Abstract

An investigation focused on the transformation and distribution behaviors of trace elements and natural radionuclides around a coal gangue brick plant was conducted. Simultaneous sampling of coal gangue, brick, fly ash and flue gas were implemented. Soil, soybean and earthworm samples around the brick plant were also collected for comprehensive ecological assessment. During the firing process, trace elements were released and redistributed in the brick, fly ash and the flue gas. Elements can be divided into two groups according to their releasing characteristics, high volatile elements (release ratio higher than 30%) are represented by Cd, Cu, Hg, Pb, Se and Sn, which emitted mainly in flue gas that would travel and deposit at the northeast and southwest direction around the brick plant. Cadmium, Ni and Pb are bio-accumulated in the soybean grown on the study area, which indicates potential health impacts in case of human consumption. The high activity of natural radionuclides in the atmosphere around the plant as well as in the made-up bricks will increase the health risk of respiratory system.

Similar content being viewed by others

Introduction

The coal gangue is non-combustible materials which are physically separated from bulk coal during coal-mining activities. The average gangue production ranges from 10% to 15% of the raw coal production, which depends on the geological and mining characteristics1. The rapid development of coal mining industry in China over the last 20 years has resulted in the large amount of coal gangue accumulation. According to incomplete statistics, more than 4.5 billion tons of coal gangue was accumulated around the nationwide coalfields2. Alternatives to the disposal of coal gangue in accumulation are indispensable because of increasing stringent environmental regulations. For the considerable content of clay minerals and high calorific value, brick making using coal gangue is one of the predominate solid wastes recycling utilizations. The processes of coal gangue brick making consist of crushing, screening, ageing, molding, drying and firing in oven3.

Besides the valuable mineral compositions (clay minerals, carbon), coal gangue also contains most naturally occurring trace elements. It is obvious that trace elements are available to undergo numerous reactions resulting in their mobilization as volatile phase during coal gangue conversion processes4,5,6. The emission characterizations of trace elements during transportation7,8 and combustion9,10,11 have received increasing interest from regulatory authorities and scientists. However, those work are mainly concentrated on coal combustion, whereas the studies on the unintentional release and environmental impacts of trace elements in coal mining accessary industries are limited12,13. Zhou et al conducted a simulation experiment of coal gangue brick firing to evaluate the volatilization of elements13. However, the practical behaviors of these elements cannot be accurately predicted in a laboratory analysis, due to various complex factors such as combustion temperature14, redox conditions15 and interaction between different species in practical coal gangue firing16.

It has been reported that trace element in coal are mainly associated with inorganic minerals (clay minerals, sulfides and carbonate minerals)17. The environmental impact of trace elements during combustion depends on the association and the concentration of trace element11. For the high content of mineral composition in coal gangue compared with coal, the behaviors of trace elements during coal gangue combustion are more complicated. After combustion, trace elements may be absorbed on fine particulates (PM2.5 or PM10) that suspend in the air. These fine particulates can be inhaled by human directly or deposited in the surrounding soil18. Generally, brick plants are commonly built at suburban area where close to the cultivation area. Consequently, trace elements can be accumulated in soil and crops thus finally affect human health through food chain indirectly. Therefore, it is of extreme significance to evaluate the environmental and health impacts of trace elements releasing from coal gangue brick making plant.

In addition, coal gangue also contains trace amount of naturally occurring radioactive materials including uranium, thorium and their radioactive decay products19,20,21. As the combustion residues (brick) are finally used in the construction industry, the transformation behavior and health impact of natural radionuclides in coal gangue as well as brick products are needed to be comprehensively investigated. The overall objectives of the study are to determine (1) the partition and transformation behaviors of trace elements and natural radionuclides during coal gangue firing processes; (2) the distribution behavior of trace element in soil and crop around the brick plant.

Results and Discussion

The properties of coal gangue

The main chemical compositions of coal gangue are SiO2, Al2O3, Fe2O3 and CaO, which occupies 58, 24, 7 and 5 wt.%, respectively. According to the basic requirements for brick materials reported by Raut et al22, these coal gangue accumulated in Huainan Coalfield is a suitable raw materials for brick making. According to Figure 1, the mineral phases of coal gangue are kaolinite, quartz, illite, chlorite, ankerite, dolomite, calcite and pyrite. The high content of SiO2 and Al2O3 in the coal gangue suggests high compositions of clay minerals (i.e., kaolinite and illite) and quartz. The high content of Fe2O3 is mainly related with carbonate (i.e., dolomite) and sulfide minerals (i.e., pyrite). Calcium oxides in coal gangue are predominantly contributed by carbonate minerals (i.e., calcite, ankerite and dolomite).

During coal gangue combustion, minerals are involved in various physic-chemical transformation, i.e., dehydration and dehydroxylation, carbonization, decomposition, reduction, volatilization, crystallization6. After combustion, minerals in coal gangue are transformed to mullite, quartz, lime, hematite, anhydrite and magnetite. Mullite is important function group for brick properties. When comparing the intensity peak of coal gangue and brick, the specific peak of pyrite and calcite disappeared, indicating that pyrite and calcite are decomposed completely during firing. Many studies confirmed that iron group (i.e., Cr, Ni, Co) and chalcophile elements (i.e., Cu, Zn, As, Se, Pb and Hg) in coal gangue are predominantly associated with carbonate and sulfide minerals23,24,25,26,27. It is reported that the transformation behaviors of trace elements are related to various factors, i.e., physic-chemical properties of trace element, stability of their host minerals, combustion temperature and devices28,29,30. Therefore, as the mineral decomposition under high temperature, elemental association among minerals in the products are reorganized.

