Abstract

A ball dropped over a solid surface bounces several times before a complete stop. The bouncing can be reduced by introducing a liquid into the ball; however, the first rebound remains largely unaffected by the fluid. Granular materials can also work as dampers. We investigated the rebound of a container partially filled with a given mass of grains mi. During the collision, the kinetic energy of the container is partially transferred to the grains, the rebound is damped and the fast energy dissipation through inter-particle collisions and friction decreases the bouncing time dramatically. For grain-filled cylinders, a completely inelastic collision (zero rebound) is obtained when mi ≥ 1.5εomc, where εo and mc are the coefficient of restitution and mass of the empty container. For grain-filled spheres, the first rebound is almost undamped, but the second collision is completely inelastic if mi ≫ mc. These findings are potentially useful to design new granular damping systems.

Similar content being viewed by others

Introduction

The bounce of a ball dropped over a solid surface is a prolific topic in physics and engineering1,2,3,4,5,6,7. This simple system constitutes the basis to describe the rebound of sophisticated objects and more complex systems; for example, bouncing viscoelastic spheres8, non-homogeneous balls9, solid spheres into fluids10, balls11, dimers12 and trimers13 on vibrated plates and vibrated granular materials14,15,16,17.

Certain applications require materials that minimize the loss of energy during the rebound; e.g., in the design of small rubber balls in sport science18. On the other hand, in some cases it is necessary to damp the impact in order to protect the bouncing object, as in the landing of a massive spacecraft in Mars exploration missions19 (where a rover, protected by its lander structure and airbags, hits the ground and bounces several times before reaching the repose). A recent research20 showed that the rebound of a hollow sphere can be damped when it is partially filled with a liquid. The presence of the fluid does not affect the first rebound, but the second rebound is mitigated by the sloshing and collapsing of the liquid. The maximum damping is obtained when the liquid occupies about 30% of the available space and less notorious for larger liquid volumes.

Granular materials can also damp impacts and oscillations due to their ability to dissipate mechanical energy through inelastic collisions and friction between particles21,22. Recently, a considerable amount of research focused on the efficiency of granular dampers (GD) has been developed22,23,24,25,26,27. A granular damper consists of a number of grains enclosed in a receptacle that is attached or embedded in a vibrating structure22,26. In comparison with classical viscous dampers, GD exhibit several advantages for applications under extreme conditions: they are simple, easy to maintain, robust, very durable, no sensitive to temperature and effective over a wide range of frequencies23,24,25. It is only natural that these new dampers have a broad spectrum of applications (reducing vibrations in aerospace industry28,29, sports30, medical tools31, oscillatory saws32, dead-blow hammers33, etc). Through particle dynamics simulations34, it has been found that the damping mechanism is mainly dominated by friction for small particles, but the collisions effect becomes important as the particle size increases. However, when the number of particles is large, the total energy dissipated (collisional and frictional) is independent of the friction and restitution characteristics of the particles27. Moreover, in box-type GD, the damping efficiency is related to the available space for the grains in the container of confinement. Too confined, the grains behaves like a solid, the damping is weak. Too loose, the grains do not interact enough with the borders to damp the oscillations24,26.

In this work, we consider the damping effect of a granular material contained in a cell that freely bounces on a flat surface (i.e. the combination of a bouncing ball-and a granular damper). The main objective was to determine how the effective coefficient of restitution (ε) of the charged container, as well as the bouncing dynamics, depend on the internal mass of grains. For this purpose, cylindrical containers partially filled with grains were impacted vertically on a solid base. Different parameters were varied: the internal mass mi, the granular material, the length L, the mass mc and the coefficient of restitution ε0 of the empty container and its impact velocity. We found that ε decreases linearly with mi to practically zero when mi = mcrit ~ 1.5ε0mc. Over this critical mass, the container impacts without bouncing. However, when the container is totally full of grains, it becomes "solid" and ε increases notably. Our results are explained using a momentum exchange model. Moreover, we found that the container geometry plays an important role in the bouncing dynamics. In contrast with the cylindrical geometry, a grain-filled sphere never suffers a zero rebound. However, for mi ≫ mc, the second rebound is always completely inelastic, independently of the volume of grains. This latter result also contrasts with the bouncing of a fluid-filled sphere20, which damping is less effective as the internal liquid volume increases and bounces several times before the complete stop.

