Abstract

5-Aminovalerate is a potential C5 platform chemical for synthesis of valerolactam, 5-hydroxyvalerate, glutarate and 1,5-pentanediol. It is a metabolite of l-lysine catabolism through the aminovalerate pathway in Pseudomonas putida. l-Lysine monooxygenase (DavB) and 5-aminovaleramide amidohydrolase (DavA) play key roles in the biotransformation of l-lysine into 5-aminovalerate. Here, DavB and DavA of P. putida KT2440 were expressed, purified and coupled for the production of 5-aminovalerate from l-lysine. Under optimal conditions, 20.8 g/L 5-aminovalerate was produced from 30 g/L l-lysine in 12 h. Because l-lysine is an industrial fermentation product, the two-enzyme coupled system presents a promising alternative for the production of 5-aminovalerate.

Similar content being viewed by others

Introduction

Polyamides (also known as nylons) are a class of plastics with a variety of uses as textiles and mechanical parts1. Polyamides are formed either as co-polymers via condensation of diacids with diamines, or as homopolymers of amino acids1,2,3,4. Nylon-5 is a polyamide homopolymer produced from amino acid monomers of 5-aminovalerate5. Although nylon 5 has not achieved commercial realization, it possesses properties similar to those of nylon-4,6 and serves as a suitable substitute5. Thus, it would be desirable to find an effective method for the biotechnological production of 5-aminovalerate.

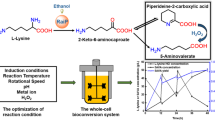

5-Aminovalerate is naturally produced from l-lysine through the 5-aminovalerate pathway6,7. l-Lysine monooxygenase (DavB) and 5-aminovaleramide amidohydrolase (DavA) play key roles in the 5-aminovalerate pathway of various microorganisms6,7. DavB catalyzes the oxidation of l-lysine to produce 5-aminovaleramide. DavA then catalyzes 5-aminovaleramide into 5-aminovalerate6,7.

Fermentation of high concentrations of l-lysine is easily carried out8,9,10,11,12,13,14. Currently, l-lysine has an annual production of more than 2 million tons15. Considering current preparation processes, l-lysine might be a suitable starting material for 5-aminovalerate production. In a previous study, recombinant Escherichia coli strains expressing the davB and davA genes of Pseudomonas putida KT2440 were constructed for the production of 5-aminovalerate from l-lysine16. When the recombinant E. coli was cultured in a medium containing both glucose and l-lysine, 3.6 g/L (30.7 mM) 5-aminovalerate was produced from 7 g/L (47.9 mM) l-lysine16.

Production of 5-aminovalerate from l-lysine by enzymatic methods is another area of emphasis. The advantages of this method are the simple composition of the reaction mixture, high conversion rate of substrate and convenience of recovery17. For example, l-lysine α-oxidase can oxidize l-lysine into 6-amino-2-ketocaproic acid with a high conversion rate18,19,20. Hydrogen peroxide, which is produced during the process of l-lysine oxidization, will further oxidize 6-amino-2-ketocaproic acid to form 5-aminovalerate as the final product21. Under optimum conditions for enzyme activity, 17.5 g/L (120 mM) l-lysine was transformed into 13.4 g/L (114 mM) 5-aminovalerate after aerobic incubation for 5 days at 37°C21.

As shown in Fig. 1, DavB and DavA formed a coupled system for the production of 5-aminovalerate from l-lysine. In this work, DavB and DavA from P. putida KT2440 were expressed and purified. After optimization of the biocatalysis conditions, production of 5-aminovalerate from l-lysine with high yield and high concentration was accomplished through the DavB and DavA coupled system.

