Abstract

Transparent flexible fluorine-doped indium zinc oxide (IZO:F) thin-film transistors (TFTs) were demonstrated using the spin-coating method of the metal fluoride precursor aqueous solution with annealing at 200°C for 2 hrs on polyethylene naphthalate films. The proposed thermal evolution mechanism of metal fluoride aqueous precursor solution examined by thermogravimetric analysis and Raman spectroscopy can easily explain oxide formation. The chemical composition analysed by XPS confirms that the fluorine was doped in the thin films annealed below 250°C. In the IZO:F thin films, a doped fluorine atom substitutes for an oxygen atom generating a free electron or occupies an oxygen vacancy site eliminating an electron trap site. These dual roles of the doped fluorine can enhance the mobility and improve the gate bias stability of the TFTs. Therefore, the transparent flexible IZO:F TFT shows a high mobility of up to 4.1 cm2/V·s and stable characteristics under the various gate bias and temperature stresses.

Similar content being viewed by others

Introduction

Amorphous metal-oxide semiconductors (AOSs) have been extensively studied as the active layers in thin-film transistors (TFTs) and AOSs have many advantages such as high mobility, optical transparency and the possibility of low temperature processing on flexible plastic substrates1,2,3. Amorphous metal-oxides are widely used to fabricate the active channel layer in TFTs since the amorphous-state is attractive for large-area uniformity. Also, the solution processes have been developed due to the possibility of next-generation techniques for the low-cost fabrication of large-areas without using vacuum deposition techniques3. However, the high-temperature annealing step is inevitable for oxidation and impurity removal in the solution process. Thus, the high-temperature process acts as a hurdle in the fabrication of flexible devices using the plastic film substrates, which requires processing temperature below 250°C3,4,5,6,7,8,9,10,11. Many attempts have been made to lower the annealing temperature to realize flexible TFTs with high performance. One of the recent innovative results is the photo-annealing method at room-temperature, which is the lowest annealing temperature, demonstrating flexible indium gallium zinc oxide (IGZO) TFT on the polyacrylate films with a typical mobility of 3.77 cm2/V·s5. Photochemical activation was induced by deep-ultraviolet (DUV) light, which decomposed the organic residues to densify thin films at room temperature. Another example, a ‘sol-gel on chip’ process used water-vapour annealing of the thin films spin-coated using non-hydrolyzed metal alkoxide derivative precursor solutions. This accelerated the hydrolysis and enhanced the rate of formation of the metal oxide which enabled to fabricate a reliable metal oxide TFT at the low-temperature of 230°C6. On the other hand, ‘the combustion’ process used self-energy generating combustion chemistry of the precursor solution mixed with an organic fuel and an oxidizer. The high local temperature produced through the combustion enabled the formation of metal oxide at low temperature. This method could be implemented to fabricate a high-performance and optically transparent TFT at temperatures as low as 200°C7. These low-temperature solution-processes enabled the flexible metal oxide TFTs to be fabricated on the plastic film substrates.

Recently, we have reported the aqueous precursor solution-processed indium oxide (IO) and indium zinc oxide (IZO) TFTs on transparent flexible plastic films with excellent TFT characteristics and gate bias stability8. Instead of water vapor annealing in the case of a ‘sol-gel on chip’, we used the water solvent and soluble metal nitrate precursors, which enables the preparation of precursor solution without additional additives and catalysts, as well as the fabrication of TFTs at low temperature6,8. Above all, water is an impurity-free solvent since it has no volatile organic compounds or organic residues to be removed for achieving high-performance oxide TFTs3,11. Thus, the aqueous precursor solutions can make the pure metal oxide without high-temperature annealing. In addition, another aqueous precursor solution process is using the metal fluoride precursors dissolved in water11. The fabricated fluorine doped zinc tin oxide (ZTO:F) TFTs showed a field-effect mobility of 2.85 cm2/V·s at 250°C annealing. Activated hydrolysis and condensation reactions of metal fluoride precursors in the aqueous solution can readily form a metal oxide network enabling low-temperature solution-processed TFTs. As the carrier concentration is known to increase with the addition of the fluorine dopant, the fluorine-doped oxide TFTs showed the highest conductivity and mobility12,13,14. A similar ionic radius of fluorine compared to oxygen allows the substitution of the oxygen in the lattice or oxygen vacancy by fluorine11,13. However, the difference in the atomic valence and the electronegativity of the oxygen and the substituted fluorine generates a free electron, which can enhance the mobility of the TFTs. Also, the reduction of the oxygen vacancy acting as the electron tap sites by fluorine substitution might improve the gate bias stability of the TFTs. Thus, the ZTO:F TFT utilized the advantages of the aqueous solution process and fluorine-doping effect to fabricate high performance TFTs annealed at the low annealing temperature of 250°C in spite of indium-free composition.

In this paper, we used indium fluoride (InF3) instead of tin fluoride (SnF2) to fabricate lower-temperature annealed fluorine-doped indium zinc oxide (IZO:F) TFTs with higher field effect mobility. Originally, indium metal creates the high mobility because the large spherical 5s orbitals form strong ionic bonds and efficiently transport electrons in the oxides1,2,3,10. The optimized compositions according to the annealing temperatures were found to have the best TFT characteristics. Then, the transparent flexible TFT was successfully fabricated on polyethylene naphthalate (PEN) film substrate with annealing at 200°C. Its superior stability over gate bias and temperature as well as excellent TFT characteristics will be demonstrated sufficiently to be practically applied.

