Abstract

Polymer modified fillers in composites has attracted the attention of numerous researchers. These fillers are composed of core-shell structures that exhibit enhanced physical and chemical properties that are associated with shell surface control and encapsulated core materials. In this study, we have described an apt method to prepare polyimide (PI)-modified aluminum nitride (AlN) fillers, AlN@PI. These fillers are used for electronic encapsulation in high performance polymer composites. Compared with that of untreated AlN composite, these AlN@PI/epoxy composites exhibit better thermal and dielectric properties. At 40 wt% of filler loading, the highest thermal conductivity of AlN@PI/epoxy composite reached 2.03 W/mK. In this way, the thermal conductivity is approximately enhanced by 10.6 times than that of the used epoxy matrix. The experimental results exhibiting the thermal conductivity of AlN@PI/epoxy composites were in good agreement with the values calculated from the parallel conduction model. This research work describes an effective pathway that modifies the surface of fillers with polymer coating. Furthermore, this novel technique improves the thermal and dielectric properties of fillers and these can be used extensively for electronic packaging applications.

Similar content being viewed by others

Introduction

Surface modification of fillers in composites has recently received great attention due to as produced core-shell structures with unusually remarkable properties, such as large surface area, low density and potential applications. The composites have myriad applications in controlled release, catalysis and chemical storage1,2,3,4,5,6,7,8,9. These core-shell structures are gaining quite a lot of attention because they exhibit significant synthetic challenges. The resulting nanostructures exhibit enhanced physical and chemical properties owing to their shell surface control and encapsulated core materials. Ganguli's photocatalytic studies10 have indicated that the ZnO/CdS core/shell nanorod arrays exhibit better degradation efficiency compared to bare ZnO and CdS under simulated solar radiation. The shell thickness also affected the photocatalytic efficiency that plays a pivotal role in the degradation of rhodamine B. The shell thickness of 30 nm CdS exhibited highest photocatalytic efficiency. Therefore, polymer composites made of core-shell structured fillers will have superior properties than bare core or shell based polymer composites. In recent times, several research studies have elucidated the controlled preparation of surface-modified fillers, such as metal@SiO211,12,13,14,15, metal@metal16,17, metal@carbon18,19,20,21, metal@ploymer22,23,24,25, etc. However, we need to devise newer methodologies to synthesize surface-modified fillers that can electronically encapsulate high performance polymer composites.

Aluminum nitride (AlN) has been extensively used as substrate material owing to its numerous attractive properties, such as high thermal conductivity, low thermal expansion coefficient, attractive dielectric properties and excellent mechanical properties26. In polymer-based composites, AlN has been used to increase stiffness, reduce thermal expansion and increase thermal conductivity of composites26,27,28,29,30,31. Gonsalves et al.32,33 studied the preparation and properties of AlN-polyimide (PI) nanocomposite. According to these researchers, the thermal conductivity increased greatly when AlN was added to the PI matrix. At the same time, the coefficient of thermal expansion (CTE) also decreased significantly. However, several research studies have not elucidated the use of polymer coating of AlN with well-defined core-shell structures. These are used for high performance electronic packaging of composite materials. In this research study, we developed a new method to coat a thin layer of PI on the surface of AlN particles. Thereafter, PI modified AlN particles were dispersed in epoxy resin. By adopting this approach, we could enhance the thermal and dielectric properties of the core-shell particle incorporated composite containing 10–40 weight percent of fillers. At 40 wt% of filler loading, the highest thermal conductivity of the PI-modified AlN composite reached 2.03 W/mK. This enhances the thermal conductivity by approximately 10.6 times than that of the epoxy matrix used. The experimental results of thermal conductivity were in good agreement with the calculated value from a parallel conduction model. This research study shows an effective pathway to modify the surface of fillers with polymer coating. Furthermore, the thermal and dielectric properties of these fillers can be enhanced with the adoption of this novel methodology and they can be extensively used for electronic packaging applications.

