Abstract

Hydrogen bond is a typical noncovalent bond with its strength only one-tenth of a general covalent bond. Because of its easiness to fracture and re-formation, materials based on hydrogen bonds can enable a reversible behavior in their assembly and other properties, which supplies advantages in fabrication and recyclability. In this paper, hydrogen bond nanoscale networks have been utilized to separate water and oil in macroscale. This is realized upon using nanowire macro-membranes with pore sizes ~tens of nanometers, which can form hydrogen bonds with the water molecules on the surfaces. It is also found that the gradual replacement of the water by ethanol molecules can endow this film tunable transport properties. It is proposed that a hydrogen bond network in the membrane is responsible for this switching effect. Significant application potential is demonstrated by the successful separation of oil and water, especially in the emulsion forms.

Similar content being viewed by others

Introduction

The unique smartness of switchable materials has encouraged great research interests due to the fascinating applications in chemistry1,2,3,4,5,6, physics7, biology8 and many other disciplines based on the good controllability and reversibility. For constructing the internal structure of these interesting materials, noncovalent bonds, for example hydrogen bond9,10,11,12,13,14,15,16,17,18,19, can usually play crucial roles because of their easiness to fracture and re-form with even a little bit energy needed. In this article, a hydrogen bond nanoscale network throughout a nanowire membrane has been utilized to separate water and oil in macroscale, which shows excellent responsive effect to water and ethanol which we call ‘keys’. The switching effect can be easily controlled by these keys that the ethanol turned it on while water turned it off. Based on this controllable performance, the successful separation of oil and water was realized, especially in the emulsion forms. This application, to some extent, is prospective to open a new way in connecting nano-materials to macro-materials via noncovalent bonds.

Water and nonpolar liquids like cyclohexane and carbon tetrachloride are immiscible in nature, so in principle water film can be utilized to prevent the flow of nonpolar liquid and find its application in vast areas including demulsification and separation of oil and water. However it is impossible to realize in macroscale world because the shape of liquid water will change upon even a very small pressure induced by the flow of nonpolar liquid so that the water film will collapse. In real applications, most existing methods for separation of water/oil are based on amphipathic properties20,21; and these methods usually need to use a certain kind of polymer or organic matter to change the surface properties of the separation mediums into super-hydrophobic or super-hydrophilic ones. To some extent, they are multistep and energy-consuming processes. Besides, the control over the switchable transport performance was not so easy or even impossible in some cases. In this report, we find that when the size of the water film is confined in tens of nanometers, it can effectively prevent the transport of nonpolar liquids. This is realized upon the using of the MnO2 nanowire macro-membranes with pore sizes ~tens of nanometers, which can form hydrogen bonds with the water molecules on the surfaces of the nanowires throughout the membrane. It is also found that when the membrane was treated by water and ethanol alternately, the gradual replacement of the water molecules by ethanol molecules can endow this film tunable transport properties towards nonpolar liquids. It was proposed that a hydrogen bond network in the membrane was responsible for this switching effect, which was subsequently confirmed by V2O5 nanobelt25 membrane.

Results

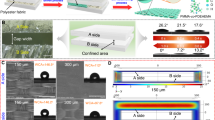

First, we report the synthesis of the inorganic membranes of α-MnO2 nanowires (NWs) prepared by a modified method developed by Wang et al22. The composing NWs with high aspect ratios were about 15 nm in diameter and tens of micrometers in length. These NWs were single crystals as indicated by the HRTEM image (Fig. S1 in Supplementary Information). The fabricating procedure and the cyclic utilization process of the membrane are shown in Fig. 1 a–c. As is displayed, the membrane can be easily obtained by means of suction filtration from the NWs-suspension produced by ultrasonication. After being used, it can be re-dispersed into NWs-suspension in water again by ultrasonication and thus re-form a new membrane by suction filtration, by which it can be recycled numerous times in utilization without any damage. The as-prepared NWs-membranes are free-standing, flexible with excellent mechanical strength. The thickness of the membranes could be easily tuned by using different amount of MnO2 nanowires (Details can be found in experimental section): for example, 80 ml of this suspension could give a ~70 μm membrane while 60 ml of this suspension could produce a ~45 μm membrane (Fig. 1 d–f.); a similar membrane was obtained by V2O5 nanobelts according to the same procedure as the case of MnO2 (Fig. 1g–h.). The membranes were also found as porous by filtration test of Au nanoparticles with different sizes (Fig. S2 in Supplementary Information).