Results

Thermal evolution of metal fluoride aqueous precursor solution

It is known that the metal fluoride precursors in water are hydrolyzed into zinc hydroxyl fluoride [Zn(OH)F] and indium hydroxide [In(OH)3] producing a by-product of hydrofluoric acid [HF], as shown in equation (1) at room temperature14,16. Although this chemical reaction produced HF as a by-product, the measured pH of the precursor solution was 3.6.This weak acidic solution does not harm the device as well as the environment. Since the produced HF is mostly removed into the atmosphere during the spin-coating process and evaporated during the annealing process, the IZO:F thin film can avoid chemical attack from acidic solution. The surface of coated thin films was smooth without any defects which were examined by scanning electron microscopy (SEM) and atomic force microscopy (AFM) (in Supplementary Section 1). In order to understand the formation mechanism of the IZO:F thin film, the thermal evolution of the precursor solution to form the IZO:F thin films was correlated between thermogravimetric analysis (TGA) and Raman spectra, as shown in Fig. 117,18,19,20,21,22,23,24.

Proposed thermal evolution mechanism of IZO:F precursor solution.

(a) TGA data of the IZO:F, InF3 and ZnF2 dried precursor solutions. (b) Raman spectra (90–800 cm−1) were measured in the hydrolyzed IZO:F, InF3 and ZnF2 precursor solutions annealed for 1 hr at the indicated temperatures of 100°C(red line,  ), 250°C(blue line,

), 250°C(blue line,  ) and 500°C(green line,

) and 500°C(green line,  ), respectively. The black line(

), respectively. The black line( ) is the InF3 and ZnF2 data at room temperature.

) is the InF3 and ZnF2 data at room temperature.

Figure 1a shows the TGA data of dried InF3, ZnF2 and IZO:F precursor solutions. The InF3 precursor solution has two steps of thermal decomposition temperatures of around 240°C and 400°C, which indicate the structural and mass changes from the indium hydroxide into the amorphous and crystalline indium oxide by a thermal-driven reaction19. The ZnF2 precursor solution is slowly decomposed until 450°C and then weight is abruptly decreased to form zinc oxide17. On the other hand, the thermal decomposition of the mixed precursor solution starts at low temperature and is gradually made by approximately 450°C to form indium zinc oxide. Since the hydrolysis and condensation reactions have already occurred in aqueous solution via the self-condensation reaction shown in equation (2), which can lower kinetic energy, the precursor continuously loses its weight11. This interpretation is confirmed in the Raman spectra of the InF3, ZnF2 and mixed precursor solution according to the heating temperature (Fig. 1b). The Raman spectra of the InF3 and ZnF2 powder at room temperature are clearly changed to the metal hydroxide form when the water is vaporized from the metal precursor solution at 100°C. Raman peaks related to the indium hydroxide [In(OH)3] and the zinc hydroxyl fluoride [Zn(OH)F] are observed as represented in equation (1)19,20,21,22,23. Raman peak at 497 cm−1 attributes to the indium oxyhydroxide peak [InO(OH)], which is formed during the hydrolysis of indium fluoride17. The small weight loss in the TGA originated from the conversion of InO(OH) → In2O3 + H2O17.

At about 240°C, the conversion of metal hydroxide into metal oxide via thermally-driven condensation processes mainly occurs by In(OH)3 in equation (3). Then, the In(OH)3 is dehydrated, causing a loss of about 10 wt% water. Also, the Raman bands change to new strong a-In2O3 and a-ZnO peaks19,24. However, ZnO peaks are not shown in the spectrum of IZO:F precursor due to the relatively low concentration of zinc precursor. Thus, the fabricated IZO:F film at 200°C might be the coexistence of incomplete oxide forms of hydroxide structure such as In(OH)3 and Zn(OH)F. At above 450°C, the total weight loss is about 25% and the dehydroxylation of Zn(OH)F is accelerated by high temperature. Then, Zn(OH)F changes into zinc oxide (ZnO) and begins to evaporate the gas phase of ZnF2, as represented in equation (4). Since the ZnF2 is very volatile itself17, the amount of the doped fluorine decreases as the annealing temperature increases. Even though the ZnF2 is volatile, it can be relatively stable due to the hydrogen bond (Zn–F···HO–M)17,22. The ZnF2 and InF3 precursor almost change to the crystalline peak at a high temperature of 500°C. The Raman peaks of the ZnO and the intense peak of In2O3 are also shown at 100 and 125 cm−1, respectively19,24.