Results

Expression and purification of DavB and DavA

The genes davB and davA were amplified by polymerase chain reaction (PCR) from the genome of P. putida KT2440. The fragments were sequenced. The deduced amino acid sequences had no mutational changes in the DavB and DavA proteins of P. putida KT24406. DavB and DavA were expressed and purified to homogeneity through Ni-affinity chromatography. The purified DavB and DavA proteins were both detectable as single bands of 62.4 kDa and 29.3 kDa on SDS-PAGE, respectively (Fig. S1). DavB is a FAD-dependent monooxygenase that catalyzes oxidative decarboxylation of l-lysine with a specific activity of 6.1 U/mg. DavA is a hydrolase that catalyzes the production of 5-aminovalerate from 5-aminovaleramide. The specific activity of DavA was not determined because of the lack of commercial 5-aminovaleramide.

Feasibility of 5-aminovalerate production using the coupled system

To identify the l-lysine oxidation activity of DavB, 5 g/L l-lysine was used as a substrate in 100 mM phosphate buffer (pH 7.4). DavB was added to the reaction broth at a concentration of 0.5 g/L. The reaction was conducted at 30°C for 3 h. Catalytic conversion of 4.5 g/L l-lysine resulted in the accumulation of 5-aminovaleramide in the reaction mixture (Fig. S2A and Table S1). Although 5-aminovaleramide hydrolyzed spontaneously into 5-aminovalerate, only 1.1 g/L 5-aminovalerate was obtained without the addition of DavA (Fig. S2A). Alternatively, when 0.5 g/L DavA was also added to the reaction mixture, 3.4 g/L 5-aminovalerate was obtained from 5 g/L l-lysine (Fig. S2B and Table S1). The yield of 5-aminovalerate was 0.85 mol/mol. Thus, it is desirable to use the DavB and DavA coupled system for 5-aminovalerate production from l-lysine with high yield.

Optimization of biocatalysis conditions

To achieve higher product concentration, the biocatalytic conditions of 5-aminovalerate production from l-lysine were optimized. The influence of reaction pH and temperature on 5-aminovalerate production in 100 mM phosphate buffer containing 10 g/L l-lysine, 0.5 g/L DavB and 0.5 g/L DavA were determined. The pH was adjusted ranging from 5.0 to 9.0. The reaction was initiated by adding the DavB and DavA at 30°C followed by incubation for 3 h. As shown in Fig. 2A, 5-aminovalerate production was the highest at pH 7.0. The transformation of l-lysine to 5-aminovalerate decreased under acidic or alkaline conditions.

To determine the effect of reaction temperature, the same reaction mixture was used as described above (pH at 7.0). After bioconversion at 16, 25, 30, 37, 45, or 55°C for 3 h, the highest 5-aminovalerate production was obtained at 37°C, as shown in Fig. 2B. To determine the effect of l-lysine concentration, reactions with six different l-lysine concentrations (5, 10, 30, 50, 70, or 90 g/L) were conducted at pH 7.0 and 37°C. Samples were taken after 3 h. Conversion rates were determined under each reaction condition. The optimal l-lysine concentration was found to be 30 g/L as shown in Fig. 2C. 5-Aminovalerate production increased as the l-lysine concentration increased up to 30 g/L and decreased thereafter. The ratio of DavA to DavB (0.5 g/L) was also optimized using 30 g/L l-lysine as the substrate at a pH of 7.0 and a temperature of 37°C. As shown in Fig. 2D, 5-aminovalerate production was highest when the ratio of DavA to DavB was 1:1. A ratio of 1:1 (DavA/DavB) was used in subsequent experiments.

Production of 5-aminovalerate from l-lysine under optimal conditions

After optimizing the reaction conditions, the biocatalytic production of 5-aminovalerate from l-lysine was conducted as follows: the reaction mixture contained 30 g/L l-lysine as substrate and 0.5 g/L each of DavB and DavA as the biocatalysts. The reaction was performed at 37°C and a pH of 7.0. As shown in Fig. 3, under the optimal conditions, 20.8 g/L (178 mM) 5-aminovalerate was obtained from 30 g/L (205 mM) l-lysine after 12 h. The yield of 5-aminovalerate from l-lysine was 0.87 mol/mol.

