Abstract

We report microstructural design via control of BaZrO3 (BZO) defect density in high temperature superconducting (HTS) wires based on epitaxial YBa2Cu3O7-δ (YBCO) films to achieve the highest critical current density, Jc, at different fields, H. We find the occurrence of Jc(H) cross-over between the films with 1–4 vol% BZO, indicating that optimal BZO doping is strongly field-dependent. The matching fields, Bφ, estimated by the number density of BZO nanocolumns are matched to the field ranges for which 1–4 vol% BZO-doped films exhibit the highest Jc(H). With incorporation of BZO defects with the controlled density, we fabricate 4-μm-thick single layer, YBCO + BZO nanocomposite film having the critical current (Ic) of ~1000 A cm−1 at 77 K, self-field and the record minimum Ic, Ic(min), of 455 A cm−1 at 65 K and 3 T for all field angles. This Ic(min) is the largest value ever reported from HTS films fabricated on metallic templates.

Similar content being viewed by others

Introduction

Synthesis of epitaxial nanocomposite films containing self-assembled, ordered arrays of nanodots/nanorods/nanopillars of one type of complex material embedded in another complex functional material has stimulated research in a wide range of application areas such as multiferroics, magnetoelectrics, thermoelectrics, ultra-high density storage and high temperature superconductors1,2,3,4,5. In these application areas, the nanocomposite films can offer new or significantly enhanced functionalities which are not attainable from individual materials or phases comprising the composite. One of the fascinating examples is high temperature superconducting (HTS) nanocomposites based on YBa2Cu3O7-δ (YBCO) containing a few volume% (vol%) insulating columnar defects comprised of simple or double perovskite-structured materials with simple (or distorted) cubic structure that include BaZrO3 (BZO), BaSnO3, Ba2RETaO6 and Ba2RENbO65,6,7,8,9,10,11,12. Driscoll et al.13 were the first to demonstrate that incorporation of randomly oriented, disk shaped BZO nanoparticles with a modal size of ~10 nm was beneficial to pinning13. It was subsequently demonstrated that spontaneous self-assembly of well-ordered, vertically aligned, nanocolumns parallel to the YBCO c-axis was possible by incorporation of the materials listed above5,6,7,8,9,10,11,12 and that such self-assembly occurs via spontaneous phase separation and a strain-driven ordering process driven by minimization of strain fields arising from the lattice mismatch (5 ~ 12%) between the embedded nanophase and the YBCO matrix14. Since these columnar defects typically form ordered arrays of columns with diameters (5 ~ 10 nm) comparable to the diameter of a magnetic vortex core ≈ 2 × ξ(T), (ξ(T) = superconducting coherent length for YBCO,  , ξ(0) = 1.5 ~ 2 nm), they effectively pin or immobilize magnetic flux lines (or vortices), resulting in a dramatic improvement of the critical current density, Jc, in the presence of applied magnetic fields, particularly when the field is parallel to the orientation of the aligned defects, H∥c-axis5,6,7,8,9,10,11,12.

, ξ(0) = 1.5 ~ 2 nm), they effectively pin or immobilize magnetic flux lines (or vortices), resulting in a dramatic improvement of the critical current density, Jc, in the presence of applied magnetic fields, particularly when the field is parallel to the orientation of the aligned defects, H∥c-axis5,6,7,8,9,10,11,12.

HTS wires based on YBCO nanocomposite films are an essential component to realize a wide range of environmentally friendly, highly efficient electric power devices with small weight and footprint15. Since the field and temperature regimes in which these devices are operated are different15, vortex pinning via columnar defects needs to be tailored to achieve the highest Jc at the desired fields and temperatures required by the specific applications. An ideal strategy to achieve such a goal is to incorporate as many columnar defects as the number of vortices generated at the operating magnetic field. Fewer defects would leave unpinned vortices and extra defects would compromise the volume of superconducting phase, both limiting Jc16. Since vortex spacing depends on the magnetic field strength, nanocolumn spacing to accommodate all vortices is expected to be field-dependent. For this reason, the effect of BZO nanocolumn density on the Jc as a function of magnetic field strength, orientation and operating temperature needs to be comprehensively understood. Ultimately, we should be able to tailor the BZO defect density to achieve an optimal superconducting performance at a given application specific, operating temperature and applied magnetic field. Although previous work has reported the importance of controlling the columnar defect density to enhance and tailor the in-field Jc properties17,18,19,20, there is no report of systematic variation of the optimal columnar defect density as a function of magnetic field strength, orientation and operating temperature.

