Abstract

Monodisperse Cu2ZnSnS4 (CZTS) nanocrystals with tunable shape, crystalline phase and composition are synthesized by efficient thermolysis of a single source precursor of mixed metal-oleate complexes in hot organic solvents with dissolved sulfur sources. Suitable tuning of the synthetic conditions and the Cu/(Zn + Sn) ratio of the precursor has enabled precise control of the crystalline phase in the form of kesterite, or a newly observed wurtzite structure. Nanocrystals with morphology in the form of spherical, rice-like, or rod-like shapes are obtained over a wide range of compositions (0.5 ≤ Cu/(Zn + Sn) ≤ 1.2). Both the final products and intermediates for each shape exhibit consistent composition and structure, indicating homogenous nucleation and growth of single-phase nanocrystals. Thin films prepared from colloidal nanocrystal suspensions display interesting shape-dependent photoresponse behavior under white light illumination from a solar simulator.

Similar content being viewed by others

Introduction

Thin film solar cells fabricated using colloidal semiconductor nanocrystals represent a promising low-cost approach to reducing the fabrication cost of solar cells1,2,3. The size, shape, crystal phase and composition of the nanocrystals play an important role in determining the performance of solar conversion devices4,5,6. Cu2ZnSnS(Se)4 (CZTS(Se)) compositions with kesterite structure have recently attracted a great deal of attention as novel alternative solar cell materials with suitable direct band gap (~1.4–1.5 eV), large optical absorption coefficient (104–105 cm−1) and having non-toxic and earth-abundant constituents7,8,9,10,11,12. Single-junction solar cells fabricated using polycrystalline CZTS(Se) thin films as an absorber layer have achieved solar energy conversion efficiencies as high as 12.6%7. Alternative approaches combining scalable solution processes, such as spray coating, spin-casting and roll-to-roll printing, to fabricate thin film nanocrystal solar cells using inks of colloidal CZTS(Se) nanocrystals can further reduce the fabrication cost9,10,11,12. For example, a robust thin film coating method with composition tunability of CZTS(Se) thin films using kesterite-structured spherical nanocrystal suspensions has provided a cell efficiency of 7.2%9. Recently, annealing mixed sulfide nanoparticles with variable ratios has enabled formation of kesterite-structured CZTSSe films with tunable chemical composition and thus yielded an even higher efficiency of 8.5%10. As for the crystal structure, the random distribution of A and B ions in the recently reported wurtzite phase chalcogenides offers flexibility for stoichiometry control, which is advantageous for fabrication of photovoltaics since it provides the ability to tune the Fermi energy over a wide range13,14. Thus, much effort has been devoted to the development and application of wurtzite-phase nanomaterials, such as CuInS213,14,15, CuInxGa1-xS216, Cu2SnSe317, CuFeS218, Cu2CdSnSe419, etc. There are only a few reports on the synthesis of wurtzite phase CZTS nanocrystals20,21,22. Moreover, the synthesis of ternary and quaternary chalcogenide nanocrystals remains a challenge because of the difficulty in controlling the morphology, phase structure and stoichiometry.

One of the more successful routes for the synthesis of chalcogenide nanocrystals involves the thermal decomposition of organometallic compounds, such as metal acetylacetonates11,23,24, metal carbonyls25,26,27, etc., in high boiling point solvents by hot-injection in the presence of surfactants. This procedure has been utilized for the formation of a variety of monodisperse binary- and ternary- chalcogenide nanoparticles with good crystallinity, uniform size and simple shapes23,24,25,26,27. Recently, inexpensive, environmental-friendly metal-oleate complexes have been developed for the thermolytic synthesis of monodisperse oxides28,29,30,31 and chalcogenides32,33,34,35. However, synthesis of chalcogenide nanocrystals using metal-oleate complexes has thus far been limited to binary and ternary copper-indium-sulfide nanocrystals34 and heterostructures35. Herein, we report a simple, highly efficient synthesis process for producing monodisperse single-phase quaternary CZTS nanocrystals by injection of a novel single source precursor of homogeneously mixed metal-oleate complexes into hot solvents with dissolved sulfur source(s). Appropriate choice of the reaction temperature, higher than the decomposition temperature of constituent oleates, is critical for the compositional and structural uniformity of the nanocrystals (see Supplementary Fig. S1 online). The stoichiometry of the CZTS nanocrystals can be tuned over a wide composition range (0.5 ≤ Cu/(Zn + Sn) ≤ 1.2) by simply varying the Cu/(Zn + Sn) ratio of the metal-oleate complex precursor. Tuning the reaction temperature, the nature of solvents including oleylamine (OLA), 1-octadecene (ODE) and oleic acid (OA) and sulfur reactants including elemental sulfur (S) and dodecanethiol (Dod-SH), has further enabled us to both tailor the morphology in the form of sphere, rod, or rice-like shape and control the crystal phase in the form of the kesterite or wurtzite structure.