The experimental set-up is shown in Fig. 1a and described in the methods section. The characteristic of the containers and grain properties are summarized in Table 1. A video illustrating the main results reported in this manuscript can be found in the supplementary material.

(a) Sketch of the experimental set-up.(b-f) Snapshots of the bouncing cylinder (mc = 10.5 g) with different values of inner mass mi: (b) empty (mi/mc = 0), (c) 1.5 g (mi/mc = 0.14), (d) 3.5 g (mi/mc = 0.33), (e) 10.5 g (mi/mc = 1) and (f) 15 g (mi/mc = 1.43). (g) Vertical position of the containers as a function of time for different values of mi. Inset: v vs t for the empty container. Red lines have a slope of g = 9810 mm/s2. (h) Restitution coefficient for the first four consecutive bounces of containers with mi = 0 g ( ), 1.5 g (

), 1.5 g ( ), 3.5 g (

), 3.5 g ( ), 7 g (

), 7 g ( ), 10.5 g (

), 10.5 g ( ), 15 g (

), 15 g ( ) and 18 g (

) and 18 g ( ).

).

Results

Internal mass dependence

Figures 1(b–f) show snapshots of the bouncing dynamics of cylindrical containers filled with different masses of steel beads (spherical particles of 2 mm diameter). The parameters ε0 = 0.9, L = 5 cm, mc = 10.2 g and H = 10 cm were kept constant. For the empty case (mi = 0), a classical bouncing dynamics is observed (b). However, this bouncing is reduced dramatically as mi increases (c–e). Finally, for mi = 15 g, the container does not bounce (f). In order to characterize this bouncing dynamics, the vertical position h of the geometric centre of the tube was measured and plotted as a function of time in Fig. 1g. We used the first derivative v = dh/dt to obtain the vertical velocity of the container vs time. For clarity, only the empty case is plotted in the inset of Fig. 1g. This inset also shows that the air drag over the container can be neglected (red lines slope = 9810 mm/s2). The coefficient of restitution, ε = va/vb (where vb and va are the velocities before and after the impact) was plotted in Fig. 1h for the first four impacts, numbered by nb. For the empty container ( ), ε ≈ 0.9 is independent of nb and therefore of the impact velocity. On the other hand, ε varies considerably for grain-filled containers. For nb = 1, ε decreases as the internal mass increases. After this initial impact, the particles go upwards faster than the container and form a cluster at the top of the cavity. For the second impact (nb = 2), the container is "free of particles” because they are in free fall inside the cavity, thus ε is maximum. Thereafter, the falling particles start to collapse on the container bottom. This collapse damps the following rebounds and reduces dramatically the coefficient of restitution. Above mi = 15 g, ε ≈ 0 (

), ε ≈ 0.9 is independent of nb and therefore of the impact velocity. On the other hand, ε varies considerably for grain-filled containers. For nb = 1, ε decreases as the internal mass increases. After this initial impact, the particles go upwards faster than the container and form a cluster at the top of the cavity. For the second impact (nb = 2), the container is "free of particles” because they are in free fall inside the cavity, thus ε is maximum. Thereafter, the falling particles start to collapse on the container bottom. This collapse damps the following rebounds and reduces dramatically the coefficient of restitution. Above mi = 15 g, ε ≈ 0 ( ) indicates a completely inelastic collision.

) indicates a completely inelastic collision.

