Abstract

Authors reported an effective path to increase the electrical conductivity while to decrease the thermal conductivity and thus to enhance the ZT value by nano-inclusions. By this method, the ZT value of Nb-doped SrTiO3 was enhanced 9-fold by yttria stabilized zirconia (YSZ) nano-inclusions. YSZ inclusions, located inside grain and in triple junction, can reduce the thermal conductivity by effective interface phonon scattering, enhance the electrical conductivity by promoting the abnormal grain growth and thus lead to the obvious enhancement of ZT value, which strongly suggests that, it is possible to not only reduce the thermal conductivity, but also increase the electrical conductivity by nano-inclusions with low thermal conductivity. This study will give some useful enlightenment to the preparation of high-performance oxide thermoelectric materials.

Similar content being viewed by others

Introduction

Thermoelectric (TE) energy conversion is a promising technology for both electricity power generation in harvesting wasted heat and electric cooling. The efficiency of TE devices is characterized by the dimensionless figure of merit, ZT = (S2σ/κ)T, where S, σ, κ and T are the Seebeck coefficient, the electrical conductivity, the thermal conductivity and the absolute temperature, respectively. To date, most of the discovered bulk materials with high ZT values exhibit thermal and chemical instability in air and are composed of toxic, scarce or expensive elements1,2,3,4,5. Recently, various ceramic oxide thermoelectric (TE) materials have attracted widespread attention, because they are economical, environmentally-friendly, possess various chemical compositions and consist of naturally abundant6,7,8,9,10,11,12,13,14. So far, among the p-type oxide thermoelectric bulk materials, the textured BiCuSeO has the highest ZT value, ~1.4 at 923 K15, which can meat the basic requirements of practical applications. Both p-type and n-type oxide materials are needed to construct an efficient thermoelectric device. However, among the n-type oxide thermoelectric bulk materials, even though Nb-doped SrTiO3 bulk ceramic has the highest ZT value so far16, but it is still very low, compared with p-type textured BiCuSeO and thus urgently needs to improve.

In 2007, Dresselhaus et al. proposed that nanocomposite thermoelectric materials would offer a promising approach for the preparation of bulk samples with nano-sized constituents17. Since then, a variety of nanocomposites with higher thermoelectric properties than bulk materials have been prepared. Tang et al. prepared Bi2Te3 bulk materials with layered nanostructure by combining melt spinning technique with spark plasma sintering and the maximum ZT value of 1.35 was obtained at 300 K18. Mi et al. prepared n-type CoSb3 nanocomposites by hot pressing the mixture of nanoscale and microsized CoSb3 powders and the maximum ZT value reached 0.71 at 700 K19. Poudel et al. fabricated nano-sized bismuth antimony telluride bulk alloys by ball milling and hot pressing method and the obtained maximum ZT value was 1.4 at 373 K20. Li et al. fabricated Yb0.2Co4Sb12+y bulk materials with nanostructure by combining melt spinning technique with spark plasma sintering and the maximum ZT value reached 1.26 at 800 K21. Li et al. also prepared n-type skutterudites InxCeyCo4Sb12 with in-situ forming nano-sized InSb phase by a melt-quench-anneal-spark plasma sintering method and the maximum ZT value of 1.43 was obtained at 800 K22. Lan et al. found that small nanosized particles located at the grain boundaries or embedded in larger particles could provide effective phonon scattering centers and thus reduced the phonon thermal conductivity efficiently23. Pei et al. found that there was an enhancement of ZT due to phonon scattering at the interfaces, when PbTe was nanostructured with large nanometer sized Ag2Te precipitates24. Ahn et al. prepared p-type PbTe-MTe (M = Cd, Hg) and found that meso-scale grain boundaries along with nanostructured precipitates play an important role in significantly reducing the lattice thermal conductivity25. Above-mentioned studies on thermoelectric materials with nanocomposite gave us some good inspirations.

Herein, we reported an effective path to enhance the thermoelectric performance of n-type oxide, Nb-doped SrTiO3 (SrNb0.15Ti0.85O3, Nb-STO), by yttria stabilized zirconia (YSZ) nano-inclusion with the low thermal conductivity. Our results show the ZT value of Nb-STO was enhanced 9-fold, due to the decreased thermal conductivity and meanwhile the increased electrical conductivity, pointing to a robust approach for high-performance n-type thermoelectric oxide.