In the present work, we show that the density of BZO columnar defects necessary to achieve optimal Jc performance systematically increases with increasing magnetic field and is also influenced by field orientation and temperature. In addition, we demonstrate that a single layer 4-μm-thick YBCO films with the controlled density of BZO nanocolumns exhibits excellent critical current (Ic) performance given by a Ic of ~1000 A cm−1 at 77 K, self-field and a minimum Ic, Ic(min), of 455 A cm−1 at 65 K and 3 T for all magnetic field orientations. Such high Ic(min) at 65 K and 3 T is the record value ever reported from HTS films fabricated on metallic templates.

Results

Engineering BZO nanocolumnar defect density for Jc optimization at different fields

Figure 1 summarizes X-ray diffraction results for YBCO films with different BZO contents up to 10 vol%. All samples with same thickness of ~0.8 μm were deposited on LMO/IBAD-MgO/Hastelloy templates via pulsed laser deposition (PLD). The detailed procedures of the samples preparation are summarized in the Experimental section. The θ–2θ scans (Fig. 1a) show that all films have sharp out-of-plane c-axis orientation with strong (00l) peak intensities of YBCO phase. For BZO-doped samples, additional peaks at 2θ = 21.6° (which is evident only for the 10 vol% BZO-doped sample due to the large concentration of BZO phase) and 43.3° correspond to (001) and (002) BZO peaks indicating the formation of epitaxial BZO nanophase within the YBCO matrix. The narrow scans (Fig. 1b) for BZO (002) peak measured at the maximum X-ray power show evidently stronger peak intensities with increasing BZO addition, despite the slight peak overlap with the MgO (200) peak, which stems from the epitaxial MgO layer comprising the template. Detailed XRD analysis based on peak broadening estimates that the size of BZO nanophase is ~6–7 nm and remains nearly unchanged up to 10 vol% BZO. Figure 1c shows the summary of full-width-half-maximum of omega and phi scans (Δω and Δϕ) for YBCO and BZO phases taken from the samples. Essentially, no meaningful variation of Δω and Δϕ in both YBCO phase and BZO nanophase is measured from all BZO-doped films. The Δω and Δϕ values of YBCO phase are in the ranges of 1.3° ~ 2° and 3.2° ~ 3.6°, respectively, while those of the BZO nanophase range from 2.1° to 2.8° and from 5.8° to 6.2°, respectively. Relatively larger Δω and Δϕ for the BZO nanophase should be attributed to the deviation of their alignments with respect to the in-plane and out-of-plane of YBCO film as well as the substrate10. Although the ω and ϕ scan results imply that all samples with BZO contents up to 10 vol% have good epitaxial YBCO phase with similar in-plane and out-of-plane textures, YBCO (113) pole figure measurements (Fig. 1d) reveal that texture degradation occurs when BZO content increases to 10 vol%. Unlike the 1–4 vol% BZO-doped samples having only strong, sharp four-fold symmetric peaks, the 10 vol% BZO-doped film exhibits an additional texture component indicated by a circular pattern along with the four-fold symmetric peaks, mostly caused by formation of misoriented and 45° rotated grains. A quantitative fraction (%cube-texture) of “cube-textured” volume out of the total volume of the layer was determined by the numerical method described elsewhere21. The 10 vol% BZO doped sample only has 90% cube-texture which is smaller than the values of 95 ~ 96% typically measured from un-doped and 1–4 vol% BZO-doped films.

X-ray diffraction results for YBCO films with different BZO additions.

(a) θ–2θ scans for the samples at X-ray power (−50 kV, 5 mA) where the intensity of (006) YBCO peak does not exceed the maximum intensity limit of the detector. (b) θ–2θ scans from 2θ = 41.5° to 45.5° at maximum X-ray power (-50 kV, 30 mA). (c) Δω and Δϕ values for YBCO phase and BZO nanophase for the films with and without BZO additions. (d) YBCO (113) pole figures for 1–10 vol% BZO-doped samples.

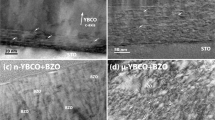

Transmission electron microscopy (TEM) examination confirms the formation of self-aligned BZO nanocolumns in YBCO + BZO nanocomposite films. As shown in Figs. 2a and 2c, cross-section TEM images for the 1 and 4 vol% BZO-doped films show BZO nanocolumns, well-ordered and in general aligned to the crystallographic c-axis of YBCO with some splayed feature with respect to the c-axis similar to previous reports7,10. Figure 2b shows a plan-view TEM image for the 2 vol% BZO-doped film containing moiré fringes caused by BZO nanoparticles which are sections of BZO nanocolumns. The TEM images confirm the increase in the columnar defect density with BZO content while their average diameters remain unchanged around 5–6 nm, consistent with the estimated values by XRD. Figure 2d shows a summary of average BZO nanocolumn spacing, d, for 1–4 vol% BZO doped samples, based on the examination of several TEM images collected from the samples containing different BZO contents. With the nanocolumn spacing, we calculated the matching field, Bφ = 2Φ0/√3a2 as ~0.8 T for 1 vol% BZO, ~6 T for 2 vol% BZO and ~15 T for 4% BZO-doped samples, where Φ0 = 2.07 × 10−11 T cm2 is the flux quantum and a is the vortex spacing that matches d at Bφ.