Length dependence

During the bouncing, the momentum exchange between the container and the beads takes place only through particle collisions with both ends of the container. Therefore, the length of the tube seems to be a key parameter. Figure 2 shows snapshots of the bouncing dynamics for different values of L (here the parameters ε0 ≈ 0.8, mi = 10.5 g, mc = 10.8 g and H = 20 cm were kept constant). The case L = ∞ corresponds to a tube without any upper end. For L = 7, 5, 4 and 3 cm, the grains have enough room to move freely during the bouncing, contrary to L = Lmin = 2.2 cm which corresponds to the minimum cavity size occupied for this mass of grains. The plot h vs t (Fig.2a) reveals that the maximum height reached by the container after the first bounce increases when L is decreased. This is not due to a different value of the coefficient of restitution, which obviously is the same for the first impact. As can be observed from the snapshots, even if in all cases the initial kinetic energy of the particles is the same after the collision, in shorter tubes more particles can reach the ceiling of the cavity and transfer their energy back to the container. The transfer increases the velocity of the container and the latter rises higher. This sudden momentum exchange is reflected in the plot v vs t in Fig. 2b at t ~ 0.06 s for closed tubes (3–7 cm). On the other hand, for Lmin = 2.2 cm, the system container-particles is almost a solid object; the particles dissipate less energy because they cannot move and therefore the container bounces higher. Note that momentum exchange is not observed for this case in Fig. 2b (black solid line). Figure 2c shows ε vs nb for the different containers lengths: as expected, for partially-filled containers ε (nb = 1) has the same value, ε is maximum for the second impact; and it decreases in the following rebounds due to the material collapse with the container bottom. This collapse is reflected by a sudden change in curvature of the v vs t plot after the second impact. In contrast, for L = ∞, the particles are most of the time in free flight after the first impact, they arrive to the base “one by one” and the damping is less notorious (o).

Snapshots of the bouncing dynamics of cylindrical containers of different lengths L. (a) h vs t, (b) v vs t and (c) ε vs nb.Colours are in correspondence with (a). (d) τ vs mi/mc for steel( ), ceramic(

), ceramic( ) and glass(

) and glass( ). Only for comparison, the time of the particles motion is shown (

). Only for comparison, the time of the particles motion is shown ( ). Inset: for a given mass of grains, τ is independent on the tube length and only increases when the available space inside the container is completely full of grains. The dotted lines correspond to the space occupied by the grains for mi = 3.5 g(

). Inset: for a given mass of grains, τ is independent on the tube length and only increases when the available space inside the container is completely full of grains. The dotted lines correspond to the space occupied by the grains for mi = 3.5 g( ), 7 g(

), 7 g( ) and 10.5 g (

) and 10.5 g ( ).

).

Total bouncing time (τ)

Surprisingly, the time elapsed from the first impact until the container stops is largely independent of the tube length. This time and therefore the damping efficiency, is only determined by mi (see Fig. 2d and inset therein). By analysing the videos, we observed that this independence is expected if Lmin < L < 〈vp〉2/2 g, where 〈vp〉 is the average velocity of the particles after the first impact. This condition ensures that the grains can interact with the bottom and ceiling of the cavity during the first bounce and dissipate most of the initial energy of the system during these two collisions. As a result, the remaining energy of the particles is not enough to reach the container ceiling in the following rebounds and the particles only hit the container bottom. In oscillating box-type GD, a significant dependence of the damping efficiency on the container length has been found24,25. In such experiments, the amplitude of vibration was large enough to produce several interactions of the particles with the ends of the box. However, when the amplitude was reduced, the particles did not have enough energy to reach the box ceiling and they only hit the box bottom, and, as in our results, the box size was also irrelevant24. The effect of mi on the total bouncing time (Fig. 2d) is discussed later in the text.

First bounce

The dependence of the coefficient of restitution on the different parameters involved in the experiments is complex. However, this is not the case for the first impact. Because of this reason, let us focus our study in the first rebound, which represents the transition between solid-like to gas-like state for the granular material contained in the ball. The energy of the impact is partitioned between the container and the numerous beads provoking the fast change of state from a granular packing to a granular gas (similar to sublimation21). The discussion about the clustering process25,35 is out of the scope of the present work. However, this represents an interesting system for further investigations in this field.