Results

The morphology of the as-synthesized nanocrystals has been investigated using transmission electron microscopy (TEM). As shown in Figure 1, monodisperse CZTS nanocrystals in the form of spherical (Figure 1a, d), rod-like (Figure 1b, e) and rice-like (Figure 1c, f) shape are obtained depending on the synthesis conditions. Figure 1a displays the TEM image of spherical CZTS nanocrystals synthesized in a mixture of OLA and ODE. The average size of the nanocrystals is 12.3 ± 0.6 nm. In contrast, rod-like CZTS nanocrystals (Figure 1b) with an average length of 45.4 ± 3.5 nm and diameter of 12.6 ± 2.3 nm are synthesized in ODE. The use of 25 ml OA as a solvent leads to the formation of rice-like CZTS nanocrystals (Figure 1c), with average dimensions of 10.2 ± 2.8 nm in length and 8.4 ± 2.2 nm in maximum diameter. High-resolution (HR)-TEM images of individual nanocrystals for the three different shapes show clear lattice fringes, indicating the single crystalline nature of the nanocrystals. The d spacing measured for 1D rod-like (Figure 1e) and rice-like (Figure 1f) nanocrystals are 0.314 ± 0.006 and 0.318 ± 0.005 nm, respectively, corresponding to the (002) lattice plane of wurtzite CZTS, indicating preferential growth along the [001] direction.

Unlike binary and ternary chalcogenides, quaternary CZTS offers more flexible physical properties because of the increased chemical and structural degrees of freedom7,8,9,10,11,12. However, this freedom also creates a challenge in controlling the stoichiometry and crystal structure. CZTS usually crystallizes in the kesterite or stannite structure. Recently, a new wurtzite crystal structure has been reported20,21,22. We have successfully synthesized CZTS nanocrystals with different crystal structure by varying the type of sulfur source and/or the reaction temperature. The use of Dod-SH has been considered to be a primary factor for the formation of wurtzite CZTS20 due to its strong coordination with metal cations. Wurtzite CZTS nanorods have been synthesized using a mixture of thiols with ODE as solvent21. In the present study, we found that the synthesis in ODE with the use of excess Dod-SH (40 times that of Cu2ZnSn(C18H33O2)10) results in the formation of wurtzite and kesterite structure at low (200–280°C) and high (>300°C) synthesis temperatures, respectively (Table 1). This temperature-dependent phase formation preference may be partially attributed to the loss of Dod-SH capping ligand at higher temperatures (>300°C), which has also been observed for the synthesis of CuInS236 and Cu2FeSnS437 nanocrystals. By replacing Dod-SH with elemental S, pure kesterite CZTS can form at both low (200°C) and high (300°C) temperatures with stoichiometric sulfur/metal ratio, while wurtzite CZTS is formed at 250°C for a wide range of sulfur/metal molar ratios (4–32) (Table 1, see Supplementary Fig. S1 online). Elemental S has widely been used for the synthesis of kesterite CZTS nanocrystals9,11,12, but we have observed that by using excess sulfur (sulfur/metal molar ratio = 8), wurtzite CZTS can also be successfully obtained at a higher temperature (300°C) (see Supplementary Fig. S1c online). The excess sulfur likely plays the role of a capping ligand that binds to specific crystal planes and favors the growth of the wurtzite phase. In general, the nature of sulfur source, reaction temperature, sulfur/metal molar ratio are primary factors that influence the crystals phase of CZTS nanocrystals.

The X-ray diffraction (XRD) patterns of typical as-synthesized CZTS nanocrystal samples and crystal structures of wurtzite-type and kesterite-type Cu2ZnSnS4 are shown in Figure 2. Rietveld refinements (blue line in Figure 2 and Supplementary Table S1–S4) are utilized to further analyze the basic crystal structure parameters of CZTS nanocrystals based on the experimental XRD patterns. Figure 2a shows the experimental (red dots) and simulated XRD pattern (red line) for the wurtzite CZTS nanocrystals. Since no standard XRD pattern belonging to wurtzite CZTS exists in the database, a simulated pattern has been obtained based on the structure. Both the experimental and simulated patterns match well, confirming the wurtzite structure of the nanocrystals. The crystal structure parameters obtained from Rietveld refinement of the experimental pattern are a = 3.809 Å and c = 6.300 Å with space group of P63mc. Figure 2b shows the experimental (red dots) and standard XRD pattern (red line) of typical Kesterite CZTS nanocrystals. The peak position and relative intensity of the primary diffraction peaks for the nanocrystals agree well with the standard kesterite diffraction pattern (space group  ; a = 5.427 Å; c = 10.840 Å. JCPDS No. 26–0575, Figure 2b). The kesterite and stannite powder XRD patterns differ only slightly in the splitting of the higher order peaks, such as of (220)/(204) and (116)/(312), due to small differences in the tetragonal distortion (c/2a). Thus, it is difficult to unambiguously distinguish between the kesterite and stannite structures using XRD alone because of peak broadening, as reported previously12. Some of the minor peaks are also not clearly observed because of the small size of the nanocrystals. Similar Rietveld refinements (Figure 2b blue line and Supplementary Table S3, S4) have been done for kesterite CZTS nanocrystals. The crystal structure parameters obtained from Rietveld refinement of the experimental pattern are a = 5.432 Å and c = 10.764 Å with space group of

