Abstract

Optical microcavities are important for both fundamental studies of light-matter interaction and applications such as microlasers, optical switches and filters etc... Tunable microresonators, in which resonant modes can be manipulated, are especially fascinating. Here we demonstrate a unique approach to mechanically tuning microresonators formed by polymer droplets with varying sizes. The droplets are self-assembly inside an elastic medium. By incorporating different dye molecules into the droplets, optically pumped lasing with selective wavelengths in a range of about 100 nm are achieved. Lasing action is ascribed to whispering gallery modes, verified by rigorous characterizations. Single longitudinal mode lasing is obtained when the droplet diameter is reduced to about 14 μm. Tuning lasing modes are clearly demonstrated by mechanical deformation. Our finding provides an excellent platform for exploring flexible and tunable microlasers for plastic optoelectronic devices.

Similar content being viewed by others

Introduction

With high quality (Q) factor and small mode volume, whispering gallery microcavities are highly important for fundamental studies of light-mater interaction and applications such as microlasers, optical filters and biosensors1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19. Readily, a droplet can be served as a good whispering gallery cavity15,16,17,18,19,20. In principle, the refractive index of a droplet is higher than that of the surrounding medium where the light will be trapped inside due to total internal reflection at the liquid-air interface and selectively enhanced by the so-called whispering gallery modes (WGMs)15. The development of droplet-lasing started from an ethanol or water droplet, which are free-falling16,17, free-standing18, or standing on a super hydrophobic substrate19 with air as the surrounding medium. However, the mechanical instability and its short lifetime due to evaporation severely affect the performance of this laser and largely hinder their practical applications.

The lifetime of droplet-lasing has been improved in a microfluidic structure where water droplet is replaced by another liquid with surrounding medium of oil or water21,22. Typically, a microchannel can generate a single droplet with size in a range of tens of microns21, which is not appropriate for studying the size-dependent WGM properties and single mode lasing emission. Another issue is that the poor handling feasibility of a droplet in a fluidic liquid (due to flow of liquid carrier) is not convenient for constructing optical devices23. To overcome this drawback, the idea of using elastomer as the carrier instead of liquids has been introduced23. However, the existing method either is difficult to generate a droplet with diameter smaller than 50 μm or requires a costly facility23,24.

In this article, we report a novel material composition combined with a simple but effective approach to obtaining high quality flexible microcavities with varying diameter (D) from around 200 to 5 μm. The one-step fabrication of a series of cavities facilitates the systematic investigation of size dependent cavity characteristics, because the material composition and the surrounding environment are strictly identical. Upon optical pumping, single longitudinal mode emission is observed from dyes-doped droplets with D ~ 14 μm. Multiple modes lasing with selective wavelengths in a range of 100 nm are achieved. The lasing mechanism is carefully investigated and ascribed to WGMs. In particular, we demonstrate the capability of tuning the lasing modes from droplet by mechanical deformation.

Results

Self-assembly formed polymer droplets in PDMS

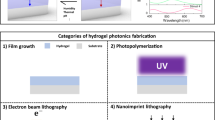

Figures 1a–1d demonstrate our approach and the formation processes of the droplets. Firstly, a drop of dye-doped polymer solution (see Methods for details) is deposited on the corner of sample holder as shown in Figure 1a. Then, a metal rod with a sharp tip9 is approached vertically down and immersed into the drop25. Subsequently, the tip is retracted from the drop and immersed into the PDMS (Sylgard 184 Silicon Elastomer from Dow Corning) filled in the sample holder. Immediately, the rod is forced to move with constant speed and parallel to the sample holder's side until the solution totally leaves the tip. By doing so, a fiber-shape of the solution is created with decreasing diameter from the starting (S) to the ending (E) points as shown in Figure 1b. Because of the surface tension that "wants" to minimize the surface area, the fiber is spontaneously broken into numerous small pieces and later well-aligned droplets with spherical shapes are self-assembled (Figure 1d).

Direct drawing technique and self-assembled formation processes of polymer droplets.

(a)–(d) Schematic diagram demonstrates the direct drawing approach to create well-aligned polymer droplets with continuous decreasing size from starting (S) to ending (E) point. (e)–(j) The droplets were self-assembly formed (top-down view) as function of time (indicated in the top-middle part of each image). (k) Small droplets were obtained in the E region. The images were taken by a 10× objective under halogen illumination.