The fabrication process and images of the membrane.

(a)–(c) recycling process for fabrication and utilization of the membrane. (a) the suspension of the MnO2 NWs produced by ultrasonic treatment. (b) the process of suction filtration for the suspension to make the membrane. (c) the as-obtained MnO2 nanowire membrane. (d) the SEM image showing the MnO2 nanowires constructing the membrane. (e)–(f) the edge view and the cross section view of the membrane. (g) the as-obtained V2O5 nanowire membrane. (h) the SEM image showing the V2O5 nanowires constructing the membrane.

Water, which exhibited an apparent contact angle (δ) of 0 degree on this membrane (Fig. 2 a, water with different pH values of 2, 4, 6, 8 and 10 has been tried and similar results have been obtained), passed through it easily. This hydrophilicity was imparted by the aqueous environment during the preparation of the nanowires and the simultaneous wetting of the construction process of the membrane by water. It is worth to note that cyclohexane on the membrane also spread out very quickly and its δ (including a class of other non-polar liquids) showed nearly 0 degree as well (the behavior of a cyclohexane droplet on the membrane is shown in Fig. 2 b); as a result they could pass the dry membrane smoothly. The same situation also occurred to V2O5 nanobelt membrane that the droplet of either water or cyclohexane on the membrane spread out very quickly and both contact angles showed 0 degree (Fig. 2 c,d). This amphiphilic feature is quite different from the traditional commercial-available membranes, which usually have specific hydrophilic or hydrophobic surface properties and are impossible to be tuned continuously and reversibly from hydrophilic to hydrophobic in a facile way.23 While the nanowire membrane in dry state remained as permeable for both polar and nonpolar liquids, it was found that the transport properties of this membrane could be easily tuned by a facile wetting process. When the membrane was wetted by water at first (immersed for even less than 1 second at room temperature without any other treatment), cyclohexane could no longer pass through it in spite of its porous network structure, even under the pressure of suction filtration with the vacuum degree −0.1 MPa. Further experimental evidences demonstrated that after the membrane was treated by the keys (immersed for less than 1 second at room temperature without any other treatment), taking ethanol as an example, it became ‘open’ and let cyclohexane pass through smoothly. In contrast, when further treated with water, the membrane became ‘closed’ again and cyclohexane can no longer pass through it. When treated by ethanol and water alternately, the membrane could be switched on and off in turn. More interestingly, the degree of the ‘switch’ could be successfully controlled by changing the ratio of EtOH/H2O (r) in the water and ethanol mixed solution. By studying the relationship between r and the extent of the switch, we got the working curves of this switch effect between r and the flow rate of cyclohexane, benzene, dichloromethane and through the membrane (Fig. 2, e, MnO2 membrane; f, V2O5 membrane), respectively. We can learn from the curve that there exists a critical value of r, namely, r = 0.5. Only when r is greater than 0.5 can this switch be turned on; in this working range, the extent of the switching effect increases with r.

Contact angles and working curves of the membranes.

(a)–(d) spreading and permeating behaviors of a droplet on the nanowire membrane. (a) a water droplet spreads quickly on a MnO2 membrane within only 7s. (b) a cyclohexane droplet spreads quickly on this membrane within only 4s. (c) a water droplet spreads quickly on a V2O5 membrane within only 4s. (d) a cyclohexane droplet spreads quickly on this membrane within only 0.3s. (e)–(f) working curves of the switch effect between r and flow rate (ml.min−1.m−2) of different organic liquids with EtOH as the ‘key’. (e). working curves of MnO2 membrane. (f) working curves of V2O5 membrane.