Partition behavior of trace elements

The partition behaviors of trace elements during coal gangue firing are dominated by certain factors including the content and modes of occurrence of trace elements in coal gangue, physic-chemical reactions between elements and minerals and combustion parameters (temperature, device)26,27,28,29. The mode of occurrence of trace element is one of the most important determinants. The trace element in coal gangue can be associated with both inorganic and organic matter, sometimes most of them can occur in both forms. It has been identified that trace element associated with organic matter and sulfides are more easily volatilized28. Trace elements (As, Cd, Cu, Hg, Ni, Pb, Se and Zn) in coal gangue are primarily associated with sulfide minerals2. These elements may release from the combusted coal gangue into atmosphere during coal gangue firing in the brick making plant, which may lead to potential environmental and health implications. Therefore, trace elements As, Cd, Cr, Co, Cu, Hg, Ni, Pb, Se, Sn, V, Zn are selected for systemic investigation. Trace elemental content in coal gangue, brick, fly ash and the background values of world coal gangue31 are presented in Table 1. It is worth noting that trace elements in the selected coal gangue are within the range of background values of world coal gangue.

During the firing process, trace elements are released from coal gangue and redistributed in the brick, fly ash and flue gas. The content of As, Cd, Cr, Cu, Hg, Pb, Se, Sn and Zn in the fly ash are higher than that in the coal gangue and brick, indicating that these elements are easily volatilized under high temperature and condensed on the surface of fly ash when escaping from the high temperature zone. Furthermore, it reveals high affinity of these elements with finer particulates (fly ash)32. Cobalt, Ni and V are higher in brick when compared with coal gangue and fly ash, illustrating that these elements are non-volatilized and tend to accumulate in coarse particles.

Mass balances are preformed to analyze the trace element transformation, a comparison was established for each component as follows (Eq. (1))

Where CCG, CB, CF and CG are the concentration of trace element, expressed in mg/kg or μg/m3, in coal gangue, brick, fly ash and flue gas, respectively. The parameters FCG, FB, FF and FG represent the input/output ratios of element in coal gangue, brick, fly ash and flue gas, expressed in kg/(kg coal gangue) and m3/(kg coal gangue), respectively. The parameters CCG × FCG, CB × FB, CF × FF and CG × FG are the mass (mg) of element in coal gangue, brick, fly ash and flue gas by kg of coal gangue, respectively.

According to the brick plant historical data, the generation ratios of mineral residue in brick and fly ash form during coal gangue firing are 99% and 1%, respectively. Meanwhile, the fly ash (heated smoke dust) are introduced into drying kiln for supplying heated air and approximately 30% of the fly ash may be adsorbed in the drying kiln. Fly ash in the drying kiln is cleaned up after production. Therefore, the FB and FF can be obtained as follows: FB = % mineral residue × 0.99, FF = % mineral residue × 0.01. FG was calculated by the following multiplication: FG is the total gas emission value (m3/(kg coal gangue)).

When all the parameters of Eq. (1) were acquired, the mass balances of toxic elements were calculated for coal gangue, bottom ash, fly ash and flue gas. The particulates associated with the gas phase were included in elements flue gas mass balances. The mass balances were present in Table 2. The acceptable results were obtained for all the trace elements, the mass balances were less than 75% for all the elements except As, Hg and Se, of which the values are 81.2, 78.6 and 86.3%, respectively. For the large amount of parameters involved on the mass balance, the summation of these deviations (approximately 20%) should not be neglected. Therefore, mass balances less than 75% were acquired for certain elements. Reddy et al (2005) evaluated the mass balances of trace elements in Western India coal fired power plant and reported that the mass balances for all the elements were less than 50% except for As and Hg5.

Volatilization is the primary partition behavior of trace element during coal gangue firing, which is dominated by coal gangue properties such as particle size, heating temperature and the association of trace elements25. The distribution of trace element during combustion processes is shown in Table 2. According to the volatilization of trace elements, these selected trace elements can be classified into two groups: Cluster one includes high volatile elements (release ratio higher that 30%) are represented by Cd, Cu, Hg, Pb, Se and Sn, which emitted mainly in flue gas, especially for Hg, whose volatilization ratio being 76.9%. Cluster two, represented by Cr, Co and V, has lower volatilization ratio (less than 5%) and are mostly retained in brick. Besides, As, Ni and Zn are catalogued between Cluster one and Cluster two, which have volatilization ratios between 10% and 20%.

For the high volatilization of the selected environmental sensitive trace elements (Cd, Cu, Hg, Pb, Se and Sn), the potential environmental and health impacts are of extreme importance thus discussed below.