Results

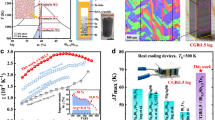

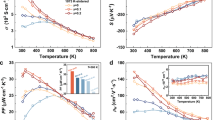

Fig. 1 showed the temperature dependent thermal and electric transport properties of YSZ/Nb-STO composite, namely, the thermal conductivity (κ), electrical conductivity (σ) and Seebeck coefficient (S). Significantly, YSZ inclusion reduced the thermal conductivity (Fig. 1(a)) and meanwhile increased the electrical conductivity (Fig. 1(b). However, Seebeck coefficients were subjected to a very small impact by YSZ inclusion (Fig. 1(c)). The thermal conductivity and the electrical conductivity at 900 K were reduced ~15% and increased 10-fold, respectively.

Fig. 2 showed the temperature dependent electrical conductivity and thermal conductivity of pure YSZ bulk ceramic, with the relative density of 91.6%, prepared by the conventional normal pressure sintering method at 1500°C for 3 h in an Ar atmosphere. The thermal conductivity and the electrical conductivity of YSZ bulk were much lower than those of pure Nb-STO ceramic showed in Fig. 1(a) and Fig. 1(b).

The thermoelectric power factor S2σ and dimensionless figure of merit ZT of the composite were shown in Fig. 3. The power factor was increased more than 7-fold as compared with the sample without YSZ inclusion (Fig. 3(a)), which is mainly beneficial from the increased electrical conductivity. Owing to the low thermal conductivity and high electrical conductivity, the ZT value is enhanced 9-fold, up to 0.21 at 900 K.

Discussion

The carrier concentration (n), Hall mobility (μ), carrier effective mass (m*/m0) and m*/n2/3 at room temperature were summarized in the Table 1. With YSZ inclusion, the mobility was enhanced significantly, however, relatively, there was little change in the carrier concentration, which contributed to the enhancement of the electrical conductivity, according to the relation formula:

For degenerate semiconductors (parabolic band, energy-independent scattering approximation), the Seebeck coefficient (S) is given by26:

where kB is Boltzmann constant and h is Planck constant. The equation indicates the Seebeck coefficient strongly depends on the value, m*/n2/3. Table 1 exhibited YSZ inclusion had very small impact on the value, m*/n2/3, which led to that Seebeck coefficient was almost independent of YSZ inclusion.

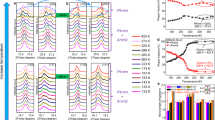

Temperature dependent electronic thermal conductivity (κe), lattice thermal conductivity (κL) and phonon mean free path (Lphonon) of YSZ/Nb-STO composites were shown in Fig. 4. The κe was subtracted from the total thermal conductivity by using the Wiedemann-Franz law:

where L is the Lorenz factor, 2.45 × 10−8 V2/K2. The resulting κL was obtained by the relation:

Lphonon was evaluated by the following equations27,28,

where VL, Vs, C, were the longitudinal sound velocity, transverse sound velocity and specific heat capacity, respectively. Fig. 4(c) revealed that YSZ inclusion significantly decreased Lphonon and further induced the reduction in κL (Fig. 4(b)).