Chemical composition of IZO:F thin films

Chemical compositions of the IZO:F thin films annealed at different temperatures were analysed from Zn 2p peaks and In 3d peaks in XPS, as shown in Supplementary Section 2. The analysed indium and zinc atomic ratio was 1.7:1 and 1:2.1 in thin films prepared with 2:1 and 1:2 of InF3:ZnF2 ratios in the precursor solutions, respectively. This means that the metal composition of the precursor solution was rarely changed during the IZO:F thin film formation and the zinc precursor was stable up to 350°C (do not volatized into zinc fluoride). But the result of chemical ratio shows zinc-rich composition at all the annealing conditions, since the zinc precursor was more soluble than the indium precursor. However, the concentration of the doped fluorine in the thin films is dependent on the annealing temperature since the fluorine is susceptible to be volatized. Fluorine content was calculated from the area of the F 1s peak at 684.8 eV, which was assigned to the M–F bond25. The fluorine concentration over metal contents is as small as 2.7 atomic% for 200°C annealing and is reduced as annealing temperature and time increase, disappearing completely at 300°C. The loss of fluorine with high-temperature annealing over 350°C was also observed in ZTO:F thin films fabricated from metal fluoride precursor solution15. Thus, the fluorine doping in indium zinc oxide thin film is only made at low-temperature annealing. The O 1s peak was generally analysed to confirm the degree of oxidation or verify the quality of oxide thin films. It was deconvoluted into three different oxygen peaks at 530.7, 532.0 and 532.9 eV, which can be assigned to oxygen in the oxide lattice without vacancy, with the oxygen vacancy and with the hydroxyl group, respectively26. Their contents in the thin films annealed at different temperatures were calculated and listed in Supplemental Table S2. The oxygen vacancy site and hydroxyl group can act as electron and hole trap sites, respectively and deteriorate the quality of oxide thin films6,9,10. Thus, they are one of the critical factors when considering the long-term stability and reliability issues in the TFT. The concentration of the oxygen vacancy is invariant, depending on the annealing temperature. On the other hand, the hydroxyl group content is as small as 13.1% for the 200°C annealing and decreases in small degrees according to annealing temperature. This implies that thermal oxidation is easily induced in the thin films, even in low-temperature annealing. These results are in good agreement with the previous conclusions of the self-condensation reaction, which can activate the formation of hetero-metal oxide by nucleophilic substitution reaction in water11. Also, the oxygen in oxide lattice and oxygen vacancy is slightly increased according to the increasing annealing temperature due to the thermal-driven condensation3,10,26.

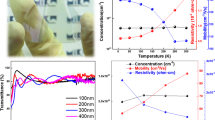

Composition optimization of IZO:F TFT annealed at various temperatures

For preliminary tests with an un-patterned gate and channel structure on an Si wafer (Supplement 3a), the IZO:F TFTs optimized the chemical composition ratio of the InF3 and ZnF2 precursors to achieve the best TFT characteristics at different annealing temperatures. The IZO:F thin film annealed at the highest temperature of 350°C was analysed by transmission electron microscopy (TEM), as shown in Supplements 3b and c. It was found that the thin film with a thickness of 5 nm is amorphous state confirmed by the diffraction pattern. The TFT fabrication process is explained in the Methods section. Figure 2 shows the transfer curves of IZO:F TFTs with various channel layer compositions annealed at different temperatures. For the 350°C annealing shown in Fig. 2a, the IZO:F TFTs with a low concentration of ZnF2 precursor show a monotonous increase in current with the gate voltage indicating conductor-like behaviour. With further addition of ZnF2 precursor (X = 0.10), the current level is lowered and transformed into a semiconductor. As the ZnF2 precursor content increases (X = 0.12), the on-state current is reduced, whereas the off-state current is almost constant with positive shift of the threshold voltage. This indicates the electrical conductivity property of the IZO:F thin film converts from a conductor to a semiconductor and to an insulator with the addition of ZnF2 precursor. The optimized composition for the best TFT characteristics is the ratio of 0.05 M InF3 and 0.1 M ZnF2 precursors (X = 0.10). It shows high-performance transistor characteristics in which a field effect mobility (μ) of nearly 20 cm2/V·s and an on-off current ratio (Ion/Ioff) of approximately ~107 were measured at a drain-source voltage (VDS) of 40 V and a gate voltage (VG) swing from −20 V to 40 V. The turn-on voltage (Von) was around 0 V, the calculated threshold voltage (Vth) was 9.8 V and the subthreshold swing (S.S.) value was 0.24 V/dec10. Usually, higher-temperature annealing creates higher density thin films with fewer impurities9,10. Also, it generates many free electrons that can enhance the mobility of the TFTs since the oxygen-vacancy formation is accelerated by the thermal-driven condensation reaction represented in equation (5)3,10,26.

The generation of a doubly-charged oxygen vacancy  and two free electrons is accelerated by the temperature from the oxide lattice

and two free electrons is accelerated by the temperature from the oxide lattice  . Thus, the IZO:F thin film annealed at 350°C can result in high mobility with an excellent switching property to be used for flat panel displays. The IZO:F TFT annealed at 300°C shows similar transition behaviour from conductor to semiconductor with an increase in the ZnF2 precursor content, as shown in Fig. 2b. However, the transition is gradually made for the composition to be optimized at x = 0.10 mol for the best TFT characteristic: μ = 18.2 cm2/V·s, Ion/Ioff = ~107 and S.S. = 0.27 V/dec. The optimized composition is the same as the annealed condition at 350°C, but the TFT performance is slightly degraded. This is due to the lower oxidation of the thin films with the existence of residual hydroxyl-related impurities and a small number of oxygen-vacancies. On the other hand, all of the IZO:F TFT annealed at 250°C and 200°C show switching characteristics indicating semiconductor-like behaviour, regardless of precursor composition, as exhibited in Fig. 2c and d. The variations with growing the ZnF2 precursor composition are to shift the turn-on voltage positively and to reduce the on-state current. The precursor composition is optimized at x = 0.05 mol to meet the Von of 0 V with greater InF3 precursor composition to compensate for the deteriorated TFT performance at low temperature. The μ decreases to 16.4 cm2/V·s and it results from the imperfect densification and oxidation of the thin films annealed at 250°C. The characteristics of the IZO:F TFT are also sensitive to the annealing time, especially for the low annealing temperatures. In case of 200°C annealing, the thermal condensation of the IZO:F TFT is saturated at an annealing time of 2 hrs and its mobility is around 6.4 cm2/V·s, Ion/Ioff of around ~108, which is enhanced by the reduced off current and S.S. value of 0.19 V/dec. In summary, Table 1 lists the electrical characteristics of the IZO:F TFTs annealed at various temperatures with their chemical compositions. In addition, Fig. 2e–h show the transfer curves with the mobility change of the optimized composition TFTs at each annealing temperature (Output curves are show in Supplement 4). The hysteresis between forward and backward biases in the transfer curve gradually diminishes with increasing annealing temperature. This is because the thin film becomes more oxidized with fewer hydroxyl groups and defects when annealed at higher temperature. These results agree with the previously-mentioned results of the thermal evolution of IZO:F precursor solution.

