Abstract

Here we present an ultraviolet responsive inorganic-organic hybrid solar cell based on titania/poly(3-hexylthiophene) (TiO2/P3HT) heterojuction. In this solar cell, TiO2 is an ultraviolet light absorber and electronic conductor, P3HT is a hole conductor, the light-to-electrical conversion is realized by the cooperation for these two components. Doping ionic salt in P3HT polymer can improve the photovoltaic performance of the solar cell. Under ultraviolet light irradiation with intensity of 100 mW·cm−2, the hybrid solar cell doped with 1.0 wt.% lithium iodide achieves an energy conversion efficiency of 1.28%, which is increased by 33.3% compared to that of the hybrid solar cell without lithium iodide doping. Our results open a novel sunlight irradiation field for solar energy utilization, demonstrate the feasibility of ultraviolet responsive solar cells and provide a new route for enhancing the photovoltaic performance of solar cells.

Similar content being viewed by others

Introduction

Solar energy has been considered as a green and renewable alternative energy source to traditional fossil fuels1. Solar cell is an attractive photovoltaic device for producing electrical energy directly from sunlight, without producing noise, toxic substance and greenhouse gas emission2. In various solar cells, the utilized solar radiation is mainly in visible light range, which occupies the largest part of solar radiation from the sun to the earth. However, ultraviolet light is few to be utilized in various solar cells. Although the ultraviolet light flux from the sun to the earth is small, the photon energy for the ultraviolet light is high1,2,3. The development of ultraviolet responsive solar cell is very significant in theory and actual application for photovoltaic and photoelectric devices. Unfortunately, no ultraviolet responsive solar cell has been reported so far.

Results

The design of an ultraviolet responsive solar cell

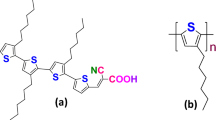

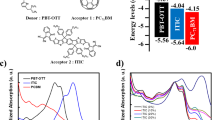

In order to devise the solar cell, it needs to choose a suitable ultraviolet light absorber. As we know that titania (TiO2) possesses a unique structure and wonderful properties, which has emerged as excellent photocatalytic and photoelectric materials3,4,5. Titania can not only harvest ultraviolet light with wavelength shorter than 380 nm, but also is an n-type semiconductor, which can be used as an electron acceptor offering a pathway for electronic transmission in solar cells3. On the other hand, poly(3-hexylthiophene) (P3HT) and poly(3-octylthiophene-2, 5-diyl) (P3OT) as key materials in polymer solar cells have recently aroused wide attentions6,7,8. P3HT is a p-type semiconductor polymer and has high hole mobility (10−4~10−2 cm2 V−1s−1); it is usually used as an electron donor in polymer solar cells. Combining these two primary components of TiO2 and P3HT, an ultraviolet responsive inorganic-organic hybrid solar cell is designed. According to references3,9,10, the LUMO/HOMO energy levels of P3HT, P3OT and TiO2 are about −3.53/−5.20, −2.85/−5.25 and −4.2/−7.4 (eV vs Vacuum), respectively. Under ultraviolet photoexcitation, electron-hole pairs are created in the TiO2 semiconductor and then are dissociated into free charge carriers (electrons and holes). The electrons are transferred to the conducting glass substrate (FTO) via TiO2 grid; the holes are reduced by electron donation from the valence band of P3HT and then from the platinum-plated (Pt) counter electrode, with the circuit being completed via electron migration through the external load. Overall, the device generates electric power from ultraviolet light without suffering any permanent chemical transformation. Fig. 1B shows the schematic energy levels of the components and the photoelectric conversion process.

Phase and morphology

The X-ray diffraction (XRD) pattern of prepared TiO2 is shown in Fig. 2A, the scanning electron microscope (SEM) images of TiO2, TiO2/P3HT and TiO2/glass (cross sectional) are shown in Figs. 2B, 2C and 2D. It can be seen that the prepared TiO2 is pure anatase phase, the particle size is about 50 nm and the TiO2 is soaked and coated with P3HT. The interface between TiO2 and glass is clear, which will lead to the interfacial transfer resistance of carriers.