Scanning electron micrographs (SEM) of YSZ/Nb-STO composite (Fig. 5(a) and (b)) showed the grain size was increased obviously by YSZ inclusion. To confirm where YSZ existed in bulk Nb-STO ceramic, transmission electron microscope (TEM) observation and selected area electron diffractions (SAED) were carried out. The SAED patterns in Fig. 5(c-ii) and Fig. 5(d-ii), taken from large crystalline area in Fig. 5(c) and Fig. 5(d), were only well-matched with a cubic strontium titanate crystal. However, the SAED patterns in Fig. 5(c-i) and Fig. 5(d-i), taken from black nano-sized particles in Fig. 5(c) and Fig. 5(d), revealed some diffraction spots except the diffraction spots of strontium titanate, which matched the diffraction spots of YSZ very well. Above-mentioned evidences fully proved that YSZ inclusions located inside the grain (Fig. 5 (c)) and in the triple junction (Fig. 5(d)) and these inclusions were nano-sized, from several tens nanometers to several hundreds nanometers. YSZ has much lower thermal conductivity, ~2.5 Wm−1K−1 below 1200 K29, compared with SrTiO330.YSZ nano-inclusions inside the grain and in the triple junction could scatter the phonons effectively and thus brought about the decrease in the phonon mean free path, the lattice thermal conductivity and the total thermal conductivity, in sequence. As for SrTiO3 ceramic with oxide additives, such as TiO2, Al2O3 and SiO2, at the sintering temperature of over than 1400°C, the liquid phase formed at triple grain junctions and exhibited complete wetting of the grain boundaries31. YSZ/Nb-STO sample exhibited the abnormal grain growth in our experiment, which could be a similar liquid phase sintering behavior to SrTiO3 ceramic with added TiO2, Al2O3 and SiO2 in Ref. 31. According to the liquid-phase sintering theory proposed by Kingery32, the liquid phase formation could lead to the complete wetting of the grain boundaries, increase the grain boundary mobility and thus markedly accelerate the sintering rate and grain growth. The abnormal crystal growth of strontium titanate grain could obviously diminish the number density of grain boundaries and further reduce interface scattering of electrons remarkably, which partly contributed to the increased mobility and further to the enhanced electrical conductivity. On the other hand, Compared with pure Nb-STO, the relative density of YSZ/Nb-STO composite was increased from 63.1% to 79.4%, which was also partly contributed to the enhanced electrical conductivity. Fig. 6 showed the interaction schematic of phonon-nanoinclusion and electron-nanoinclusion. Oxide nano-inclusion with the low thermal conductivity, located inside the grain and in the triple junction, can reduce the thermal conductivity by effective interface phonon scattering, enhance the electrical conductivity by promoting the abnormal grain growth and increasing the relative density and thus lead to the obvious enhancement of ZT value of Nb-STO.

Microstructures and SAED patterns of YSZ/Nb-STO composite.

(a) SEM of sample without YSZ inclusion; (b) SEM of sample with YSZ inclusion; (c) TEM of sample with YSZ inclusion inside grain; (d) TEM of sample with YSZ inclusion in triple junction; (c-i) SAED pattern taken from i-area in Fig. 5(c); (c-ii) SAED pattern taken from ii-area in Fig. 5(c); (d-i) SAED pattern taken from i-area in Fig. 5(d); (d-ii) SAED pattern taken from ii-area in Fig. 5(d).

In summary, YSZ nano-inclusion could effectively reduce the thermal conductivity and increase the electrical conductivity of Nb-STO and thus obviously enhance the ZT value, which strongly suggested that oxide nano-inclusion with low thermal conductivity could be an effective strategy to enhance the thermoelectric properties of oxide thermoelectric materials with high thermal conductivity. Oxide nano-inclusion distributed inside the grain and in the triple junction can obviously reduce the phonon mean free path by the effective interface phonon scattering and further apparently lead to the decrease in the thermal conductivity. Meanwhile, the oxide nano-inclusion with high surface activation can promote the grain growth, diminish the number density of grain boundaries, increase relative density and thus improve the carrier mobility and the electrical conductivity. Our research may give some helpful enlightenment to develop high-performance oxide thermoelectric materials.

Methods

Sample preparation

Commercial YSZ (8 mol% yttria-stabilized zirconia) particles with the size of 25 ~ 30 nm were used as an oxide inclusion. Nb-doped SrTiO3 ceramic sample with YSZ inclusion of 3 wt% were fabricated by the conventional normal pressure sintering method at 1500°C for 3 h in an Ar atmosphere. The relative densities of Nb-doped SrTiO3 ceramic without added YSZ and with YSZ inclusion of 3 wt% are 63.1% and 79.4%, respectively.