. Thus, the IZO:F thin film annealed at 350°C can result in high mobility with an excellent switching property to be used for flat panel displays. The IZO:F TFT annealed at 300°C shows similar transition behaviour from conductor to semiconductor with an increase in the ZnF2 precursor content, as shown in Fig. 2b. However, the transition is gradually made for the composition to be optimized at x = 0.10 mol for the best TFT characteristic: μ = 18.2 cm2/V·s, Ion/Ioff = ~107 and S.S. = 0.27 V/dec. The optimized composition is the same as the annealed condition at 350°C, but the TFT performance is slightly degraded. This is due to the lower oxidation of the thin films with the existence of residual hydroxyl-related impurities and a small number of oxygen-vacancies. On the other hand, all of the IZO:F TFT annealed at 250°C and 200°C show switching characteristics indicating semiconductor-like behaviour, regardless of precursor composition, as exhibited in Fig. 2c and d. The variations with growing the ZnF2 precursor composition are to shift the turn-on voltage positively and to reduce the on-state current. The precursor composition is optimized at x = 0.05 mol to meet the Von of 0 V with greater InF3 precursor composition to compensate for the deteriorated TFT performance at low temperature. The μ decreases to 16.4 cm2/V·s and it results from the imperfect densification and oxidation of the thin films annealed at 250°C. The characteristics of the IZO:F TFT are also sensitive to the annealing time, especially for the low annealing temperatures. In case of 200°C annealing, the thermal condensation of the IZO:F TFT is saturated at an annealing time of 2 hrs and its mobility is around 6.4 cm2/V·s, Ion/Ioff of around ~108, which is enhanced by the reduced off current and S.S. value of 0.19 V/dec. In summary, Table 1 lists the electrical characteristics of the IZO:F TFTs annealed at various temperatures with their chemical compositions. In addition, Fig. 2e–h show the transfer curves with the mobility change of the optimized composition TFTs at each annealing temperature (Output curves are show in Supplement 4). The hysteresis between forward and backward biases in the transfer curve gradually diminishes with increasing annealing temperature. This is because the thin film becomes more oxidized with fewer hydroxyl groups and defects when annealed at higher temperature. These results agree with the previously-mentioned results of the thermal evolution of IZO:F precursor solution.

TFT performance of IZO:F TFT annealed at various annealing temperatures.

To optimize the chemical composition, ZnF2 (x value) ratio was varied from 0.05–0.12 mol and the total concentration was fixed at 0.15 mol. The transfer characteristics of IZO:F transistors on Si substrates annealed at the indicated temperatures of (a) 350°C, (b) 300°C, (c) 250°C and (d) 200°C. (e–h) The optimized transfer curve and mobility of forward ( ,

,  ) and reverse bias (

) and reverse bias ( ,

,  ) at the indicated temperatures.

) at the indicated temperatures.

Fabrication and characterization of flexible IZO:F TFT on PEN film annealed at 200°C

A transparent IZO:F TFT annealed at 200°C was implanted on a flexible PEN film; a schematic diagram of the device structure and a photograph of the fabricated transparent flexible TFT are displayed in Fig. 3a and b. The fabrication process is explained in the Methods section. The active layer was patterned and the Al2O3 thin films deposited by an atomic layer deposition (ALD) were applied to both the gate dielectric layer (200 nm thickness) and the passivation layer (9 nm thickness). Figure 3c and d show the representative output and transfer curves of the transparent flexible IZO:F TFTs. The output characteristics of IZO:F active thin layers are saturated at various gate voltages (0 ~ 20 V) and exhibit the good n-channel property. A Ion/Ioff of approximately ~108 was measured at VDS of 20 V and VG swing from −20 V to 20 V. The flexible IZO:F TFT has the high field effect mobility and small subthreshold swing: μ = 4.1 cm2/V, Vth = 5.5 V and S.S. = 0.20 V/dec. Also, no hysteresis was found between forward and backward biases in the transfer curve. Generally, the un-patterned TFT shows overestimation of field effect mobility due to the peripheral current and the off current is reduced by about one order from the eliminating leakage current in the patterned TFT structure15,27. Thus, a 30% reduction of the μ was observed and the TFT switching ability of Ion/Ioff was enhanced in the patterned flexible TFT.

Characterization of flexible IZO:F TFT on PEN film annealed at 200°C.

(a) The cross-sectional image of a channel region (150 nm ITO gate/200 nm Al2O3 gate dielectric/150 nm ITO SD/5 nm IZO:F active layer at 200°C 2 hrs/9 nm Al2O3 passivation) and (b) a picture of flexible IZO:F on a PEN film substrate (Insertion picture is an SEM image of the channel region).(c) Output curve from 0 to 20 V of VG ( : VG = 0 V,

: VG = 0 V,  : VG = 10 V,

: VG = 10 V,  : VG = 20 V) and (d) transfer curve of forward (

: VG = 20 V) and (d) transfer curve of forward ( ,

,  ) and reverse bias (

) and reverse bias ( ,

,  ) in the flexible IZO:F with a channel width of 160 μm and a 160 μm at VDS of 20 V.