Behavior of natural radionuclides

The primary natural radionuclide contributors to external exposure from gamma and alpha radiation are the thorium series (represented by 232Th), uranium series (represented by 226Ra), 40K and 210Po. The major thorium and uranium decay series are summarized by Friedlander et al33. The radioactivity concentration of natural radionuclides in coal gangue, brick and fly ash are shown in Table 3. The average activity concentration of 238U, 232Th, 226Ra, 210Pb, 210Po and 40K are 46.6, 87.0, 38.8, 42.6, 23.8 and 540 Bq/kg for coal gangue, 67.1, 113, 54.8, 28.3, 12.2 and 729 Bq/kg for brick, 85.8, 139, 72.0, 122, 78.5 and 758 Bq/kg for fly ash, 93.2, 144, 76.3, 636, 386 and 747 Bq/kg for particulates associated with flue gas, respectively. The activity concentration of 40K takes up approximately 70% of the total natural radionuclides of the coal gangue, fly ash and brick, indicating that 40K is the main radioactive contributor. The concentration comparison of these radionuclides in coal, coal gangue and soil from Anhui34, China35, Slovenia36 and Indian37 are also shown in Table 3. When compared with coal and coal gangue from other research areas, activity concentrations of 232Th and 40K are higher in coal gangue from study area, suggesting elevated potential health impacts. The natural radionuclides are enriched in the coal gangue, fly ash and brick products as compared with soil background values of Anhui Province and world, which deserves further attention in terms of potential environmental and ecological impacts.

The transformation behaviors of natural radionuclides during combustion depend on several factors include: content and mode of occurrence of radionuclides in coal gangue, ash yield of coal gangue, combustion temperature, ratio between solid phase and gas phase and the efficiency of the precipitated equipment20,22. Enrichment factors of the natural radionuclide are calculated to characterize their transformation behaviors. The enrichment factor is defined as the ratio of the content of a radionuclide (R) and 40K in the sample (fly ash or brick) divider by the corresponding ratio in the coal gangue39.

The enrichment factor represents the apparent enrichment phenomenon due to the less of the organic matter and volatile matter during combustion39. In case the content of 40K remains more or less constant in all samples, 40K is used as conservative element in the formula for calculation. The EF values of 238U, 232Th, 226Ra, 210Pb and 210Po are 1.32, 1.14, 1.32, 2,04 and 2.35 in fly ash, 1.07, 0.96, 1.04, 0.49 and 0.38 in brick, 1.45, 1.20, 1.42, 10.8 and 11.7 in particulates associated with flue gas, respectively, which is within the range of previous studies20,37,38. Cevik et al studied the radionuclide behaviors of Turkey coals and found that the enrichment factors of natural radionuclides in fly ash and bottom ash were approximately two20.

Natural radionuclide in coal gangue may be associated with both inorganic (clay minerals, silt and other inorganic sedimentary material) and organic matter. Coles et al reported that natural radionuclides in coals are mainly associated with alumino-silicate minerals39. It has been hypothesized that thorium in coal gangue is normally bound to zircon (ZrSiO4), which is a chemical resistant mineral and usually deposits in coal along with other silicate-based minerals39. During combustion, much of the alumino-silicate minerals undergo a melt phase and finally drop out as brick or fly ash, with most natural radionuclides still retain in the alumino-silicate minerals that exist in brick and fly ash. Furthermore, when compare the enrichment factors of fly ash and brick, the radionuclides are more enriched in fly ash, indicating that radionuclides appeal to be more concentrated in the submicron particles. For 210Pb and its daughter 210Po, which are expected to be found in two main chemical forms: associated with sulfide minerals or organic matter. Both the sulfide minerals and organic matter are decomposed during high temperature combustion, the lead and polonium could be formed as the solid particles and suspended in flue gases. The EF values of 210Pb and 210Po are higher than 2 in fly ash, which could be explained by the vaporization-condensation phenomenon.

Meanwhile, the activity concentration of 222Rn in the surrounding air around the brick making plant is 337 Bq/m3, which is remarkably higher than the recorded concentration in Anhui40 and World air38. The potential environmental and health impacts of natural radionuclides are discussed below.

Gaseous emission of trace elements

Flue gas emits into the atmosphere during coal gangue brick firing processes, the following formula is adopted to calculate the gaseous emission (GE) of trace elements41.

Where GE is the gaseous emission of trace elements during brick firing processes per year, Cb is the amount of coal gangue for brick making per year, Cc is the concentration of trace elements in coal gangue and Vr is the volatilization ratio of trace element. According to the brick plant historical data, the coal gangue consumption for brick making is 300,000 tons per year. Once all the factors of the above equation are obtained, the gaseous emissions of trace elements from brick making are calculated and tabulated in Table 2. It is estimated that about 1370 kg arsenic, 55 kg cadmium, 496 kg chromium, 76 kg cobalt, 2770 kg copper, 35 kg mercury, 1200 kg nickel, 529 kg lead, 477 kg selenium, 429 kg tin, 424 kg vanadium, 23.1 t zinc will released into the atmosphere from the coal gangue brick making plant per year.

The uncertainties remain in the estimation of trace elements emissions from coal gangue brick making process could be usually ascribed to following aspects: (1) the uncertainty in the averaged concentration of trace element in coal gangue, the concentration of trace elements in coal gangue mined from different seams, even in the same seam, varies substantially owing to the heterogeneity and significant distinction of depositional environmental, (2) the uncertainty in emission factors of trace elements, the release rates of trace elements during coal gangue combustion varies substantially due to the various associations. The uncertainties of trace elements were quantified by Monte Caro simulation42 and presented in Table 2, emissions of As, Cr, Co, Cu, Se, Sn, V and Zn are considered to have the least uncertainty (−7% to 6% for As, −11% to 14% for Cr, −8% to 10% for Co, −8% to 7% for Cu, −10% to 14% for Se, −13% to 11% for Sn, −10% to 10% for V and −9% to 12% for Zn) among all of the selected trace elements. These elements have demonstrated relatively lower variation for the concentrations and emission factors. The uncertainties of Cd, Hg, Ni and Pb are ranged from −28% to 25%, −24% to 36%, −30% to 23% and −39% to 40%, respectively, which mainly attributed to the variation of concentration between different seams or regions. Thus, more detailed investigation and field tests for these elements are extreme significance for a better understanding of the gaseous emissions of these elements.