Results and Discussions

Figure 1a shows a schematic diagram that illustrates the preparation of PI modified AlN particles. Briefly, AlN surface was first functionalized by 3-mercaptopropionic acid (MPA) to avoid the agglomeration in ethanol. Thereafter, poly(amic acid) (PAA) modified AlN was synthesized using 3,3′,4,4′-benzophenonetetracarboxylic dianhydride (BTDA) and bis(4-aminophenyl) ether (ODA) monomers in dimethylacetamide (DMAc) solution. Finally, PI modified AlN was obtained after imidization of PAA modified AlN, which is referred as AlN@PI. Figures 1b and 1c illustrate the scanning electron microscopy (SEM) images of untreated AlN particles and AlN@PI, respectively. As shown in the Figure 1b, the diameter of pure AlN particles is approximately 1 μm. As shown in Figure 1c, PI is thoroughly coated on the surface of AlN particles after surface modification. In this case, the particles were attached to each other. The polymer shell seemed to form necking between particles. This necking could be beneficial for heat transfer in composites.

Figure 2 illustrates SEM images of AlN@PI/epoxy composites with different filler contents. The AlN@PI particles are homogenously distributed within the epoxy matrix. No obvious aggregation of the AlN@PI particles in the composite can be observed even with higher filler loading. High filler loadings (>35 vol%) are typically necessary to achieve an appropriate level of thermal conductivity in thermally conducive polymer composites, which leads to significant processing challenge. Moreover, a high inorganic filler loading also dramatically alters the mechanical behavior and density of polymers. At the same time, it increases the thermal conductivity of composites. Hence, we need to maintain a comparatively low level of filler loading in composites for ensuring good flowability.

The thermal conductivities of all composites greatly depend on the properties of polymers and fillers, such as their content, components and the surface treatment of filler. The thermal conductivity and dielectric constant of all composites increase with the increase of the filler loading. Have to point out is that it is disfigurement such as air hole, impurity etc. in composites that is a very important factor to account the effective thermal conductivity of composites34,35. In Figure 3, we have compared the thermal conductivity of AlN@PI/epoxy and untreated AlN/epoxy composites containing 10–40 weight percent of fillers. An obvious increase in the thermal conductivity of composites is achieved by increasing the composition of filler loadings from 10% to 40%. The thermal conductivity values of AlN@PI/epoxy composites are larger than that of AlN/epoxy at every stage. In other words, it implies that untreated A1N particles are less effective than PI-modified AlN particles, which are used as fillers in composites to improve thermal conductivity in polymer composites. At 40 wt% of fillers loading, the highest thermal conductivity of the composite can reach 2.03 W/mK. At higher filler loading, the thermal conductivity of composites decreases due to voiding that is associated with imperfect filler packing and preparation technology34. So, we chose the 40% filler for performing this experiment. In this case, the composite material ensures excellent mechanical properties and processing performance.

(a) Thermal conductivity of AlN@PI/epoxy and untreated AlN/epoxy composites using 10–40 wt% of fillers. (b) Experimental results and modified model values of thermal conductivity as a function of filler loading of the AlN@PI/epoxy composites. The frequency dependency of (c) relative permittivity and (d) tan delta of the AlN@PI/epoxy and AlN/epoxy composites with different weight percent of fillers in frequency range (2 MHz–1 GHz).

Figures 3c and 3d illustrate the frequency dependency of relative permittivity and tan delta of AlN@PI/epoxy and AlN/epoxy composites with different loading of fillers in the frequency range (2 MHz–1 GHz). Figure 3c illustrates a slight decrease in the permittivity of composites with an increase in frequency. At each filler loading, the relative permittivity of AlN@PI/epoxy composites is found to be larger than that of AlN/epoxy when the same frequency is maintained. All the relative permittivity curves versus frequency are nearly parallel to the frequency axis in the logarithmic scale. The relative permittivity of 40 wt% composite is 6.57 at 100 MHz. As shown in Figure 3d, all tan deltas of composites also hold a low level in the frequency range of 2 MHz–1 GHz. At a certain frequency, the tan delta decreases by increasing the concentrations of fillers, which is characterized with an increase in the porosity of the composite36. In general, PI possesses a low dielectric constant (~3.4 @1 MHz) and tan delta of a few parts per thousand, while it was coated on the AlN particles as a filler in composite, arising from the formation of bond bridge between organic and inorganic materials, that is, filler and polymer. Furthermore, the resulting tan delta is decreased significantly, thereby indicating that the extent of interfacial polarization is substantially augmented with a gradual reduction in frequency. In fact, interfacial polarization plays a crucial role in polymer composite materials, because additives, fillers and even impurities have larger masses than the low molecular weight dipoles, making these systems heterogeneous. It is a well-known fact that both relative permittivity and tan delta depend on electronic, ionic, dipole-orientation and space charge polarizations26,37. It is the porosity ratio, air volume fraction in composites that is also a very important factor to effect the thermal and dielectric properties of composites. The present system of composite is a triphase mixture of materials having different dielectric properties. It can be seen that composite possess a good compact and less porosity structure at 40% fillers from Fig. 2d SEM image. Therefore, we conclude that it can be attributed to not only the physicochemical characteristics of materials but also process conditions. Moreover, the composite with a distinct interphase between three phases illustrates an apparent loss at whole frequencies.