Figure 3a shows the values of ε for the first impact as a function of mi/mc ( ) obtained from the data reported in Fig. 1h. Note that three different regimes are observed: (I) for 0 < mi/mc < 1.5, ε decreases linearly from a quasi-elastic collision (ε0 = 0.9) to almost zero. (II) For 1.5 < mi/mc < 2.3, ε ≈ 0 indicating a completely inelastic collision and (III) for mi/mc > 2.3, ε starts to augment again and a small increment in mass produces a big increment in the coefficient of restitution. The linear decrease indicates that a percentage of the initial momentum of the container is transferred during the impact to the grains and this transfer augments with the number of particles. The transition at mi/mc ≈ 1.5 indicates the minimum mass of grains mcrit necessary to remove all the initial momentum of the container. Over this critical value, the collision is completely inelastic. The sudden increase of ε observed at mi/mc = 2.3 occurs because the available internal space inside the container (V = 4.75 cm3) becomes full of particles for this mass value. Then, the particles do not have enough room to move and the damping is less efficient. Considering the random close packing φ = 0.64, the maximum mass is mi = ρφV ≈ 23.5 g, which corresponds to mi/mc = 2.3. When the tube was tapped to increase the packing, a small free space was created and some particles were added to fill the empty space. A new measurement of ε increases from 0.15 to 0.4 by only adding 10 particles. This indicates that, for the highest packing of grains, the bouncing dynamics approaches to the behaviour of a solid object. To show that the coefficient of restitution augments because of the lack of free space and not due to the mass, a longer container (with same mc) with a larger inner mass of particles (mi = 28.5 g, i.e. mi/mc = 2.8) was used, obtaining again ε = 0, see (

) obtained from the data reported in Fig. 1h. Note that three different regimes are observed: (I) for 0 < mi/mc < 1.5, ε decreases linearly from a quasi-elastic collision (ε0 = 0.9) to almost zero. (II) For 1.5 < mi/mc < 2.3, ε ≈ 0 indicating a completely inelastic collision and (III) for mi/mc > 2.3, ε starts to augment again and a small increment in mass produces a big increment in the coefficient of restitution. The linear decrease indicates that a percentage of the initial momentum of the container is transferred during the impact to the grains and this transfer augments with the number of particles. The transition at mi/mc ≈ 1.5 indicates the minimum mass of grains mcrit necessary to remove all the initial momentum of the container. Over this critical value, the collision is completely inelastic. The sudden increase of ε observed at mi/mc = 2.3 occurs because the available internal space inside the container (V = 4.75 cm3) becomes full of particles for this mass value. Then, the particles do not have enough room to move and the damping is less efficient. Considering the random close packing φ = 0.64, the maximum mass is mi = ρφV ≈ 23.5 g, which corresponds to mi/mc = 2.3. When the tube was tapped to increase the packing, a small free space was created and some particles were added to fill the empty space. A new measurement of ε increases from 0.15 to 0.4 by only adding 10 particles. This indicates that, for the highest packing of grains, the bouncing dynamics approaches to the behaviour of a solid object. To show that the coefficient of restitution augments because of the lack of free space and not due to the mass, a longer container (with same mc) with a larger inner mass of particles (mi = 28.5 g, i.e. mi/mc = 2.8) was used, obtaining again ε = 0, see ( ) in Fig. 3a.

) in Fig. 3a.

(a) Restitution coefficient ε vs mi/mc for the first bounce of a cylinder with steel particles and ε0 = 0.9( ,

, ),ε0 = 0.8(

),ε0 = 0.8( ,

, ) and ε0 = 0.7(

) and ε0 = 0.7( ).(b) ε vs mi/mc for cylinders with different granular materials: steel(

).(b) ε vs mi/mc for cylinders with different granular materials: steel( ), ceramic(

), ceramic( ) and glass(

) and glass( ).Here, ε0 = 0.8 for the three cases. (c) ε-ε0 vs mi/mc for all the above conditions. The legend shows all the details about mi, mc, ε0, H and granular materials used in (a-c). The solid black line corresponds to the best fit of equation (1).

).Here, ε0 = 0.8 for the three cases. (c) ε-ε0 vs mi/mc for all the above conditions. The legend shows all the details about mi, mc, ε0, H and granular materials used in (a-c). The solid black line corresponds to the best fit of equation (1).