Discussion

With concerns about environmental problems and fossil fuel resource availability, there has been much interest in replacement of petro-chemical derived materials with biologically based, degradable plastic polymers22,23,24,25,26. The production of biodegradable plastics requires the availability of high amounts of monomeric units, such as 3-hydroxypropionate27,28, lactic acid29,30, succinic acid31,32 and 1,3-propanediol33,34. 5-Aminovalerate, another monomeric unit produced from renewable sources, can be used to produce the biologically based, degradable plastic polymer, nylon-5. This compound can also be used as a C5 platform chemical for synthesizing 1,5-pentanediol, glutarate and 5-hydroxyvalerate16,35. For the utilization of this important intermediate, an efficient 5-aminovalerate producing process is desirable.

5-Aminovalerate synthesis from l-lysine is mediated by DavB and DavA in P. putida KT2440. Previous studies have tried to produce 5-aminovalerate from l-lysine using whole-cell cultures of E. coli containing the davB and davA genes. Since 5-aminovalerate is further converted to glutarate via glutarate semialdehyde in these microorganisms, it proved difficult to produce 5-aminovalerate with high yield. In a previous work, Park et al. constructed a recombinant E. coli strain for the production of 5-aminovalerate from l-lysine16. The yield of 5-aminovalerate from l-lysine in this study was 0.64 mol/mol.

Alternatively, enzymatic synthesis of 5-aminovalerate using immobilized l-lysine α-oxidase has been developed21. Production of 13.4 g/L 5-aminovalerate from 17.5 g/L l-lysine was accomplished using this method, which is the highest reported yield of 5-aminovalerate to date. In the present work, coupled reactions catalyzed by purified DavB and DavA were used to produce 5-aminovalerate from l-lysine. Although the yield of 5-aminovalerate (0.87 mol/mol) was lower than the process using l-lysine α-oxidase (0.95 mol/mol), the highest reported product concentration (20.8 g/L) for 5-aminovalerate production from l-lysine was accomplished using the DavB and DavA coupled system. Because of the simple composition of the biocatalytic system, 5-aminovalerate can easily be separated from the reaction broth. Although most of the l-lysine was biotransformed, 5-aminovaleramide accumulation in the reaction mixture was detected indicating the presence of inactive DavA at the end of the reaction (Fig. S3). Increasing the stability and reusability of biocatalysts, especially DavA, through co-immobilization of DavB and DavA might make the coupled process more practical in future research.

In conclusion, the potential C5 platform chemical 5-aminovalerate was produced from l-lysine through a DavB and DavA coupled system. The concentration and yield of 5-aminovalerate were 20.8 g/L and 0.87 mol/mol, respectively. Because l-lysine can be easily produced by fermentation, the biocatalysis process introduced in this study provides a technically and economically valuable method for 5-aminovalerate production.

Methods

Chemicals

5-Aminovalerate, l-lysine, isopropyl-β-D-1-thiogalactopyranoside (IPTG), phenylisothiocyanate (PITC), phenylmethanesulfonyl fluoride (PMSF) and dithiothreitol (DTT) were all purchased from Sigma. PCR primers were obtained from Sangon (Shanghai, China). Ampicillin was purchased from Amresco (USA). Restriction enzymes were obtained from Fermentas (Lithuania). T4 DNA ligase and FastPfu DNA polymerase were purchased from MBI (USA) and Transgen Biotech (China), respectively. All other chemicals were of analytical grade and commercially available.

Bacterial strains, primers and plasmids

Bacterial strains, primers and plasmids used in this study are listed in Table 1. E. coli BL21(DE3) was used for protein expression. E. coli DH5a was used for general cloning. Luria-Bertani (LB) medium was used for E. coli cultivations. P. putida KT2440 was cultured in minimal salt medium (MSM) supplemented with 10.0 g/L dl-lactate as the carbon source36,37. Ampicillin was used at a concentration of 100 μg/mL.