The UV-vis and infrared spectra analysis

The UV-vis absorption spectra of TiO2, P3HT, P3OT, P3HT/TiO2, P3OT/TiO2 were measured and are displayed in Fig. 3. As expected, TiO2 has no absorption band in visible range and shows the characteristic spectrum with its fundamental absorption of Ti–O bond in ultraviolet light range from 320 to 400 nm. From the spectrum of the P3HT/TiO2, it can be seen the two absorption bands in ultraviolet light region and in visible light region, respectively. The former band from 320 to 400 nm is assigned to the characteristic absorption of TiO2. The latter band with a peak wavelength of 510 nm is attributed to the electron transition (π–π*, 2.43 eV) from the valence bond (HOMO) to the conduction band (LUMO) of P3HT. Similarly, the P3OT/TiO2 also has two absorption bands: one band is for the TiO2, the other band with peak wavelength of 540 nm is for the electron transition (π–π*, 2.30 eV) from the HOMO to the LUMO of P3OT. In addition, it is notable that the absorption band of P3HT/TiO2 is stronger and wider than that of P3OT/TiO2, which is due to the fact that with the alkyl carbon chain increase in thiophene ring 3-substituted (Fig. 1A), the polymer ionization energy decrease, leading to the lower band gap energy for the P3OT than P3HT11.

Fig. 4 shows the Fourier transform infrared (FTIR) spectra of TiO2, P3HT, P3OT, P3HT/TiO2 and P3OT/TiO2. The curves of both P3HT and P3OT have similar absorption bands, since they have a similar structure and similar groups (Fig. 1A). In their spectra, there is a low-intensity peak at about 3056 cm−1, which is attributed to the thiophene ring Cβ−H stretching vibration. The three peaks at 2850–2958 cm−1 are for the C−H bond asymmetric and symmetric stretching vibration. The peak at 1510 cm−1 corresponds to thiophene ring C = C stretching vibration. The peaks at 1456 and 1377 cm−1 are due to the asymmetric and symmetric deformation vibrations of C−H bond. The peak at 823 cm−1 is attributed to the C−H vibration out-of-plane of the thiophene ring. The peak at 725 cm−1 is the characteristic absorption of S atom on the polythiophene ring. These are the characteristic peaks for P3HT and P3OT12,13. In TiO2 spectrum, there is no obvious absorption in visible and infrared range from 500 to 3500 cm−1. A weak absorption peak at 1627 cm−1 belongs to the O−H bending vibration of the absorbed H2O on the TiO2 surface. Owing to small amount of P3OT and P3HT in the P3OT/TiO2 and P3HT/TiO2, the absorption peaks for P3HT and P3OT are suppressed. There is no obvious absorption for the P3HT in the P3HT/TiO2 and the P3OT in P3OT/TiO2.

The photovoltaic performance of the hybrid solar cell

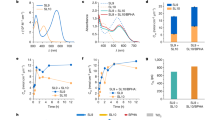

Fig. 5A shows the monochromatic incident photo-to-electron conversion efficiency (IPCE) curves for the hybrid solar cells with P3HT/TiO2, P3OT/TiO2 and TiO2, respectively. Three solar cells show strong photoelectric response to ultraviolet light ranged from 300 to 400 nm and the highest IPCE value of 23.59% at 350 nm is obtained by the solar cell based on P3HT/TiO2. The IPCE value in ultraviolet range is mainly caused by the strong absorption of TiO2, since TiO2 has an absorption peak around 350 nm for the direct band gap photo-electron excitation14. The IPCE values decrease in the order: P3HT/TiO2, P3OT/TiO2, pristine TiO2, which is accorded with the absorption intensity order in ultraviolet range shown in the Fig. 3, indicating that the photoelectric conversion can be achieved through the excitation of TiO2. The IPCE peak values for the cells with P3HT/TiO2 and P3OT/TiO2 films are higher than that of pristine TiO2 film in ultraviolet range, which is due to that the P3HT and P3OT can harvest ultraviolet light and improve carrier transportation function15. Furthermore, the higher IPCE value for P3HT/TiO2 than that of P3OT/TiO2 results from the better conductivity of P3HT than P3OT (shown in Fig. 6), which is ready for the better photovoltaic performance for the solar cell based on P3HT/TiO2 than that for the solar cell based on P3OT/TiO2.