; a = 5.427 Å; c = 10.840 Å. JCPDS No. 26–0575, Figure 2b). The kesterite and stannite powder XRD patterns differ only slightly in the splitting of the higher order peaks, such as of (220)/(204) and (116)/(312), due to small differences in the tetragonal distortion (c/2a). Thus, it is difficult to unambiguously distinguish between the kesterite and stannite structures using XRD alone because of peak broadening, as reported previously12. Some of the minor peaks are also not clearly observed because of the small size of the nanocrystals. Similar Rietveld refinements (Figure 2b blue line and Supplementary Table S3, S4) have been done for kesterite CZTS nanocrystals. The crystal structure parameters obtained from Rietveld refinement of the experimental pattern are a = 5.432 Å and c = 10.764 Å with space group of  . No additional peaks belonging to ZnS, SnS and Cu2S are observed in the diffraction patterns, which confirm the synthesized CZTS nanocrystals are single phase.

. No additional peaks belonging to ZnS, SnS and Cu2S are observed in the diffraction patterns, which confirm the synthesized CZTS nanocrystals are single phase.

(a, b) Experimental (red dots), simulated (red line) and Rietveld fit (blue line) XRD patterns of representative CZTS nanocrystals with (a) wurtzite and (b) kesterite structures. Standard XRD pattern (JCPDS No. 26-0575) of kesterite structured CZTS is also given in Figure 2b. (c) Illustration of crystal structure of unit cell and 2 × 2 × 2 unit cells of wurtzite-type Cu2ZnSnS4 and unit cell of kesterite -type Cu2ZnSnS4.

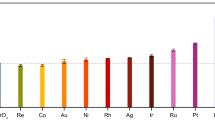

Previous studies have shown that the elemental composition of CZTS nanocrystals strongly influences the performance of the final device. The best CZTS devices have been obtained with Cu-poor and Zn-rich stoichiometry, with Cu/(Zn + Sn) ratio in the range of 0.8 to 0.95, to avoid the formation of impurity binary or ternary copper chalcogenides that can degrade device performance9,38,39. However, a recent study on CZTSe nanocrystal solar cells shows that an intermediate Cu-rich precursor together with KCN treatment for etching the CuxS impurities results in enhanced cell efficiency of 7.5%, partly because of the better current collection properties40. Thus, precise compositional control of quaternary chalcogenide nanocrystals is very important. In our study, the elemental composition of as-synthesized CZTS nanocrystals is readily controlled by simply varying the molar ratio of Cu/(Zn + Sn) in the as-prepared CuxZnSn-(C18H33O2)6+2x metal-oleate precursor, with ratios from 0.5 to 1.2 in interval steps of 0.1. The crystal structure of all the as-synthesized CZTS nanocrystal products under appropriate reaction conditions has been confirmed to be pure wurtzite structure without any other binary or ternary impurities, as confirmed by XRD (see Supplementary Fig. S2 online). This further illustrates the advantage of wurtzite structure for flexible stoichiometry control. The average elemental composition of the synthesized CZTS nanocrystals, as determined by Energy-dispersive X-ray spectroscopy (EDAX), show the composition is tunable and consistent Cu/(Zn + Sn) ratios for the CZTS nanocrystal products (Supplementary Table S5) are observed. Note that CZTS nanocrystals with decreasing copper content show some deviation from the expected elemental ratio, which may be due to the difficulty in forming a stoichiometric solid solution with larger Sn atoms, similar to that reported for Cu-In-S nanocrystals15. The optical properties of CZTS nanocrystals with wurtzite and kesterite structures have been studied by UV-Vis absorption spectroscopy (see Supplementary Fig. S3 online). The band gaps have been obtained by plotting (Ahν)2 versus hν (A = absorbance, h = Planck's constant and ν = frequency) and extrapolating the linear portion of the spectrum in the band edge region. The band gaps are determined to be 1.56 ± 0.04 eV and 1.45 ± 0.03 eV for the wurtzite and kesterite CZTS nanocrystals, respectively. These values are close to the theoretical energy gap of ~1.5 eV for kesterite CZTS41 and the reported 1.4–1.6 eV values for the kesterite9,10,11,12 and wurtzite20,21,22 CZTS nanocrystals.