) in the flexible IZO:F with a channel width of 160 μm and a 160 μm at VDS of 20 V.

The gate bias stability of the TFT is significant in the assessment of materials and devices for many display applications. The shift in the transfer characteristics with negative (negative bias stress, NBS) and positive (positive bias stress, PBS) gate bias stress (VDS = 20 V and Vg = ±20 V) for the flexible IZO:F TFT is shown in Fig. 4a and b. They shift to positive voltages of 0.02 V (NBS) and 0.45 V (PBS) with 1 hr of stress. The threshold voltage shift, ΔVth, for NBS is negligible and slightly higher for PBS. This is good bias stability behaviour as observed in other vacuum-deposited or solution-processed oxide TFTs. In particular, the NBS is much better than those of other reported solution-processed oxide TFTs, including IZO and ZTO:F TFTs8,11,15. Also, ΔVth for PBS is comparable to previously-reported values of the oxide TFTs5,9,10,28. The negative and positive gate bias temperature stress (NBTS and PBTS) were also measured at an additional thermal stress of 60°C, as shown in Fig. 4c and d. The ΔVth increased by thermal activation energy to 1.46 V and 0.79 V under the NBTS and PBTS, respectively. Contrary to better NBS to PBS without thermal stress, NBTS degraded more than PBTS. Thus, thermal stress is more sensitive to negative gate bias resulting in larger ΔVth than positive gate bias.

Gate bias stability of flexible IZO:F TFT.

It was measured under the (a) negative gate bias stress (NBS, VGS = −20 V), (b) positive gate bias stress (PBS, VGS = 20 V), (c) negative gate bias temperature stress (NBTS, VGS = −20 V, 60°C) and (d) positive gate bias temperature stress (PBTS, VGS = 20 V, 60°C), respectively. The stress condition was a VDS of 20 V and the stress duration for 1 hr in the dark chamber.

Discussion

A simple and inexpensive aqueous precursor solution-based coating process would be attractive for the fabrication of high performance oxide TFT with low-temperature annealing. Recently, it was reported that flexible indium oxide (IO) and indium zinc oxide (IZO) TFTs on the plastic films were fabricated using metal nitrate precursors dissolved in water solvent with low-temperature annealing at 200°C and 250°C, respectively8. The high polarity and dielectric constant of water promote the oxide formation at low temperature through the favourable dissociation of ionic species and low-temperature thermal decomposition of metal complexes in the solution, as well as the activation of oxolation in the thin film8,10. Since the aqueous solution has no organic content, the resultant oxide thin films contain no carbon impurities after thermal annealing. Thus, the aqueous precursor solution can readily fabricate higher-quality metal oxide thin films than alcohol precursor solution and reduce defects and impurities resulting in high-performance TFTs with better stability.

Recently, it was found the fluorine was doped in zinc tin oxide TFTs using metal fluoride aqueous precursor solution and they exhibited high field effect mobility with good gate bias stability11,15. In the same way, the fluorine was doped in an indium zinc oxide composition for annealing at low temperature below 250°C. However, the higher-temperature annealed thin films contain no fluorine due to higher volatility. Thus, fluorine doping was allowed in the IZO thin films prepared from metal fluoride precursor solution below 250°C. As schematically illustrated in Fig. 5, doped fluorine can substitute for oxygen [equation (6)] or occupy oxygen vacancy sites [equation (7)] in the IZO atomic structure because fluorine and oxygen have similar ionic sizes13. Since zinc-fluorine chemical bonding (Zn–F) was stable up to 250°C, as found in TGA and Raman spectra results in Fig. 1, fluorine is more favourable for bonding with zinc than with indium.

Doping of fluorine atom in indium zinc oxide atomic structure.

Doped fluorine atoms (a) substitute the oxygen lattices generating the free electrons to enhance the field effect of mobility, (b) occupy the oxygen vacancies reducing the electron trap sites to improve the negative gate bias stability and (c) form hydrogen bond with hydroxyl group passivating the hole trap sites to improve the positive gate bias stability in TFT.

As described in equation (6), the substitution of an oxygen ion with a fluorine ion creates a free electron due to the difference in the electrovalence of fluorine (F−) and oxygen (O2−)16. The generated free electrons act as the charge carrier, which enhances the mobility of the TFT. This causes the high mobility of 4.1 cm2/V·s, even in the flexible TFT on the PEN films annealed at 200°C. On the other hand, the occupation of an oxygen vacancy site by a fluorine ion consumes a free electron in combination with the removal of an oxygen vacancy site acting as an electron trap site in the TFT. The occupation of an oxygen vacancy site made by fluorine doping can improve the positive gate bias stress, PBS and PBTS, since the electron trap density is reduced with the disappearance of the oxygen vacancy. As expected, thermal stress stimulates the injection of a thermally-activated electron from deep level trap sites into the conduction band and a quick movement toward the drain electrode due to a lateral electrical field28.