The photovoltaic performances of the hybrid solar cells were determined by measuring photocurrent-photovoltage (J–V) characteristic curves under ultraviolet light irradiation. Fig. 5B shows the J–V curves for the hybrid solar cells with P3HT/TiO2 containing 1.0 wt.% of LiI under ultraviolet light irradiation with different intensities. It can be seen that, with the increase of the irradiated ultraviolet light intensity, the short-circuit current density (JSC) of the hybrid solar cell increases, the open-circuit voltage (VOC) and fill factor (FF) are kept in about 0.9 V and 0.56, respectively. Under the ultraviolet light irradiation of 100 mW·cm−2, the solar cell achieves the best photovoltaic performance, the JSC reaches 2.50 mA·cm−2 and the light-to-electrical energy conversion efficiency (η) reaches 1.28%.

The influence of doping polymer on the performance of the hybrid solar cells

It is said that the photovoltaic performance of the solar cells can be improved by doping appropriate ions in P3HT or P3OT polymer16,17. Many kinds of inorganic ions, such as Cl−, Br−, F−, NO3−, ClO4−, BF4− and HSO4− ions18, have been attempted to improve the conductivity of the polymers. The conductivities of P3HT and P3OT solutions containing different LiI amounts were measured and shown in Fig. 6. With the increase of the amount of LiI doped, the conductivities of P3HT and P3OT systems increase linearly until the LiI content reaches 1.0 wt.% and then rise gently. Singh et al19 had confirmed that the conductivity improvement by doping inorganic ions in P3HT film originated from the ions hopping process. The improvement of conductivities of P3HT and P3OT systems is ready for the enhancement of the photovoltaic performance of hybrid solar cells.

The photovoltaic parameters of the hybrid solar cells based on P3HT/TiO2 and P3OT/TiO2 containing KI or LiI were measured and summarized in Table 1. It can be seen that with the increase of doping ion amount, the VOC and FF values of the hybrid solar cells stay unvaried, the JSC values increase, which results in the η value increase. The JSC improvement is due to the change of conductivity of the polymer systems. It is notable that the JSC and η values of the solar cells containing LiI are higher than those of the solar cells containing KI with a same concentration, which indicates that LiI has a better effect than KI on improving the photovoltaic performance of the solar cells. The η values for the hybrid solar cells based on P3HT/TiO2 and P3OT/TiO2 doped with 1.0 wt.% LiI are 1.28% and 1.16%, which are increased by 33.3% and 32.1%, respectively, compared to those of the hybrid solar cells without LiI doping. We believe that the photovoltaic performance of ultraviolet responsive solar cell will be further improved by optimizing preparation conditions.

Stability of hybrid solar cells

Fig. 7 shows the stability of the hybrid solar cells with P3HT/TiO2 and P3OT/TiO2 stored in dark and soaked in full sunlight. Seen from Figs. 7A and 7B, with the extension of storing, the photovoltaic parameters, such as JSC, VOC, FF and η, first increase and then decrease, which is due to the fact that the penetration and full contact of P3HT or P3OT with TiO2 needs some time. The variety trends of the photovoltaic parameters for both cells are almost similar, after being tested for 168 h (one week), the FF, VOC, JSC and η values decrease about 8.1%, 5.8%, 13.5% and 24.1%, respectively.

As shown in Figs. 7C and 7D, when the hybrid solar cells without being sealed were continuously soaked in a full sunlight, the VOC values kept stable within test 400 sec and JSC values increase within 20 sec and then kept stable. It indicates that the hybrid solar cells have good stability and durability.

Discussion

In summary, using poly (3-hexylthiophene) (P3HT) or poly (3-octylthiophene-2, 5-diyl) (P3OT) as hole conductor and TiO2 anatase nanocrystal as ultraviolet light absorber and electronic conductor, novel ultraviolet responsive inorganic-organic hybrid solar cells based on FTO/TiO2/P3HT/Pt and FTO/TiO2/P3OT/Pt are fabricated, respectively. Under ultraviolet light irradiation with an intensity of 100 mW·cm−2, the two hybrid solar cells obtain light-to-electrical energy conversion efficiency of 0.96% and 0.81%, respectively. Doping ionic salt in the polymer can improve the photovoltaic performance of the solar cells. Two hybrid solar cells doped with 1.0 wt.% LiI achieve the energy conversion efficiency of 1.28% and 1.16%, which are increased by 33.3% and 32.1% compared to those of the hybrid solar cells without LiI doping, respectively. The photovoltaic performance of the ultraviolet responsive solar cell should be further improved by optimizing components and preparation conditions. No ultraviolet responsive solar cell has been reported so far. The aforementioned results open a novel sunlight irradiation field for solar energy utilization, demonstrate the feasibility of ultraviolet responsive solar cells and provide a new route for enhancing the photovoltaic performance of solar cells.

