3SO3 + 10% wt ZrO2) mixture while the Li2S8-added membrane (PEO-Li2S8 in Fig. 1 inset) was prepared by loading Li2S and Sulfur powder, in the molar ratio of 1:7, to the pristine sample; after hot-pressing, the PEO-Li2S8 membrane was continuously heated at 90°C for 8 hours, in order to obtain Li2S8 polysulfide in the membrane bulk. The diameter of the membrane was of 10 mm, the weight and the thickness were of 8 mg and 100 µm, respectively while the Li2S8 weight was about 0.4 mg. The final gel polymer electrolyte (indicated by the acronym GPS-Li2S8) was formed by swelling the PEO20LiCF3SO3 + 10% wt ZrO2 + 5% Li2S8 membrane (PEO-Li2S8) for 10 min with an LP30 (EC:DMC, 1:1, LiPF6 1M) solution and finally removing the excess solution to obtain the gelled membrane reported in Fig. 2b inset. The conductivity of the membranes was determined by impedance spectroscopy using R2032 coin-type cell. The cell included stainless steel blocking electrodes and the electrolyte was trapped within a 125-μm-thick Teflon O-ring of 10-mm internal diameter (cell constant k = 0.016 cm−1). The measurements were performed within 35°C–115°C temperature range, applying AC signal with amplitude of 10 mV and frequency ranging from 100 kHz to 100 Hz, using a VSP Biologic instrument. The galvanostatic cycling tests were carried out with a Maccor series 4000 battery tester using polypropylene Swagelok T-type cells, 1.0 cm diameter, assembled in argon-filled glovebox (H2O and O2 content less than 1 ppm). The half cells were prepared by coupling the electrode under study with a lithium foil (Chemetall, thickness 200 µm, counter and reference electrode) and the GPS-Li2S8 membrane as electrolyte-separator. The S-C and Lix-Sn-C lithium-half cells were cycled at a current of 84 mA g−1 and 100 mA g−1 as referred to S and Sn-C active mass, corresponding to C/20 and C/4 rates, respectively. The tests were conducted using 1 V as discharge limit and 20 hours as charge limit for the S-C semi-cell and 0.01 V–1.5 V voltage range for the LixSn-C semi-cell. The LixSn-C/GPS-Li2S8/S-C full cell was prepared by using the same cell configuration above described. The lithium-ion cell was cathode limited and cycled at a current of 84 mA g−1s (C/20) using 0.4 V as discharge limit and 20 hr as charge limit and at 335 mA g−1s (C/5) in the voltage range between 0.2 V–3.8 V.

References

Ji, X., Lee, K. T. & Nazar, L. F. A highly ordered nanostructured carbon–sulphur cathode for lithium–sulphur batteries. Nature Materials. 8, 500–506 (2009).

Rauh, R. D., Abraham, K. M., Pearson, G. F., Surprenant, J. K. & Brummer, S. B. A Lithium/Dissolved Sulfur Battery with an Organic Electrolyte. J. Electrochemical Society 126, 523–527 (1979).

Armand, M. & Tarascon, J. M. Building Better Batteries. Nature 451, 652–657 (2008).

Peled, E., Sternberg, Y., Gorenshtein, A. & Lavi, Y. Lithium-Sulfur Battery: Evaluation of Dioxolane-Based Electrolytes. J. Electrochemical Society 136, 1621–1625 (1989).

Hassoun, J. et al. Nickel-layer protected, carbon-coated sulfur electrode for lithium battery. J. Electrochemical Society 159, A390–A395 (2012).

Barchasz, C. et al. Lithium/sulfur Cell Discharge Mechanism: An Original Approach for Intermediate Species Identification. Analytical Chemistry 84, 3973–3980 (2012).

Chung, S.-H. & Manthiram, A. Lithium-Sulfur Batteries with Superior Cycle Stability by Employing Porous Current Collectors. Electrochimica Acta 107, 569–576 (2013).

Wang, H. et al. Graphene-Wrapped Sulfur Particles as a Rechargeable Lithium-Sulfur Battery Cathode Material with High Capacity and Cycling Stability. Nano Letters 11, 2644–2647 (2011).

Xiao, L. et al. A Soft Approach to Encapsulate Sulfur: Polyaniline Nanotubes for Lithium-Sulfur Batteries with Long Cycle Life. Advanced Materials 24, 1176–1181 (2012).

Kim, J. et al. An Andvanced Lithium-Sulfur Battery. Advanced Functional Materials 23, 1076–1080 (2013).

Jayaprakash, N., Shen, J., Moganty, S. S., Corona, A. & Archer, L. A. Porous Hollow Carbon@Sulfur Composites for High-Power Lithium-Sulfur Batteries. Angewandte Chemie Int. Ed. 50, 5904–5908 (2011).

Lu, S. T., Chen, Y., Wu, X. H., Wang, Z. D. & Li, Y. Three-Dimensional Sulfur/Graphene Multifunctional Hybrid Sponges for Lithium-Sulfur Batteries with Large Areal Mass Loading. Sci. Rep. 4, 4629–4632 (2014).

Sun, F. et al. Bottom-up Catalytic Approach towards Nitrogen-Enriched Mesoporous Carbon/Sulfur Composites for Superior Li-S Cathodes. Sci. Rep. 3, 2823–2830 (2013).

Zheng, S. Y. et al. High Performance C/S Composite Cathodes with Conventional Carbonate-Based Electrolytes in Li-S Battery. Sci. Rep. 4, 4824–4830 (2014).