Typical cross-sectional and plan-view TEM micrographs for YBCO + BZO nanocomposite films.

(a) and (c) Cross-sectional TEM images of 1 and 4 vol% BZO-doped films respectively. (b) Plan-view TEM image for 2 vol% BZO-doped film. (d) Average BZO nanocolumn spacing, d and corresponding matching field, Bφ, as a function of BZO doping concentration.

When BZO doping is further increased to 10 vol%, we observed a morphological change in the array of BZO defects as shown in Fig. 3. Essentially, some BZO defects start to be aligned horizontally (along ab-planes) along with BZO nanocolumns aligned vertically (along c-axis) denoted by blue and red arrows (Fig. 3a). Since the imaging conditions that bring out BZO defects aligned vertically and horizontally are slightly different, the defects aligned to the ab-planes are more clearly observed in a different image of the same specimen taken from different imaging conditions (Fig. 3b). Vertically aligned BZO nanocolumns are very dense and the average BZO column spacing can be estimated to be less than 10 nm, much narrower than that for the 4 vol% BZO-doped sample. The appearance of semi-continuous, planar BZO defect arrays is anticipated when the BZO doping concentration is high enough to minimize the distance between adjacent BZO nanodots nucleating within the same ab-plane, as shown in our previous work14. Further increase in BZO content is expected to produce continuous planar BZO layers in the YBCO matrix. Indeed, YBCO/BZO multilayer structure containing planar BZO defects arrays was reported from YBCO + BZO nanocomposite films with high BZO concentration such as 50 mol% YBCO and 50 mol% BZO22.

Cross-sectional TEM micrographs for 10 vol% BZO-doped film.

(a) An image shows semi-continuous BZO nanodots arrays aligned to the ab-planes as well as dense BZO nanocolumns aligned to the c-axis of the film. (b) An image taken from the same TEM specimen at a different image condition highlights more clearly planar BZO defects aligned to the ab-planes. Note that some of BZO defects aligned vertically and horizontally are denoted as red and blue arrows.

Table 1 summarizes superconducting transition temperature, Tc and self-field Jc at 77 K and 65 K for the set of un-doped and BZO-doped YBCO films with different BZO contents. Note that as denoted in Table 1, 1 vol% BZO is equivalent to 1 wt% and 2.4 mol% BZO. Several 0.5 and 1 vol% BZO-doped films are reproducibly measured to have Tc of 87.5 ~ 87.7 K, essentially unchanged from those (Tc = 87.5 ~ 88.0 K) obtained from pure YBCO films grown on IBAD-MgO templates in identical PLD conditions. When BZO doping is over 1 vol%, Tc starts to drop monotonically with a drop rate of ~0.46 K/vol% (0.2 K/mol%). In a previous work23, we suggested that the origin of Tc reduction with increasing BZO doping should be attributed to local strain field caused by the lattice mismatch (~8%) between YBCO and BZO phases and the consequent local oxygen deficiency that possibly occurs around BZO nanocolumns. Microstrain measurement of BZO-doped samples based on Williamson-Hall plots24,25 shows that the strain field monotonically increases as BZO content increases23. High resolution, scanning TEM analysis confirms that a local area surrounding a BZO nanocolumn having approximately an outer diameter of ~15–20 nm, is highly strained and also oxygen deficient23. When average BZO columns spacing is near or above this diameter by increasing BZO doping, an overlap of strained REBCO regions surrounding BZO nanocolumns is expected to occur and Tc starts to decrease. As aforementioned, the BZO doping level that results in the average BZO column spacing near or above ~15–20 nm is around 2–4 vol%, which is the concentration at which Tc apparently starts to decrease. For the self-field Jc at 77 K and 65 K, the Jc values are noticeably improved with BZO doping up to 1 vol%. The highest Jc of 4.1 MA cm−2 at 77 K and 12.2 MA cm−2 at 65 K are achieved from the 1 vol% BZO-doped sample. After an initial enhancement, the Jc gradually degrades up to 0.34 MA cm−2 at 77 K with further increasing BZO up to 10 vol%. Such Jc variation suggests that even at self-field, additional BZO defects enhance the pinning and Jc performance of the films and 1 vol% BZO is an optimum doping level resulting in the highest Jc at 77 K and 65 K.