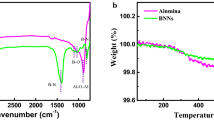

The thermal conductivity of AlN@PI/epoxy composites is greatly enhanced by adding PI-modified AlN particles that act as fillers. Table 1 provides a comparative overview of thermal conductivity and dielectric permittivity enhancement of AlN@PI/epoxy with reported ceramic/polymer composites. The thermal conductivity enhancement of AlN@PI/epoxy is the highest for low filler loading26,27,28,29,30,31. Table 1 also illustrates that filler modification is responsible for low filler loading. The thermal conductivity of AlN@PI/epoxy is enhanced by about 10.6 times than the pure epoxy. Moreover, the thermal conductivity of AlN@PI/epoxy is approximately 1.5–6 times higher than that from above-mentioned research works26,27,28,29,30,31. As shown in Figure 4a, the chemical structure of pure AlN, pure PI and AlN@PI were investigated using Fourier Transform Infrared Spectroscopy (FTIR). There are three strong peaks near 3000 cm−1 which disappeared after reacting with PAA, thereby indicating that there exists a strong interaction between –NH2 groups and AlN in the three spectrums. The results indicate that PI has yielded a large coverage on the surface of AlN particles by forming robust bindings. The bindings of PI to the surface of AlN particles are characterized by strong C-H stretching (2925 cm−1) and C-N stretching (1435 cm−1) absorptions, both of which are attributed to PI.

Figure 4b illustrates TGA results of 10–40 wt% of AlN@PI/epoxy composites under nitrogen atmosphere. The typical weight loss is observed at approximately 400°C. Due to the incomplete combustion of samples in nitrogen atmosphere, the eventual stable positions of all curves are higher than that of actual weight percentage. However, the chart illustrates the regularity and consistency of all samples. In addition, the composites show a high heat resistance to temperature at 250°C, which would be beneficial for electronic devices.

The effective thermal conductivity of a composite is strongly affected by its composition, structure, intrinsic thermal conductivity, filler particle size, shape and interfacial thermal resistance, etc. The interfacial thermal resistance exerts a significant impact on the thermal conductivity of composite38,39. To elucidate the effective thermal conductivities of two-phase mixtures and polyphase mixtures of composites, several equations incorporating theoretical and empirical models have been developed40,41,42,43,44,45,46. Herein, we applied the modified parallel conduction model to calculate the thermal conductivity of AlN@PI/epoxy composites and compared it with our experimental data. The equations 1– 3 were used to predict thermal conductivity values,

where, k represents thermal conductivity, c stands for composite, m stands for matrix, f stands for filler and ϕ is the volume fraction of filler.

For series conduction model, the following equation is commonly used,

In this work, a similar conduction model is adopted,

where kc, kf1, kf2, km and ka are the thermal conductivities of composite, AlN, PI, epoxy matrix and air, respectively. ϕ1, ϕ2, ϕm and ϕ are the content fractions of AlN, PI, epoxy matrix and air in composites, respectively. The ϕ value can be obtained by correlating relative density with theoretical density.

In Figure 3b, we have compared the experimental and modified model values of thermal conductivity of the composites with different volume proportions of surface modified fillers. We found that the predicted thermal conductivity values of composites are in good agreement with the experimental results. Moreover, when the volume fraction of fillers increases, the corresponding thermal conductivity also increases gradually. In this model, several actual factors, such as disfigurement and impurity can be neglected for facilitating calculation. On the other hand, it was found that the porosity ratio (air volume fraction in composites) is an important factor that affects effective thermal conductivity in this conduction model, even though the content and density of air are much less than those of the fillers and PI matrix. The experimental results are lower than the simulation model values at all time.