The self-assembled processes are presented in Figures 1e–1j as a function of time. It can be seen that in the first 8 seconds the fiber broke into several long fiber pieces (Figure 1f). Then the long fiber pieces continuously broke into shorter fiber pieces (Figure 1g) and shrunk to form spindles which are linked together (Figure 1h). After around 40 seconds, droplets are self-assembly formed (Figure 1i) but it takes 10 seconds more to get a spherical shape (Figure 1j). Interestingly, we have observed a process that two droplets were coalesced to form a single bigger droplet (Figures 1i and 1j). As a result, it creates an opportunity to study optical properties of dynamic processes, in which the cavity is continuously changing its size and configuration. In addition, a number of highly uniform droplets with D ~ 14 μm were obtained as shown in Figure 1k. These small size droplets exhibited single longitudinal mode lasing emission, which will be shown later.

In comparison with the reported work where an organic solvent were used as droplet material23, the idea of using the polymer as droplet material carries the following advantages: (i) A diffusion rate of the polymer into PDMS is much lower than that of organic solvent. (ii) It does not require a surfactant (used in the previous work to prevent the diffusion of organic solvent into the carrier) that makes the structure complex and might affect the performance of the droplet.

In addition, the density of epoxy resin (the main component of the solution) and PDMS are 1.16 and 0.98 g cm−3, respectively. The slight higher density makes epoxy resin easier to immerse into PDMS. The small difference in density of the two materials facilitates the locating of the droplets. In fact, it was found that the position of the droplets was very stable, probably because of the following reasons: (i) the droplet's size is only tens of microns so gravity force from a droplet is small. (ii) The gravity force from the droplet is almost equivalent to the buoyancy from the carrier. (iii) The epoxy and PDMS are semi-solid materials with high viscosity, therefore, the fluid friction at the surface of droplet and carrier is strong. These three factors prevent the droplet moving downward or flowing horizontally.

WGM lasing from polymer droplets

Figures 2a and 2b show the photoluminescence (PL) images of a typical droplet by pumping at different positions. Under optical excitation, two bright rims at the boundary of the droplet were observed though residual forward Rayleigh scattering. Moreover, these rims are in opposite to centre of the droplet. This observation confirms that the lasing cavity is formed in vertical plane or incident plane of excited beam as schematically drawn in Figure 2g15. The bright rims are lasing emission coupled out of droplet cavity and located at focus plane of the objective. Obviously, the cavity plane is not in horizontal plane. Otherwise, a bright circular covered whole droplet boundary13 should be seen in the PL image instead of the two rims.

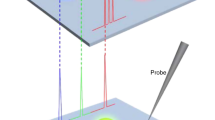

Optical field inside a typical droplet under optical pumping.

(a) and (b) The PL images of a droplet under optical pumping illuminating by a bright spot (indicated by the white cross). (c) Schematic view of WGMs in a droplet. The electric field orientation of excitation beam (noted as the white arrows) is perpendicular to the WGM plane.

Figure 3a presents a lasing spectrum from RhB-doped droplet with D ~ 24 μm under the green excitation with pump pulse energy (PPE) approximate 1.35 μJ. It is clear that the spectrum displays two separated lasing envelope, which is well-explained by using the asymptotic solutions in Refs. 22 and 26. Assuming D = 24.22 μm (that close to value estimated from optical image) with refractive index of surrounding medium is 1.4127 and droplet 1.53, theoretically identified positions of transverse electric (TE) and transverse magnetic (TM) modes with radial mode number r = 1 are indicated below the spectrum. It can be seen that the lasing peaks can be well-matched with mode numbers m = 174 to 178. In addition, the intensity of TE modes is higher than that of TM modes, which might be due to lower Q factor of TM modes17. The Q factor of the droplet's cavity is estimated >5 × 103. Figure 3b shows the integrated PL intensity of the peaks as a function of PPE. A nonlinear increase of emission with increasing PPE can be seen, which clearly indicates of the lasing action. The lasing threshold for TE and TM polarization are approximately 125 and 195 nJ, respectively. In other words, the ratio of lasing threshold with TE and TM polarization is about 1:1.5. As indicated in the Figure 3c, a lasing spectrum with only TE polarization appeared when the PPE is below threshold of lasing with TM polarization.

Lasing spectrum from a RhB-doped droplet upon optical excitation.

(a) A set of WGMs lasing spectrum from a droplet (D ~ 24 μm) with both TE and TM polarization. The inset shows a magnified of the highest intensity TE and TM lasing peaks with the spectrum linewidths are approximately 0.13 nm. The calculated WGMs positions with TE and TM polarization for a spherical cavity are aligned below the lasing spectrum. (b) The integrated PL intensity dependent on TE and TM polarization. (c) Lasing spectrum with only TE polarization under PPE = 170 nJ, which is below threshold of lasing with TM polarization.