In the presence of applied magnetic fields, the strong dependence of the optimum BZO doping level on the applied magnetic field strength is observed. Figure 4 shows Jc and pining force (Fp) as a function of applied magnetic field, Jc(H) and Fp(H), for YBCO films with different BZO contents, for the field parallel to YBCO c-axis, (H∥c) at 77 K and 65 K. The inset of Fig. 4a also displays the normalized Jc(H) data at 77 K to determine α values in the power-law dependence of Jc on H, Jc ~ H−α valid in the range of ~0.2–1.5 T, which are also summarized in Table 1. Compared to the un-doped sample, the 1–4 vol% BZO-doped samples show a significantly improved Jc(H), much higher Fp(H) and smaller α values, indicating the efficacy of BZO columnar defects as strong c-axis pinning centers. The highest Fp(max) values of 9.5 GN m−3 at 77 K, 2 T and 74 GN m−3 at 65 K, 5 T as well as the smallest α value of ~0.33 are obtained from the 2 vol% BZO-doped sample. Unlike these samples, 10 vol% BZO-doped sample shows much poorer Jc(H) and Fp(H) at both temperatures, primarily due to the detrimental problems caused by excess BZO doping as will be discussed later. Another essential feature observed in the figures is the occurrence of Jc(H) (or Fp(H)) cross-over between the films with 1–4 vol% BZO, indicating that the optimal BZO doping is strongly field-dependent. The Jc(H) data at 77 K show that the 1 vol% BZO-doped film has the highest Jc(H) in the self-field and up to the first cross-over field of ~1.6 T. When the field is higher than ~1.6 T, the 2 and 4 vol% BZO doping levels lead to the highest Jc(H) up to and over the second cross-over field of ~7.3 T, respectively. Jc(H) data at 65 K also show the same trend, but the cross-over fields are moved to higher fields as indicated in the figure.

Field dependent Jc and Fp for H∥c with the magnetic field up to 8 T for pure YBCO and YBCO + 1–10 vol% BZO films.

(a) Jc(H) at 77 K, (b) Jc(H) at 65 K, (c) Fp(H) at 77 K and (d) Fp(H) at 65 K. The inset of Fig. 4(a) shows normalized Jc, Jc(H)/Jc(sf), for the samples. All samples have an identical film thickness of ~0.8 μm.

Figures 5a–5c show angular dependent Jc, Jc(θ), for the samples at different temperatures and field regimes. The measurement was made in the maximum Lorentz force configuration in which the applied field direction is always perpendicular to the direction of current flow. 1–4 vol% BZO-doped films show higher Jc(θ) than the un-doped sample for the entire angular range. In addition to higher Jc(θ) at and near H∥c stemming directly from strong c-axis correlated pinning via BZO nanocolumnar defects, the overall improvement in Jc(θ) for angles away from H∥c can be attributed to the enhanced pinning via strong BZO defect-vortex interaction that still exist, although the pinning strength gradually decreases due to the reduced area of vortex confined by BZO columns with angles away from H∥c16. This is the primary reason why the enhancement in Jc(θ) near H∥ab for 2 and 4 vol% BZO-doped samples is limited and eventually negligible at 65 K, 3 and 5 T. Despite this fact, the 1 vol% BZO-doped sample maintains higher Jc(θ) near H∥ab than the 2 and 4 vol% BZO-doped samples, which lead to the highest Jc(min) for all field orientations, as shown in Fig. 5d. Note that the Jc(min) is considered a critical performance parameter particularly for devices with wound wire architectures such as motors, generators and high field magnets, so that HTS wires having higher Jc(min) are more desirable for these device applications.

Growth of thick YBCO films with engineered nanocolumns

Considering Jc(H,θ,T) data for ~0.8 μm thick YBCO nanocomposite films with different BZO contents reported in Figs. 4 and 5, we grew ~4-μm-thick YBCO films containing 1 vol% BZO in order to achieve superior Ic performance at self-field and in moderate magnetic field range of 0.5–3 T at 77 K and 65 K. To quantitatively evaluate the performance improvement by incorporating BZO defects, 4-μm-thick, un-doped films were also prepared in identical growth conditions. Phase and microstructural properties for both 4-μm-thick HTS films with and without 1 vol% BZO are summarized in Fig. 6. The most striking difference in structural properties between the un-doped and BZO-doped samples is the amount of a-axis oriented grains which are one of the major detrimental factors precluding a proportional increase of Ic with thickness26. Quantitative volumetric amount of a-axis grains in the films is determined by XRD, comparing the intensity of (001) normal with (100) normal peaks obtained in YBCO (102) χ-scans, I(100)/[I(001) + I(100)] × 100, as shown in Fig. 6b. The BZO-doped thick film is measured to have only ~3 vol% of a-axis oriented grains which is remarkably reduced from ~30 vol% of a-axis oriented grains measured from the un-doped thick sample. Plan-view scanning electron microscopy images (Figs. 6c and 6d) show that the BZO-doped thick film has denser and smoother surface morphology with significantly reduced a-axis oriented surface particles/grains compared to the un-doped thick film.

