Abstract

In this letter, we report, for the first time, the real-time in situ nucleation and growth of Ag filaments on α-Ag2WO4 crystals driven by an accelerated electron beam from an electronic microscope under high vacuum. We employed several techniques to characterise the material in depth. By using these techniques combined with first-principles modelling based on density functional theory, a mechanism for the Ag filament formation followed by a subsequent growth process from the nano- to micro-scale was proposed. In general, we have shown that an accelerated electron beam from an electronic microscope under high vacuum enables in situ visualisation of Ag filaments with subnanometer resolution and offers great potential for addressing many fundamental issues in materials science, chemistry, physics and other fields of science.

Similar content being viewed by others

Introduction

In science, discovering new ways of thinking about facts is more important than obtaining these facts1. The investigation of nanocrystal growth is a rich research field that impacts both fundamental and applied science because controlling nanoscale sizes and morphologies can directly affect functional applications2. By observing nanocrystal structures microscopically, insight into the growth mechanism can be used to design a method to control nucleation, which is one of the most challenging processes in nanoscience and nanotechnology3. With ever-increasing temporal and spatial resolution allowing for atomic scale nanomaterial characterisation, the advent of highly sophisticated electron- and photon-based spectroscopies and scanning probe microscopies is primarily responsible for the developments in this field. In particular, measurements using a transmission electron microscopy (TEM) heating holder for in situ analysis provided an in-depth understanding of the crystal growth process and further application of this method has attracted considerable interest4,5,6. Recently, de Jonge and Ross7 reviewed in situ liquid TEM characterisation because it facilitates the study of step-by-step nanoscale evolution8,9. In this manuscript, for the first time, we report the real-time in situ formation and growth of Ag filaments on α-Ag2WO4 crystals using an accelerated electron beam under high vacuum.

Noble metal nanoparticle preparation is an interdisciplinary subject that is attracting intense research and development due to both the fundamental and applied scientific value of nanometer scale metals10,11,12. In particular, the synthesis and surface chemistry of Ag nanoparticles have been extensively reported13. Very recently, Xia et al.14 outlined the current developments in the shape-controlled synthesis of Ag nanocrystals and Li et al.15 reviewed research focused on Ag nanowire preparation using a soft solution method as well as applications using the Ag nanowires. Recently, we have obtained silver tungstate (α-Ag2WO4) crystals using various methods (coprecipitation, sonochemistry and hydrothermal treatment) and their corresponding photoluminescence properties have been studied16. An overview of results reported from the various growth experiments reveals the absence of research on nanocrystal growth by electron irradiation.

In this research, we used an electron beam to grow Ag nanofilaments from α-Ag2WO4 crystals. X-ray diffraction (XRD), field emission scanning electron microscopy (FE-SEM), selected-area electron diffraction (SAD), TEM and high-resolution microscopy (HRTEM) have been employed to study these materials. Through the use of these complementary techniques as well as first-principles calculations based on density functional theory (DFT), we determined the electronic structure of the α-Ag2WO4 bulk. We investigated the formation of Ag nanofilament, which was followed by a subsequent growth process from the nano- to micro-scale. This observation facilitated an in-depth investigation of the physicochemical property behaviour and possible applications in various fields (i.e., sensors, catalysis, optical devices and bio systems).

Results

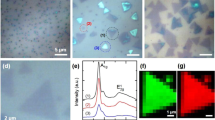

TEM images obtained at 5 s intervals, which show the interesting growth of the Ag filaments from the α-Ag2WO4 matrix, are displayed in Figures 1(a–h) (indicated by blue arrows). The red arrows indicate another region that illustrates particle absorption by the matrix. To the best of our knowledge, this phenomenon (growth and re-absorption of Ag) is new for this material and occurs in all of the regions that the electron beam irradiated. Importantly, when the TEM microscope is used, the growth process is faster and more intense than when the SEM microscope is used due to the higher electron energy and dosage associated with TEM. As shown in the earlier stage of growth for another series of images (Supplementary Movie S1), an initial superficial Ag particle is formed from the α-Ag2WO4 matrix which follows the growth of the filaments over time. In addition, to thoroughly investigate these nucleation and growth processes, the different regions of the sample where the Ag filaments are present were analysed using TEM and HRTEM.