Characterizations of size-dependent WGM lasing

The WGM lasing characteristics were further investigated by studying lasing spectra of the droplets with different sizes. Figure 4a illustrates series of spectra of RhB (similar behaviors were observed for the case of R6G and R19P) doped droplets as function of D. As D decrease from around 31 to 16 μm, we have observed: (i) The lasing envelope shifted from 653 to 600 nm. This phenomenon has been reported and well-explained in Ref. 22. As is well-known, the lasing out-coupling is very sensitive to both the Q factor and the confinement of the cavity. Due to the absorption tail and a better confinement in the large droplets, the short wavelength component is unable to be extracted out of the cavity22. Therefore, only the long wavelength is able to be observed and the lasing peak exhibits a blue-shift with the decreasing of droplet diameter22. (ii) The free spectral range (FSR) increased together with decreasing in number of lasing modes. The FSR curve (the inset) shows a relationship between the FSR (experimentally determined by analyzing the lasing spectrum as indicated in Figure 4a) and droplet's size (estimated based on microscopy image). It is well-fitted by a α/D function, where α is a constant. This should be understandable because FSR = λ2/(πDneff), where λ is resonant wavelength, neff is effective refractive index of droplet. The number of lasing modes decreased from 8 to 2 due to the less overlap of WGMs and the gain profile. In principle, if the FSR is comparable or smaller than the width of optical gain spectrum, single longitudinal mode lasing can be obtained18. Following this principle, single longitudinal mode lasing at three separated wavelengths was observed when D ~ 14 μm as shown in Figure 4b. Likely, in our experiments the observation of single longitudinal mode lasing was closely related to the cavity size instead of the gain materials. Moreover, the spectral linewidth of the single mode is around 0.15 nm, which is comparable with that of single mode lasing based on other kind of cavities such as distributed feedback (DFB)27 or Fabry-Perot (F-P)28 cavity which heavily replies on complicated nano- and micro-fabrication.

Mechanical tunable WGM Lasing

The PDMS can be easily cured by adding suitable amount of curing agent (ratio 10:1). The structure was left at room temperature for about 2 days for solidification. Then, it can be taken out for optical measurement as shown in Figure 5a. When the PDMS elastomer (with a good elastic property) is mechanically stretched from both sides, the droplet deformed from sphere to ellipsoid as illuminated in Figures 5b and 5c. As a result, the optical cavity of the droplet is changed under the deformation, which makes it possible to tune the resonant modes23,29. Figure 5d shows the lasing spectra of a typical droplet as a function of deformation ratio (ΔD%). It can be seen that the lasing envelope exhibited a red-shift behavior with increasing of ΔD%, which is due to a slight increase of the optical cavity. In addition, for the investigated range, the shift values of lasing modes (Δλ) showed a linear relationship with ΔD% and depend on droplet's size (Figure 5e). Comparatively, for the same deformation ratio, smaller droplets exhibited higher resonant wavelength tunability. For instance, for ΔD% = 3% it is expected that Δλ ~ 0.50 and 0.16 nm for droplet with D ~ 64 and 90 μm, respectively. Moreover, the droplets also emitted good lasing performances under certain bending condition, which is promising for application in flexible plastic photonic devices.

Tunable WGM Lasing through mechanical deformation.

(a) Directions of deformation. (b) and (c) The top down optical images of a typical droplet before and after deformation, respectively. (d) Lasing spectra from a RhB-doped droplet with different deformation ratio (ΔD%). D and D′ are estimated from optical images with absolute variation about 5%. (e) Shift of lasing modes (Δλ) of various droplets as function of deformation ratio.

Discussion

We have demonstrated a facile approach for cost effective, self-assembled high quality optical microcavities with wide range of selective sizes. The proposed technique does not require any micro-fabrication process or costly apparatus but very effective. Low threshold lasing emission with both TE and TM polarization were observed. Single longitudinal mode lasing was obtained from small droplets. Specially, the self-assembled processes are able to control by modifying the ratio of PS and epoxy resin. It is also expected that other kinds of geometry like cylindrical cavity (fiber), spindle-cavity can be obtained for certain ratio of PS and epoxy resin. Therefore, it provides a platform for fundamental studies of light-matter interaction in numerous cavities with different configurations. The achievement of tuning lasing modes from droplets inside cured PDMS is important for fabrication tunable microlasers. In addition, the polymer carrier remains in semi-liquid form at room temperature for several hours. Therefore, a waveguide can be integrated into the system for the output coupling30. As a result, the system is promising candidate for optical filters in plastic optoelectronic devices.

