Abstract

Ti2AlN nanolayered ternary alloy has been plastically deformed under confining pressure at 900°C. The dislocation configurations of the deformed material have been analyzed by transmission electron microscopy. The results show a drastic evolution compared to the dislocation configurations observed in the Ti2AlN samples deformed at room temperature. In particular, they evidence out-of-basal-plane dislocations and interactions. Moreover numerous cross-slip events from basal plane to prismatic or pyramidal planes are observed. These original results are discussed in the context of the Brittle-to-Ductile Transition of the nanolayered ternary alloys.

Similar content being viewed by others

Introduction

Ti2AlN belongs to the 211 family of Mn+1AXn phases, where n = 1 to 3, M is a transition metal, A is an A-group element and X is nitrogen or carbon1. These ternary hexagonal nanolayered compounds combine properties of both ceramics (refractory, high stiffness, low density, low ductility at room temperature) and metals (high thermal and electric conductivity, thermal shock resistance, low hardness, mechanical resistance) which make them attractive for a wide range of potential applications. However, their elementary deformation mechanisms and the exact role of microstructural defects are not fully understood yet.

Although there is little literature on dislocations in MAX phases, it is well established that deformation at room temperature involves dislocation movement; these dislocations are a-type basal dislocations (b =  <11–20>) and glide in the basal plane2,3 forming large dislocation pile-ups and walls2,4,5,6,7. The latter may interact to form pairs of low angle tilt boundaries (kink bands) leading to strong local crystal rotation associated with delamination in basal planes8. Out-of-basal-plane dislocations have been observed by Transmission Electron Microscopy (TEM), in as-grown Ti4AlN39 and by Atomic Force Microscopy (AFM) in nano-indented Ti3SnC210 but they do not play a key role in the plastic deformation at Room Temperature (RT) in standard deformation conditions. On the contrary, numerous dislocation dipoles, alignments, nodes have been observed in RT-deformed Ti2AlN3. Such dislocation reactions may result in the formation of dislocation cells as observed in Ti2AlN3. The presence of dislocation interactions and networks has to be considered in the comprehension of the deformation mechanisms. Moreover dislocations were also observed to align along specific directions leading to segments with screw, 30°, 60° or edge character, indicative of an elevated lattice friction3.

<11–20>) and glide in the basal plane2,3 forming large dislocation pile-ups and walls2,4,5,6,7. The latter may interact to form pairs of low angle tilt boundaries (kink bands) leading to strong local crystal rotation associated with delamination in basal planes8. Out-of-basal-plane dislocations have been observed by Transmission Electron Microscopy (TEM), in as-grown Ti4AlN39 and by Atomic Force Microscopy (AFM) in nano-indented Ti3SnC210 but they do not play a key role in the plastic deformation at Room Temperature (RT) in standard deformation conditions. On the contrary, numerous dislocation dipoles, alignments, nodes have been observed in RT-deformed Ti2AlN3. Such dislocation reactions may result in the formation of dislocation cells as observed in Ti2AlN3. The presence of dislocation interactions and networks has to be considered in the comprehension of the deformation mechanisms. Moreover dislocations were also observed to align along specific directions leading to segments with screw, 30°, 60° or edge character, indicative of an elevated lattice friction3.

Importantly, MAX phases exhibit a Brittle-to-Ductile Transition (BDT) between 800°C and 1100°C1,8,11. In many materials such BDT is attributed to an increase of the available glide systems12,13. Based on the drop of the fracture toughness, Barsoum and co-workers ruled out the activation of out-of-basal-plane slip2,6,11,14,15. Consequently, they made the assumption that BDT is due to a temperature dependent grain boundary decohesion stress and/or delamination stress6. However Li et al. recalled that the activation of out-of-basal-plane slip systems could not be excluded as long as no observation by TEM of deformed samples had been reported14.

The general objective of our work is to study the evolution of the deformation microstructure with the temperature. Dislocation microstructure in polycrystalline Ti2AlN deformed at room temperature has been analyzed in a previous paper3 from compression tests performed under gaseous (Ar) confining pressure. Indeed this confining pressure impedes crack opening due to the brittleness of the material. In this paper, we present an original and detailed TEM dislocation analysis of Ti2AlN deformed at 900°C – that is above the BDT temperature - under the same gaseous confining condition (≈350 MPa). Burgers vectors are determined from extinction conditions using the weak beam technique and dislocation lines are obtained from observations along different orientations. In order to give elements to the comprehension of the BDT, the dislocation configurations are compared to the ones observed at RT.