In order to evaluate its potential as an active layer for photovoltaic applications, we have measured the optical, photoconductivity and electrical properties of wurtzite CZTS nanocrystal films with shape variation. The morphology and thickness of the thin films have been investigated using a Scanning Electron Microscope (SEM). As shown in Figure 3(a, b), the surface of the CZTS nanorod films displays good uniformity over a large area with very few cracks and the cross-section of the film exhibits densely packed structure with thickness of ~500 nm. The optical properties for wurtzite CZTS with spherical, rod-like and rice-like shapes have been investigated using UV-vis absorption spectroscopy (Figure 3c). The band gap for rod-like CZTS nanocrystals has been determined to be around 1.55 ± 0.04 eV, which is in accordance with reported values20,21,22. A blue shift to longer wavelength is observed for both spherical and rice-like CZTS nanocrystals, with band gaps of around 1.65 ± 0.03 eV. As compared to rod-like nanocrystals, spherical and rice-like CZTS nanocrystals have smaller particle size of around 10–12 nm (Figure 1a,c). Thus the blue shift may be due to size effect, which has previously also been observed for CuInS2 nanocrystals42. The photoresponse properties of the films have been studied with FTO and ITO glass as bottom and top electrode, respectively. I–V curves of thin films after annealing at 300°C have been measured both in the dark and under illumination using a solar simulator (AM 1.5 G irradiation, 100 mW·cm−2). A current enhancement is observed under illumination for all samples, as shown in Figure 3d, which has also been reported for other semiconductor nanocrystal films20. The dark current for three samples varies in the sequence rice-like < spherical < rod-like CZTS thin films, whereas the measured photocurrents are higher by 39% for rice-like, 17.2% for spherical shape and 27.1% for rod-like CZTS thin films at 1000 mV as compared to the dark current. The photoresponse behavior exhibits obvious shape-dependent properties. The comparatively lower photocurrent for spherical shaped and rice-like CZTS nanocrystals may be due to charge recombination at the grain boundaries. In contrast, 1D rod-like CZTS thin films display the highest photocurrent, benefitting from improved charge transfer characteristics similar to other 1D nanostructures, such as TiO2 nanotube and nanowires43,44. Besides, the nanorods display better photocurrent behaviour than nanospheres could also be indicative of the inefficiency of removal of oleate coating for the spherical CZTS. The difference of photocurrents between particles with rice and sphere-like shapes is interesting because the rice-like shaped particles likely have a less dense capping layer at the sharp apex and thus facilitate carrier transfer.

SEM images of (a) top and (b) cross-section view of CZTS thin film fabricated from CZTS nanorods. (c) Room temperature absorption spectra for spherical, rod-like and rice-like CZTS nanocrystals. Inset shows extrapolation of the spectra in the band edge region for determination of the band gap. (d) Photocurrent response of CZTS nanocrystal thin films made from a-b spherical, c-d rod-like and e-f rice-like CZTS nanocrystals.

Efficiency of the semiconductor NPs as the PV materials is strongly dependent on the possibility to remove the insulating gaps between the NPs in the deposited films45,46. We have also investigated the shape-dependent variations in terms of electrical conductivity, carrier concentration and Hall mobility. The electrical properties have been studied by Hall effect measurements with applied magnetic field of 0.56 T using four point probe with the Van der Pauw method. As determined from the Hall coefficient, all the different shape samples exhibit p-type conductivity. The resistivity, carrier concentrations and Hall mobility of CZTS for various shapes are summarized in Table 2. The CZTS thin film composed of rod-like nanocrystals exhibits the lowest resistivity, which may be due to efficient charge transfer for 1-D structure and this is consistent with the high current observed in the I–V curve (Figure 3d). Furthermore, the rod-like CZTS display the highest carrier concentration as compared to the spherical and rice-like nanocrystals, which is beneficial for photovoltaic application. As for the Hall mobility, spherical and rice-like NCs show similar values and are higher than that for the rod-like sample.

The preliminary results based on photo-response behavior demonstrate that CZTS nanocrystals have potential for use as the active layer in thin film solar cells. 1D nanostructures with tunable geometric parameters, such as length and diameter, can allow to maximize the optical absorption and improve charge transfer characteristics. Their electrical properties satisfy the requirements for potential application in thin film photovoltaic cells.

Discussion

Metal-oleate complexes formed via low-temperature reaction of the constituent metal halides with sodium oleate have been utilized for the thermolysis synthesis of a variety of monodisperse oxides28,29,30,31. The synthesis of chalcogenide nanocrystals using metal-oleate complexes has thus far been limited to copper-indium sulfide nanocrystal heterostructures13,35. Instead of forming nanocrystals of uniform composition, segregation of Cu2S/In2S3 and Cu2S/CIS results in the formation of unusual heterostructures of various shapes. This behavior can primarily be attributed to the differences in the decomposition temperature of the Cu- and In-oleate precursors. In the present study, the homogeneous nucleation and growth of CZTS nanocrystals with well-controlled morphologies are due to the use of a single source precursor of Cu2ZnSn-oleate complexes. The TGA curves (Figure 4a) for the Cu2(C18H33O2)4 and Sn(C18H33O2)4 complexes exhibit similar weight loss behavior over a close temperature range, while the TGA curve of the Zn(C18H33O2)2 complex shows weight loss at higher temperatures. In contrast, the TGA curve of the mixed Cu2ZnSn-oleate complexes shows a small weight loss below 200°C and a much large, rapid and continuous weight loss at temperatures above 250°C, indicating that the Cu2ZnSn-oleate complex is intimately mixed, essentially forming a single precursor of Cu2ZnSn(C18H33O2)10 complex with similar decomposition temperatures. This is critical for the compositional and structural uniformity of the nanocrystals. This has also been conclusively demonstrated in our earlier study of the synthesis of ferrites using well-mixed metal-oleate complexes as precursors31. Besides the TGA curves, the DSC curves for Cu2(C18H33O2)4, Sn(C18H33O2)4, Zn(C18H33O2)2 and Cu2ZnSn(C18H33O2)10 complexes have been measured as shown in Figure 4b that provide useful information regarding the thermal changes of the complexes during the heating-up process. An endothermic peak below 100°C indicates the existence of small amount of water in the Zn(C18H33O2)2 complex due to its propensity for hydrolysis in air. The temperature for the weight losses (Figure 4a) matches well with that for the thermal changes (Figure 4b), which further confirms the formation of a single precursor of Cu2ZnSn(C18H33O2)10 complex.