Cloning and expression of davB and davA

Genomic DNA of P. putida KT2440 was extracted using the Wizard Genomic DNA Purification Kit (Promega, Madison, WI, USA). The davB gene was amplified from genomic DNA of P. putida KT2440 using primer B1 with a BamHI restriction site insertion and primer B2 with an EcoRI restriction site insertion. The PCR product was ligated to the pEasy-Blunt vector. The resulting plasmid was designated pEasy-Blunt-davB. pEasy-Blunt-davB was then digested with BamHI and EcoRI. The gel purified davB fragment was ligated to pETDuet-1 vector that had been digested with the same restriction enzymes. The davA gene fragment was obtained from the genome of P. putida KT2440 using primers A1 (with a BamHI restriction site) and A2 (with an EcoRI restriction site), ligated to the pEasy-Blunt vector and then ligated to the pETDuet-1 vector using the process described above.

Purification of DavB and DavA

E. coli BL21(DE3) carrying plasmid pETDuet-davB or pETDuet-davA was grown at 30°C in LB medium with 100 μg/mL ampicillin to an optical density of 0.5 at 620 nm. IPTG was added at a concentration of 0.5 mM to induce the expression of DavB or DavA. After cultivation for another 3 h at 30°C, cells were harvested and washed with 0.85% (wt/vol) sodium chloride solution by centrifugation at 8,000 rpm for 5 min. The cell pellet was subsequently suspended in binding buffer (pH 7.4; 20 mM sodium phosphate, 20 mM imidazole and 500 mM sodium chloride) containing 0.5 mM PMSF, 1 mM DTT and 10% glycerol. Cells were disrupted by sonication (Sonics 500 W; 20 KHz) for 10 min in an ice bath. The cell lysate was centrifuged at 8,000 rpm for 30 min at 4°C. The supernatant was loaded onto a HisTrap HP column (5 mL) and eluted with 40% binding buffer and 60% elution buffer (pH 7.4; 20 mM sodium phosphate, 500 mM imidazole and 500 mM sodium chloride) at a flow rate of 5 mL/min. The fractions containing DavB or DavA were concentrated by ultrafiltration, desalted with gel G-25 and detected by sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE).

Production of 5-aminovalerate from l-lysine

DavB and DavA were coupled for 5-aminovalerate production from l-lysine. A typical coupled reaction was carried out in a 50-mL Erlenmeyer flask with 10 mL reaction broth containing 100 mM phosphate buffer (pH 7.4), 10 g/L l-lysine, 0.5 mg/mL DavB and 0.5 mg/mL DavA. The reaction was conducted at 30°C 200-rpm shaking. Samples (0.2 mL) were taken periodically and centrifuged at 12,000 rpm.

Analytical methods

Cell growth was measured via optical density measured at 620 nm (OD620) using an Ultrospec™ 2100 pro UV/visible spectrophotometer. The oxidase activity of DavB for l-lysine was assayed by measuring the rate of oxygen consumption as follows: the reaction mixture contained 10 mM l-lysine, 100 mM phosphate buffer (pH 7.4) and an appropriate amount of enzyme in a final volume of 0.5 mL. The enzyme activity assay was started with the addition of enzyme solution. Consumption of oxygen was measured using a Clark-type oxygen electrode (Oxytherm System; Hansatech Instruments Ltd). One unit of enzyme activity was defined as the amount of enzyme catalyzing the consumption of one micromole of O2 per min. The protein concentration was determined by the Lowry procedure using bovine serum albumin as the standard38.

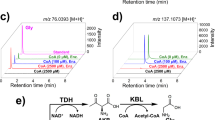

Aqueous concentrations of l-lysine and 5-aminovalerate were measured using a high-performance liquid chromatography (HPLC) system (Agilent 1100 series, Hewlett-Packard) equipped with a UV-Vis detector. Derivatization of 5-aminovalerate and l-lysine by PITC was performed before injection and separation on a ZORBAX SB-C18 (5 μm, 4.6 mm × 250 mm) maintained at 38°C39,40. The mobile phase (supplied at 1 mL/min) consisted of a solution of (A) pH 6.5, 100 mM sodium acetate-acetonitrile (97:3) and (B) acetonitrile-deionized (4:1) ramping (A:B) from 0:100 to 100:0 over 1 h.