Results

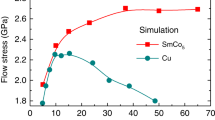

Figure 1 shows the stress-strain curves of Ti2AlN recorded at RT and at 900°C and obtained under the same gaseous confining pressure of ≈350 MPa, the RT curve being extracted from the reference 3. In such experimental conditions, the confining pressure hinders crack propagation but does not modify the dislocation behavior16. In these conditions, significant plastic strain has been reached: εP = 5% at RT and εP = 3.5% at 900°C after return to room pressure. Noteworthy, the tests have been arbitrarily stopped at these strains, without rupture for both samples, since steady-state was reached. Both curves exhibit a linear elastic regime followed by a plastic regime. The RT-case is characterized by a stress peak σp followed by a softening regime and the start of a zero hardening regime. The high-temperature curve does not show any clear stress peak but rather a constant hardening regime followed by a long zero hardening regime. In addition, the maximum stress is lower at 900°C (900 MPa) than at RT (σp = 1300 MPa), while the yield strength (defined as stress at 0.2% strain) is lower at 900°C (750 MPa) than at RT (1100 MPa).

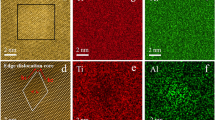

Figure 2 shows typical dislocation microstructures of the samples deformed respectively at RT and at 900°C and gives evidence of the drastic evolution of the dislocation configurations between both samples. On figure 2.a (RT case), straight, segmented dislocations lying in the (0001) plane are observed, similar to the configuration analyzed in reference 3. Figure 2.b (900°C case) exhibits curved dislocations with segments obviously lying out-of-basal plane (localized by black arrows in Figure 2.b). Two characteristic configurations of the 900°C deformed sample are studied in detail below. The first configuration, labeled I in the following is presented in Figure 3, the second one, labeled II, is presented in Figure 4.

Three electron beams along [-1100], [-12-10] and [-12-1-1] directions were used to observe the configurations to be discussed. These electron beams provide five diffraction vectors for the weak beam analysis of both configurations: g1 = 11-20, g2 = 10-10, g3 = 01-13, g4 = -1103 and g5 = 000δ.

Figure 3 shows micrographs of configuration I, obtained with g1, g2 and g4. Due to the complexity of this configuration, we are focusing here on two segments, 1 and 2 (see schematic in Figure 3-d). Table 1 reports the observed contrasts for both segments using g1, g2, g3, g4 and g5. Segments 1 and 2 are out of contrast with the diffraction vectors g3 and g5, confirming that they belong to the same dislocation. According to these extinction conditions, their Burgers vector is lying in the basal plane (out of contrast with g5) and is consistent with b1 = ± [2-1-10]. The analysis of dislocation lines shows that the segment 1 is lying in (0001) plane and aligned along [2-1-10]. However the segment 2 is clearly parallel to [0001]. Consequently this dislocation is contained in the prismatic plane (0-110). Dislocation nature of the segments 1 and 2 is screw and edge respectively. The configuration I is the first evidence of dislocation cross-slip from basal dislocation to prismatic plane {0-110}, as schematized in Figure 3d.

[2-1-10]. The analysis of dislocation lines shows that the segment 1 is lying in (0001) plane and aligned along [2-1-10]. However the segment 2 is clearly parallel to [0001]. Consequently this dislocation is contained in the prismatic plane (0-110). Dislocation nature of the segments 1 and 2 is screw and edge respectively. The configuration I is the first evidence of dislocation cross-slip from basal dislocation to prismatic plane {0-110}, as schematized in Figure 3d.

The configuration II is presented in Figure 4. The micrographs are also obtained with g1, g2, g3, g4 and g5. Here again, due to the complexity of this configuration, we are focusing on specific segments of the configuration, here 1, 2, 3 and 4. The analysis of dislocation contrasts is presented in Table 1.

In the same manner as for configuration I, the segments 1 and 2 belong to the same dislocation since they have the same extinction conditions with g3 and g5. The segment 1 is parallel to [11-20] and lies in (0001). On the contrary, the segment 2 is out of the basal plane. Available observation conditions impeded to define precisely its line direction; nevertheless one can assert that both segments 1 and 2 are contained in a pyramidal plane. Concerning Burgers vector, the extinction conditions with g3 and g5 reveal that it is consistent with b1 = b2 = ± [2-1-10]. Noteworthy, segment 1 (lying in the basal plane) is not a screw dislocation, the angle between its dislocation line and its Burgers vector being equal to 60°.