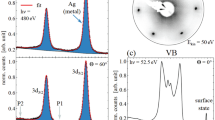

Figures 2a–c show a time-resolved series of FE-SEM images obtained under high vacuum (1 × 10−5 Pa) and the crystal morphology simulation during the growth of Ag filaments stimulated by the electron beam on the α-Ag2WO4 surface. The α-Ag2WO4 crystal has a hexagonal rod-like elongated shape (see Fig. 2a) and the corresponding morphology was modelled using the crystallographic data listed in the Supplementary Information (see Table SI1). Figure 2a shows a FE-SEM image of the α-Ag2WO4 crystals that were acquired after a rapid approach and focus adjustment (time zero). This image reveals that after receiving a small electron dose, the α-Ag2WO4 crystal surface contains a small amount of Ag nanoparticles. Figure 2b confirms that after 6 min of exposure to a 30 kV electron beam, the metallic Ag nanoparticles on the α-Ag2WO4 crystal surface begin to grow. A reasonable amount of electrons induces the appearance of several defects in the surface which produces a continuous axial flow of metallic Ag particles. FE-SEM analyses revealed that this axial Ag growth process is highly reproducible. Figure 2c shows that increasing the exposure time to 10 min produces two effects: 1) Ag nanoparticles change to filamentary Ag; and 2) the nucleation of new Ag nanoparticles on the crystal surface. Figures 2a–c indicate that the Ag filament formation process from unstable α-Ag2WO4 crystals is a reduction process converting the [AgO2], [AgO4], [AgO6] or [AgO7] clusters into Ag0. Therefore, this redox process promotes the transformation of α-Ag2WO4 crystals with an ordered structure to a disordered structure.

Series of in situ FE-SEM images of the Ag growth after the absorption of energetic electrons by the α-Ag2WO4 crystal surface at 30 kV without a heating holder.

(a) FE-SEM image focused on the α-Ag2WO4 crystal surface with rapid acquisition, time zero and modelled α-Ag2WO4 crystals before receiving electrons; (b) FE-SEM image focused on the same α-Ag2WO4 crystal surface region after 6 min of image acquisition and modelled surface defects on the α-Ag2−xWO4 crystal, with several points related to the appearance of Ag nanoparticles; (c) FE-SEM image focused on the same α-Ag2WO4 crystal surface region after 10 min of acquisition and modelled surface defects on the α-Ag2−xWO4 crystal, with several points related to the appearance of Ag nanorods.

Recently, using the chemical reduction method, Tsuji et al.17 monitored the rapid transformation of various Ag nanostructures from Ag+ ions to Ag0 in solution by time-dependent surface plasmon resonance. In another example, using in situ TEM images, Yasuda et al.18 observed indium oxide reduction at 820°C for metallic indium and intermetallic species (PdIn3). In the present work, using energetic electrons and in absence of an external heat treatment, we observed the formation of Ag nanorods in the solid state. This process does not follow an epitaxial growth mechanism.

Figures 3a–d show low-magnification and HRTEM images of the Ag-Ag2WO4 interface. The beam effect on the original α-Ag2WO4 crystal allows the Ag to form particles and/or filaments and induce amorphisation of the α-Ag2WO4 crystals. To fully understand these structural and chemical changes in the α-Ag2WO4 crystals, X-ray energy dispersive spectroscopy (EDS) analysis was performed at several points along the filamentary grown region (crosses inside the yellow circle in Fig 3c) and these results are presented in Figures 3e–h. The region adjacent to the Ag filament (Region 1) is composed of tungsten oxide with a small amount of Ag. The small amount of Ag in this region is expected once the Ag atoms migrate to form the filaments. The C and Cu contributions observed in the EDS analysis are from the Lacey Cu grid. At the interface (Region 2) where the matrix and filament are superposed, the primary elements are W, Ag and O. In this region, we observe contributions from the metallic Ag particle/filament and amorphous matrix. Therefore, the relative intensity of Ag increased compared to region 1. In the filament (Regions 3 and 4), the EDS analysis indicates that the filament is primarily composed of Ag atoms with a small amount of W and O. No significant change in the chemical composition was observed along the filament. The EDS and HRTEM results confirm that the crystalline Ag with a minor amount of W and O atoms are segregated indicating that a small portion of the W and O atoms from the matrix was pulled into the filament during the fast Ag filament growth.