References

Adkins, J., Pugh, S., McKenna, R. & Nielsen, D. R. Engineering microbial chemical factories to produce renewable “biomonomers”. Front. Microbiol. 3, 313 (2012).

Qian, Z. G., Xia, X. X. & Lee, S. Y. Metabolic engineering of Escherichia coli for the production of putrescine: a four carbon diamine. Biotechnol. Bioeng. 104, 651–662 (2009).

Qian, Z. G., Xia, X. X. & Lee, S. Y. Metabolic engineering of Escherichia coli for the production of cadaverine: a five carbon diamine. Biotechnol. Bioeng. 108, 93–103 (2011).

Le Vo, T., Kim, T. & Hong, S. Effects of glutamate decarboxylase and gamma-aminobutyric acid (GABA) transporter on the bioconversion of GABA in engineered Escherichia coli. Bioprocess Biosyst. Eng. 35, 645–650 (2012).

Bermudez, M., Leon, S., Aleman, C. & Munoz-Guerra, S. Comparison of lamellar crystal structure and morphology of nylon 46 and nylon 5. Polymer 41, 8961–8973 (2000).

Revelles, O., Espinosa-Urgel, M., Fuhrer, T., Sauer, U. & Ramos, J. L. Multiple and interconnected pathways for l-lysine catabolism in Pseudomonas putida KT2440. J. Bacteriol. 187, 7500–7510 (2005).

Revelles, O., Espinosa-Urgel, M., Molin, S. & Ramos, J. L. The davDT operon of Pseudomonas putida, involved in lysine catabolism, is induced in response to the pathway intermediate delta-aminovaleric acid. J. Bacteriol. 186, 3439–3446 (2004).

Adachi, N. et al. Direct l-lysine production from cellobiose by Corynebacterium glutamicum displaying beta-glucosidase on its cell surface. Appl. Microbiol. Biotechnol. 97, 7165–7172 (2013).

Chen, Z., Meyer, W., Rappert, S., Sun, J. & Zeng, A. P. Coevolutionary analysis enabled rational deregulation of allosteric enzyme inhibition in Corynebacterium glutamicum for lysine production. Appl. Environ. Microbiol. 77, 4352–4360 (2011).

Coello, N., Montiel, E., Concepcion, M. & Christen, P. Optimisation of a culture medium containing fish silage for l-lysine production by Corynebacterium glutamicum. Bioresour. Technol. 85, 207–211 (2002).

Geng, F., Chen, Z., Zheng, P., Sun, J. & Zeng, A. P. Exploring the allosteric mechanism of dihydrodipicolinate synthase by reverse engineering of the allosteric inhibitor binding sites and its application for lysine production. Appl. Microbiol. Biotechnol. 97, 1963–1971 (2013).

Meiswinkel, T. M., Rittmann, D., Lindner, S. N. & Wendisch, V. F. Crude glycerol-based production of amino acids and putrescine by Corynebacterium glutamicum. Bioresour. Technol. 145, 254–258 (2013).

Takeno, S., Murata, R., Kobayashi, R., Mitsuhashi, S. & Ikeda, M. Engineering of Corynebacterium glutamicum with an NADPH-generating glycolytic pathway for l-lysine production. Appl. Environ. Microbiol. 76, 7154–7160 (2010).

van Ooyen, J., Noack, S., Bott, M., Reth, A. & Eggeling, L. Improved l-lysine production with Corynebacterium glutamicum and systemic insight into citrate synthase flux and activity. Biotechnol. Bioeng. 109, 2070–2081 (2012).

Anastassiadis, S. l-lysine fermentation. Recent Pat. Biotechnol. 1, 11–24 (2007).

Park, S. J. et al. Metabolic engineering of Escherichia coli for the production of 5-aminovalerate and glutarate as C5 platform chemicals. Metab. Eng. 16, 42–47 (2013).