[2-1-10]. Noteworthy, segment 1 (lying in the basal plane) is not a screw dislocation, the angle between its dislocation line and its Burgers vector being equal to 60°.

The segment 3 of configuration II is out of the basal plane. Again, its line could not be determined. This segment does not exhibit the same extinction conditions as those of segments 1 and 2, confirming that segment 3 has a different Burgers vector from the dislocation formed by 1 and 2, as expected from the dislocation nodes rule b1 = b2 = b3 + b3′ (the segment 3′ is shown on Figure 4). This observation reveals an out-of-basal-plane interaction as localized by arrows in the micrographs of Figure 4. Moreover the segment 3 is observed to be out of contrast with g4 and g5. Consequently its Burgers vector is consistent with b3 =  [11-20].

[11-20].

Concerning the segment 4, Figure 4 shows that, from geometrical considerations, it is lying out of the basal plane and highly curved. It interacts with segment 3 and another dislocation thus forming a node. The details of this interaction could not be determined. Similarly to segments 1 and 2, segment 4 is out of contrast with g3 and g5. Consequently its Burgers vector is b4 =  [2-1-10].

[2-1-10].

Discussion

TEM observations show that Ti2AlN was plastically deformed at 900°C through the production and movement of dislocations. Comparison between configurations observed in RT- and 900°C-deformed samples provides evidence of a radical evolution of dislocation configurations. While at room temperature, dislocations lines are straight and confined to the basal plane, at 900°C, they present much more complex nature: (1) dislocations lines are curved; (2) they cross-slip from basal plane to 1st order prismatic and pyramidal planes and (3) they react and form junctions out of the basal plane. All these dislocations are of a-type i.e. with a Burgers vector lying in the basal plane, which explains the easiness of cross-slip.

Our study reveals unambiguously and for the first time in MAX phases, that at high temperature out-of-basal-plane dislocations are not anecdotal events and therefore cross-slip plays a key role in the deformation. This increase of available glide systems at high temperature (basal, prismatic and pyramidal planes) is likely to promote significant ductility at high temperature. In conclusion, these major changes in the plasticity mechanism are expected to play a key role in the appearance of the BDT with temperature notably with respect to the decrease of the yield strength when increasing temperature.

While the high temperature response of MAX phases was supposed to be only based on temperature dependent grain boundary decohesion and/or interplanar delamination stress17, the present work provides new elements through the observation of cross slip events. Further experiments would now be performed at intermediate temperatures to correlate precisely the apparition of the BDT with an abrupt or gradual change of plasticity mechanism as in the case of semi-conductor12,13.

Methods

Synthesis procedure

The synthesis procedure for the Ti2AlN sample has been described in detail elsewhere3. Briefly, titanium (grain size < 149 μm), AlN (<10 μm) were mixed in stoichiometric proportions. The mixture was placed into a Hot Isostatic Pressing (HIP) chamber to be heated up to 1450°C under a pressure of 80 MPa for 4 hours. Porosity measurements, X-ray diffraction and Scanning Electron Microscopy (SEM) studies revealed that the Ti2AlN sample was dense with randomly oriented grains with a typical size of 15 μm.

Compression test

In order to reach significant plastic strain, uniaxial compression test was performed in the Paterson's apparatus at 900°C under an argon confining pressure of 350 MPa at a strain rate equal to 5·10−5 s−1. Deformation under confining pressure requires samples cut into parallelepipeds with typical size 3 × 3 × 7 mm3. All faces were carefully mechanically polished and inserted into fully annealed aluminium or iron cylinders to fit into the deformation assembly of the compression apparatus. After deformation, the samples were removed from Al or Fe jackets for TEM analysis.

Transmission electron microscopy

The thin foil for TEM observations was cut at 45° from the compression axis and prepared by slow mechanical polishing and dimpling down to a few microns. Subsequently the thin foil was glued on molybdenum grid and thinned down to electron transparency in a Precision Ion Polishing System (PIPS from Gatan). TEM observations were performed on a Phillips CM20 microscope operating at 200 kV.

References

Barsoum, M. & El-Raghy, T. The MAX phases: unique new carbide and nitride materials. Am. Sci. 89, 334–345 (2001).