Methods

Materials

Poly(3-hexylthiophene) (P3HT, average Mn ~ 62000, purity 99.995%) was purchased from Fusol Material Co., Ltd. Taiwan. Ploy(3-octylthiophene-2, 5-diyl) (P3OT, average Mn ~ 25000, purity 99.995%) was purchased from Advanced Technology and Industrial Co., Ltd., Hong Kong. 1, 2-dichlorobenzene (CB), anhydrous ethanol (ETOH), isopropanol, nitric acid (HNO3), acetic acid (HAc), tetrabutyltitanate [Ti(OBu)4] and titanium tetrachloride (TiCl4) were analytic grade purity and purchased from Shanghai Chemical Agent Ltd, China. Polyethylene glycol with an average molecular weight of 20,000 (PEG-20000) and Triton X-100 were purchased from the same company. All reagents were used without further purification.

A conductive glass plate (FTO glass, fluorine-doped tin oxide over-layer, sheet resistance of 8 Ω/□, purchased from Hartford Glass Co., USA) was cut into 1 × 2 cm2 sheets and used as a substrate for precipitating TiO2 film.

Preparation of TiO2 film

A conductive glass sheet (FTO) was immersed in an isopropanol solution for 48 h to remove any surface impurities. It was then cleaned in a Triton X-100 aqueous solution, washed with ethanol and treated with a 50 mM TiCl4 aqueous solution at 70°C for 30 min to produce a good interfacial contact between the TiO2 layer and the conductive glass substrate.

A TiO2 colloid was prepared as described previously20,21,22. Tetrabutyltitanate (10 ml) was rapidly added to the mixed solution of distilled water (100 ml) and ETOH (100 ml) and white precipitate was formed immediately. The precipitate was filtered using a glass frit and washed with distilled water. Under vigorous stirring, the filter cake was added to aqueous solution (150 ml) containing 1 ml HNO3 and 10 ml HAc at 80°C, until the slurry became a translucent blue-white liquid. The blue-white liquid was autoclaved at 200°C for 12 h to form milky white slurry. The resultant slurry was concentrated to 1/4 of its original volume, then PEG-20000 (10 wt.% slurry) and a few drops of the emulsification agent of Triton X-100 were added to form a TiO2 colloid.

To reduce the recombination of the electrons on the conductive glass with P3HT or P3OT, a thin TiO2 blocking layer was deposited on the FTO glass substrate by immersing the glass in 0.15 M TiCl4 isopropanol solution for 12 h, followed by sintering at 450°C for 30 min in air. Subsequently, two TiO2 layers with particle sizes of 50 nm, thickness of 10 μm were coated on the blocking layer by using a doctor blade method and then sintered at 450°C for 30 min in air. The TiO2 film was immersed in 0.15 M TiCl4 isopropanol solution for 10 min again, followed by sintering at 450°C for 30 min in air to increase roughness and surface area. The active area of TiO2 film was controlled to be about 0.1 cm2.

Fabrication of hybrid solar cells

P3HT was dissolved in predetermined mass of 1, 2-dichlorobenzene solvent to form a conductive polymer solution with concentration of 20 g·L−1 under stirring at 45°C for 24 h23. Then under stirring, 25 mg of lithium iodide (LiI) was added in P3HT solution to form a doped P3HT solution (LiI, 1.0 wt.%).