(a) θ–2θ scans and (b) (102) χ-scans for un-doped and 1 vol% BZO-doped, 4 μm thick YBCO films.

Plan-view SEM images for (c) un-doped and (d) 1 vol% BZO-doped, 4 μm thick YBCO films on IBAD-MgO template with LaMnO3 cap layer. The results indicate that the a-axis growth in thick films is significantly suppressed by BZO addition.

Figure 7 shows transport Ic versus magnetic field at 77 K and 65 K for 4-μm-thick films with and without 1 vol% BZO. The Ic data at 75.5 K for the film containing 1 vol% BZO were also measured and shown in the inset of Fig. 7b for comparison with the previously reported high Ic data at 75.5 K27,28. The BZO-doped thick film has the self-field Ic values of 995 A cm−1 at 77 K and 1188 A cm−1 at 75.5 K, which correspond to the Jc of 2.5 and 3 MA cm−2, respectively. The self-field Ic at 77 K for the BZO-doped sample is more than twice as large as the Ic of 465 A cm−1 of the un-doped thick film. In fact, multiple samples containing 1 vol% BZO showed the self-field Ic of 750 ~ 1000 A cm−1 at 77 K, while un-doped samples have the Ic of 450 ~ 530 A cm−1. Due to a limit in the maximum current (~25 A) that can be applied to the patterned sample (215 μm in width), the self-field Ic at 65 K cannot be directly measured. However, the Ic over 1000 A cm−1 at 65 K are retained at fields up to 1 T for H∥c and 1.5 T for H∥ab. In the presence of applied magnetic fields, superior Ic(H) with excellent Ic retention properties can be seen in the BZO-doped thick sample, compared to the un-doped thick film. At 77 K, 1 T, the Ic of ~ 340 A cm−1 for H∥c is only reduced by a factor of ~2.9 from the Ic at self-field, indicating a massive enhancement in pinning via BZO columnar defects. At 65 K, the Ic for H∥c and H∥ab are well over 150 A cm−1 at fields up to 8 T. All these Ic values are 2- or 3-fold larger than those for the un-doped thick sample.

The field dependent Ic at 77 K and 65 K for (a) H∥c and (b) H∥ab with the magnetic field up to 8 T for un-doped and 1 vol% BZO-doped, 4 μm thick YBCO films.

The inset of Fig. 7(b) shows Ic(H) data measured at 75.5 K for the BZO-doped thick film.

Angular dependent Ic at 77 K, 1 T and 65 K, 3 T are shown in Fig. 8. Compared to the un-doped thick film, the BZO-doped thick film shows the remarkably improved Ic for all field angles. The BZO-doped thick film has the Ic(min) of 196 A cm−1 at 77 K, 1 T and 455 A cm−1 at 65 K, 3 T which are about three times larger than those for the un-doped thick film. At 75.5 K, 1 T, the BZO-doped film is also measured to have the Ic(min) of 251 A cm−1 (the data not shown here) which is nearly 30% increase in the value at 77 K, 1 T.

Discussion

Since Bφ is the field at which the density of vortices matches that of the BZO nanocolumns, Figure 2d provides key information on how much BZO doping is approximately required to accommodate vortices generated in a specific field range16. For instance, 1 and 2 vol% BZO should be the optimum levels to maximize the pinning and Jc performance at low fields of ~0.8 T and modest fields of ~6 T respectively, but the doping level should increase to 4 vol% at much higher fields around 15 T. 10 vol% BZO-doped samples contain very dense BZO defects aligned both parallel and perpendicular to the YBCO c-axis that may effectively enhance the pinning for fields over 15 T (see Fig. 3). However, significant reduction in YBCO phase volume fraction (proportional to the amount of BZO volume fraction) as well as the degradation of cube texture (see Fig. 1d) and Tc (see Table 1) via excess BZO doping should result in negative impacts on the Jc particularly at high temperatures of 77 K and 65 K, over any gain caused by the enhanced pinning via the BZO defects as shown in Figs. 4 and 5. When comparing the field ranges for which the 1–4 vol% BZO-doped films exhibit the highest Jc(H,T) in Fig. 4 with the Bφ values estimated from the respective BZO column densities, we find that the Bφ values are close to or within these field ranges. The results demonstrate that optimal BZO nanocolumns density to achieve the highest Jc is different at different fields and temperatures, dictating that the number density of columnar defects is an effective way to achieve the highest Jc at any targeted field-temperature range.