In summary, we have presented homogeneous polymer composites comprising of surface modified AlN particles with an epoxy matrix. PI is used as the surface modification agent that is successfully coated on the surface of AlN particles. The results clearly illustrate that the polymer coating on AlN cores can significantly improve the thermal conductivity and dielectric properties of composites, whereas the dielectric losses are maintained at a relatively low level compared with that of uncoated AlN particles. The highest thermal conductivity of the composite can reach 2.03 W/mK at 40 wt% fillers loading. This shows that it exhibits 10.6 times of enhancement in thermal conductivity than that of epoxy matrix. The relative permittivity of 40 wt% composite is 6.57 at 100 MHz. In addition, the underlying mechanism of thermal conductivity was discussed systematically. The simulation thermal model was also proposed, thereby illustrating their agreement with experimental results. Our results indicate that the polymer coating is an effective surface modification method that is used to form core-shell structure, which can be used for fabricating ceramic-polymer composites of high thermal conductivity.

Methods

Materials

The monomers of BTDA and ODA of PI were supplied by Alfa Aesar Co. The solvent of DMAc (Sigma-Aldrich Company) and (3-Aminopropyl) triethoxysilane (APTS) (Sigma-Aldrich Company) were stirred using powdered calcium hydride overnight. Thereafter, this solvent was distilled under reduced pressure and stored over 4 Å molecular sieves, prior to use. AlN powder was supplied by Dow Chemical Co. The average diameter of AlN particles was about 1 μm at a loading of 3.26 g/cm3. The specific surface area of AIN particles was greater than 75 m2/g. The AlN powder was white in color and in the form of small agglomerates. All the monomers and AlN powder were dried in a vacuum oven at 120°C for 3–5 h prior to use. The epoxy resin is a mixture of diglycidyl ether of bispenol A and 3,4-epoxy cyclohexylmethyl-3,4-epoxy cyclohexyl carboxylate. Hexahydro-4- methyl phthalic anhydride and 1-cyanoethyl-2-ethyl-4- methylimidazole were used as curing agent and catalyst, respectively. Other chemicals and solvents were commercially obtained and used, as received. Table S1 illustrates the typical properties of aluminum nitride, BTDA/ODA polyimide and epoxy resin.

Synthesis of PI precursor, BTDA-ODA PAA

PAA was synthesized using BTDA and ODA monomers with the same molar ratio, which was used to dissolve in DMAc solution. The reaction vessel consisted of a three-neck round-bottom flask equipped with nitrogen inlet, thermo-meter and a condenser with a Dean-Stark trap. All monomers were added to a reaction vessel and were stirred at an ambient temperature until ODA and BTDA were dissolved completely. Then, the temperature of this solution was raised to 35°C. After attaining a temperature of 35°C, the process of stirring was continued for 24 h. As shown in Figure 1a, a viscous PAA solution was obtained.

Surface modification of AlN fillers

AlN powder (2 g) was dispersed in ethanol (500 ml) by gentle stirring and sonication. To avoid the agglomeration of AlN particles, MPA was used to functionalize AlN surface. Then, BTDA (1.5 g), ODA (2.48 g) and DMAc (15 ml) were added into the mixtures and a 1/1 molar ratio of BTDA/ODA was maintained. Subsequently, the mixtures were stirred with nitrogen inlet and a condenser for 24 h. Thereafter, the synthesized PAA was successfully coated on the surface of AlN particles. The solution was separated from the suspension by subjecting it to centrifugation at 5,000 rpm for 30 mins. Then, these obtained particles were step-dried at the following intervals: 80°C for 1 h, 120°C for 1 h, 200°C for 1 h and 300°C for 1 h in a vacuum oven, respectively. Finally, we obtained polymer modified AlN powders with PI, referred as AlN@PI.

Preparation of AlN@PI-epoxy composites

The four different weight fractions (10–40) AlN@PI/epoxy composites were prepared by homogeneously mixing epoxy resins with surface modified AlN powder. This was done by performing sonication for 5 mins. In this process, a small amount of acetone was added to help the dispersion of AlN and then removed by a vacuum at elevated temperatures. Thereafter, the curing agent and catalyst were added and mixed by stirring. The composite was transferred to an aluminum foil mold and cured at 150°C for 2 h in a vacuum oven.