Barsoum, M. & Radovic, M. Mechanical properties of the MAX phases. Enc. Mater. Sci. Techno. 16, 1–16 (2004).

Guitton, A., Joulain, A., Thilly, L. & Tromas, C. Dislocation analysis of Ti2AlN deformed at room temperature under confining pressure. Philos. Mag. 92, 4536–4546 (2012).

Farber, L., Levin, I. & Barsoum, M. High-resolution transmission electron microscopy study of a low-angle boundary in plastically deformed Ti3SiC2 . Philos. Mag. 79, 163–170 (1999).

Kooi, B., Poppen, R., Carvalho, N., Hosson, J. & Barsoum, M. Ti3SiC2: A damage tolerant ceramic studied with nanoindentations and transmission electron microscopy. Acta Mater. 51, 2859–2872 (2003).

Barsoum, M. & Radovic, M. Elastic and mechanical properties of the MAX phases. Annu. Rev. Mater. Res. 41, 195–227 (2011).

Barsoum, M., Zhen, T., Kalidindi, S., Radovic, M. & Murugaiah, A. Fully reversible, dislocation-based Ti3SiC2 to 1 GPa. Nature Mater. 2, 107–111 (2003).

Barsoum, M., Farber, L. & El-Raghy, T. Dislocations, kink bands and room-temperature plasticity of Ti3SiC2 . Metall. Mater. Trans. A. 30, 1727–1738 (1999).

Joulain, A., Thilly, L. & Rabier, J. Revisiting the defect structure of MAX phases: the case of Ti4AlN3 . Philos. Mag. 88, 1307–1320 (2008).

Tromas, C., Villechaise, P., Gauthier-Brunet, V. & Dubois, S. Slip line analysis around nanoindentation imprints in Ti3SnC2: a new insight into plasticity of MAX-phase materials. Philos. Mag. 91, 1265–1275 (2010).

Zhang, Z. F. & Sun, Z. M. Shear fracture behavior of Ti3SiC2 induced by compression at temperatures below 1000°C. Mater. Sc. Eng. A. 408, 64–71 (2005).

Kedjar, B., Thilly, L., Demenet, J.-L. & Rabier, J. Plasticity of indium antimonide between −176 and 400°C under hydrostatic pressure. Part I: Macroscopic aspects of the deformation. Acta. Mat. 58, 1426–1440 (2010).

Kedjar, B., Thilly, L., Demenet, J.-L. & Rabier, J. Plasticity of indium antimonide between −176°C and 400°C under hydrostatic pressure. Part II: Microscopic aspects of the deformation. Acta. Mat. 58, 1418–1425 (2010).

Li, J. F., Pan, W., Sato, F. & Watanabe, R. Mechanical properties of polycrystalline Ti3SiC2 at ambient and elevated temperatures. Acta Mater. 49, 937–945 (2001).

Wan, D. T., Meng, F. L., Zhou, Y. C., Bao, Y. W. & Chen, J. X. Effect of grain size, notch width and testing temperature on the fracture toughness of Ti3Si(Al)C2 and Ti3AlC2 using the chevron-notched beam (CNB) method. Euro. Ceram. Soc. 28, 663–669 (2008).

Pizzagalli, L., Demenet, J. L. & Rabier, J. Theoretical study of pressure effect on the dislocation core properties in semiconductors. Phys. Rev. B. 79, 045203, 1–7 (2009).

Barsoum, M. “Mechanical Properties: High Temperature”. in MAX Phases: Properties of Machinable Ternary Carbides and Nitrides, (1st Edition p363–397). Germany: Wiley-VCH; (2013).

Author information

Authors and Affiliations

Contributions

All the TEM observations were performed by A.G. and A.J. A.G. wrote the main manuscript text. L.T. and A.G. performed the mechanical deformations. C.T. and A.G. prepared Figures 3 and 4. All the authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Guitton, A., Joulain, A., Thilly, L. et al. Evidence of dislocation cross-slip in MAX phase deformed at high temperature. Sci Rep 4, 6358 (2014). https://doi.org/10.1038/srep06358

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep06358

This article is cited by

-

Dynamic Response of TI2ALC Under Radial Confinement at High Temperature

Journal of Dynamic Behavior of Materials (2017)

-

On the small angle twist sub-grain boundaries in Ti3AlC2

Scientific Reports (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.