In order to investigate this interesting phenomenon further, we tried many more kinds of polar organic solvents and the results turned out that a class of polar organic solvents such as alcohol, acetone and acetonitrile also had the same effect on the switch-adjusting of the transport performance of the membrane as ethanol. Similarly, not only the transport performance of cyclohexane could be controlled by these ‘keys’, but also the flow of a class of non-polar organic solvents through the membranes could be controlled, such as cyclohexane, n-hexane, benzene and carbon tetrachloride etc., according to which we can conveniently switch the ‘on/off’ states. Fig. 3, (a) and (b) shows obviously that the oil (here we used cyclohexane and carbon tetrachloride) were held back by the MnO2 membrane when the switch was ‘off’ (the membrane has been treated with H2O). For clarity, we used blue water colored by Cu(NO3)2, the whole process underwent a suction filtration treatment with the vacuum degree –0.1 MPa. We can clearly see that after filtration, blue water went through the membrane thoroughly while the oil remained still on the membrane no matter the water layer was at the bottom (video-1 in Supplementary Information) or on the top of the two phase; specially, in this separation process, when CCl4 served as the oil lying on the bottom layer, we needed to give a disturbance to the mixture system during the suction filtration process; once bringing the water (even a very little amount) into contact with the membrane, water lying on the upper layer would then follow and break into the CCl4 layer to reach the membrane quickly and continuously; by this way, a water passage in the CCl4 layer formed and the water finally got through the membrane successfully (video-2 in Supplementary Information). We have also tuned the pH value of the water in the range of 2–10 and similar experimental results were observed, which demonstrated that pH value of solvents has little influence on the switchable performance of the membrane. From this sharp contrast of different behaviors of water and oil on the membrane, the separation of water/oil was well confirmed.

The process of separation of oil and water. Here, water colored blue by Cu(NO3)2 was used for clarity.

(a) cyclohexane was used as a kind of oil lying on the upper layer while water at the bottom layer. After suction filtration, the cyclohexane was stopped on the membrane while the blue aqueous solution passed through the membrane. (b) a process similar to that in (a) except that carbon tetrachloride was used as another kind of oil lying at the bottom layer while water at the upper layer. (c) emulsion, taking water/cyclohexane system as an example, was successfully separated.

Besides these water/oil mixture with apparent phase interfaces, we further found that the water-cyclohexane emulsion was also successfully separated into pure water and oil by using this nanowire membrane. As is shown in Fig. 3c, the original milky white emulsion was quickly separated into two kinds of transparent liquids through suction filtration process in 5 min. The emulsion underwent a demulsification process and then the water phase went through the membrane while the oil phase was held off on the membrane. The membrane remained intact during the whole process (video-3 in Supplementary Information).

Discussion

We know that many materials would perhaps display some fascinating properties in nanoscale, as compared with their physical and chemical properties in macro scale. Here the fine NWs interweaved with each other to form a porous membrane with the pore size in tens of nanometers. We found that H2O molecule, a well-known and most ordinary molecule, played a crucial role in the switch effect of our nanowire membrane. From the crystallographic structure of MnO2 (Fig. 4(7)), we know that there are innumerous oxygen atoms exposed on the surfaces of these composing MnO2 NWs. It is these oxygen atoms that serve as the hydrogen bond acceptors (with water molecules as the donors), supplying the binding sites for connecting water molecules due to the attractive interaction between the hydrogen bond acceptors and donors. Consequently, a dense water molecule layer coats on the surfaces of the MnO2 NWs (Fig. 4, a). Water molecules of this layer not only serve as hydrogen bond donors for surface oxygen atoms but also as hydrogen bond acceptors for even more water molecules, which eventually produces a ‘hydrogen bond network film’ in the pores throughout the membrane and the whole structures are stabilized by these hydrogen bonds. As a control experiment, the situation of V2O5 nanobelt membrane was tested and the permeating behaviors towards different kinds of liquids were found the same as those of MnO2 nanowire membrane which was stated above. In order to confirm the hydrogen bond mechanism proposed in this manuscript, the crystallographic structure of V2O5 was investigated (Fig. 4. c and d); from its crystallographic structure, we know that there are also a large number of oxygen atoms exposed on the surfaces of the nanobelts, which can exactly act as hydrogen bond acceptors. Consequently, a ‘hydrogen bond network film’ can be easily formed with water or ethanol in the same way as that of MnO2. All the results and analysis of this control experiment confirmed the hypothesis. The results of FT-IR also confirmed this fact. From the spectrum (Fig. 4, b), an obvious peak at 3403 cm−1 was observed for the wetted membrane compared with the dried one, showing the existence of water molecule with the formation of H-bond. Besides, the vibration peak of ‘Mn-O’ at 539 cm−1 for the dried pure MnO2 underwent an apparent red shift to 530 cm−1 after the membrane was wetted, indicating that the chemical environment of ‘Mn-O’ in the pure MnO2 had been changed after the membrane was wetted, turning into ‘Mn-O…H-O-H’.