To better understand the formation of 1D rod-like and rice-like CZTS nanocrystals, the nucleation and growth processes for each shape have been systematically studied. As seen in Figure 5, by merely changing the aging time, along with increasing the size of nanocrystals the shape of the nanocrystals varies from spherical nanodots at 0.5 min (Figure 5a), to elongated nanocrystals at 1.5 min (Figure 5b), mixed short nanorods at 5 min (Figure 5c) and nanorods at 10 min (Figure 5d). The final products formed at 30 min are uniform nanorods (Figure 1b) having the wurtzite structure (see Supplementary Fig. S4a online). In contrast, the formation of rice-like nanocrystals involves initial formation of spherical nanodots at 0.5 min (Figure 5e), dominant spherical nanodots mixed with a few long tadpole-like nanocrystals at 1.5 min (Figure 5f) and rice-like shapes with increased size after 5 and 10 min (Figure 5g–h). Further aging for 20 min results in the formation of uniform rice-like nanocrystals (Figure 1c) with the wurtzite structure (see Supplementary Fig. S4b online).

The shape of the nanocrystal products is found to be strongly influenced by the precursor concentration and nature of solvents47,48,49,50. At high precursor concentrations, many nuclei with uniform small size (Figure 5i) are formed abruptly because of the rapid decomposition of most of the precursor. All the nuclei then grow uniformly at a high rate until the residual precursor is consumed, eventually forming monodisperse spherical nanocrystals (Figure 1a). In contrast, low precursor concentration in neutral ODE or acidic OA allows for relatively slow nucleation, with most of the precursor still present in the solvent. Thus, larger nuclei grow at the expense of smaller nuclei (Figure 5a–b, e–f). The relatively slow growth rate of larger nuclei results in the formation of metastable 1D nanostructures, such as rod-like (Figure 5c–d), tadpole-like and rice-like shapes (Figure 5g–h). It is noted that a few tadpole-like nanocrystal intermediate with relatively large size (Figure 5f) initially formed are then converted into uniform small size rice-like nanocrystals with prolonged reaction time. This process is somewhat different from the well-known interparticle Ostwald ripening process, which occurs at monomer concentrations several times lower than for intrerparticle ripening49. On the other hand, the etching effect of free OA, which can dissolve the relatively small nanocrystals and balance between the process of growth and dissolution of nanocrystals, will further influence the morphology evolution during crystal growth50. The wurtzite structure of CZTS nanocrystals that favors the growth of anisotropic rod-like and rice-like shapes has also been observed for the synthesis of other wurtzite-structured semiconductors, such as CIGS, ZnO, etc16,51,52.

In conclusion, we have reported a solution-based method for the synthesis of CZTS nanocrystals by hot-injection of a single source mixed metal-oleate complex into hot organic solvents with dissolved sulfur sources. Depending on the reaction conditions, monodisperse CZTS nanocrystals with both wurtzite and kesterite crystal structures can be synthesized with spherical, rice-like and rod-like shapes. The band gaps for CZTS nanocrystals with wurtzite and kesterite structures are determined to be 1.56 and 1.45 eV, respectively. The composition of the as-synthesized CZTS nanocrystals can be readily controlled over a wide range (0.5 ≤ Cu/(Zn + Sn) ≤ 1.2) by merely changing the molar ratio of cations in the precursor. The synthesized CZTS nanocrystals, showing obvious shape-dependent photoresponse behavior, with highest obtained photocurrent for rod-like CZTS nanocrystals, are promising as light absorber materials.

Methods

Preparation of mixed metal-oleate complexes Cu2ZnSn-(C18H33O2)10

For the preparation of metal-oleate complexes, 20 mmol sodium oleate and a mixture of 4 mmol Cu2+, 2 mmol Zn2+ and 2 mmol Sn4+ chlorides were dissolved in mixed solvents of 20 ml H2O, 15 ml ethanol and 30 ml hexane at 60°C under reflux for 4 h. The resulting metal-oleate complex Cu2ZnSn-(C18H33O2)10 was obtained by separation of the water phase and subsequent evaporation of the residual ethanol and hexane at 70°C and water at 110°C.