Methods

Droplet material syntheses

The droplet material herein is a composited polymer solution that was made as follows. Firstly, polystyrene (PS) (molecular weight is ~2000, from Sigma-Aldrich) was dissolved in dichloromethane (purity 99.76%) with concentration approximately 14 wt%. After that, epoxy resin13 was mixed in solvated PS solution. The weight ratio of epoxy resin and PS is about (12–15) :1. It is worth to note that the introduction of PS (refractive index is 1.59 at 630 nm31) helps to increase refractive index of the composition is therefore improving quality factor of the microcavity. While epoxy resin provides high viscous and large surface tension value, which is important for the self-assembled process. For lasing emission, three different molecular dyes (from Sigma-Aldrich) were doped as gain materials. They are Rhodamine B (RhB), Rhodamine 6G (R6G) with 2–2.5 wt% and Rhodamine 19 Perchlorate (R19P) with 1–1.5 wt%. The dye content of gain materials are ~95%, 95% and 99% for RhB, R6G and R19P, respectively.

Optical measurements

A micro-photoluminescence (μ-PL) system was used to exam optical properties of individual dye doped droplets. In this setup, the excitation was a second harmonic generation from Nd:YAG laser (wavelength: 532 nm, frequency: 60 Hz, pulse duration: 1 ns). The excitation laser beam was guided at an angle ~45° to normal of the sample holder to excite the droplet. The excitation spot has an elliptical shape of about 1 × 1.2 mm. The emission from droplet was collected by an objective (50×, NA = 0.42). The spectrum was recorded by a charged coupled device (CCD). During the measurement, a long-pass filter was used to block the pump laser.

References

Vahala, K. J. Optical microcavities. Nature 424, 839–846 (2003).

Vollmer, F. & Arnold, S. Whispering-gallery-mode biosensing: label-free detection down to single molecules. Nat. Methods 5, 591–596 (2008).

Ilchenko, V. S. & Matsko, A. B. Optical resonators with whispering-gallery modes-part II: applications. IEEE J. Sel. Top. Quantum Electron. 12, 15–32 (2006).

Sun, L. et al. Direct Observation of Whispering Gallery Mode Polaritons and their Dispersion in a ZnO Tapered Microcavity. Phys. Rev. Lett. 100, 156403 (2008).

Santiago-Cordoba, M. A., Boriskina, S. V., Vollmer, F. & Demirel, M. C. Nanoparticle-based protein detection by optical shift of a resonant microcavity. Appl. Phys. Lett. 99, 073701–073703 (2011).

Zhang, Y., Zhou, H., Liu, S. W., Tian, Z. R. & Xiao, M. Second-Harmonic Whispering-Gallery Modes in ZnO Nanotetrapod. Nano Lett. 9, 2109–2112 (2009).

Yang, L., Carmon, T., Min, B., Spillane, S. M. & Vahala, K. J. Erbium-doped and Raman microlasers on a silicon chip fabricated by the sol–gel process. Appl. Phys. Lett. 86, 091114 (2005).

Chen, R., Ling, B., Sun, X. W. & Sun, H. D. Room Temperature Excitonic Whispering Gallery Mode Lasing from High-Quality Hexagonal ZnO Microdisks. Adv. Mater. 23, 2199–2204 (2011).

Ta, V. D., Chen, R., Ma, L., Ying, Y. J. & Sun, H. D. Whispering Gallery Mode Microlasers and Refractive Index Sensing based on Single Polymer Fiber. Laser Photonics Rev. 7, 133–139 (2013).

Moon, H.-J., Chough, Y.-T. & An, K. Cylindrical Microcavity Laser Based on the Evanescent-Wave-Coupled Gain. Phys. Rev. Lett. 85, 3161–3164 (2000).

Lee, M.-C. M. & Wu, M. C. Tunable coupling regimes of silicon microdisk resonators using MEMS actuators. Opt. Express 14, 4703–4712 (2006).

Tang, S. K. Y. et al. A multi-color fast-switching microfluidic droplet dye laser. Lab Chip 9, 2767 (2009).

Ta, V. D., Chen, R. & Sun, H. D. Self-Assembled Flexible Microlasers. Adv. Mater. 24, OP60–OP64 (2012).

Chen, R., Ta, V. D. & Sun, H. D. Single Mode Lasing from Hybrid Hemispherical Microresonators. Sci. Rep. 2, 244 (2012).