(a) Schematic diagram for the switch effect of the membrane. (1) the as-obtained macroscopic membrane. (2) The randomly arranged NWs. (3) A higher magnification of (2), by which innumerous nanopores were formed. (4) Water films formed in the nanopores based on H-bond. (5) Hydration surface of the NWs based on H-bond. (6) Intrinsic structure of the MnO2 NWs. (7–10) The mechanism of the recycle process of the membrane between hydration and alcoholization. (7) The Crystal structure of the MnO2 showing a (110) plane on which a lot of oxygen atoms exposed to the surface to provide binding sites of H-bond. (8) A hydration surface. (9) An alcoholization surface. (10) Water can pass through the membrane smoothly while oil cannot when the ‘switch’ was closed. (11) Oil could pass through the membrane smoothly when the ‘switch’ was open. (b) the IR spectrum of the membrane. (c–d) the Crystal structure of the V2O5 from different view.

It is this attracting ability that induces the construction of a dense ‘hydrogen bond network’ which has the potential to interact with the surrounding molecules. We believe that this kind of noncovalent bond plays a critical role in determining the fascinating switching properties of our prepared membrane and that it is this water film that helps to prevent cyclohexane (involving a class of non-polar solvents mentioned above) from passing through the membrane. In order to further confirm this hypothesis, a control experiment was carried out by drying the wet membrane and then cyclohexane transported through the membrane smoothly. Right after this, we re-wetted this membrane with water and at this time all the cyclohexane was stopped by the membrane completely again, which definitely demonstrated the key role of H-bond in this membrane. According to this hypothesis, the pore size of the membrane should be small enough, only by which can the hydrogen bond network film be maintained steadily. Therefore, another control experiment was carried out that an ordinary filter paper with the pore size about several micrometers was used in the experiment of separation of the emulsion mentioned above. As a result, the emulsion passed through smoothly and neither pure water nor cyclohexane was obtained (video-4 in Supplementary Information).

From the researching results above, we know that the above phenomenon was not limited to MnO2 NWs and V2O5 nanobelts. Actually, we also found similar switching effect in other NW membranes, for example Liang’s work (Carbonaceous Nanofiber)24, which at the same time can serve as evidences of the hydrogen bond mechanism proposed above. Actually, the forming and breaking of the hydrogen bond in water makes a dynamic equilibrium and water molecules exist in the form of clusters with different numbers of molecules ((H2O)n) which was researched at unprecedented levels26,27. When the water-wetted membrane was treated with ethanol, the ethanol molecules would immediately mix with the water cluster system to kick off a hydrogen-bond rearrangement process, forming a new cluster system28 (Fig. S3 in Supplementary information). At the same time, many other ethanol molecules would be captured by those oxygen atoms exposing on the surfaces of the NWs because of the formation of hydrogen bond. Consequently the water layer coating on the surface of NWs would be easily replaced by an ethanol layer and the water film between the pores in the membrane would be finally replaced by an ‘ethanol film’ throughout the membrane in the same way as that of water film mentioned above (Fig. 4a, (9)). Because the oxygen atoms and hydrogen atoms in ethanol connected together to form hydrogen bonds, the lipophilic ethyl group was exposed to the surface of the NWs, which made the cyclohexane easily pass through. Obviously, the degree of the switch should be controlled by the ratio of water and ethanol of water/ethanol mixture solution, which was verified by the control experiments. When water was more than ethanol, the effect of water dominated the result and the switch lay ‘off ’. However, when ethanol was more than water, the situation would be completely opposite and the switch would be turned ‘on’. From this mechanism, we believed that the ‘water film’ and the ‘ethanol film ’ could be managed to transform into each other simply by treating the membrane with water and ethanol, respectively, which reasonably explained the switching effect of those non-polar organic solvents mentioned above.