Distribution behaviors of trace element in soil and crop around the brick plant

A consensus is emerging that dust can travel long distances along with the wind-blown, as exemplified by Asian dust storms that result in the transport to America43. Similarly, the gaseous emission from the coal gangue firing processes may transport and deposit in the soil and biota around the plant thereout increase the trace elements content in the soil and biota. A comparison of the chemical composition of the local soil and the background value of Huainan soil44 shows marginal enrichment of trace elements of arsenic (by a factor of 2), cadmium (2.3), chromium (1.3), cobalt (1.4), copper (1.9), mercury (1.5), nickel (1.5), lead (1.3), selenium (1.1), tin (1.8), vanadium (1.1) and zinc (1.4) (Table 4). The elevated trace elements concentration in the local soil is consistent with previously reported by Tang et al45. Tang et al determined the concentration of trace elements in soil around a power plant, found that the concentration of trace elements in soil surrounding the power plant is higher than the corresponding content in the soil aloof from the power plant45.

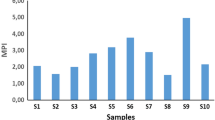

The aerosol particles with diameters less than 10 um (PM10) are supposed to be inhaled through respiratory system and will affect the human organs (lung, bronchus and respiratory tract)46. The process of particulate resuspension depend on factors such as the aerosol particulate size, the physic-chemical properties, wind direction and speed as well as the relatively humidity47. The distribution of trace elements in the soil around the plant is presented at Figure 2. Soil in the northwest and southwest direction has a distinct higher content of trace elements relative to the northeast and southwest soil. It could be inferred that wind is effective in transporting trace elements to some distance rather than directly deposit in the soil near the plant. Trace elements in the flue gas are adsorbed on the finer particulates and form aerosol. For the southeast soil, trace elements such as Se, Cd, Cu, Ni, As, Cr and Zn are enriched at distance of 800 m away from the brick plant, with EFs being 1.6, 3.8, 2.1, 1.7, 2.4, 1.4 and 1.5, respectively44. Mercury, Pb and Sn are enriched at distance of 400 m away from the brick plant and enrichment factor is 2.8, 1.6 and 1.9, respectively. It can be obviously shown that trace elements are mainly deposited at the distance between 400 m and 800 m. Furthermore, results demonstrate those trace elements (Se, Cd, Cu, Ni, As, Cr and Zn) tend to absorb on smaller particulates than Hg, Pb and Sn. The similar tendencies can be found at the northwest soil, except for Se and Sn, selenium and tin at northwest soil are enriched at distance of 400 m. For the northeast and southwest soil, trace elements are mainly enriched at distance between 50 m and 400 m, however the elemental content is slightly higher than the background values of Huainan soil. The distribution pattern of trace elements at northeast and southwest direction may be explained by a deficiency of migration agent (wind). The enrichment of Co is found at distance of 2000 m away from the brick plant. As aforementioned, Co is a non-volatilized element during coal gangue firing, the enrichment here may be explained by an existence of hotspot, which is not impacted by the brick making.

The high contents of trace elements in the fly ash, flue gas and aerosol particulates (Table 1 and Table 4), the existence of fly ash aerosol particulates and the activity of natural radionuclides (Table 3) exposure (both external and incorporated) can disrupt human health both directly (mainly through inhalation and skin exposure) and indirectly (through the food chains antagonistically or synergistically). The concentrations of trace elements in soybean and earthworm around the brick plant are summarized in Table 4. The widely range of trace elements among earthworms may be attributed to the various trace element concentrations in different sampling sites. Marinussen et al (1997) used to evaluate the Cu accumulation in the earthworm in a heavy metal contaminated soils and reported that the tissue Cu concentration increased proportionally with the total Cu content in soils48. The concentrations of trace elements in earthworms in this study were also increased with the increasing of trace element contents in their corresponding soils, which could be identified by the positive relations between the trace element concentrations in earthworms and corresponding soil (r = 0.669 for As, r = 0.524 for Cd, r = 0.528 for Co, r = 0.782 for Cr, r = 0.382 for Cu, r = 0.707 for Hg, r = 0.629 for Ni, r = 0.485 for Pb, r = 0.663 for Sn, r = 0.388 for Se, r = 0.711 for V and r = 0.499 for Zn, respectively) (SI Figure S1). When compared the concentrations of trace elements in soybean with the permissible value in food (GB2762-2005), elements such as Cd, Ni and Pb are much higher in the soybean, while As, Hg and Se are close to the permissible values. An enrichment of cadmium in earthworm is also presented when compare with that in soil (Table 4). These trace elements are recognized as human carcinogens by International Agency for Research on Cancer (IARC) which is related with increasing risks of lung and skin cancers, especially for arsenic, cadmium and nickel, which are classified as Group 1 human carcinogen.