P3HT was loaded on the TiO2 film by immersing the film in P3HT solution for 24 h. A hybrid solar cell was fabricated by injecting the doped P3HT solution into the aperture between the loaded TiO2 film electrode and a platinum-plated (Pt) counter electrode. The two electrodes were clipped together and cyanoacrylate adhesive was used as sealant. A hybrid solar cell FTO/TiO2/P3HT/Pt thus was obtained. And the detailed fabrication procedure was described by us elsewhere22. For comparison, a hybrid solar cell of FTO/TiO2/P3OT/Pt also was fabricated by the same method as an FTO/TiO2/P3HT/Pt solar cell. The schematic structure diagram of the hybrid solar cell is shown in Fig. 1C.

Measurements

The X-ray diffraction (XRD) patterns of the samples were recorded by using an X-ray diffractometer (BRUKER D8, Karlsruhe, Germany) with CuKa radiation (λ = 1.5405 Å). The 2θ angle of the XRD spectra was recorded at a scanning rate of 3° min−1. The morphology of TiO2 was observed using a scanning electron microscope (Hitachi S-4800, Japan). The samples for SEM were prepared by spray gold processing (E-1010, Ion Sputter, Hitachi, Japan). The ultraviolet–visible (UV–vis) absorption spectra of samples were measured with an ultraviolet-visible spectrophotometer (UV-2550, Shimadzu, Japan). Fourier transform infrared (FTIR) spectra were identified using a spectrophotometer (470 FTIR, Nicolet Nexus, Japan) equipped with an IR data management system. The conductivities of the samples were measured by using model DDB-6200 digitized conductivity meter (Shanghai Reici Instrument Factory, China). The instrument was calibrated with 0.01 M KCl aqueous solution prior to experiments.

The photovoltaic performance of the hybrid solar cells was determined by measuring photocurrent-photovoltage (J–V) characteristic curve under ultraviolet light irradiation. The ultraviolet light source came from a xenon arc lamp (CHFXM500, Trusttech Co., Ltd, China) with a filter stop (ZWB3, Optical Co., Ltd. Changchun, China) to remove the light with the wavelength higher than 420 nm. This J–V measurement was implemented in ambient atmosphere by using an electrochemical measurement system (CHI660D) to control the voltage and current. The fill factor (FF) and the light-to-electrical energy conversion efficiency (η) of the solar cell were calculated according to the following equations2:

where JSC is the short-circuit current density (mA·cm−2), VOC is the open-circuit voltage (V), Pin is the incident light power and Jmax (mA·cm−2) and Vmax (V) are the current density and voltage at the point of maximum power output in the J–V curves, respectively.

The spectral response of the solar cell was determined by measuring the wavelength dependence of the incident photon-current efficiency (IPCE) and focusing light from one xenon lamp through monochromator (PXJ43B11, Japan) onto the cell. The IPCE value of the solar cell was calculated according to the following equation2:

References

Cook, T. R. et al. Solar energy supply and storage for the legacy and non legacy worlds. Chem. Rev. 110, 6474–6502 (2010).

Hagfeldt, A., Boschloo, G., Sun, L., Kloo, L. & Pettersson, H. Dye-sensitized solar cells. Chem. Rev. 110, 6595–6663 (2010).

Gratzel, M. Photoelectrochemical cells. Nature 414, 338–344 (2001).

Linsebigler, A. L., Lu, G. & Yates, J. Photocatalysis on TiOn surfaces: Principles, mechanisms and selected results. Chem. Rev. 95, 735–758 (1995).

Fujishima, A. & Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 238, 37–38 (1972).

Gunes, S., Neugebauer, H. & Sariciftci, N. S. Conjugated polymer-based organic solar cells. Chem. Rev. 107, 1324–1338 (2007).

Sariciftci, N. S., Smilowitz, L., Heeger, A. J. & Wudl, F. Photoinduced electron transfer from a conducting polymer to buckminsterfullerene. Science 258, 1474–1476 (1992).

Huynh, W. U., Dittmer, J. J. & Alivisatos, A. P. Hybrid nanorod-polymer solar cells. Science 295, 2425–2427 (2002).

Previti, F., Patane, S. & Allegrini, M. Polymer heterostructures with embedded carbon nanotubes for efficient photovoltaic cells. Appl. Surf. Sci. 255, 9877–9879 (2009).

Ji, J., Lin, Y., Lu, H., Wang, L. & Wei, S. Synthesis and photoluminescence of poly(3-hexylthiophene)/titania nanostructured hybrids. Thin Solid Films 511–512, 182–186 (2006).