These dual roles of the fluorine-doping (generation of extra charge carriers and reduction of electron trap sites) can facilitate both the higher mobility and the improved positive gate bias stability in the TFT. However, the solution process can easily produce hydroxyl groups in the oxide thin films. They can be the hole trap sites in the TFT that are sensitive to negative gate bias6,9. In fluorine-doped oxide thin films, the fluorine ions that have the strongest electronegativity form hydrogen bonds with the hydroxyl groups (F···HO–M), as represented in Fig. 5. This can passivate the hole trap sites of the hydroxyl groups to show almost perfect NBS. However, during thermal stress, the hydrogen bonds between fluorine ions and hydroxyl groups are disturbed and broken into negatively-charged radicals due to their low dissociation energy29. Both the separated fluorine ions and hydroxyl groups may provide more hole trap sites at the elevated temperature. Thus, the NBTS is slightly more degenerated than the PBTS. On the other hand, after cooling to room temperature, the hydrogen bonds are reconstructed to show superb NBS in the TFT. In addition to the material composition and atomic structure, the TFT structure has quite favourable conditions to make high gate bias stability. The Al2O3 passivation can effectively block the back-channel effect from moisture and oxygen30,31,32. The well-patterned TFT structure can reduce the peripheral current and leakage current to avoid overestimation of the trap site and gate capacitance (Cg), which is proportion to the created electron charge27,32.

Using the metal fluoride aqueous solution process, high-performance IZO:F TFT with high mobility and good gate bias stability was fabricated at low temperature and the transparent flexible device on PEN film was demonstrated. Due to high polarity of water, the indium and zinc fluorides are easily hydrolysed and condensated to form hetero-metal oxide by nucleophilic substitution reaction in water11. Furthermore, the aqueous precursor solution contains no organics, enabling thin films to be impurity-free. Thus, the dense and uniform films were obtained with low-temperature annealing to fabricate the well-switched TFTs. The use of metal fluoride precursors made fluorine-doping in the IZO thin films annealed at low temperature below 250°C. The doped fluorine in the channel layer composition plays advantageous roles to develop the high-performance oxide TFTs. Firstly, the substitution of oxygen by the doped fluorine producing the charge carriers of free electron enhances the field effect mobility of the TFT. Secondly, the occupation of oxygen vacancy sites by the doped fluorine eliminates the electron trap sites to improve the positive gate bias stability. Also, the hydroxyl group, which is the source of negative gate bias instability, can be passivated by the formation of the hydrogen bond with the doped fluorine ion. Therefore, the fluorine-doping is effective to improve both the mobility and stability of the solution-processed oxide TFT for its application to displays. Thus, the fluorine-doped metal oxide is a novel composition that can be applied to high-performance oxide TFTs. Finally, a transparent flexible IZO:F TFT composed of Al2O3 gate dielectric and passivation layers was fabricated with 200°C annealing. The demonstrated flexible TFT represents comparative TFT characteristics to vacuum-deposited oxide TFTs on the glass substrate: μ = 4.1 cm2/V, Ion/Ioff = ~108, Vth = 5.5 V, S.S. = 0.20 V/dec and excellent gate bias stability, NBS ΔVth = 0.02 V, NBTS ΔVth = −1.46 V, PBS ΔVth = 0.45 V and PBTS ΔVth = 0.79 V.

Methods

Precursor solution synthesis and characterization

The 0.15 M precursor solution for the IZO:F was prepared by directly dissolving various molar ratios of indium flouride trihydrate (InF3·3H2O > 99%) and zinc flouride (ZnF2, 99%) in water (H2O, ACS reagent) at room temperature. All reagents were purchased from Sigma-Aldrich and were used without further purification. The aqueous solution was stirred for 4 hrs and filtered through a 0.22 μm syringe filter. The thermal behavior of the IZO:F precursor was investigated by using a thermogravimetric analyzer (TA Instrument). The IZO:F precursor solution was dried at 100°C to remove the water solvent and the powder was analyzed. Also, the individual thermal behavior of InF3 and ZnF2 hyrolyzed solutions were analyzed using the same procedure. The temperature ramping rate was 5 °C/min and the analyzer was heated up to 800°C. To measure the Raman spectra, the IZO:F solution and individual InF3 and ZnF2 precursor solutions were annealed at 100, 250 and 500°C for 1 hr on slide glasses. The collected powders were analyzed by a LabRAM (HR) Raman spectrometer that has a 514 nm line from an Ar+ laser. The Raman peaks were assigned by the references and reconfirmed by the measured individual precursor data. The broad Raman peaks were deconvoluted by Gaussian curve using the PeakFit program according to the reference information.

Thin film transistor fabrication and characterization

To fabricate the device, 100 nm SiO2 was thermally grown as a gate dielectric layer on the top of a heavily boron (p+)-doped Si wafer. The SiO2/Si substrates were sonicated with acetone, isopropyl alcohol and D.I. water, respectively. The synthesized IZO:F precursor solution was spin-coated at 5,000 rpm for 30 s on substrates that were treated by oxygen plasma and the coated layer was annealed on a hot plate at various temperatures under ambient atmosphere. The Al source and drain electrodes were deposited by an e-beam evaporator (pressure ~10−6 Torr) through a shadow mask that has a channel length and width of 100 and 1,000 μm, respectively. The surface morphology and roughness of the oxide thin films were characterized by field-emission scanning electron microscopy (FE-SEM, Philips XL30) and atomic force microscopy (AFM, Park system XE-100) with non-contact mode. The chemical composition of oxide films was examined by XPS (Sigma Probe, Thermo VG Scientific). The data were collected using monochromatic Al K radiation (1486.6 eV) in an ultra-high vacuum system with a base pressure of ~10−10 Torr. The surface of the thin film can be contaminated and the interior of the IZO:F film was analyzed after sputtering by Ar bombardment for 20 s. The C 1s peak of hydrocarbon at 285.0 eV disappeared in bulk samples while the Ar 2p peak at 242.0 eV was generated. High-resoluton cross-sectional transmission electron microscopy images and selected area diffraction patterns (HR-TEM, JEOL, JEM-2100F) were obtained with an electron accelataion voltage of 200 kV. Electrical characterization was performed using the semiconductor parameter analyzer 4156A. The saturation mobility was extracted using the following equation from transfer characteristics:

where, Ci, W and L are the capacitance of the gate dielectric per unit area, the channel width and length, respectively. The sub-threshold slope (S.S.) was calculated as the minimum value of the inverse slope of the log10(ID) versus VG:

Flexible TFT fabrication and stability measurements

To conveniently fabricate the flexible TFT, a 1-mm thick PEN film was attached on the carrier glass, followed by the coating of barrier film, alumina. The modified PEN has a smooth surface and low water permeation. At first, the metal electrodes of the gate deposited transparent ITO that was 150 nm in thickness by RF magnetron sputtering at room temperature and patterned by photolithography. The Al2O3 as a gate insulator was deposited by atomic layer deposition (ALD) at 150°C using tri-methyl aluminum and water as an Al source and oxygen precursors, respectively. The source and drain electrodes were deposited and patterned in the same way as the gate electrode. The active layer of the synthesized IZO:F precursor solution was spin-coated at 5000 rpm for 30 s after oxygen plasma treatment of the substrate and the coated layer was annealed on a hot plate at 200°C for 2 hrs under ambient atmosphere. Finally, Al2O3 thin film was deposited by ALD at 180°C to protect the oxide layer and then simultaneously patterned both the protection layer and oxide layers. The electrical performance measurements were carried out in a dark chamber using an Agilent B1500A semiconductor parameter analyzer. The gate bias stress of ±20 V was applied for 1 hr with VDS = 0 V and additional thermal stress of 60°C was applied during the heating stage.

References

Nomura, K. et al. Room–temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 432, 488–492 (2004).

Hosono, H. et al. Ionic amorphous oxide semiconductors: Material design, carrier transport and device application. J. Non-Cryst. Solids 352, 851–858 (2006).

Pasquarelli, R. M., Ginleyb, D. S. & O'Hayrea, R. Solution processing of transparent conductors: from flask to film. Chem. Soc. Rev. 40, 5406–5441 (2011).

Song, K. et al. Fully Flexible Solution-Deposited ZnO Thin-Film Transistors. Adv. Mater. 22, 4308–4312 (2010).

Kim, Y.-H. et al. Flexible metal-oxide devices made by room-temperature photochemical activation of sol-gel films. Nature 489, 128–133 (2012).

Banger, K. K. et al. Low-temperature, high-performance solution-processed metal oxide thin-film transistors formed by a ‘sol-gel on chip’ process. Nat. Mater. 10, 45–50 (2011).

Kim, M. G., Kanatzidis, M. G., Facchetti, A. & Marks, T. J. Low-temperature fabrication of high-performance metal oxide thin-film electronics via combustion processing. Nat. Mater. 10, 382–388 (2011).

Hwang, Y. H. et al. An aqueous route for low temperature processable oxide flexible transparent thin-film transistors on a plastic substrate. NPG. Asia 5, e45 (2013).

Rim, Y. S. et al. Simultaneous modification of pyrolysis and densification for low-temperature solution-processed flexible oxide thin-film transistors. J. Mater. Chem. 22, 12491–12509 (2012).

Park, J. S., Maeng, W.-J., Kim, H.-S. & Park, J.-S. Review of recent developments in amorphous oxide semiconductor thin-film transistor devices. Thin Solid Films. 520, 1679–1693 (2012).

Jeon, J.-H., Hwang, Y. H., Jin, J. & Bae, B.-S. Low-temperature aqueous solution processed fluorine-doped zinc tin oxide thin-film transistors. MRS comm. 2, 17–22 (2012).

Shanthi, E., Banerjee, A. & Chopra, K. L. Dopant effects in sprayed tin oxide films. Thin Solid Films 88, 93–100 (1982).

Tseng, H.-H. et al. Defect passivation with fluorine in a TaxCy/high-k gate stack for enhanced device threshold voltage stability and performance. IEDM Tech. Dig. 29, 4.1–4.4 (2005).

Morales-Saavedra, O. G., Castaneda, L., Banuelos, J. G. & Ortega-Martinez, R. Morphological, Optical and Nonlinear Optical properties of Fluorine-Indium-Doped Zinc Oxide Thin Films. Nonlinear optics and spectroscopy 18, 283–291 (2008).

Jeon, J.-H., Hwang, Y. H. & Bae, B.-S. Bias-temperature-illumination stability of aqueos solution processed fluorine doped zinc tin oxide (ZTO:F) transistor. Electrochem. Solid State Lett. 15, H123–H125 (2012).

Lee, D.-H., Chang, Y.-J., Herman, G. S. & Chang, C.-H. A general route to printable high-mobility transparent amorphous oxide semiconductors. Adv. Mater. 19, 843–847 (2007).

Srivastava, O. K. & Secco, E. A. Studies on metal hydroxyl compounds. I. Thermal analyses of zinc derivatives ε-Zn(OH)2, Zn5(OH)8Cl2H2O, β-ZnOHCl and ZnOHF. Can. J. Chem. 45, 579–583 (1967).