For the high rate of soil-to-plant transfer, cadmium is a toxic element found in common human foodstuffs (rice, oilseed and seafood). Accumulating evidence links environmental exposure to cadmium with increased cancer incidence49. Reeves and Vanderpool reported that cadmium in sunflower kernels had a high toxic potential to kidney50. Long-term exposure to cadmium has been related to diabetes, diabetic nephropathy, hypertension, lung and mammary gland cancer49. Nickel is an essential trace element for plant growth at low concentration. The predominant mechanism of nickel being adsorbed by plants are active transport and passive diffusion51. The soluble nickel compounds are taken up by plants passively, through a cation transport system. Once absorbed by roots of plant, nickel is easily transported to shoots via the xylem through the transpiration stream and can accumulate in neonatal organs such as buds, fruits and seeds and lead to the accumulation in the soybean seeds51. As a Group 1 human carcinogen, a large quantity of nickel intake can lead to adverse health effects such as asthma, chronic bronchitis, birth defects, lung, nose, larynx and prostate cancer. Significant correlations are found between exposure to trace elements (arsenic, mercury and lead) and cancers in the skin, lung and bladder. Moreover, the ecological and health effects of mercury and arsenic in the soil and crops depend on their chemical forms. The inorganic arsenic compounds are more toxic than the organic arsenic compounds. However for Hg, the organic Hg species are more bioavailable and toxicity than inorganic Hg species.

238U, 226Ra, 232Th, 210Pb, 210Po, 40K and 222Rn, which are the main sources of low-dose ionizing radiation exposure in the brick plant, can retain in human lung for long times after inhalation, generally participating in the blood circulation and depositing in bones, finally affect the respiratory system22. Consequently, the combined radioactivity of coal gangue at the brick plant, together with trace elements such as As, Cd, Hg, Ni and Pb, may increase the overall adverse health impacts in exposed populations, particularly for the workers in the brick plant and the residents living around the brick plant (especially for the village at distance between 400 m and 800 m away from the brick plant).

This study provides an initial assessment of the environmental and health impacts associated with a coal gangue brick plant. The selected trace elements are classified as two groups by the criterion of their volatilization. High volatile elements (volatilization ratio higher than 30%) regarding as Cluster one are represented by Cd, Cu, Hg, Pb, Se and Sn, in which can be emitted form flue gas. Cluster two, represented by Cr, Co and V which have low volatilization (less than 5%) and are mostly retained in brick. Arsenic, nickel and zinc are catalogued between Cluster one and Cluster two, whose volatilization lies between 10% and 20%. The volatilized trace elements are adsorbed on the small particulates and released into the atmosphere. Through the wind-driven, flue gas travels and deposits mainly at the northeast and southwest direction around the brick plant, especially at the distance between 400 m and 800 m away from the brick plant. Cadmium, Ni and Pb are accumulated in the soybean grown on the study soil, which may pose potential health impacts. The high activity of natural radionuclides (238U, 226Ra, 232Th, 210Pb, 210Po, 40K and 222Rn) in the brick, fly ash and plant air may increase the risk of damaging respiratory system. It may cause serious environmental and health issues if no countermeasure will be adopted.

Methods

Plant description

This study is carried out at a typical coal gangue brick making plant in China with an annual brick production of eighty million bricks. The firing duration and temperature are 1 h and 950–1150°C, respectively. The raw coal gangue is the by-product of coal mining in the Huainan Coalfield, Anhui. The physical-chemical properties of the selected coal gangue are listed in Table 5.

Sample collection

The processes for coal gangue brick making are crushing, mixing, aging, molding, drying in oven, firing and testing3. Coal gangue, brick, fly ash and fuel gas samples were collected from the molding room, products after firing, dust-collector and stack, respectively. The chimney height of the selected coal gangue brick making plant is approximately 23 m. Flue gas samples were collected from the stack sampling site isokinetically and the sampling period sustained for 1 h according to the American Standard Method EPA 29. Trace elements in the flue gas were trapped with an aqueous acidic solution (H2O2 and KMnO4) and retained in the impingers. Particulates associated with the flue gas were obtained in a filter placed before the impingers. The recovered samples were digested and prepared for Hg analysis by cold vapor atomic absorption spectroscopy (CVAAS). The content of As, Cd, Cr, Co, Cu, Ni, Pb, Se, Sn, V and Zn were determined by inductively coupled plasma mass spectrometry (ICP-MS). For the solid materials sampling, approximately 100, 100 and 10 kg of coal gangue, brick and fly ash were sampled at the aforementioned site for individual sample, corresponding to the sampling of flue gas for 1 h. All the test analysis for each sampling site were implemented in triplicates to guarantee the repeatability. To obtain representative samples, the initial samples were quartered and crushed to pass through a 2 mm sieve in order to be homogenous for the subsequent analysis.

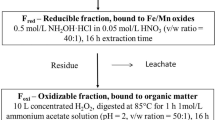

In order to evaluate the potential environmental and health impacts, soil, soybean and earthworm samples around the brick making plant were collected. According to local perennial wind direction, samples were collected from the southeast (SE), southwest (SW), northeast (NE) and northwest (NW) directions at distance of 50, 400, 800, 1200, 2000 m from the brick plant (shown in Figure 3). Soil samples were taken from the upper 2 cm of soil in farmland that had not been disturbed for several months. Soybean and earthworm (Eisenia fetida) samples were collected around each soil sampling site. Subsamples were scraped from four separate level area around each site then pooled to a integrate sample. Only the adult earthworms with well-developed clitella were used for the experiment. Individual of the same size (approximately 90–100 mm) and body weight (about 400–450 mg) were selected to ensure uniform sampling at each site. The earthworms were placed in a Petri dish with a small amount of soil. After back to laboratory, the selected earthworms were cleaned with deionized water thoroughly and quickly and put into a clean Petri dish with a filter paper (the filter paper was moistened by deionized water) at room temperature for 48 h to void their guts completely. The earthworms were freeze-killed, freeze-dried and crushed to pass through a 2 mm mesh for the subsequent analysis. The soybean samples were dried at 60°C and sieved through 2 mm griddle for the subsequent analysis.