Li, Y., Chen, J. & Lun, S. Y. Biotechnological production of pyruvic acid. Appl. Microbiol. Biotechnol. 57, 451–459 (2001).

Chauhan, N., Narang, J., Sunny & Pundir, C. S. Immobilization of lysine oxidase on a gold-platinum nanoparticles modified Au electrode for detection of lysine. Enzyme Microb. Technol. 52, 265–271 (2013).

Kusakabe, H. et al. A new antitumor enzyme, l-lysine alpha-oxidase from Trichoderma viride. Purification and enzymological properties. J. Biol. Chem. 255, 976–981 (1980).

Lukasheva, E. V. & Berezov, T. T. l-Lysine alpha-oxidase: physicochemical and biological properties. Biochemistry (Mosc). 67, 1152–1158 (2002).

Pukin, A. V., Boeriu, C. G., Scott, E. L., Sanders, J. P. M. & Franssen, M. C. R. An efficient enzymatic synthesis of 5-aminovaleric acid. J. Mol. Catal. B Enzym. 65, 58–62 (2010).

Asada, Y., Miyake, M., Miyake, J., Kurane, R. & Tokiwa, Y. Photosynthetic accumulation of poly-(hydroxybutyrate) by cyanobacteria–the metabolism and potential for CO2 recycling. Int. J. Biol. Macromol. 25, 37–42 (1999).

Jung, Y. K., Kim, T. Y., Park, S. J. & Lee, S. Y. Metabolic engineering of Escherichia coli for the production of polylactic acid and its copolymers. Biotechnol. Bioeng. 105, 161–171 (2010).

Yang, T. H. et al. Biosynthesis of polylactic acid and its copolymers using evolved propionate CoA transferase and PHA synthase. Biotechnol. Bioeng. 105, 150–160 (2010).

Reinecke, F. & Steinbuchel, A. Ralstonia eutropha strain H16 as model organism for PHA metabolism and for biotechnological production of technically interesting biopolymers. J. Mol. Microbiol. Biotechnol. 16, 91–108 (2009).

Rojas-Rosas, O., Villafana-Rojas, J., Lopez-Dellamary, F. A., Nungaray-Arellano, J. & Gonzalez-Reynoso, O. Production and characterization of polyhydroxyalkanoates in Pseudomonas aeruginosa ATCC (9027) from glucose, an unrelated carbon source. Can. J. Microbiol. 53, 840–851 (2007).

Rathnasingh, C., Raj, S. M., Jo, J. E. & Park, S. Development and evaluation of efficient recombinant Escherichia coli strains for the production of 3-hydroxypropionic acid from glycerol. Biotechnol. Bioeng. 104, 729–739 (2009).

Rathnasingh, C. et al. Production of 3-hydroxypropionic acid via malonyl-CoA pathway using recombinant Escherichia coli strains. J. Biotechnol. 157, 633–640 (2012).

Zhou, S., Causey, T. B., Hasona, A., Shanmugam, K. T. & Ingram, L. O. Production of optically pure D-lactic acid in mineral salts medium by metabolically engineered Escherichia coli W3110. Appl. Environ. Microbiol. 69, 399–407 (2003).

Mazumdar, S., Clomburg, J. M. & Gonzalez, R. Escherichia coli strains engineered for homofermentative production of D-lactic acid from glycerol. Appl. Environ. Microbiol. 76, 4327–4336 (2010).

Bechthold, I., Bretz, K., Kabasci, S., Kopitzky, R. & Springer, A. Succinic acid: a new platform chemical for biobased polymers from renewable resources. Chem. Eng. Technol. 31, 647–654 (2008).

Jiang, M. et al. Succinic acid production from corn stalk hydrolysate in an E. coli mutant generated by atmospheric and room-temperature plasmas and metabolic evolution strategies. J. Ind. Microbiol. Biotechnol. 41, 115–123 (2014).