The experiments were repeated using containers with different coefficients of restitution (ε0 = 0.8  and ε0 = 0.7

and ε0 = 0.7  ) released from H = 20 cm, see Fig. 3a. In all cases, ε decreases linearly with mi/mc from ε0 to practically zero at a given critical mass. This behaviour suggests a linear fit of the form: ε = ε0 − kmi/mc. In so doing, we found that the fitted slope k is the same for the four sets of experiments, which are only shifted by the intercept ε0. On the other hand, the slope varies slightly when the granular material is changed (k = 0.58, 0.71 and 0.75 ± 0.02 for steel, ceramic and glass beads, respectively), see fig. 3b. Then, k must be related to the material properties. The inset in Fig. 3b shows that k decreases linearly with the density of the grains ρ. This fact can be explained considering the energy dissipation capacity24. For a given mass mi, the number of particles N is inversely proportional to ρ (e.g., if mi = 10.5 g, Ns ≈ 320, Nc ≈ 740 and Ng ≈ 960). A larger number of particles implies more collisions and therefore higher energy dissipation. According to this fit, all the above data were summarized in the plot ε-ε0 vs kmi/mc (Fig. 3c). Note that the collapse is remarkable.

) released from H = 20 cm, see Fig. 3a. In all cases, ε decreases linearly with mi/mc from ε0 to practically zero at a given critical mass. This behaviour suggests a linear fit of the form: ε = ε0 − kmi/mc. In so doing, we found that the fitted slope k is the same for the four sets of experiments, which are only shifted by the intercept ε0. On the other hand, the slope varies slightly when the granular material is changed (k = 0.58, 0.71 and 0.75 ± 0.02 for steel, ceramic and glass beads, respectively), see fig. 3b. Then, k must be related to the material properties. The inset in Fig. 3b shows that k decreases linearly with the density of the grains ρ. This fact can be explained considering the energy dissipation capacity24. For a given mass mi, the number of particles N is inversely proportional to ρ (e.g., if mi = 10.5 g, Ns ≈ 320, Nc ≈ 740 and Ng ≈ 960). A larger number of particles implies more collisions and therefore higher energy dissipation. According to this fit, all the above data were summarized in the plot ε-ε0 vs kmi/mc (Fig. 3c). Note that the collapse is remarkable.

Discussion

Let us now analyse the momentum conservation of the container-particles system during the first bounce. It is difficult to manage momentum exchange systems that involve simultaneous contacts36,37,38,39,40. Indeed, the forces acting at the contact points between the grains are strongly interdependent; therefore, the calculation of the momentum distribution is complex. In this problem, we propose to decompose the process in three steps (Fig. 4): (i) First, we consider the container and grains as two separated systems impacting the base with a velocity v0. (ii) In so doing, the vertical velocity of the container after the collision is ε0v0 and the average velocity of the grain cluster is 〈vgc〉. Here, it is assumed that 〈vgc〉 ≪ ε0v0 due to the fast energy dissipation in the granular material. (iii) Then, the empty container transfers part of its momentum to the grains via a wave front of collisions travelling through the cluster. Finally, the container emerges with a velocity vc and the particles with an average velocity 〈vp〉. In Fig. 4a, 〈vp〉 and vc are shown as function of mi/mc. Multiplying these velocities by mi and mc, respectively, one obtains the momenta P after the collision, see Fig. 4b. Note that the momentum of the container decreases whereas the average momentum of the grains increases, as a result of the momentum exchange. Applying the momentum conservation we have: mcε0v0 + mi〈vgc〉 = mcvc + mi〈vp〉. Since ε = vc/v0, this expression reduces to:

where Δvp = 〈vp〉-〈vgc〉. Let us remind that equation (1) expresses the momentum transfer: mcΔvc = miΔvp. The above model describes accurately the experimental data shown in Fig. 3. It is noteworthy that Δvp/v0 = k remains constant for a given material. This means that ε is independent of the impact velocity. Moreover, from equation (1), one finds that the critical mass to obtain a completely inelastic collision is given by:

Considering that k ~ 0.58 to 0.75 for the wide range of granular materials densities analysed (~2–8 g/cm3), one can approximate mcrit ~ 1.5ε0mc. In summary, the knowledge of the mass of the empty container and its coefficient of restitution are, in a first approximation, sufficient to determine the amount of granular material necessary to obtain a zero rebound, independently of the properties of the granular material. This outstanding conclusion is similar to the universal response of optimal granular dampers found recently using numerical simulations27: whenever a large number of particles is used, the total energy dissipated (collisional and frictional) is largely independent of the friction and restitution characteristics of the particles.