Sample characterization

The thermoelectric performances, such as the Seebeck coefficient and electrical conductivity, were measured at 300–900 K in an Ar atmosphere by using an automatic thermoelectric measuring apparatus (Ozawa RZ2001K). The thermal diffusivity was measured by the usual laser flash method (ULVAC-RIKO TC-9000V). The carrier concentration and mobility was measured by the Van der Pauw's method (RESITEST 8300).The microstructures were observed on a scanning electron microscope (SEM) and a JEM-2010 transmission electron microscope (TEM). The specific heat capacity was measured by a differential scanning calorimeter system (TA Instrument DSC-2910). The mean phonon velocity was measured by an ultrasonic pulse-echo method (Panametrics-NDT 5800). The electrical properties (electrical conductivity and Seebeck coefficient) and thermal conductivity were measured in in-plane and cross-plane directions. YSZ/Nb-STO polycrystalline ceramic composite exhibited the isotropic electrical conductivity, Seebeck coefficient and thermal conductivity.

References

Zebarjadi, M. et al. Perspectives on thermoelectrics: from fundamentals to device applications. Energy Environ. Sci. 5, 5147–5162 (2012).

Heremans, J. P., Wiendlocha, B. & Chamoire, S. M. Resonant levels in bulk thermoelectric semiconductors. Energy Environ. Sci. 5, 5510–5530 (2012).

Biswas, K. et al. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 489, 414–418 (2012).

Snyder, J. G. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Poudel, B. et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634–638 (2008).

Li, F. et al. Polycrystalline BiCuSeO oxide as a potential thermoelectric material. Energy Environ. Sci. 5, 7188–7195 (2012).

Li, J. et al. A high thermoelectric figure of merit ZT > 1 in Ba heavily doped BiCuSeO oxyselenides. Energy Environ. Sci. 5, 8543–8547 (2012).

Lan, J. L. et al. Doping for higher thermoelectric properties in p-type BiCuSeO oxyselenide. Appl. Phys. Lett. 102, 123905–123908 (2013).

Liu, Y. et al. Remarkable enhancement in thermoelectric performance of BiCuSeO by Cu deficiencies. J. Am. Chem. Soc. 133, 20112–20115 (2011).

Wang, Y. et al. High temperature thermoelectric response of electron-doped CaMnO3 . Chem. Mater. 21, 4653–4660 (2009).

Inoue, Y., Okamoto, Y. & Morimoto, J. Thermoelectric properties of porous zinc oxide ceramics doped with praseodymium. J. Mater. Sci. 43, 368–377 (2008).

Peleckis, G., Motohashi, T., Karppinen, M. & Yamauchi, H. Enhanced thermoelectric properties of NaxCoO2 whisker crystals. Appl. Phys. Lett. 83, 5416–5418 (2003).

Ohta, H. et al. Giant thermoelectric Seebeck coefficient of a two-dimensional electron gas in SrTiO3 . Nature Mater. 6, 129–134 (2007).

Ohta, S. et al. Large thermoelectric performance of heavily Nb-doped SrTiO3 epitaxial film at high temperature. Appl. Phys. Lett. 87, 092108–092110 (2005).

Sui, J. et al. Texturation boosts the thermoelectric performance of BiCuSeO oxyselenides. Energy Environ. Sci. 6, 2916–2920 (2013).

Ohta, S., Ohta, H. & Koumoto, K. Grain size dependence of thermoelectric performance of Nb-doped SrTiO3 polycrystals. J. Ceram. Soc. Japan 114, 102–105 (2006).

Dresselhaus, M. S. et al. New directions for low-dimensional thermoelectric materials. Adv. Mater. 19, 1043–1053 (2007).

Tang, X. F. et al. Preparation and thermoelectric transport properties of high-performance p-type Bi2Te3 with layered nanostructure. Appl. Phys. Lett. 90, 012102–012104 (2007).

Mi, J. L., Zhao, X. B., Zhu, T. J. & Tu, J. P. Improved thermoelectric figure of merit in n-type CoSb3 based nanocomposites. Appl. Phys. Lett. 91, 172116–172118 (2007).

Poudel, B. et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 320, 634–638 (2008).