Wood, S. A. & Samson, I. M. The aqueous geochemistry of gallium, germanium, indium and scandium. Ore. Geol. Rev. 28, 57–102 (2006).

Yang, J., Frost, R. L. & Martens, W. N. Thermogravimetric analysis and hot-stage Raman spectroscopy of cubic indium hydroxide. J. Therm. Anal. Calorim. 100, 109–116 (2010).

Mastelaro, V., Ribeiro, S., Messaddeq, Y. & Aegerter, M. EXAFS and Raman spectroscopy study of binary indium fluoride glasses. J. Mater. Sci. 31, 3441–3446 (1996).

Porto, S. P. S., Fleury, P. A. & Damen, T. C. Raman spectra of TiO2, MgF2, ZnF2, FeF2 and MnF2 . Phys. Rev. 154, 522–526 (1966).

Peter, S., Weckler, B., Roisnel, T. & Lutz, H. D. Linear, bent and trifurcated OH- F- hydroge bonds: Neutron powder diffraction, infrared and Raman spectroscopies of Zn(OD)F I and Zn(OD)F la*. Bull. Chem. Technol. Macedonia 16, 21–32 (1997).

Lutz, H. D., Schmidt, M. & Weckler, B. Infrared and Raman studies on calcium, zinc and cadmium hydroxide halides Ca{O(H,D)}Cl, Cd{O(H,D)}Cl, Zn{O(H,D)}F and β-Zn{O(H,D)}Cl. J. Raman Spectrosc. 24, 797–804 (1993).

Cusco, R. et al. Temperature dependence of Raman scattering in ZnO. Phys. Rev. B 75, 165202 (2007).

Kawamotoa, Y., Ogurab, K., Shojiyab, M., Takahashib, M. & Kadono, K. F1s XPS of fluoride glasses and related fluoride crystals. J. Fluorine Chem. 96, 135–139 (1999).

Jeong, S., Ha, Y.-G., Moon, J., Facchetti, A. & Marks, T. J. Role of gallium doping in dramatically lowering amorphous-oxide procession temperautures for solution-derived indium zinc oxide thin-film transistors. Adv. Mater. 22, 1346–1350 (2010).

Wager, J. F., Keszler, D. A. & Presley, R. E. Transparent Electronics Chap. 5 (Springer, USA, 2008).

Ji, K. H. et al. The effect of density-of-state on the temperature and gate bias-induced instability of InGaZnO Thin Film Transistors. Electrochem. Solid State Lett. 157, H983–H986 (2010).

Atkins, P., Overton, T., Rourke, J., Weller, M. & Armstong, F. Inorganic Chemistry Chap. 9 (Oxford, UK, 2006).

Jeong, J. K., Yang, H. W., Jeong, J. H., Mo, Y.-G. & Kim, H. D. Origin of threshold voltage instability in indium-gallium-zinc oxide thin film transistors. Appl. Phys. Lett. 93, 123508 (2008).

Liu, P.-T., Chou, Y.-T. & Teng, L.-F. Environment-dependent metastability of passivation-free indium zinc oxide thin film transistor after gate bias stress. Appl. Phys. Lett. 65, 233504 (2009).

Park, J.-S., Jeong, J. K., Chung, H.-J., Mo, Y.-G. & Kim, H. D. Electronic transport properties of amorphous indium-gallium-zinc oxide semiconductor upon exposure to water. Appl. Phys. Lett. 92, 072104 (2008).

Acknowledgements

This work was supported by the Materials Original Technology Program (10041222) funded by the Ministry of Knowledge Economy (MKE, Korea) and a National Research Foundation of Korea (NRF) grant funded by the Korean government (MEST) (No. 2010-0009898).

Author information

Authors and Affiliations

Contributions

J.-S.S., J.-H.J. and B.-S.B. designed the research plan; J.-S.S. carried out the synthesis of the precursor solution, fabrication of the device and characterization work under the supervision of Professor B.-S.B.; J.-S.S., M.R. and S.-H.K.P. fabricated the flexible device; J.-H.J., Y.H.H. and H.P. discussed the results; and J.-S.S. and B.-S.B. wrote the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Solution-Processed Fluorine-doped Indium Zinc Oxide Thin-Film Transistors Fabricated on Flexible Film at Low Temperature

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Seo, JS., Jeon, JH., Hwang, Y. et al. Solution-Processed Flexible Fluorine-doped Indium Zinc Oxide Thin-Film Transistors Fabricated on Plastic Film at Low Temperature. Sci Rep 3, 2085 (2013). https://doi.org/10.1038/srep02085

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02085

This article is cited by

-

Structural, Optical, Electrical, and Nanomechanical Properties of F-Doped Sno2 Fabricated by Ultrasonic Spray Pyrolysis

Electronic Materials Letters (2024)

-

Significant Lifetime Enhancement in QLEDs by Reducing Interfacial Charge Accumulation via Fluorine Incorporation in the ZnO Electron Transport Layer

Nano-Micro Letters (2022)

-

Fluorine-induced surface modification to obtain stable and low energy loss zinc oxide/perovskite interface for photovoltaic application

Advanced Composites and Hybrid Materials (2022)

-

Multi-stacking Indium Zinc Oxide Thin-Film Transistors Post-annealed by Femtosecond Laser

Electronic Materials Letters (2021)

-

Effects of Oxygen Plasma Power on Electrical Characteristics in Multi-Stacked Indium Zinc Oxide Transistors

Electronic Materials Letters (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.