Additional series of TEM and HRTEM images of the grown Ag filaments.

(a) Low-magnification image of the interface between the tungsten oxide rods and the Ag nanoparticle. (b) The same region shown in high resolution indicating the crystalline Ag planes and amorphous tungsten oxide matrix; (c) Low-magnification image of several tungsten oxide rods. Ag filamentary growth occurs in several rods and chemical analysis (EDS) was performed at the points labelled 1, 2, 3 and 4. (d) HRTEM image of the rod-filament interface inside the yellow circle. (e–h) EDS plots of the regions marked in (c).

Figure 4 displays the structure modification effect in the α-Ag2WO4 crystal induced by the electron beam. The early characterisation step indicated (see Fig. 4a) that the Ag filaments have not begun to grow from the α-Ag2WO4matrix. The corresponding electron diffraction pattern (SAD; see Fig. 4b) shows a set of rings indicating the polycrystalline nature of the α-Ag2WO4 crystals (indexed as the orthorhombic structure). These results are in agreement with the XRD results (see Fig. S1. in Support Information). However, after focusing the electron beam on the sample for a few seconds, the Ag nanofilaments begin to grow in several regions of the α-Ag2WO4 crystal (see Fig. 4c). In addition, the regions adjacent to the filamentary growth, denoted by the red circle, tend to disrupt, which was confirmed by the amorphous diffraction pattern (see Fig. 4d) and is in agreement with the high-resolution images of the matrix after filamentary growth (Figs. 3b,d). This result indicates that the Ag mass transport modifies the original structure of the compound, which no longer present long-range order.

α-Ag2WO4 crystals before and after irradiation by the electron beam.

(a) TEM image showing an overview of the various α-Ag2WO4 nanorods before filament growth; (b) SAD polycrystalline orthorhombic structure pattern through electron diffraction ring indexation [(1 = (101), 2 = (310), 3 = (002), 4 = (400), 5 = (132), 6 = (341), 7 = (402) and 8 = (361) or (233)]; (c) Rods with filamentary growth after irradiation by the electron beam; (d) SAD pattern of the red circle region adjacent to the filament growth indicating amorphisation of the rod structure.

Discussion

This behaviour can be explained by the structural and electronic information recently published by our group16. α-Ag2WO4 crystals have an orthorhombic structure and can be described as a network of constituent polyhedra that are formed by distorted [WO6] clusters with an octahedral configuration and distorted deltahedral [AgO7], octahedral [AgO6], tetrahedral [AgO4] and angular [AgO2] clusters (see Supporting Information for more details regarding this structure). The corresponding electronic structure dictates its stability and activity16.

In addition, this core-shell arrangement has a core that is composed of internal [WO6], [AgO6] and [AgO7] clusters, whereas the external portion is formed by [AgO4] and [AgO2] clusters. When an electron beam irradiates this material, these distorted clusters produce a lattice distortion that is propagated along the material, altering the electronic distribution along these polar cluster networks. Because the absorption of one electron is typically a quantum phenomenon, first-principles calculations were performed to verify the polar nanodomains in α-Ag2WO4 at the atomic level. The details of our calculations are reported in the Supplementary Information (see Figs. S2–S5).

The theoretical results indicate that the [AgO4] clusters are the most positively charged, whereas the [AgO2] clusters are the most negatively charged. Therefore, it is feasible that electron absorption occurs at the [AgO4] cluster. Our method utilises irradiation with electrons, which generates a redox environment. We propose the following mechanism: upon electron irradiation, the external and positively charged [AgO4] clusters become polarised to form highly reactive moieties that can be rapidly used to reduce the adjacent angular [AgO2] clusters undergoing a disproportionation rearrangement. This procedure produces [AgO6] clusters and metallic Ag, which flows to the surface and results in local amorphisation of the α-Ag2WO4 crystal. Based on these theoretical results, a reasonable mechanism has been proposed to explain the experimental results (supporting information) obtained in this work.