Radioactivity analysis

The selected powdered coal gangue, brick, fly ash, particulates in flue gas samples were homogenized and dried at 100°C for 24 h to eliminate moisture. The cooled dry samples (50 g) were placed in a gas-light, radon impermeable cylindrical (diameter of 40 mm) polyethylene containers for 30 d to establish radioactive equilibrium between 226Ra and its relatively short-lived daughter series (222Rn, 218Po, 214Pb, 214Bi and 214Po). The same period also reached the equilibrium between 228Ra and its immediate daughter 228Ac within the 232Th decay series. Once the equilibrium is established, the disintegration rates of the radioactive elements are equaled to their decay products. Thus, the disintegration rates of 228Ra could be measured by its daughter 228Ac. Generally, the activities of 208Tl (which emits photons at 583 keV) and 228Ac (338 keV, 911 keV) in equilibrium with their parents could be represented the activity of 232Th, while the 226Ra activity being represented by activities of 214Pb (295 keV, 352 keV) and 214Bi (609 keV, 1120 keV and 1764 keV)36. In addition, the activities of 238U is determined via its daughter 234Th (63.3 keV). The concentration of 238U, 232Th, 226Ra, 210Pb and 40K were determined by a high-purity germanium gamma ray spectrometer. For 210Po, five gram of the selected samples was treated with HNO3 and then with 4N HCl. After digestion, the digested solution was evaporated to nearly dryness and quantified to 80 mL by adding 1N HCl with ascorbic acid(to reduce the interference of Fe (III)). The tracer (3 Bq/mL) includes 209Po was applied and added into the solution. Then the clean silver planchets were immersed in the solution under 85°C and agitated continuously for 7 h. Finally, the silver planchets were dried by infra-red lamp and the alpha activity of 210Po was counted by alpha spectrometry. Meanwhile, a RAD7 detector was placed at the center of the coal gangue brick making plant at 1.5–2 m height to continuously measure the radon concentration in the environment.

Chemical analysis

The powdered solid samples (coal gangue, brick, fly ash, particles) and standard reference materials were digested using an acidic solution (HCl:HNO3:HF = 3:3:2) in a microwave oven in Teflon beaker at 120°C maintained for 20 min followed by 180°C for 25 min. The rest of HF was neutralized with HBO3. After digestion, the solution was filtered through a 0.45 um filtering membrane and quantified to final 25 ml solution with 3 wt.% HNO3 for the subsequent analysis. This sample digestion procedure was used in several previous studies successfully2,9,13,14. The content of environmental sensitive trace elements in coal gangue, brick and fly ash samples were measured by ICP-MS except for Hg was determined by cold vapour atomic absorption spectrometry.

The quality control was subjected to standard reference materials NIST 1632b (coal) and GBW07406 (GSS- 6) (soil), the analytical values for all the selected trace elements were within the certified values and the recovery ranged from 86% to 103%. The recovery for standard calibration was 89% to 98%, suggesting that there were trace amount of analyte losses during extraction procedures. Meanwhile, reagent blanks were paralleled in the whole analysis to eliminate background contamination. The acceptable precision is within ±5 wt.% for trace elements. The apparatus is required to recalibrate, if difference between the standards and the calibrated values is higher than 5%. In order to guarantee the repeatability and accuracy, all analysis was repeated three times for each sample. The relative standard deviations of the triplicate analysis ranged from −2.16% to 2.68%, which was within the accepted level of ±5 wt.%.

References

Liu, H. B. & Liu, Z. L. Recycling utilization patterns of coal mining in China. Resour., Conserv. Recycl. 54, 1331–1340 (2010).

Zhou, C. C. et al. Mobility behavior and environmental implications of trace elements associated with coal gangue: A case study at the Huainan Coalfield in China. Chemosphere 95, 193–199 (2014).

Kumar, S. A perspective study on fly ash-lime-gypsum bricks and hollow blocks for low cost housing development. Constr. Build. Mater. 16, 519–525 (2002).

Mu, L. et al. Emission characteristics of heavy metals and their behavior during coking processes. Environ. Sci. Technol. 46, 6425–6430 (2012).

Reddy, M. S., Basha, S. & Jha, H. V. J. Evaluation of the emission characteristics of trace metals from coal and fuel iol fired power plants and their fate during combustion. J. Hazard. Mater. B123, 242–249 (2005).

Vassilev, S. V., Braekman-Danheux, C., Laurent, P., Thiemann, T. & Fontana, A. Behaviour, capture and inertization of some trace elements during combustion of refuse-derived char from municipal solid waste. Fuel 78, 1131–1145 (1999).

Johansson, C., Norman, M. & Burman, L. Road traffic emission factors for heavy metals. Atmos. Environ. 43, 4681–4688 (2009).