Humar, M., Ravnik, M., Pajk, S. & Muševič, I. Electrically tunable liquid crystal optical microresonators. Nature Photon. 3, 595–600 (2009).

Qian, S. X., Snow, J. B., Tzeng, H. M. & Chang, R. K. Lasing Droplets: Highlighting the Liquid-Air Interface by Laser Emission. Science 231, 486–488 (1986).

Lin, H. B., Huston, A. L., Justus, B. L. & Campillo, A. J. Some characteristics of a droplet whispering-gallery-mode laser. Opt. Lett. 11, 614–616 (1986).

Schäfer, J. et al. Quantum Dot Microdrop Laser. Nano Lett. 8, 1709–1712 (2008).

Kiraz, A. et al. Single glycerol/water microdroplets standing on a superhydrophobic surface: Optical microcavities promising original applications. J. Nanophotonics 1, 011655 (2007).

Mølhave, K., Kristensen, A. & Mortensen, N. in Advanced Photonic Structures for Biological and Chemical Detection Integrated Analytical Systems (ed Xudong, Fan) Ch. 17, 471–486 (Springer US, 2009).

Tanyeri, M., Perron, R. & Kennedy, I. M. Lasing droplets in a microfabricated channel. Opt. Lett. 32, 2529–2531 (2007).

Tang, S. K. Y., Derda, R., Quan, Q., Loncar, M. & Whitesides, G. M. Continuously tunable microdroplet-laser in a microfluidic channel. Opt. Express 19, 2204–2215 (2011).

Saito, M., Shimatani, H. & Naruhashi, H. Tunable whispering gallery mode emission from a microdroplet in elastomer. Opt. Express 16, 11915–11919 (2008).

Saito, M. & Koyama, K. Deformable Microdroplet Cavity Fabricated by an Inkjet Method. Jpn. J. Appl. Phys. 49, 092501 (2010).

Xing, X., Wang, Y. & Li, B. Nanofibers drawing and nanodevices assembly in poly(trimethylene terephthalate). Opt. Express 16, 10815–10822 (2008).

Lam, C. C., Leung, P. T. & Young, K. Explicit asymptotic formulas for the positions, widths and strengths of resonances in Mie scattering. J. Opt. Soc. Am. B 9, 1585–1592 (1992).

Song, W., Vasdekis, A. E., Li, Z. & Psaltis, D. Low-order distributed feedback optofluidic dye laser with reduced threshold. Appl. Phys. Lett. 94, 051117 (2009).

Aubry, G. et al. A multicolor microfluidic droplet dye laser with single mode emission. Appl. Phys. Lett. 98, 111111 (2011).

Ilchenko, V. S. et al. Strain-tunable high-Q optical microsphere resonator. Opt. Commun. 145, 86–90 (1998).

Hossein-Zadeh, M. & Vahala, K. J. Fiber-taper coupling to Whispering-Gallery modes of fluidic resonators embedded in a liquid medium. Opt. Express 14, 10800–10810 (2006).

Kasarova, S. N., Sultanova, N. G., Ivanov, C. D. & Nikolov, I. D. Analysis of the dispersion of optical plastic materials. Opt. Mater. 29, 1481–1490 (2007).

Acknowledgements

This research is supported by the Singapore National Research Foundation under its Competitive Research Programme (CRP Award No. NRF-CRP6-2010-02), the Singapore Ministry of Education through the Academic Research Fund (Tier 1) under the Project No. RG63/10.

Author information

Authors and Affiliations

Contributions

This work was proposed by V.D.T., R.C. and H.D.S. H.D.S. supervised the overall project. V.D.T. and R.C. designed, fabricated the samples and did all optical measurements. Characterization experiments were performed by V.D.T. with assistance from R.C. All authors discussed the results and substantially contributed to the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Ta, V., Chen, R. & Sun, H. Tuning Whispering Gallery Mode Lasing from Self-Assembled Polymer Droplets. Sci Rep 3, 1362 (2013). https://doi.org/10.1038/srep01362

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01362

This article is cited by

-

RGB WGM lasing woven in fiber braiding cavity

Science China Information Sciences (2022)

-

Biophotonic probes for bio-detection and imaging

Light: Science & Applications (2021)

-

Continuous-wave upconversion lasing with a sub-10 W cm−2 threshold enabled by atomic disorder in the host matrix

Nature Communications (2021)

-

Review of biosensing with whispering-gallery mode lasers

Light: Science & Applications (2021)

-

Quantitative imaging of the complexity in liquid bubbles’ evolution reveals the dynamics of film retraction

Light: Science & Applications (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.