Understanding of the effect of BZO doping on Jc(H, θ) at 77 K and 65 K for YBCO + BZO nanocomposite films provides key information to achieve high Ic performance at technically important field-temperature ranges for various electric power applications, such as i) 0–0.5 T, 65–77 K (for underground transmission cable, transformer and fault current limiter) and ii) 3–5 T, 65 K (for large-scale motors and generators)15. Growth of a single layer YBCO film with high Ic (77 K, sf) over 1000 A cm−1 has been considered a very challenging work due to an exponential decay of critical current density, Jc, making a proportional increase in Ic with the film thickness not feasible. The decay in Jc with thickness can be attributed to a number of factors including roughening of film, loss of epitaxy or degradation of texture and reduction in the defect density of naturally formed defects26,29,30. To date, there have been only a few reports on fabrication of a single layer, thick YBCO films having self-field Ic close to or over 1000 A cm−1 at 75.5–77 K27,28,31,32. Very recently, Ic (77 K, sf) of 1018 A cm−1 was reported in 5.9 μm thick DyB2Cu3O7-δ grown on the metallic templates prepared by inclined substrate deposition32. For the films grown on IBAD metallic templates, the self-field Ic of 944 A cm−1 at 77 K and 1007 A cm−1 at 76.55 K were obtained from a piece of the wire with 3.3 μm thick, 5 mol% Zr-doped (Y,Gd)BCO film31. For the films grown on single crystal substrates, the highest Ic of ~1500 A cm−1 at 75.5 K, self-field was reported from 9 μm thick YBCO films containing 5 mol% BZO and 5 mol% Y2O328. Recent reports suggest that incorporation of BZO and (or) other defects into thick YBCO films is a very effective means to achieve the improved Ic at self-field as well as in magnetic fields27,28,31.

Figure 9 compares the Ic and engineering critical current density, JE, data at a field-temperature regime of 65 K, 3 T for the BZO-doped sample with those for the previous record performance HTS wires comprised of ~3 and 4 μm thick YBCO + BZO nanocomposite films6,7. The Ic(min) of 455 A cm−1 for the thick sample reported in this study corresponds to JE of 43.7 kA cm−2 and 84.2 kA cm−2 with and without considering a 50 μm thick Cu stabilizer which may be needed in application. Both Ic and JE performances are much higher than the previous values and are significantly exceeding the performance levels of 20 kA cm−2 needed for the applications6. Higher Ic and JE can provide wider gap from the operating current levels of a given application and thus, are always highly desirable as a greater safety buffer, to further reduce AC losses and to avoid exceeding Ic locally due to any perturbation.

Angular dependence of Ic and JE for a 4 μm thick film of YBCO + 1 vol% BZO at a temperature-field regime of 65 K and 3 T. For comparison, Ic and JE data for 3 and 4 μm thick YBCO + BZO films previously reported in refs.

[6] and [7] are also plotted with open symbols. Since the total thickness of the 4 μm thick samples including substrate (~54 μm) considered for the JE calculation is slightly different from that of the 3 μm thick sample (~53 μm) plotted together in the figure, JE values for the 3 μm thick film sample are 2% or 1% (when considering additional 50 μm Cu stabilizer) higher than the JE values plotted in the graph.

In summary, we systematically investigated the influence of BZO nanocolumnar defect density on structural and superconducting properties of YBCO + BZO nanocomposite films. The nanocomposite films with up to 4 vol% BZO contents have highly cube-textured, epitaxial YBCO phase and BZO nanophase with the morphology of vertically ordered nanocolumns. Compared to the un-doped sample, the 1–4 vol% BZO-doped samples showed a significantly improved Jc performance for entire magnetic field ranges with much higher Fp and smaller α values due to the presence of strong pinning via BZO columnar defects. More importantly, we show that the optimum density of BZO nanocolumnar defects is strongly field-dependent and thus, different BZO doping levels are needed to optimize pinning and to achieve the highest Jc properties at different magnetic fields, particularly when the field is parallel to the orientation of BZO defects, H∥c. Finally, we have fabricated thick, single-layer nanocomposite films with the controlled BZO concentration showing a self-field Ic of ~1000 A cm−1 at 77 K and the record Ic(min) of 455 A cm−1 at 65 K and 3 T ever reported from HTS films fabricated on metallic templates.

Methods

All YBCO films with and without different vol% of BZO were prepared by pulsed laser deposition (PLD) using a KrF (λ = 248 nm) excimer laser at a repetition rate of 10 Hz. Laser energy density and substrate to target distance were optimized to be 2 J cm−2 and 5 cm, respectively. The PLD target (2 inch diameter, 0.25 inch thick) was made by mixing commercially available YBCO powder and BaZrO3 nanopowder using standard ball mixer, followed by densification at 950°C for 2 h. The film growth temperature, Ts, was 790°C and the oxygen partial pressure, P(O2), was 230 mTorr. All depositions were performed on IBAD-MgO templates with a LaMnO3 cap layer that were supplied from Superpower Inc.