Synthesis of Cu2ZnSnS4 nanocrystals

All the experiments were carried out in a fume hood under inert N2 atmosphere using standard Schlenk techniques. In a typical synthesis of spherical nanocrystals, 2 g Cu2ZnSn-(C18H33O2)10 was dissolved in 2 ml ODE at 120°C under starring, forming a homogeneous precursor solution. 5 ml Dod-SH was dissolved in a mixture of 10 ml OLA and 15 ml ODE in a four-neck round-bottom flask and stirred at room temperature for 30 min with nitrogen purging. The solution was then heated to 250°C and 2 ml precursor solution was rapidly injected into the solution under a N2 atmosphere with continuous stirring. The reaction solution was maintained at 250°C for 30 min and was subsequently cooled down to room temperature. A mixture of hexane and ethanol was used to precipitate the product and collect it via centrifugation. Rod and rice-shaped nanocrystals were synthesized by injecting 0.4 ml precursor solution in 25 ml ODE and 25 ml OA, respectively. The other procedures were the same as described for the synthesis of spherical nanocrystals.

Deposition of Cu2ZnSnS4 thin films

The Cu2ZnSnS4 thin films were deposited by a spray-painting method. Firstly, the Cu2ZnSnS4 nanocrystals with different shapes were dispersed in ethanol to form an ink with concentration of ~2.5–5 mg/ml. Cu2ZnSnS4 thin films were spray-deposited using the suspension onto FTO glass, followed by annealing under N2 atmosphere at 300°C for 30 min. The photoresponsive properties of the NCs have been studied with FTO and ITO glass as bottom and top electrode, respectively.

Characterization

The morphology and size distribution of the nanocrystals were studied using transmission electron microscopy (TEM, FEI Tecnai F-20). X-ray powder diffraction (XRD, Bruker D8) was used to study the structure of the nanocrystals. The optical properties were investigated using a UV-Vis spectrometer (Varian Cary 50). The composition of the nanocrystals was determined using energy-dispersive x-ray spectroscopy (EDAX). Thermogravimetric analyses (TGA) were performed on a NETZSCH STA 449C thermogravimetric analyzer. For determining the photoresponse behaviour, a solar simulator with an illumination intensity of one sun (AM 1.5, 100 mW/cm2, Newport Corporation) was used as the light source for illumination. An EG&G potentiostat was used to measure the photoresponse of the thin films. The carrier concentration, Hall mobility and electrical resistivity were obtained using a Hall effect measurement system (HMS-3000, Ecopia) with applied magnetic field of 0.56 T by a four point probe with the Van der Pauw method.

References

Habas, S. E., Platt, H. A. S., van Hest, M. F. A. M. & Ginley, D. S. Low-cost inorganic solar cells: from ink to printed device. Chem. Rev. 110, 6571–6594 (2010).

Ip, A. H. et al. Hybrid passivated colloidal quantum dot solids. Nature Nanotech. 7, 577–582 (2012).

Koleilat, G. I. et al. Folded-light-path colloidal quantum dot solar cells. Sci. Rep. 3, 2166 (2013)

El-Sayed, M. A. Small is different: shape-, size- and composition-dependent properties of some colloidal semiconductor nanocrystals. Acc. Chem. Res. 37, 326–333 (2004).

Xia, Y., Xiong, Y., Lim, B. & Skrabalak, S. E. Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics? Angew. Chem. Int. Ed. 48, 60 (2009).

Kongkanand, A., Tvrdy, K., Takechi, K., Kuno, M. & Kamat, P. V. Quantum dot solar cells. tuning photoresponse through size and shape control of CdSe-TiO2 architecture. J. Am. Chem. Soc. 130, 4007–4015 (2008).

Wang, W. et al. Device characteristics of CZTSSe thin-film solar cells with 12.6% efficiency. Adv. Energy. Mater. 4, 1301465 (2014).

Woo, K. et al. Band-gap-graded Cu2ZnSn(S1-x,Sex)4 solar cells fabricated by an ethanol-based, particulate precursor ink route. Sci. Rep. 3, 3069 (2013).

Guo, Q. et al. Fabrication of 7.2% efficient CZTSSe solar cells using CZTS nanocrystals. J. Am. Chem. Soc. 132, 17384–17386 (2010).

Cao, Y. et al. High-efficiency solution-processed Cu2ZnSn(S,Se)4 thin-film solar cells prepared from binary and ternary nanoparticles. J. Am. Chem. Soc. 134, 15644–15647 (2012).

Steinhagen, C., Panthani, M. G., Akhavan, V., Goodfellow, B., Koo, B. & Korgel, B. A. Synthesis of Cu2ZnSnS4 nanocrystals for use in low-cost photovoltaics. J. Am. Chem. Soc. 131, 12554–12555 (2009).

Guo, Q., Hillhouse, H. W. & Agrawal, R. Synthesis of Cu2ZnSnS4 nanocrystal ink and its use for solar cells. J. Am. Chem. Soc. 131, 11672–11673 (2009).

Conner, S. T., Hsu, C., Weil, B. D., Aloni, S. & Cui, Y. Phase transformation of biphasic Cu2S-CuInS2 to monophasic CuInS2 nanorods. J. Am. Chem. Soc. 131, 4962–4966 (2009).