An expression for the total bouncing time can be derived using mcrit. In Fig. 2d, it was shown that T decreases notably as mi increases. Given that T(mi = 0) = T0 and T(mcrit) = 0, a plausible dependence for T(mi) can be written as follows: T(mi) = T0(1 − mi/mcrit)/(1 + βmi/mcrit), where β is a free parameter. This function was plotted in Fig. 2b (solid lines) using equation (2) with ε0 = 0.8 and the values of k found previously for steel, ceramic and glass particles. Again, the good agreement with the experimental measurements supports the momentum transfer model.

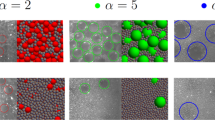

Finally, we compared briefly the previous results with the ones obtained using a sphere partially filled with different masses of grains. Unlike the cylindrical geometry, we found that the first bounce of the sphere was largely unaffected by the internal material (as in the case of a liquid-filled sphere10), however, the second impact is totally inelastic. This completely inelastic bounce was observed when mi ≫ mc for different filling volumes Vf (see Fig. 5a). Only the sphere completely full of grains and the empty sphere bounce several times before a complete stop. For partially filled spheres the coefficient of restitution is always zero at the second impact, see Fig. 5b. It is important to clarify that the damping of the first rebound increases with Vf due to the larger deformation of the ball, as was corroborated using spheres with equivalent mass of liquid. Nevertheless, following the second impact, the liquid-filled sphere displays a series of small consecutive bounces, whereas the grain-filled sphere stops dramatically, see Figs. 5c–d. Snapshots in Fig. 6 reveal that the liquid reacts more quickly to the sphere impact than the grains. However, whereas the liquid is always in contact with the sphere surface, the grains are decoupled from the sphere and form a granular gas that collapses at the second impact. This abrupt collapse dissipates all the energy of the system. In contrast, the water continues splashing inside the other sphere which remains rebounding. Additional research in this regard and the role of confinement produced by the geometry will be presented in a future work.

Bouncing dynamics of a sphere partially filled with different volumes of grains Vf: (a) h vs t and (b) ε vs nb for Vf/Vsphere = 0( ), 0.11(

), 0.11( ), 0.20(

), 0.20( ), 0.32(

), 0.32( ), 0.50(

), 0.50( ), 0.75(

), 0.75( ) and 1(

) and 1( ).The damping of the first rebound increases with the volume of grains due to the deformation of the ball, but a zero rebound never occurs. However, the second collision is completely inelastic in all cases. These results are in clear contrast with the liquid-filled sphere behaviour, where the maximum damping is obtained with a liquid volume of 30%. (c-d) Montages showing the rebound of a sphere partially filled with 15 g of (c) water and (d) grains.

).The damping of the first rebound increases with the volume of grains due to the deformation of the ball, but a zero rebound never occurs. However, the second collision is completely inelastic in all cases. These results are in clear contrast with the liquid-filled sphere behaviour, where the maximum damping is obtained with a liquid volume of 30%. (c-d) Montages showing the rebound of a sphere partially filled with 15 g of (c) water and (d) grains.

Snapshots of the bouncing dynamics of a sphere partially filled with 15 g of (a) water and (b) grains.

These images allow us to observe the motion of the internal material. The liquid reacts violently to the impact and forms a jet inside the sphere. Note that the liquid is always in contact with the container, in contrast with the “granular gas” decoupled from the inner surface of the sphere. The abrupt collapse of the grains dissipates all the energy of the system during the second impact.

Methods

Cylindrical containers

Transparent acrylic tubes of different lengths L were closed with rounded steel caps (a sphere of 6 mm welded to a washer of 14 mm diameter). Each tube was filled with a given mass mi of small spherical particles. Then, the container was released from a given height H over a massive horizontal steel base, see details in Table 1. A glass tube was used to maintain the projectile aligned vertically, as is shown in Fig. 1a. The projectile impacts and bounces over the solid surface until reach the repose. The experiments were filmed with a high speed camera at 1000 fps and the videos were analysed using ImageJ to obtain the dynamics. The experiments were repeated five times for the following parameters: mi, L, mc, ε0, ρgrains and v0 (see details in Table 1). On the other hand, solid steel bars of equivalent masses mi were glued into the container. By impacting these projectiles, we found that ε0 does not change significantly (less than 5%) in the range of masses used in the experiments. Then, the results reported here are due to the grains-container interaction and not to an effect of the total mass of the projectile. Moreover, using free-fall experiments, the air influence was checked to be negligible on the container motion and on the motion of one simple particle.