Characterizations

Transmission electron microscopy (TEM) was carried out using JEOL TEM 100CX. SEM (LEO 1530 and 1550) was used to characterize the morphology of AlN@PI/epoxy composite surfaces using an accelerating voltage of 3 kV, where the samples were sputter-coated with a thin layer of gold for better imaging. The dielectric properties of composites were be measured from 1 MHz to 3 GHz by RF impedance analyzers of E4991A (Agilent) with the 16453A dielectric material test fixture. Thermomechanical analyzer (TMA, Q-400 TA Instruments) was used to measure the CTE of composites. The thermal diffusivity (α) of AlN@PI/epoxy composites was measured using laser flash method with a LFA 447 (NETZSCH). The thermal conductivity was calculated by λ = αρCp, in which ρ and Cp are the density and heat capacity of AlN@PI/epoxy composites, respectively. The Cp was measured using differential scanning calorimetry (DSC, Q-600 TA Instruments). All thermal measurements were carried out at room temperature.

References

Li, C. R., Zhang, X. N. & Cao, Z. X. Triangular and fibonacci number patterns driven by stress on core/shell microstructures. Science 309, 909–911 (2005).

Zhou, Y. C. et al. A poly(vinylidene fluoride) composite with added self- passivated microaluminum and nanoaluminum particles for enhanced thermal conductivity. Appl Phys Lett 98, 182906 (2011).

Zhou, Y. C. et al. Enhanced high thermal conductivity and low permittivity of polyimide based composites by core-shell Ag@SiO2 nanoparticle fillers. Appl Phys Lett 101, 012903 (2012).

Heckel, J. C., Kisley, L. M., Mannion, J. M. & Chumanov, G. Synthesis and self- assembly of polymer and polymer-coated Ag nanoparticles by the reprecipitation of binary mixtures of polymers. Langmuir 25, 9671–9676 (2009).

Lai, X. Y. et al. General synthesis and gas-sensing properties of multiple-shell metal oxide hollow microspheres. Angew Chem Int Ed 50, 2738–2741 (2011).

Gai, S. et al. Synthesis of magnetic, up-conversion luminescent and mesoporous core–shell-structured nanocomposites as drug carriers. Adv Funct Mater 20, 1166–1172 (2010).

Zalich, M. A., Baranauskas, V. V., Riffle, J. S., Saunders, M. & Pierre, T. G. Structural and magnetic properties of oxidatively stable cobalt nanoparticles encapsulated in graphite shells. Chem Mater 18, 2648–2655 (2006).

Lu, Y. et al. Hydrophilic Co@Au yolk/shell nanospheres: synthesis, assembly and application to gene delivery. Adv Mater 22, 1407–1411 (2010).

Graf, C., Vossen, D., Imhof, A. & Blaaderen, A. A general method to coat colloidal particles with silica. Langmuir 19, 6693–6700 (2003).

Khanchandani, S., Kundu, S., Patra, A. & Ganguli, A. K. Shell thickness dependent photocatalytic properties of ZnO/CdS core-shell nanorods. J Phys Chem C 116, 23653–23662 (2012).

Zhou, Y. C. & Wang, H. An Al@Al2O3@SiO2/polyimide composite with multilayer coating structure fillers based on self-passivated aluminum cores. Appl Phys Lett 102, 132901 (2013).

Zhou, Y. C., Bai, Y. Y., Yu, K., Kang, Y. & Wang, H. Excellent thermal conductivity and dielectric properties of polyimide composites filled with silica coated self-passivated aluminum fibers and nanoparticles. Appl Phys Lett 102, 252903 (2013).

Ung, T., Liz-Marzan, L. M. & Mulvaney, P. Controlled method for silica coating of silver colloids. Influence of coating on the rate of chemical reactions. Langmuir 14, 3740–3748 (1998).

Gong, J. L., Jiang, J. H., Liang, Y., Shen, G. L. & Yu, R. Q. Synthesis and characterization of surface-enhanced Raman scattering tags with Ag/SiO2 core-shell nanostructures using reverse micelle technology. J Colloid Interf Sci 298, 752–756 (2006).