This kind of switchable nanowire-membrane materials is of great promise, primarily due to the excellent separation effect of water and oil based on hydrogen bond network---the result of a typical noncovalent interaction. Weak though this noncovalent bond is, it’s extremely sensitive to hydrogen bond donor and acceptor, which makes the switchable performance of the membrane unprecedentedly convenient compared with reports in previous literatures20,21,29, just by using water and ethanol alternately. It has shown how to enable the connection between nanoscale and macro-scale to come true by utilizing noncovalent bonds.

Methods

Chemicals

All the chemicals during the reaction were used as received without additional purification. The 3-D macro-assembly structure is prepared.

Synthesis of MnO2 NWs

According to a modified method of Wang22, briefly, MnSO4.H2O (0.008 mol) and an equal amount of ammonium per sulfate ((NH4)2S2O8) were put into 36 ml distilled water under continuous stirring at room temperature to form a transparent solution, then, (NH4)2SO4 (0.023 mol) was added into the reaction system, which was then transferred into a 40 ml Teflon-lined stainless steel autoclave, sealed and maintained at 180°C for 12 h.

Preparation of NWs-membrane

As is shown in Fig. 1.A, the process can be briefly described as follows: A black homogeneous nanowire suspension is prepared by dispersing the above as-obtained sample (0.008 mol MnSO4 as the reactant) in 400 ml deionized water by ultrasonic processing. We set the total ultrasonic time to 1.0 hour, but this period of time is not continuous; instead, it is 5 seconds on and 5 seconds off, alternately. That is to say, the effective time for ultrasonic processing was 0.5 hour. At the same time, the intensity of ultrasonic processing was 150 watt, with the frequency 20 KHZ and voltage 203 volt. Then the as-obtained nanowire suspension is filtered by suction filtration through a filter paper to produce a sheet of membrane; every time when we produce the membrane, the suspension with this concentration was used; the pore size of the filter paper arranges 30~50 μ m with intermediate filter speed. The diameter is 7 cm and the surface area is 38.46 cm2 calculated according to the diameter. The resulting piece of membrane is mechanically flexible and can be easily detached from the filter paper without any damage. During the process of paper making, no chemical agents, such as dispersing or reinforcing agents, were used.

The preparation of the emulsion

To be specific, 0.05 g cetyltrimethyl ammonium bromide (CTAB) was added into 350 mL, then 80 mL cyclohexane was also added. Subsequently, this mixture was underwent an ultrasound treatment for 1.0 h. But please note that, this period of ultrasound time is also not continuous; instead, it is 5 seconds on and 5 seconds off, alternately. So, the effective time for ultrasonic processing was 0.5 hour. Besides, the intensity of ultrasonic processing was 150 watt, with the frequency 20 KHZ and voltage 203 volt. After this process, a kind of emulsion with good homogeneity was obtained which was shown in Fig. S4a; and its microstructure was shown in Fig. S4 (b).

The stability of the emulsion with time

In order to study the stability of the emulsion over time, a beaker of newly prepared emulsion(~75 mL) was left still for 12 hour at room temperature. After this period of time, we found that the emulsion kept almost unchanged except a slight demulsification (Fig. S4c) and its microstructure kept the same as newly prepared (Fig. S4b).