Spherical containers

Transparent celluloid ping-pong balls were filled with different masses of steel beads or water. The spheres were dropped from H = 20 cm and filmed at 1000 fps. The analysis was similar to the used with the cylindrical geometry.

Montages

The snapshots in Figs. 2 and 5 were formed by combining a 10 pixels width line from the centre of the container from each image of the high speed videos.

Change history

15 August 2013

A correction has been published and is appended to both the HTML and PDF versions of this paper. The error has been fixed in the paper.

References

Barnes, G. Study of collisions Part I. A survey of the periodical literature. Am. J. Phys. 26, 5–8 (1958).

Bayman, B. F. Model of the behaviour of solid objects during collision. Am. J. Phys. 44, 671–676 (1976).

Falcon, E. et al. Behavior of one inelastic ball bouncing repeatedly o the ground. Eur. Phys J. B 3, 45–57 (1998).

Cross, R. The bounce of a ball. Am. J. Phys. 67(3), 222–227 (1999).

Kanso, E. & Papadopoulos, P. Dynamics of pseudo-rigid ball impact on rigid foundation. Int. J. Non-Linear Mech. 39, 299–309 (2004).

Nagurka, M. &. Huang, S. A. Mass-Spring-Damper Model of a Bouncing Ball. Int. J. Eng. 22(2), 393–401 (2006).

Bernu, B. & Mazighi, R. One-dimensional bounce of inelastically colliding marbles on a wall. J. Phys. A 23, 5745 (1990).

Ramírez, R. et al. Coefficient of restitution of colliding viscoelastic spheres. Phys. Rev. E 60, 4465 (1999).

Carre, M. J. et al. Impact of a non-homogeneous sphere on a rigid surface. J. Mech. Eng. Sci. 218(3), 273–281 (2004).

Gondret, P. et al. Bouncing motion of spherical particles in fluids. Phys. Fluids 14, 643–652 (2002).

Mehta, A. & Luck, J. M. Novel Temporal Behavior of a Nonlinear Dynamical System: The Completely Inelastic Bouncing Ball. Phys. Rev. Lett. 65, 393–396 (1990).

Dorbolo, S. et al. Dynamics of a bouncing dimer. Phys. Rev. Lett. 95, 044101 (2005).

Dorbolo, S. et al. Bouncing trimer: a random self-propelled particle, chaos and periodical motions. New J. Phys. 11, 033016 (2009).

Luding, S. et al. Studies of columns of beads under external vibrations. Phys. Rev. E 49, 2 (1994).

Umbanhowar, P. B. et al. Localized excitations in a vertically vibrated granular layer. Nature 382, 793–796 (1996).

Kudrolli, A. et al. Cluster Formation due to Collisions in Granular Material. Phys. Rev. Lett. 78, 7 (1997).

Pacheco-Vázquez, F., Caballero-Robledo, G. A. & Ruiz-Suárez, J. C. Superheated granular matter. Phys. Rev. Lett. 102, 170601 (2009).

Cross, R. Dynamic properties of tennis balls. Sports Engineering 2, 23–33 (1999).

Mars Exploration Rovers. Step by Step Guide to Entry, Descent and Landing. Jet Propulsion Laboratory, California Institute of Technology (2013). http://marsrover.nasa.gov/mission/tl_entry1.html.

Killian, T. W. et al. Rebound and jet formation of a fluid-filled sphere. Phys. Fluids 24, 122106 (2012).

Salueña, C., Pöschel, T. & Esipov, S. E. Dissipative properties of vibrated granular materials. . Phys. Rev. E 59, 4422–4425 (1999).

Sato, T. et al. Vibration isolation in a system using granular medium. JSME 38-C(3), 434–440 (1995).