Qi, Y., Liu, Q., Tang, K., Liang, Z., Ren, Z. & Liu, X. Synthesis and characterization of nanostructured wurtzite CuInS2: a new cation disordered polymorph of CuInS2 . J. Phys. Chem. C 113, 3939–3944 (2009).

Pan, D. et al. Synthesis of Cu-In-S ternary nanocrystals with tunable structure and composition. J. Am. Chem. Soc. 130, 5620–5621 (2008).

Wang, Y., Zhang, X., Bao, N., Lin, B. & Gupta, A. Synthesis of shape-controlled monodisperse wurtzite CuInxGa1-xS2 semiconductor nanocrystals with tunable band gap. J. Am. Chem. Soc. 133, 11072–11075 (2011).

Norako, M. E., Greaney, M. J. & Brutchey, R. L. Synthesis and characterization of wurtzite-phase copper tin selenide nanocrystals. J. Am. Chem. Soc. 134, 23–26 (2012).

Kumar, P., Uma, S. & Nagarajan, R. Precursor driven one pot synthesis of wurtzite and chalcopyrite CuFeS2 . Chem. Commun. 49, 7316–7318 (2013).

Cui, Y., Wang, G. & Pan D. Synthesis and photoresponse of novel Cu2CdSnS4 semiconductor nanorods. J. Mater. Chem. 22, 12471–12473 (2012).

Lu, X., Zhuang, Z., Peng, Q. & Li, Y. Wurtzite Cu2ZnSnS4 nanocrystals: a novel quaternary semiconductor. Chem. Commun. 47, 3141–3143 (2011).

Singh, A., Geaney, H., Laffir, F. & Ryan, K. M. Colloidal synthesis of wurtzite Cu2ZnSnS4 nanorods and their perpendicular assembly. J. Am. Chem. Soc. 134, 2910–2913 (2012).

Li, M. et al. Synthesis of pure metastable wurtzite CZTS nanocrystals by facile one-pot method. J. Phys. Chem. C 116, 26507–26516 (2012).

Coughlan, C., Singh, A. & Ryan, K. M. Systematic study into the synthesis and shape development in colloidal CuInxGa1−xS2 nanocrystals. Chem. Mater. 25, 653–661 (2013).

Wang, Y., Bao, N., Shen, L., Padhan, P. & Gupta, A. Size-controlled synthesis of magnetic CuCr2Se4 nanocrystals. J. Am. Chem. Soc. 129, 12408 (2007).

Cao, Y. C. & Wang, J. One-pot synthesis of high-quality zinc-blende CdS nanocrystals. J. Am. Chem. Soc. 126, 14336–14337 (2004).

Pradhan, N. & Peng, X. Efficient and color-tunable Mn-doped ZnSe nanocrystal emitters: control of optical performance via greener synthetic chemistry. J. Am. Chem. Soc. 129, 3339–3347 (2007).

Xie, R., Rutherford, M. & Peng, X. Formation of high-quality I-III-VI semiconductor nanocrystals by tuning relative reactivity of cationic precursors. J. Am. Chem. Soc. 131, 5691–5697 (2009).

An, K. et al. Synthesis, characterization and self-assembly of pencil-shaped CoO nanorods. J. Am. Chem. Soc. 128, 9753–9760 (2006).

Kwon, S. G. et al. Kinetics of monodisperse iron oxide nanocrystal formation by “heating-up” process. J. Am. Chem. Soc. 129, 12571–12584 (2007).

Chen, C., Chen, D., Jiao, X. & Chen, S. In2O3 nanocrystals with a tunable size in the range of 4–10 nm: one-step synthesis, characterization and optical properties. J. Phys. Chem. C 111, 18039–18043 (2007).

Bao, N., Shen, L., Wang, Y., Padhan, P. & Gupta A. A facile thermolysis route to monodisperse ferrite nanocrystals. J. Am. Chem. Soc. 129, 12374–12375 (2007).

Choi, S. Y., An, K., Kim, E. G., Yu, J. H., Kim, J. H. & Hyeon, T. Simple and generalized synthesis of semiconducting metal sulfide nanocrystals. Adv. Funct. Mater. 19, 1645–1649 (2009).

Zhong, H. et al. Monodispersed ZnSe colloidal microspheres: preparation, characterization and their 2D arrays. Langmuir 23, 9008–9013 (2007).

Bao, N. et al. Facile thermolysis synthesis of CuInS2 nanocrystals with tunable anisotropic shape and structure. Chem. Commun. 47, 9441–9443 (2011).

Choi, S.-H., Kim, E.-G. & Hyeon, T. One-pot synthesis of copper-indium sulfide nanocrystal heterostructures with acorn, bottle and larva shapes. J. Am. Chem. Soc. 128, 2520–2521 (2006).

Batabyal, S. K., Tian, L., Venkatram, N., Ji, W. & Vittal, J. J. Phase-selective synthesis of CuInS2 nanocrystals. J. Phys. Chem. C 113, 15037–15042 (2009).

Zhang, X. et al. Crystal phase-controlled synthesis of Cu2FeSnS4 nanocrystals with a band gap of around 1.5 eV. Chem. Commun. 48, 4956–4958 (2012).