Li, H., Tang, X., Su, X. & Zhang, Q. Preparation and thermoelectric properties of high-performance Sb additional Yb0.2Co4Sb12+y bulk materials with nanostructure. Appl. Phys. Lett. 92, 202114–202116 (2008).

Li, H., Tang, X., Zhang, Q. & Uher, C. High performance InxCeyCo4Sb12 thermoelectric materials with in situ forming nanostructured InSb phase. Appl. Phys. Lett. 94, 102114–102116 (2009).

Lan, Y. et al. Structure study of bulk nanograined thermoelectric bismuth antimony telluride. Nano lett. 9, 1419–1422 (2009).

Pei, Y. Z., Heinz, N. A., LaLonde, A. & Snyder, G. J. Combination of large nanostructures and complex band structure for high performance thermoelectric lead telluride. Energy Environ. Sci. 4, 3640–3645 (2011).

Ahn, K. et al. Enhanced thermoelectric properties of p-type nanostructured PbTe–MTe (M = Cd, Hg) materials. Energy Environ. Sci. 6, 1529–1537 (2013).

Cutler, M., Leavy, J. F. & Fitzpatrick, R. L. Electronic transport in semimetallic cerium sulfide. Phys. Rev. 133, A1143–A1152 (1964).

Clarke, D. R. Materials selection guidelines for low thermal conductivity thermal barrier coatings. Surf. Coat. Technol. 163, 67–74 (2003).

Kawaharada, Y., Kurosaki, K., Uno, M. & Yamanaka, S. Thermoelectric properties of CoSb3 . J. Alloys Compd. 315, 193–197 (2001).

Winter, M. R. & Clarke, D. R. Thermal conductivity of yttria-stabilized zirconia–hafnia solid solutions. Acta Mater. 54, 5051–5059 (2006).

Suemune, Y. Thermal conductivity of BaTiO3 and SrTiO3 from 4.5° to 300°K. J. Phys. Soc. Jpn. 20, 174–175 (1965).

Fujimoto, M. & KINGERY, W. D. Microstructures of SrTiO3 internal boundary layer capacitors during and after processing and resultant electrical properties. J. Am. Ceram. Soc. 68, 169–173 (1985).

Kingery, W. D. & Narasimhan, M. D. Densification during sintering in the presence of a liquid phase. J. Appl. Phys. 30, 307–310 (1959).

Acknowledgements

This work was partially supported by China-Japan International Cooperation Program Funds (No. 2010DFA61410 and 2011DFA50530), National Natural Science Foundations of China (No. 51272037, 51272035 and 51362026), Fundamental Research Funds for the Central Universities (No. ZYGX2010Z003) and Program for New Century Excellent Talents in University (No. NCET-12-0097).

Author information

Authors and Affiliations

Contributions

N.W. and K.K. designed the experiments. N.W. carried out the fabrication of materials and thermoelectric measurements. W.N. and M.K. contributed to microstructural characterizations. H.J.C. and H.C.H. provided helps in the experiments. N.W. and H.J.C. wrote the paper and all authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by/3.0/

About this article

Cite this article

Wang, N., Chen, H., He, H. et al. Enhanced thermoelectric performance of Nb-doped SrTiO3 by nano-inclusion with low thermal conductivity. Sci Rep 3, 3449 (2013). https://doi.org/10.1038/srep03449

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep03449

This article is cited by

-

Effects of Mn-doping on the thermoelectric properties of SrTi0.9Nb0.1O3−δ perovskite oxide

Journal of Materials Science: Materials in Electronics (2023)

-

Nanostructure and thermal power of highly-textured and single-crystal-like Bi2Te3 thin films

Nano Research (2022)

-

High breakdown strength and energy storage density of Er0.02Sr0.97TiO3@MgO2–Al2O3–SiO2 ceramics with core–shell structure sintered in oxygen atmosphere

Journal of Materials Science: Materials in Electronics (2020)

-

Tuning thermoelectric properties of Ca0.9Gd0.1MnO3 by laser processing

Journal of Materials Science: Materials in Electronics (2020)

-

Tuning the Electrical and Thermoelectric Properties of N Ion Implanted SrTiO3 Thin Films and Their Conduction Mechanisms

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.