Mao, K. et al. Simulation and characterization of particle damping in transient vibrations. J. Vib. Acoust. 126, 202–211 (2004).

Bai, X-M. et al. Investigation of particle damping mechanism via particle dynamics simulations. Granular Matter 11, 417–429 (2009).

Bannerman, M. N. et al. Movers and shakers: Granular damping in microgravity. Phys. Rev. E 84, 011301 (2011).

Sánchez, M. & Pugnaloni, L. A. Effective mass overshoot in single degree of freedom mechanical systems with a particle damper. J. of Sound and Vibration 330, 5812–5819 (2011).

Sánchez, M., Rosenthal, G. & Pugnaloni, L. A. Universal response of optimal granular damping devices. J. of Sound and Vibration 331, 4389–4394 (2012).

Panossian, H. V. Structural damping enhancement via non-obstructive particle damping technique. J. Vib. Acoust. 114(1), 101–105 (1992).

Rubin, S. & Oaks, S. Tuned broadband particulate vibration absorber. US Patent 5855260A (1999).

Ashley, S. “A New Racket Shakes Up Tennis”. Mech. Eng. 117, 80–81 (1995).

Pöschel, T. et al. Hand-Held Medical Instrument. US Patent 20100331828.

Heckel, M. et al. Granular dampers for the reduction of vibrations of an oscillatory saw. Physica A 391, 4442–4447 (2012).

Norcross, J. C. Dead-blow hammer head. US Patent 3343576.

Cheng, T. et al. Dissipation mechanisms of nonobstructive particle damping using discrete element method. Proc. SPIE 4331, 294–301 (2001).

Opsomer, E., Ludewig, F. & Vandewalle, N. Phase transitions in vibrated granular systems in microgravity. Phys. Rev. E 84, 051306 (2011).

Liu, C. et al. Frictionless multiple impacts in multibody systems. Part I. Theoretical framework. Proc. R. Soc. A 464(2100), 3193–3211 (2008).

Liu, C. et al. Energy dissipation and dispersion effects in a granular media. Phys. Rev. E 78(031307), 1–13 (2008).

Liu, C. et al. Variable structure dynamics in a bouncing dimer. INRIA Research Report 6718, (2008).

Liu, C. et al. Frictionless multiple impacts in multibody systems. Part II. Numerical algorithm and simulation results. Proc. R. Soc. A 465(2101), 1–23 (2009).

Zhao, Z. et al. Planar dynamics of a rigid body system with frictional impacts. Part II. Qualitative analysis and numerical simulations. Proc. R. Soc. A 465(2107), 2267–2292 (2009).

Acknowledgements

We thank F. Moreau for his valuable comments. We also thank to N. Vandewalle and GRASP for financial support, help and fruitful discussions. FPV is a beneficiary of a mobility grant from BELSPO/Marie Curie at the Université de Liège. SD thanks to F.R.S.-FNRS and FPV to Conacyt Mexico for financial support.

Author information

Authors and Affiliations

Contributions

F.P.V. carried out the experiments and analysed the data. Both authors discussed the results. F.P.V. wrote the manuscript. Both authors reviewed the manuscript. S.D. supervised the research.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Pacheco-Vázquez, F., Dorbolo, S. Rebound of a confined granular material: combination of a bouncing ball and a granular damper. Sci Rep 3, 2158 (2013). https://doi.org/10.1038/srep02158

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02158

This article is cited by

-

Experimental and numerical investigation of the compression and expansion of a granular bed of repelling magnetic disks

Granular Matter (2022)

-

Nonlinear dynamics of excited plate immersed in granular matter

Nonlinear Dynamics (2018)

-

Self-propulsion of a grain-filled dimer in a vertically vibrated channel

Scientific Reports (2017)

-

Experimental and numerical investigations of dissipation mechanisms in particle dampers

Granular Matter (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

) and container(

) and container( ) for different masses of steel particles. The total momentum of the system is also shown(

) for different masses of steel particles. The total momentum of the system is also shown( ). For these data, the container (ε0 = 0.8, mc = 10.8 g) was dropped from H = 20 cm.

). For these data, the container (ε0 = 0.8, mc = 10.8 g) was dropped from H = 20 cm.