Shafer, M. M. et al. Chemical speciation of vanadium in particulate matter emitted from diesel vehicles and urban atmosphere aerosols. Environ. Sci. Technol. 46, 189–195 (2012).

Tang, Q., Liu, G. J., Zhou, C. C. & Sun, R. Y. Distribution of trace elements in feed coal and combustion residues from two coal-fired power plants at Huainan, Anhui, China. Fuel 107, 315–322 (2013).

Querol, X., Juan, R., Lopez-Soler, A., Fernandez-Turiel, J. L. & Ruiz, C. R. Mobility of trace elements from coal and combustion wastes. Fuel 75, 821–838 (1996).

Huggins, F. H., Senior, C. L., Chu, P., Ladwig, K. & Huffman, G. P. Selenium and arsenic speciation in fly ash from full-scale coal burning utility plants. Environ. Sci. Technol. 41, 3284–3289 (2007).

Zhang, H., He, P. J. & Shao, L. M. Flow analysis of heavy metals in MSW incinerators for investigating contamination of hazardous components. Environ. Sci. Technol. 42, 6211–6217 (2008).

Zhou, C. C., Liu, G. J., Wu, S. C. & Lam, K. S. P. The environmental characteristics of usage of coal gangue in brick-making: A case study at Huainan, China. Chemosphere 95, 274–280 (2014).

Zhou, C. C., Liu, G. J., Yan, Z. C., Fang, T. & Wang, R. W. Transformation behavior of mineral composition and trace elements during coal gangue combustion. Fuel 97, 644–650 (2012).

Furimsky, E. Characterization of trace element emissions from coal combustion by equilibrium calculations. Fuel Process. Technol. 63, 29–44 (2000).

Yan, R., Gauthier, D. & Flamant, G. Possible interactions between As, Se and Hg during coal combustion. Combust. Flame 120, 49–60 (2000).

Ward, C. R. et al. Element mobility from fresh and long-stored acidic fly ashes associated with an Australian power station. Int. J. Coal Geol. 80, 224–236 (2009).

Ruhl, L. et al. Survey of the potential environmental and health impacts in the immediate aftermath of the coal ash spill in Kingston, Tennessee. Environ. Sci. Technol. 43, 6326–6333 (2009).

Cevik, U., Damla, N., Koz, B. & Kaya, S. Radiological characterization around the Afsin- Elbistan coal-fired power plant in Turkey. Energy Fuels 22, 428–432 (2008).

Zielinski, R. A. & Budahn, J. R. Radionuclides in fly ash and bottom ash: improved characterization based on radiography and low energy gamma-ray spectrometry. Fuel 77, 259–267 (1998).

Mora, J. C., Robles, B., Corbacho, J. A., Gasco, C. & Gazquez, M. J. Modelling the behavior of 210Po in high temperature processes. J. Environ. Radio. 102, 520–526 (2011).

Raut, S. P., Ralegaonkar, R. V. & Mandavgane, S. A. Development of sustainable construction material using industrial and agricultural solid waste: A review of waste-create bricks. Constr. Build. Mater. 25, 4037–4042 (2011).

Zhou, C. C., Liu, G. J., Fang, T., Sun, R. Y. & Wu, D. Leaching characteristic and environmental implication of rejection rocks from Huainan Coalfield, Anhui Province, China. J. Geochem. Explor. 143, 54–61 (2014).

Vassilev, S. V., Braekman-Danheux, C. & Laurent, P. Characterization of refuse-derived char from municipal solid waste. 1. Phase-mineral and chemical composition. Fuel Process. Technol. 59, 95–134 (1999).

Vassilev, S. V., Eskenazy, G. M. & Vassileva, C. G. Behaviour of elements and minerals during preparation and combustion of the Pernik coal, Bulgaria. Fuel Process. Technol. 72, 103–29 (2001).

Vassileva, C. G. & Vassilev, S. V. Behaviour of inorganic matter during heating of Bulgarian coals. 1. Lignites. Fuel Process. Technol. 86, 1297–1333 (2005).

Vassileva, C. G. & Vassilev, S. V. Behaviour of inorganic matter during heating of Bulgarian coals. 2. Subbituminous and bituminous. Fuel Process. Technol. 87, 1095–1116 (2006).

Querol, X., Fernandez-Turiel, J. L. & Lopez-Soler, A. Trace elements in coal and their behaviour during combustion in a large power station. Fuel 74, 331–43 (1995).

Guo, R. X., Yang, J. L., Liu, D. Y. & Liu, Z. Y. Transformation behavior of trace elements during coal pyrolysis. Fuel Process. Technol. 77–78, 137–43 (2002).

Querol, X. et al. Immobilization of heavy metals in polluted soils by the addition of zeolitic material synthesized from coal fly ash. Chemosphere 62, 171–80 (2006).

Ketris, M. P. & Yudovich, Y. E. Estimations of Clarkes for Carbonaceous biolithes: World averages for trace element contents in black shales and coals. Int. J. Coal Geol. 78, 135–148 (2009).

Otero-Rey, J. R. et al. As, Hg and Se flue gas sampling in a coal-fired power plant and their fate during coal combustion. Environ. Sci. Technol. 37, 5262–5267 (2003).

Friedlander, G., Kennedy, J. W. & Miller, J. M. Nuclear and radiochemistry. (Wiley, New York, 1965).

Zhu, J. Q. et al. Survey of natural radionuclide contents in soil in Anhui province. Radi. Protect. 11, 291–294 (1991) (in Chinese with English abstract).