For the first time, we have demonstrated that metallic Ag nanoparticles/nanofilaments grow in situ from α-Ag2WO4 crystals. In this experiment, an external stimulus, such as an accelerated electron beam from FE-SEM/TEM measurements, is capable of initiating the nucleation and growth of Ag filaments. XRD, FE-SEM, SAD, TEM and HRTEM techniques have been used to extensively characterise the material. To complement these experimental measurements, structural and electronic properties have been estimated using first-principles calculations.

Based on these results, we have identified that the driving force for this redox process can be attributed to order-disorder effects of the constituent clusters of α-Ag2WO4 in the short-, intermediate- and long-range structures. These interlinking patterns are responsible for the physical/chemical properties of the material. In addition, we have proposed a possible formation mechanism where: irradiated electrons are absorbed by the external and higher charged tetrahedral [AgO4] clusters, followed by a subsequent disproportionation reaction with the angular [AgO2] clusters. This procedure produces [AgO6] clusters and metallic Ag that migrate to the surface, resulting in the local amorphisation of α-Ag2WO4. We have confirmed that this material is an ideal platform with outstanding potential for use in biological, plasmonics and catalytic applications and these studies are currently in progress.

Methods

Synthesis

The α-Ag2WO4 crystals were prepared at 90°C in 1 min by the injection of precursors ions into hot aqueous solutions. A typical α-Ag2WO4 crystal synthesis procedure is described below: First, 1 × 10−3 mols of tungstate sodium dihydrate (Na2WO4.2H2O) (99.995% purity, Sigma-Aldrich) and 2 × 10−3 mols of silver nitrate (AgNO3) (99.8% purity, Sigma-Aldrich) were dissolved separately in 50 mL of deionised water. The first solution was transferred to a 250 mL glass flask and heated to 90°C under constant stirring for 10 min. Then, the second solution that contained 50 mL of AgNO3 at room temperature was pumped by a syringe and injected into the hot aqueous solutions (90°C) and a suspension was rapidly formed with a temperature reduction to 70°C. The following suspension was immersed in a beaker with 50 mL of deionised water at 5°C. These α-Ag2WO4 crystals were obtained as a fine white powder precipitated at the bottom of the glass flask. The resulting suspensions were washed several times with deionised water to remove any remaining sodium ions. Finally, these white powder precipitates were collected and dried with acetone at room temperature for 4 h.

Characterisations

The α-Ag2WO4 crystals were characterised by their XRD patterns using a D/Max-2500PC diffractometer (Rigaku, Japan) with Cu-Kα radiation (λ = 1.5406 Å) in the 2θ range from 10° to 110° with a scanning velocity of 1°/min and a step of 0.02°. The shape and size of the α-Ag2WO4 crystals were observed by FE-SEM through a Carl Zeiss microscope (Model Supra 35) operated at 30 kV and by TEM with a CM200 model microscope (Philips) operated at 200 kV. The α-Ag2WO4 microcrystals were characterised using SAD and HRTEM. The samples used to obtain the TEM images were prepared by drying droplets of the as-prepared samples from an acetone dispersion sonicated for 10 min and deposited on the Cu grids.

References

50th Anniversary Highlight, Lawrence Livermore National Laboratory, September (2002) p. 20.

Rycenga, M. et al. Controlling the synthesis and assembly of silver nanostructures for plasmonic applications. Chem. Rev. 111, 3669–3712 (2011).

Zhang, J., Huang, F. & Lin, Z. Progress of nanocrystalline growth kinetics based on oriented attachment. Nanoscale 2, 18–34 (2010).

Parent, L. R. et al. Direct in situ observation of nanoparticle synthesis in a liquid crystal surfactant template. ACS Nano 6, 3589–3596 (2012).

Xin, H. L. et al. Revealing correlation of valence state with nanoporous structure in cobalt catalyst nanoparticles by in situ environmental tem. ACS Nano 6, 4241–4247 (2012).

White, E. R. et al. In situ transmission electron microscopy of lead dendrites and lead ions in aqueous solution. ACS Nano 6, 6308–6317 (2012).

de Jonge, N. & Ross, F. M. Electron microscopy of specimens in liquid. Nat Nanotechnol 6, 695–704 (2011).