Wang, Y. & Rubbner, M. F. Stability studies of the electrical conductivity of various poly (3-alkylthiophenes). Synth. Met. 39, 153–175 (1990).

Lin, J. & Dudek, L. Synthesis and properties of poly(2,5-thienylene). J. Polym. Sci. B 18, 2869–2873 (1980).

Nicho, M., Hu, H., Lopez-Matab, C. & Escalantec, J. Synthesis of derivatives of polythiophene and their application in an electrochromic device. Sol. Energy Mater. Sol. Cells 82, 105–118 (2004).

Senadeera, G., Kitamura, T., Wada, Y. & Yanagida, S. Photosensitization of nanocrystalline TiO2 films by a polymer with two carboxylic groups, poly(3-thiophenemalonic acid). Sol. Energy Mater. Sol. Cells 88, 315–322 (2005).

Yue, G., Wu, J., Huang, Y., Xiao, Y. & Lan, Z. Iodine/iodide-free and polymer heterojunction-sensitized hybrid solar cell. Funct. Mater. Lett. 5, 1260004 (2012).

Kao, C. et al. Doping of conjugated polythiophenes with alkyl silanes. Adv. Funct. Mater. 19, 1906–1911 (2009).

McCullough, R., Sristramnagle, T., Williams, S., Lowe, R. & Jayaraman, M. Self-orienting head-to-tail poly(3-alkylthiophenes): new insights on structure-property relationships in conducting polymers. J. Am. Chem. Soc. 115, 4910–4911 (1993).

Sun, B., Jones, J., Burford, R. & Skyllas-Kazacos, M. Stability and mechanical properties of electrochemically prepared conducting polypyrrole films. J. Mater. Sci. 24, 4024–4029 (1989).

Singh, R., Singh, R., Kumar, J., Kant, R. & Kumar, V. The origin of DC electrical conduction and dielectric relaxation in pristine and doped poly(3-hexylthiophene) films. J. Polym. Sci. B 48, 1047–1053 (2010).

Wu, J. et al. An all-solid-state dye-sensitized solar cell-based poly(N-alkyl-4-vinyl-pyridine iodide) electrolyte with efficiency of 5.64%. J. Am. Chem. Soc. 130, 11568–11569 (2008).

Wu, J. et al. A novel thermosetting gel electrolyte for stable quasi-solid-state dye-sensitized solar cells. Adv. Mater. 19, 4006–4011 (2007).

Wu, J. et al. Application of a polymer heterojunction in dye-sensitized solar cells. Electrochim. Acta 55, 5798–5802 (2010).

Zhou, E. et al. Effect of branched conjugation structure on the optical, electrochemical, hole mobility and photovoltaic properties of polythiophenes. J. Phys. Chem. B 110, 26062–26067 (2006).

Acknowledgements

The authors acknowledge the financial joint support by the National High Technology Research and Development Program of China (No. 2009AA03Z217) and the National Natural Science Foundation of China (nos. 90922028, U1205112, 50842027).

Author information

Authors and Affiliations

Contributions

J.W. designed the device and experiments, G.Y., Y.X., Z.L. and Q.T. carried out most experiments. J.W. wrote the manuscript and all authors discussed the results and contributed to revisions.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Wu, J., Yue, G., Xiao, Y. et al. An ultraviolet responsive hybrid solar cell based on titania/poly(3-hexylthiophene). Sci Rep 3, 1283 (2013). https://doi.org/10.1038/srep01283

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep01283

This article is cited by

-

Continuous tuning of the plasmon resonance frequency of porous gold nanoparticles by mixed oxide layers

Journal of Porous Materials (2020)

-

Layer-by-layer deposition of TiO2–ZrO2 electrode sensitized with Pandan leaves: natural dye-sensitized solar cell

Materials for Renewable and Sustainable Energy (2019)

-

Significantly improved efficiency of organic solar cells incorporating Co3O4 NPs in the active layer

Applied Nanoscience (2018)

-

Synthesis and fabrication of TiO2–ZnO nanocomposite based solid state dye sensitized solar cell

Journal of Materials Science: Materials in Electronics (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.