Liu, F. D. et al. Investigation and analysis of the content of natural radionuclides at coal mines in China. Radi. Protect. 27, 171–180 (2007) (in Chinese with English abstract).

Vrecek, P. & Benedik, L. 210Pb and 210Po in fossil fuel combustion at the Sostanj thermal power plant (Slovenia). Czechoslov. J. Phys. 53, A51–A55 (2003).

Sahu, S. K., Tiwari, M., Bhangare, R. C. & Pandit, G. G. Enrichment and particle size dependence of polonium and other naturally occurring radionuclides in coal ash. J. Environ. Radio. 10.1016/j.jenvrad.2014.04.010 (2014).

UNSCEAR. Sources and effects of ionizing radiation. (United Nations, New York, 2000).

Coles, D. G., Ragainl, R. C. & Ondov, J. M. Behavior of natural radionuclides in Western coal-fired power plants. Environ. Sci. Technol. 12, 442–446 (1978).

Liu, H. S. et al. Survey of indoor and outdoor radon concentrations in carbonized brick dwellings in 5 provinces. Radi. Peotect. Communt. 25, 29–33 (2005) (in Chinese with English abstract).

Chen, J. et al. Atmospheric emissions of F, As, Se, Hg and Sb from coal-fired power and heat generation in China. Chemosphere 90, 1925–1932 (2013).

Zhao, Y., Nielsen, C. P., Lei, Y., McElroy, M. B. & Hao, J. Quantifying the uncertainties of a bottom-up emission inventory of anthropogenic atmospheric pollutants in China. Atmos. Chem. Phys. 11, 2295–2308 (2011).

Darmenova, K., Sokolik, I. N. & Darmenov, A. Characterization of east Asian dust outbreaks in the spring of 2001 using ground-based and satellite data. J. Geophy. Res-Atmos. 110, D2 (2005).

Yang, X. Y. et al. The soil element background values and assessment on the soil environmental quality in Huainan area. Acta Pedol. Sin. 34, 344–347 (1997) (in Chinese with English abstract).

Tang, Q., Liu, G. J., Zhou, C. C., Zhang, H. & Sun, R. Y. Distribution of environmentally sensitive elements in residential soils near a coal-field power plant: Potential risks to ecology and children's health. Chemosphere 93, 2473–2479 (2013).

Linak, W. P. et al. Ultrafine ash aerosols from coal combustion: Characterization and health effects. Proceed. Combust. Inst. 31, 1929–1937 (2007).

Nicholson, K. W. A review of particle resuspension. Atmos. Environ. 22, 2639–2651 (1988).

Marinussen, M. P. J. C., van der Zee, S. E. A. T. M. & de Haan, F. A. M. Cu accumulation in the earthworm Dendrobaena veneta in a heavy metal (Cu, Pb, Zn) contaminated site compared to Cu accumulation in laboratory experiments. Environ. Pollut. 96, 227–233 (1997).

Satarug, S., Garrett, S. H., Sens, M. A. & Sens, D. A. Cadmium, environmental exposure and health outcomes. Environ. Health Perspect. 118, 182–190 (2010).

Reeves, P. G. & Vanderpool, R. A. Cadmium burden of men and women report regular consumption of confectionery sunflower kernels containing a natural abundance of cadmium. Environ. Health Perspect. 105, 1098–1104 (1997).

Ahmad, M. S. & Ashraf, M. Essential roles and hazardous effects of nickel in plants. Rev. Environ. Contam. Toxicol. 214, 125–167 (2011).

Acknowledgements

This work was supported by National Basic Research Program of China (973 Program, 2014CB238903), National Science and Technology Support Program (2012BAC10B02), Key Program for Science and Technology Development of Anhui Province (NO. 12010402111), National Natural Science Foundation of China (NO. 41173032 and 41373110),and the Creative project of the Huainan Mining Industry (Group) Co. Ltd.

Author information

Authors and Affiliations

Contributions

G.J.L. proposed the project, C.C.Z., S.W.C. and T.F. prepared the samples, C.C.Z. performed the ICP-MS experiments, T.F. and S.W.C. performed the XRD experiments, C.C.Z. performed the data analysis and wrote the manuscript, P.K.S.L. performed the environmental implication analysis, all authors revised the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Zhou, C., Liu, G., Cheng, S. et al. The Environmental Geochemistry of Trace Elements and Naturally Radionuclides in a Coal Gangue Brick-Making Plant. Sci Rep 4, 6221 (2014). https://doi.org/10.1038/srep06221

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep06221

This article is cited by

-

Experimental study on reconstructed soil properties based on numerical analysis

Environmental Earth Sciences (2021)

-

Assessment of natural radioactivity in coals and coal combustion residues from a coal-based thermoelectric plant in Bangladesh: implications for radiological health hazards

Environmental Monitoring and Assessment (2019)

-

Geochemical valuation and intake of F, As, and Se in coal wastes contaminated areas and their potential impacts on local inhabitants, Shaanxi China

Environmental Geochemistry and Health (2018)

-

The partitioning behavior of trace element and its distribution in the surrounding soil of a cement plant integrated utilization of hazardous wastes

Environmental Science and Pollution Research (2016)

-

Trace element partitioning behavior of coal gangue-fired CFB plant: experimental and equilibrium calculation

Environmental Science and Pollution Research (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.