After deposition, samples were in-situ annealed at Ts = 500°C and P(O2) = 500 Torr and ex-situ annealed at 500°C for 1 h in flowing O2 gas after depositing sputtered Ag electrodes onto the films. The 0.5 cm wide × 2 cm long sample was patterned into a ~0.2 mm wide bridge by laser-scribing, due to the limits on the maximum measuring current in the characterization system. The standard four-point probe method with a voltage criterion of 1 μV cm−1 was used for the transport measurements. Phase and textures of the films were characterized by X-ray diffraction method. Microstructures were characterized by transmission electron microscopy using a Hitachi HF-3300 TEM/STEM with a secondary detector and an energy-dispersive x-ray spectrometer at 300 kV and field emission scanning electron microscopy using Hitachi S4800 FEG-SEM. TEM foils were prepared by the focus ion beam (FIB) technique, followed by low voltage ion milling and plasma cleaning.

References

Zheng, H. et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 303, 661–663 (2004).

Jamet, M. et al. High-curie-temperature ferromagnetism in self-organized Ge1-xMnx nanocolumns. Nat. Mater. 5, 653–659 (2006).

Mohaddes-Ardabili, L. et al. Self-assembled single-crystal ferromagnetic iron nanowires formed by decomposition. Nat. Mater. 3, 533–538 (2004).

Harman, T. C. et al. Quantum dot superlattice thermoelectric materials and devices. Science 297, 2229–2232 (2002).

Goyal, A. et al. Irradiation-free, columnar defects comprised of self-assembled nanodots and nanorods resulting in strongly enhanced flux-pinning in YBa2Cu3O7-δ films. Supercond. Sci. Technol. 18, 1533–1538 (2005).

Kang, S. et al. High-performance high-Tc superconducting wires. Science 311, 1911–1914 (2006).

Wee, S. H., Goyal, A., Zuev, Y. L. & Cantoni C. High performance superconducting wires in high applied magnetic fields via nanoscale defect engineering. Supercond. Sci. Technol. 21, 092001 (2008).

Mele, P. et al. Ultra-high flux pinning properties of BaMO3-doped YBa2Cu3O7-x thin films (M = Zr, Sn). Supercond. Sci. Technol. 21, 032002 (2008).

Wee, S. H. et al. Formation of self-Assembled, double-perovskite, Ba2YNbO6 nanocolumns and their contribution to flux-pinning and Jc in Nb-Doped YBa2Cu3O7-δ Films. Appl. Phys. Exp. 3, 023101 (2010).

Wee, S. H. et al. Enhanced flux pinning and critical current density via incorporation of self-assembled rare-earth barium tantalate nanocolumns within YBa2Cu3O7-δ films. Phys. Rev. B 81, 140503(R) (2010).

Feldmann, D. M. et al. Improved flux pinning in YBa2Cu3O7 with nanorods of the double perovskite Ba2YNbO6 . Supercond. Sci. Technol. 23, 095004 (2010).

Ercolano, G., Harrington, S. A., Wang, H., Tsai, C. F. & MacManus-Driscoll, J. L. Enhanced flux pinning in YBa2Cu3O7-δ thin films using Nb-based double perovskite additions. Supercond. Sci. Technol. 23, 022003 (2010).

Macmanus-Driscoll et al. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7-x + BaZrO3 . Nat. Mater. 3, 439 (2004).

Wee, S. H. et al. Self-Assembly of Nanostructured, Complex, Mulit-Cation Films via Spontaneous Phase Separation and Strain-driven Ordering. Adv. Funct. Mater. 23, 1912 (2013).

Larbalestier, D., Gurevich, A., Feldmann, D. M. & Polyanskii, A. High-Tc superconducting materials for electric power applications. Nature 414, 368 (2001).

Civale, L. Vortex pinning and creep in high-temperature superconductors with columnar defects. Supercond. Sci. Technol. 10, A11 (1997).

Peurla, M. et al. Optimization of the BaZrO3 concentration in YBCO films prepared by pulsed laser deposition. Supercond. Sci. Technol. 19, 767 (2006).

Kang, S. et al. Flux-pinning characteristics as a function of density of columnar defects comprised of self-assembled nanodots and nanorods in epitaxial YBa2Cu3O7-δ films for coated conductor applications. Physica C 457, 41 (2007).

Mele, P. et al. Systematic study of the BaSnO3 insertion effect on the properties of YBa2Cu3O7-x films prepared by pulsed laser ablation. Supercond. Sci. Technol. 21, 125017 (2008).