Saxena, R. K., Anand, P., Saran, S. & Isar, J. Microbial production of 1, 3-propanediol: recent developments and emerging opportunities. Biotechnol. Adv. 27, 895–913 (2009).

Pflügl, S., Marx, H., Mattanovich, D. & Sauer, M. Heading for an economic industrial upgrading of crude glycerol from biodiesel production to 1,3-propanediol by Lactobacillus diolivorans. Bioresour. Technol. 152, 499–504 (2014).

Adkins, J., Jordan, J. & Nielsen, D. R. Engineering Escherichia coli for renewable production of the 5-carbon polyamide building-blocks 5-aminovalerateand glutarate. Biotechnol. Bioeng. 110, 1726–1734 (2013).

Gao, C., Wang, X., Ma, C. & Xu, P. Production of hydroxypyruvate from glycerate by a novel biotechnological route. Bioresour. Technol. 131, 552–554 (2013).

Gao, C. et al. Efficient production of 2-oxobutyrate from 2-hydroxybutyrate using whole cells of Pseudomonas stutzeri strain SDM. Appl. Envrion. Microbiol. 76, 1679–1682 (2010).

Markwell, M. A. K., Haas, S. M., Bieber, L. L. & Tolbert, N. E. A modification of the Lowry procedure to simplify protein determination in membrane and lipoprotein samples. Anal. Biochem. 87, 206–210 (1978).

Chen, S. The facile HPLC enantioresolution of amino acids, peptides on naphthylethylcarbamate-beta-cyclodextrin bondedphases using the acetonitrile-based mobile phase after their pre-column derivatization with phenylisothiocyanate: factors that affect the resolution. Amino Acids. 26, 291–298 (2004).

Hariharan, M., Naga, S. & VanNoord, T. Systematic approach to the development of plasma amino acid analysis by high-performance liquid chromatography with ultraviolet detection with precolumn derivatization using phenyl isothiocyanate. J. Chromatogr. 621, 15–22 (1993).

Acknowledgements

This work was supported by the Chinese National Program for High Technology Research and Development (2014AA021201), the National Natural Science Foundation of China (J1103515), the Excellent Middle-Aged and Youth Scientist Award Foundation of Shandong Province (BS2013SW025) and the Independent Innovation Foundation of Shandong University (2012GN017).

Author information

Authors and Affiliations

Contributions

C.M., C.G. and P.X. conceived and designed the experiments. P.L., H.Z., M.L., M.H. and Z.L. performed the experiments. C.M., C.G. and P.X. contributed reagents and materials. P.L., H.Z. and C.G. analyzed the data. C.G., C.M. and P.X. wrote the paper. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Material

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/4.0/

About this article

Cite this article

Liu, P., Zhang, H., Lv, M. et al. Enzymatic production of 5-aminovalerate from l-lysine using l-lysine monooxygenase and 5-aminovaleramide amidohydrolase. Sci Rep 4, 5657 (2014). https://doi.org/10.1038/srep05657

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep05657

This article is cited by

-

Efficient whole-cell catalysis for 5-aminovalerate production from L-lysine by using engineered Escherichia coli with ethanol pretreatment

Scientific Reports (2020)

-

Metabolic engineering of Escherichia coli for polyamides monomer δ-valerolactam production from feedstock lysine

Applied Microbiology and Biotechnology (2020)

-

Metabolic engineering of Corynebacterium glutamicum for the production of cis, cis-muconic acid from lignin

Microbial Cell Factories (2018)

-

Expanding lysine industry: industrial biomanufacturing of lysine and its derivatives

Journal of Industrial Microbiology and Biotechnology (2018)

-

Systems metabolic engineering of Corynebacterium glutamicum for the production of the carbon-5 platform chemicals 5-aminovalerate and glutarate

Microbial Cell Factories (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

)

)  ) 5-aminovalerate. Data points represent means ± SD of three parallel replicates.

) 5-aminovalerate. Data points represent means ± SD of three parallel replicates.