Shanthil, M., Thomas, R., Swathi, R. S. & Thomas, K. G. Ag@SiO2 core-shell nanostructures: distance-dependent plasmon coupling and SERS investigation. J Phys Chem Lett 3, 1459–1464 (2012).

Liang, A. H., Liang, Y. Y., Jiang, Z. L. & Jiang, H. S. Resonance scattering spectral detection of catalase activity using Au@Ag nanoparticle as probe and coupling catalase catalytic reaction with fenton reaction. J Fluoresc 19, 1009–1015 (2009).

Liu, F. K., Tsai, M. H., Hsu, Y. C. & Chu, T. C. Analytical separation of Au/Ag core/shell nanoparticles by capillary electrophoresis. J Chromatogr A 1133, 340–346 (2006).

Su, X. C., Gutierrez, A., Yacaman, M. J., Dong, X. L. & Jin, S. Investigations on magnetic properties and structure for carbon-encapsulated nanoparticles of Fe, Co, Ni. Mater Sci Eng A 286, 157–160 (2000).

Nishijo, J., Okabe, C., Oishi, O. & Nishi, N. Synthesis, structures andmagnetic properties of carbon-encapsulated nanoparticlesvia thermal decomposition of metal acetylide. Carbon 44, 2943–2949 (2006).

Yu, D. S., Nagelli, E., Du, F. & Dai, L. M. Metal-free carbon nanomaterials become more active than metal catalysts and last longer. J Phys Chem Lett 1, 2165–2173 (2010).

Sun, X. & Li, Y. D. Ag@C core/shell structured nanoparticles: controlled synthesis, characterization and assembly. Langmuir 21, 6019–6024 (2005).

Grass, R. N., Athanassiou, E. K. & Stark, W. J. Covalently functionalized cobalt nanoparticles as a platform for magnetic separations in organic synthesis. Angew Chem Int Ed 46, 4909–4912 (2007).

Corr, S. A., Rakovich, Y. P. & Gun'ko, Y. K. Multifunctional magnetic-fluorescent nanocomposites for biomedical applications. Nanoscale Res Lett 3, 87–104 (2008).

Decher, G. F. Nanoassemblies: toward layered polymeric multicompositesi. Science 277, 1232–1237 (1997).

Donath, E., Sukhorukov, G. B., Caruso, F., Davis, S. A. & Mohwald, H. Novel hollow polymer shells by colloid-templated assembly of polyelectrolytes. Angew Chem Int Ed 37, 2201–2205 (1998).

Xie, S. H., Zhu, B. K., Li, J. B., Wei, X. Z. & Xu, Z. K. Preparation and properties of polyimide/aluminum nitride composites. Polym Test 23, 797–801 (2004).

Zhou, W. Thermal and dielectric properties of the AlN particles reinforced linear low-density polyethylene composites. Therm Acta 512, 183–188 (2011).

Zhou, Y. C. et al. Fabrication and characterization of aluminum nitride polymer matrix composites with high thermal conductivity and low dielectric constant for electronic packaging. Mater Sci Eng B 177, 892–896 (2012).

Zhu, B. L. et al. Preparation and properties of aluminum nitride-filled epoxy composites: Effect of filler characteristics and composite processing conditions. J Appl Polym Sci 127, 3456–3466 (2013).

Zhou, W. & Yu, D. Thermal and dielectric properties of the aluminum particle/epoxy resin composites. J Appl Polym Sci 118, 3156–3166 (2010).

Min, C., Yu, D., Cao, J., Wang, G. & Feng, L. A graphite nanoplatelet/epoxy composite with high dielectric constant and high thermal conductivity. Carbon 55, 116–25 (2013).

Gonsalves, K. E., Chen, X. & Baraton, M. I. Mechanistic investigation of the preparation of polymer/ceramic nanocomposites. Nanostru Mater 9, 181–184 (1997).

Chen, X., Gonsalves, K. E., Chow, G. M. & Xiao, T. D. Homogeneous dispersion of nanostructured aluminum nitride in a polyimide matrix. Adv Mater 6, 481–484 (1994).