Yuk, J. M. et al. High-resolution EM of colloidal nanocrystal growth using graphene liquid cells. Science 336, 61–64 (2012).

Park, J. et al. Direct observation of nanoparticle superlattice formation by using liquid cell transmission electron microscopy. ACS Nano 6, 2078–2085 (2012).

Burda, C., Chen, X. B., Narayanan, R. & El-Sayed, M. A. Chemistry and properties of nanocrystals of different shapes. Chem. Rev. 105, 1025–1102 (2005).

Xia, Y., Xiong, Y., Lim, B. & Skrabalak Sara, E. Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics? Angew. Chem. Int. Ed. 48, 60–103 (2009).

Murphy, C. J. et al. Gold nanoparticles in biology: beyond toxicity to cellular imaging. Acc. Chem. Res. 41, 1721–1730 (2008).

Tsuda, T. et al. Various metal nanoparticles produced by accelerated electron beam irradiation of room-temperature ionic liquid. Chem. Commun. 48, 1925–1927 (2012).

Xia, X., Zeng, J., Zhang, Q., Moran, C. H. & Xia, Y. Recent developments in shape-controlled synthesis of silver nanocrystals. J. Phys. Chem. C 116, 21647–21656 (2012).

Li, X. X., Wang, L. & Yan, G. Q. Recent research progress on preparation of silver nanowires by soft solution method and their applications. Cryst. Res. Technol. 46, 427–438 (2011).

Cavalcante, L. S. et al. Cluster coordination and photoluminescence properties of α-Ag2WO4 microcrystals. Inorg. Chem. 51, 10675–10687 (2012).

Tsuji, M. et al. Rapid transformation from spherical nanoparticles, nanorods, cubes, or bipyramids to triangular prisms of silver with pvp, citrate and H2O2 . Langmuir 28, 8845–8861 (2012).

Yasuda, K., Hirano, Y., Kamino, T., Yaguchi, T. & Hirokawa, K. Observation of vaporization in palladium-indium intermetallic compounds by graphite-furnace atomic-absorption spectrometry using transmission electron-microscopy. Anal. Sci. 11, 437–440 (1995).

Acknowledgements

The authors wish to acknowledge the National Council for Scientific and Technological Development (CNPq), São Paulo Research Foundation (FAPESP), Prometeo/2009/053 (Generalitat Valenciana) and Ministerio de Economía y Competitividad (Spain) and the Spanish–Brazilian program (PHB2009-0065-PC) for their financial support. TEM facilities were provided by LME-IQ-UNESP. The authors also wish to acknowledge Dr. L. Gracia (Universitat Jaume I) for her generous help with the theoretical calculations.

Author information

Authors and Affiliations

Contributions

L.S. Cavalcante prepared the samples; D.P. Volanti and M.O. Orlandi performed the electron microscopy data collection and structural analysis. A.F. Gouveia and V.M. Longo performed the DFT studies. E. Longo, J.A. Varela and J. Andrés conceived the project. All of the authors participated in writting the manuscript and discussion of the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Movie Growth Ag filaments

Supplementary Information

Support Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Longo, E., Cavalcante, L., Volanti, D. et al. Direct in situ observation of the electron-driven synthesis of Ag filaments on α-Ag2WO4 crystals. Sci Rep 3, 1676 (2013). https://doi.org/10.1038/srep01676

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01676

This article is cited by

-

Rational design of Ag2CO3-loaded SGO heterostructure with enhanced photocatalytic abatement of organic pollutants under visible light irradiation

Environmental Science and Pollution Research (2022)

-

Structural, morphological and photoluminescence properties of β-Ag2MoO4 doped with Eu3+

Chemical Papers (2021)

-

Melting Behavior of Bimetallic and Trimetallic Nanoparticles: A Review of MD Simulation Studies

Topics in Current Chemistry (2021)

-

Surface-dependent properties of α-Ag2WO4: a joint experimental and theoretical investigation

Theoretical Chemistry Accounts (2020)

-

Ag Nanoparticles/α-Ag2WO4 Composite Formed by Electron Beam and Femtosecond Irradiation as Potent Antifungal and Antitumor Agents

Scientific Reports (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.