Huhtinen, H., Irjala, M., Paturi, P., Shakhov, M. A. & Laiho, R. Influence of BaZrO3 dopant concentration on properties of YBa2Cu3O6+x films in magnetic fields up to 30 T. J. Appl. Phys. 107, 053906 (2010).

Wee, S. H. et al. Heteroepitaxial film silicon solar cell grown on Ni-W foils. Energy Environ. Sci. 5, 6052 (2012).

Yang, H. et al. Self-assembled multilayers and enhanced superconductivity in (YBa2Cu3O7-δ)0.5:(BaZrO3)0.5 nanocomposite films. J. Appl. Phys. 106, 093914 (2009).

Cantoni, C. et al. Strain-Driven Oxygen Deficiency in Self-Assembled, Nanostructured, Composite Oxide Films. ACS Nano 5, 4783 (2011).

Culity, B. D. & Stock, S. R. Elements of X-ray diffraction (3rd edition). Prentice Hall: Upper Saddle River, NJ, Chapter 3 (2001).

Puig, T. et al. Vortex pinning in chemical solution nanostructured YBCO films. Supercond. Sci. Technol. 21, 034008 (2008).

Foltyn, S. R. et al. Relationship between film thickness and the critical current of YBa2Cu3O7-δ-coated conductors. App. Phys. Lett. 75, 3692 (1999).

Feldmann, D. M. et al. 1000 A cm−1 in a 2 μm thick YBa2Cu3O7-x film with BaZrO3 and Y2O3 additions. Supercond. Sci. Technol. 23, 115016 (2010).

Zhou, H. et al. Thickness dependence of critical current density in YBa2Cu3O7-δ films with BaZrO3 and Y2O3 addition. Supercond. Sci. Technol. 22, 085013 (2009).

Kang, B. W. et al. Comparative Study of Thickness Dependence of Critical Current Density of Yba2Cu3O7–δ on (100) SrTiO3 and on Rolling-assisted Biaxially Textured Substrates. J. Mater. Res. 17, 1750 (2002).

Foltyn, S. R. et al. Materials science challenges for high-temperature superconducting wire. Nat. Mater. 6, 631 (2007).

Aytug, T. et al. ORNL-Superpower CRADA: Development of MOCVD-based, IBAD-2G Wires. Presented at 2008 Annual Peer Review for the U.S. Superconductivity Program for Electric Systems, Crystal city, VA, USA, July 29–31, 2008, available at: http://www.htspeerreview.com/2008/pdfs/presentations/wednesday/2G/5_2g_ornl_superpower.pdf (Accessed on March 06, 2009).

Durrschnabel, M., Aabdin, Z., Bauer, M., Prusseit, W. & Eibl, O. DyBa2Cu3O7-x superconducting coated conductors with critical currents exceeding 1000 A cm−1. Supercond. Sci. Technol. 25, 105007 (2012).

Acknowledgements

We would like to thank SuperPower Inc. for providing the Hastelloy substrates with the multilayer configuration of IBAD MgO layer/Homoepitaxial MgO layer/Epitaxial LaMnO3. This research was sponsored by the U.S. DOE Office of Electricity Delivery and Energy Reliability - Advanced Cables and Conductors under contract DE-AC05-00OR22725 with UT-Battelle, LLC managing contractor for Oak Ridge National Laboratory. Research also supported by ORNL's Shared Research Equipment (SHaRE) User Facility, which is sponsored by the Office of Basic Energy Sciences.

Author information

Authors and Affiliations

Contributions

S.H.W. designed experiment, prepared the samples by PLD, characterized structural properties of the samples by XRD and SEM and wrote the manuscript. Y.L.Z. measured superconducting properties of the samples. C.C. carried out the TEM characterization of the samples. A.G. supervised the research work and discussed the results. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Wee, S., Zuev, Y., Cantoni, C. et al. Engineering nanocolumnar defect configurations for optimized vortex pinning in high temperature superconducting nanocomposite wires. Sci Rep 3, 2310 (2013). https://doi.org/10.1038/srep02310

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02310

This article is cited by

-

Study of Superconducting Fluctuations in YBCO + xBZO Composites

Journal of Low Temperature Physics (2022)

-

Development and large volume production of extremely high current density YBa2Cu3O7 superconducting wires for fusion

Scientific Reports (2021)

-

Dynamic behavior of reversible oxygen migration in irradiated-annealed high temperature superconducting wires

Scientific Reports (2020)

-

High homogeneity 10 cm long BaTiO3-doped YBa2Cu3O7-δ films by the trifluoroacetate metal-organic deposition process

Journal of Sol-Gel Science and Technology (2020)

-

Enhanced flux pinning isotropy by tuned nanosized defect network in superconducting YBa2Cu3O6+x films

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.