Wong, C. P. & Bollampally, R. S. Thermal conductivity, elastic modulus and coefficient of thermal expansion of polymer composites filled with ceramic particles for electronic packaging. J Appl Polym Sci 74, 3396–403 (1999).

Shimazaki, Y., Hojo, F. & Takezawa, Y. Preparation and characterization of thermoconductive polymer nanocomposite with branched alumina nanofiber. Appl Phys Lett 92, 133309 (2008).

Li, Y. et al. Large dielectric constant and high thermal conductivity in poly (vinylidene fluoride)/barium titanate/Silicon Carbide three-phase nanocomposites. ACS Appl Mater & Interfaces 3, 4396–403 (2011).

Yu, S., Hing, P. & Hu, X. Dielectric properties of polystyrene aluminum-nitride composites. J Appl Phys 88, 398–404 (2000).

Zhao, X. H., Wu, Y. G., Fan, Z. G. & Li, F. Three-dimensional simulations of the complex dielectric properties of random composites by finite element method. J Appl Phys 95, 8110 (2004).

Li, C. C., Fu, L. J., Jing, O. Y. & Yang, H. M. Enhanced performance and interfacial investigation of mineral-based composite phase change materials for thermal energy storage. Sci Rep 3, 1908 (2013).

Zhou, S. X. et al. Experiments and modeling of thermal conductivity of flake graphite/polymer composites affected by adding carbon-based nano-fillers. Carbon 57, 452–459 (2013).

Hauser, R. A., Keith, J. M., King, J. A. & Holdren, J. L. Thermal conductivity models for single and multiple filler carbon/liquid crystal polymer composites. J Appl Polym Sci 110, 2914–2923 (2008).

Usowicz, B., Lipiec, J., Usowicz, J. B. & Marczewski, W. Effects of aggregate size on soil thermal conductivity: Comparison of measured and model-predicted data. Int J Heat Mass Tran 57, 536–541 (2013).

Sitprasert, C., Dechaumphai, P. & Juntasaro, V. A thermal conductivity model for nanofluids including effect of the temperature-dependent interfacial layer. J Nanopart Res 11, 1465–1476 (2009).

Seo, B. H. et al. Model for thermal conductivities in spun yarn carbon fabric composites. Polym Compos 26, 791–798 (2005).

Clancy, T. & Gates, T. Modeling of interfacial modification effects on thermal conductivity of carbon nanotube composites. Polymer 47, 5990–5996 (2006).

Liu, Y., Zhang, Z. Y., Wei, X. L., Li, Q. & Peng, L. M. Simultaneous electrical and thermoelectric parameter retrieval via two terminal current-voltage measurements on individual ZnO nanowires. Adv Funct Mater 21, 3900–3906 (2011).

Acknowledgements

The authors acknowledge funding support from the Natural National Science Foundation of China (61025002 and 51372265) and the China Scholarship Council (201206280056).

Author information

Authors and Affiliations

Contributions

Z.-Y.C. contributed to the conception and design of the experiment, analysis of the data and writing the manuscript with assistance of Y.-Y.G., C.-C.Y. and M.-K. W.-H. and W.-C.P. modified the final version of the manuscript. All authors discussed the results and commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Table S1 & Figure S1

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Zhou, Y., Yao, Y., Chen, CY. et al. The use of polyimide-modified aluminum nitride fillers in AlN@PI/Epoxy composites with enhanced thermal conductivity for electronic encapsulation. Sci Rep 4, 4779 (2014). https://doi.org/10.1038/srep04779

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04779

This article is cited by

-

Microplastics in green mussels (Perna viridis) from Jakarta Bay, Indonesia, and the associated hazards to human health posed by their consumption

Environmental Monitoring and Assessment (2023)

-

Dielectric properties and thermal conductivity of epoxy resin composite modified by Zn/ZnO/Al2O3 core–shell particles

Polymer Bulletin (2019)

-

Use of BN-coated copper nanowires in nanocomposites with enhanced thermal conductivity and electrical insulation

Advanced Composites and Hybrid Materials (2019)

-

Enhanced Thermal Conductivity of Polyimide Composites with Boron Nitride Nanosheets

Scientific Reports (2018)

-

Enhanced Thermal Conductivity and Dielectric Properties of Iron Oxide/Polyethylene Nanocomposites Induced by a Magnetic Field

Scientific Reports (2017)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.