Preparation of V2O5 nanobelts according to Liu’s work25 as a control experiment for the switching effect

Briefly, 0.64 g was added to 36 mL water under continuous stirring to form a yellow solution. Then, 0.3 ml HNO3 was added. Once HNO3 was added into the system, the mixture immediately became clear with orange color. Then, the reaction mixture was transferred into a polytetrafluoroethylene autoclave which was then kept 180°C for 12 h. When the reaction completed and the autoclave was naturally cool to room temperature, a kind of product was obtained. The final product was washed with for three times and then with ethanol for one time. Then, the obtained product was dried at 60°C for 6 h. The membranes with different thickness can be obtained following the same procedure as that of MnO2 membranes.

References

Bissell, R. A., Cordova, E., Kaifer, A. E. & Stoddart, J. F. A chemically and electrochemically switchable molecular shuttle. Nature 369, 133–137 (1994).

Huiberts, J. N., Griessen, R., Rector, J. H., Wijnaarden, R. J., Dekker, J. P., deGroot, D. G. & Koeman, N. J. Yttrium and lanthanum hydride films with switchable optical properties. Nature 380, 231–234 (1996).

Gittins, D. I., Bethell, D., Schiffrin, D. J. & Nichols, R. J. A nanometre-scale electronic switch consisting of a metal cluster and redox-addressable groups. Nature 408, 67–69 (2000).

Adler, T. B., Borho, N., Reiher, M. & Suhm, M. A. Chirality-Induced Switch in Hydrogen-Bond Topology: Tetrameric Methyl Lactate Clusters in the Gas Phase. Angew. Chem. Int. Ed. 45, 3440–3445 (2006).

Jessop, P. G., Heldebrant, D. J., Li, X., Eckert, C. A. & Liotta, C. L. Green chemistry: Reversible nonpolar-to-polar solvent. Nature 436, 1102–1102 (2005).

Sun, T. L., Wang, G. L., Feng, L., Liu, B. Q., Ma, Y. M., Jiang, L. & Zhu, D. B. Reversible Switching between Superhydrophilicity and Superhydrophobicity. Angew. Chem. Int. Ed. 43, 357–360 (2004).

Ball, P. Smart materials: Off and on reflection. Nature 391, 232–233 (1998).

Ray, P. S., Jia, J., Yao, P., Majumder, M., Hatzoglou, M. & Fox, P. L. A stress-responsive RNA switch regulates VEGFA expression. Nature 457, 915–919 (2009).

Binder, W. H., Enders, C., Herbst, F. & Hackethal, K. Complex Macromolecular Architectures 53–95 (John Wiley & Sons (Asia) Pte Ltd, 2011).

Brammer, L., Swearingen, J. K., Bruton, E. A. & Sherwood, P. Hydrogen Bonding and Perhalometallate Ions: A Supramolecular Synthetic Strategy for New Inorganic Materials. Proc. Natl Acad. Sci. USA 99, 4956–4961 (2002).

Jeffrey, G. A. An Introduction to Hydrogen Bonding 184–202 (Oxford Univ. Press, 1997)

Krieg, E., Weissman, H., Shirman, E., Shimoni, E. & Rybtchinski, B. A recyclable supramolecular membrane for size-selective separation of nanoparticles. Nat Nano 6, 141–146 (2011).

Kuznetsova, N., Rau, D. C., Parsegian, V. A. & Leikin, S. Solvent hydrogen-bond network in protein self-assembly: solvation of collagen triple helices in nonaqueous solvents. Biophys. J. 72, 353–362 (1997).

Liu, Y., Hu, C., Comotti, A. & Ward, M. D. Supramolecular Archimedean Cages Assembled with 72 Hydrogen Bonds. Science 333, 436–440 (2011).

MacGillivray, L. R. & Atwood, J. L. A chiral spherical molecular assembly held together by 60 hydrogen bonds. Nature 389, 469–472 (1997).

Madueno, R., Raisanen, M. T., Silien, C. & Buck, M. Functionalizing hydrogen-bonded surface networks with self-assembled monolayers. Nature 454, 618–621 (2008).