Todorov, T. K., Reuter, K. B. & Mitzi, D. B. High-efficiency solar cell with earth-abundant liquid-processed absorber. Adv. Mater. 22, E156–E159 (2010).

Fairbrother, A. et al. Development of a selective chemical etch to improve the conversion efficiency of Zn-rich Cu2ZnSnS4 solar cells. J. Am. Chem. Soc. 134, 8018–8021 (2012).

Mousel, M. et al. Cu-rich precursors improve kesterite solar cells. Adv. Energy Mater. 4, 1300543 (2014).

Persson, C. Electronic and optical properties of Cu2ZnSnS4 and Cu2ZnSnSe4 . J. Appl. Phys. 107, 053710-1-053710-8 (2010).

Lu, X. Zhuang, Z., Peng, Q. & Li, Y. Controlled synthesis of wurtzite CuInS2 nanocrystals and their side-by-side nanorod assemblies. Cryst. Eng. Comm. 13, 4039–4045 (2011).

Feng, X., Zhu, K., Frank, A. J., Grimes, C. A. & Mallouk, T. E. Rapid charge transport in dye-sensitized solar cells made from vertically aligned single-crystal rutile TiO2 nanowires. Angew. Chem. Int. Ed. 51, 2727–2730 (2012).

Varghese, O. K., Paulose, M. & Grimes, C. A. Long vertically aligned titania nanotubes on transparent conducting oxide for highly efficient solar cells. Nat. Nanotechnol. 4, 592–597 (2009).

Tang, J. et al. Colloidal-quantum-dot photovoltaics using atomic-ligand passivation. Nat. Mater. 10, 765–771 (2011).

Kim, J.-Y. & Kotov, N. A. Charge transport dilemma of solution-processed nanomaterials. Chem. Mater. 26, 134–152 (2014).

Yin, Y. & Alivisatos, A. P. Colloidal nanocrystal synthesis and the organic–inorganic interface. Nature 437, 664–670 (2005).

Lee, S. -M., Cho, S. -N. & Cheon Anisotropic shape control of colloidal inorganic nanocrystals. Adv. Mater. 15, 441–444 (2003).

Peng, Z. A. & Peng X. Mechanisms of the shape evolution of CdSe nanocrystals. J. Am. Chem. Soc. 123, 1389–1395 (2001).

Zhang, Y., Zhu, J., Song, X. & Zhong, X. Controlling the synthesis of CoO nanocrystals with various morphologies. J. Phys. Chem. C 112, 5322–5327 (2008).

Wang, Z. L. Zinc oxide nanostructures: growth, properties and applications. J. Phys.: Condens. Matter. 16, R829–R858 (2004).

Yang, M., Sun, K. & Kotov, N. A. Formation and assembly-disassembly processes of ZnO hexagonal pyramids driven by dipolar and excluded volume interactions. J. Am. Chem. Soc. 132, 1860–1872 (2010).

Acknowledgements

This research was supported by the Natural Science Foundation of China (No. 21006044, No. 51202110), the Natural Science Foundation of Jiangsu Province (No. BK2012426, No. BK2012041), the Key Laboratory of Material-Oriented Chemical Engineering of China under Grant No. KL10-02 and the Project of Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Contributions

N.B. contributed to the conception and design of the experiment, analysis of data and writing the manuscript with the assistance of X.Z. G.G. and C.J. carried out synthesis of materials, optical and structural characterization of products. X.Z., C.J., C.Z. and H.K. performed the photo-response investigation. Y.W. carried out the Rietveld fit and the crystal structure simulation. C.J. carried out the Hall effect measurement and A.G., L.S. and Y.W. contributed to the analysis of data and modification of the paper. X.Z. and G.G. contributed equally to this work. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supporting information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Zhang, X., Guo, G., Ji, C. et al. Efficient Thermolysis Route to Monodisperse Cu2ZnSnS4 Nanocrystals with Controlled Shape and Structure. Sci Rep 4, 5086 (2014). https://doi.org/10.1038/srep05086

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep05086

This article is cited by

-

Microwave-assisted rapid facile synthesis of pure kesterite Cu2ZnSnS4 in mixed solvents

Journal of Materials Science: Materials in Electronics (2022)

-

Influence of carrier gas pressure on the characteristics of nebulizer-sprayed Cu2ZnSnS4 absorber thin films

Journal of Materials Science: Materials in Electronics (2021)

-

Intermittent sulfurization—a method promoting Macro-Porous Cu-Poor Zn-Rich—kesterite CZTS as HTM for inverted perovskite solar cell application

Journal of Materials Science: Materials in Electronics (2020)

-

“Green” Aqueous Synthesis and Advanced Spectral Characterization of Size-Selected Cu2ZnSnS4 Nanocrystal Inks

Scientific Reports (2018)

-

Synthesis of Wurtzite Cu2ZnSnS4 Nanosheets with Exposed High-Energy (002) Facets for Fabrication of Efficient Pt-Free Solar Cell Counter Electrodes

Scientific Reports (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.