Chen, S., Dai, F., Gordin, M. L. & Wang, D. Exceptional electrochemical performance of rechargeable Li-S batteries with a polysulfide-containing electrolyte. RSC Advances 3, 3540–3543 (2013).

Aurbach, D. et al. On the Surface Chemical Aspects of Very High Energy Density, Rechargeable Li-Sulfur Batteries. J. Electrochemical Society 156, A694–A702 (2009).

Lee, D.-J. et al. Progress in lithium-sulfur batteries: The effective role of a polysulfide-added electrolyte as buffer to prevent cathode dissolution. ChemsusChem 6, 2245–2248 (2013).

Agostini, M., Lee, D.-J., Scrosati, B., Sun, Y.-K. & Hassoun, J. Characteristics of Li2S8-tetraglyme catholyte in a semi-liquid lithium-sulfur battery. Journal of Power Sources 265, 14–19 (2014).

Yang, Y., Zheng, G. & Cui, Y. A membrane-free lithium/polysulfide semi-liquid battery for large-scale energy storage. Energy & Environmental Science 6, 1552–1558 (2013).

Demir-Cakan, R., Morcrette, M., Gangulibabu Guéguen, A., Dedryvère, R. & Tarascon, J.-M. Li–S batteries: simple approaches for superior performance. Energy & Environmental Science 6, 176 (2013).

Lisbona, D. & Snee, T. A review of hazards associated with primary lithium and lithium-ion batteries. Process Safety and Environmental Protection 89, 434–442 (2011).

Tatsumisago, M. & Hayashi, A. Superionic glasses and glass–ceramics in the Li2S–P2S5 system for all-solid-state lithium secondary batteries. Solid State Ionics 225, 342–345 (2012).

Ito, S. et al. A rocking chair type all-solid-state lithium ion battery adopting Li2O–ZrO2 coated LiNi0.8Co0.15Al0.05O2 and a sulfide based electrolyte. Journal of Power Sources 248, 943–950 (2014).

Agostini, M., Aihara, Y., Yamada, T., Scrosati, B. & Hassoun, J. A lithium-sulfur battery using a solid, glass-type P2S5-Li2S electrolyte. Solid State Ionics 244, 48–51 (2013).

Appetecchi, G. B et al. Hot-pressed, solvent-free, nanocomposite, PEO-based electrolyte membranes: II. All solid-state Li/LiFePO4 polymer batteries. Journal of Power Sources 124, 246–253 (2003).

Kim, G. T. et al. UV cross-linked, lithium-conducting ternary polymer electrolytes containing ionic liquids. Journal of Power Sources 195, 6130–6137 (2010).

Hassoun, J., Lee, K.-S., Sun, Y.-K. & Scrosati, B. An Advanced Lithium Ion Battery Based on High Performance Electrode Materials. Journal of the American Chemical Society 133, 3139–3143 (2011).

Derrien, G., Hassoun, J., Panero, S. & Scrosati, B. Nanostructured Sn-C composite as an advanced anode material in high performance lithium-ion batteries. Advanced Materials 19, 2336–2340 (2007).

Hassoun, J. & Scrosati, B. Moving to a Solid-State Configuration: A Valid Approach to Making Lithium-Sulfur Batteries Viable for Practical Applications. Advanced Materials 22, 5198–5201 (2010).

Hassoun, J. & Scrosati, B. A High-Performance Polymer Tin Sulfur Lithium Ion Battery. Angewandte Chemie 49, 2371–2374 (2010).

Hassoun, J., Lee, D.-J., Sun, Y.-K. & Scrosati, B. A lithium ion battery using nanostructured Sn-C anode, LiFePO4 cathode and polyethylene oxide-based electrolyte. Solid State Ionics 202, 36–39 (2011).

Hassoun, J., Croce, F., Armand, M. & Scrosati, B. Investigation of the O2 electrochemistry in a polymer electrolyte solid-state cell. Angewandte Chemie 50, 2999–3002 (2011).

Croce, F., Appetecchi, G. B., Persi, L. & Scrosati, B. Nanocomposite polymer electrolytes for lithium batteries. Nature 394, 456–458 (1998).

Croce, F., Sacchetti, S. & Scrosati, B. Advanced, high-performance composite polymer electrolytes for lithium batteries. Journal of Power Sources 161, 560–564 (2006).

Hassoun, J., Derrien, G., Panero, S. & Scrosati, B. A nanostructured Sn-C composite lithium battery electrode with unique stability and high electrochemical performance Advanced Materials. 20, 3169–3175 (2008).

Hassoun, J. et al. A contribution to the progress of high energy batteries: A metal-free, lithium-ion, silicon-sulfur battery. Journal of Power Sources 202, 308–313 (2012).

Author information

Authors and Affiliations

Contributions

J.H. designed the experiments and supervised the work. M.A. synthesized the materials and carried out the experiments. J.H. and M.A. wrote the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Agostini, M., Hassoun, J. A lithium-ion sulfur battery using a polymer, polysulfide-added membrane. Sci Rep 5, 7591 (2015). https://doi.org/10.1038/srep07591

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep07591

This article is cited by

-

High sulfur loading application with the assistance of an extremely light-weight multifunctional layer on the separator for lithium-sulfur batteries

Ionics (2020)

-

Ultrathin dense double-walled carbon nanotube membrane for enhanced lithium-sulfur batteries

Journal of Nanoparticle Research (2020)

-

Cell Concepts of Metal–Sulfur Batteries (Metal = Li, Na, K, Mg): Strategies for Using Sulfur in Energy Storage Applications

Topics in Current Chemistry (2017)

-

A novel quasi-solid state electrolyte with highly effective polysulfide diffusion inhibition for lithium-sulfur batteries

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.