Prins, L. J., Huskens, J., de Jong, F., Timmerman, P. & Reinhoudt, D. N. Complete asymmetric induction of supramolecular chirality in a hydrogen-bonded assembly. Nature 398, 498–502 (1999).

Torres, R. A. & Bruice, T. C. Interresidue Hydrogen Bonding in a Peptide Nucleic acid RNA Heteroduplex. Proc. Natl Acad. Sci. USA 93, 649–653 (1996).

Crabtree, R. H. A New Type of Hydrogen Bond. Science 282, 2000–2001 (1998).

Xue, Z. X., Wang, S. T., Lin, L., Chen, L., Liu, M. J., Feng, L. & Jiang, L. A Novel Superhydrophilic and Underwater Superoleophobic Hydrogel-Coated Mesh for Oil/Water Separation. Adv. Mater. 23, 4270–4273(2011).

Huang, X. & Lim, T. T. Performance and mechanism of a hydrophobic-oleophilic kapok filter for oil/water separation. Desalination 190, 295–307(2006).

Wang, X. & Li, Y. Selected-Control Hydrothermal Synthesis of α- and β-MnO2 Single Crystal Nanowires. J. Am. Chem. Soc. 124, 2880–2881 (2002).

García-Payo, M. C., Izquierdo-Gil, M. A. & Fernández-Pineda, C. Wetting Study of Hydrophobic Membranes via Liquid Entry Pressure Measurements with Aqueous Alcohol Solutions. J Colloid Interface Sci. 230, 420–431 (2000).

Liang, H. W., Cao, X., Zhang, W. J., Lin, H. T., Zhou, F., Chen, L. F. & Yu, S. H. Robust and Highly Efficient Free-Standing Carbonaceous Nanofiber Membranes for Water Purification. Adv. Funct. Mater. 21, 3851–3858 (2011).

Liu, J., Wang, X., Peng, Q. & Li. Y. . Vanadium Pentoxide Nanobelts: Highly Selective and Stable Ethanol Sensor Materials. Adv.Mater. 17, 764–767(2005).

Fellers, R. S., Leforestier, C., Braly, L. B., Brown, M. G. & Saykally, R. J. Spectroscopic Determination of the Water Pair Potential. Science 284, 945–948 (1999).

Liu, K., Brown, M. G., Cruzan, J. D. & Saykally, R. J. Terahertz Laser Spectroscopy of the Water Pentamer: Structure and Hydrogen Bond Rearrangement Dynamics. J. Phys. Chem. A 101, 9011–9021 (1997).

Liu, Y., Luo, X., Shen, Z., Lu, J. & Ni, X. Studies on Molecular Structure of Ethanol-Water Clusters by Fluorescence Spectroscopy. Optical Rev. 13, 303–307 (2006).

Yuan, J. K., Liu, X. G., Akbulut, O, Hu, J. Q., Suib, S. L., Kong, J. & Stellacci, F. Superwetting nanowire membranes for selective absorption. Nature Nanotech 3, 332–336 (2008).

Acknowledgements

This work was supported by NSFC (91127040, 20921001) and the State Key Project of Fundamental Research for Nanoscience and Nanotechnology (2011CB932402).

Author information

Authors and Affiliations

Contributions

Y. L. performed the experiments, collected and analyzed the data and wrote the paper; J. F. H., P. P. W., G. L. X., B. X., S. H., W. C. Z., X. Q. L. and J. Z. helped with data analysis; X. W. conceived the experiments, analyzed results and wrote the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Video showing the separation process of cyclohexane and water

Supplementary Information

Video showing the separation process of carbon tetrachloride and water

Supplementary Information

Video showing the demulsification process over the membrane

Supplementary Information

Video showing the pass of emulsion through an ordinary filter paper

Supplementary Information

Supporting information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Long, Y., Hui, Jf., Wang, Pp. et al. Hydrogen Bond Nanoscale Networks Showing Switchable Transport Performance. Sci Rep 2, 612 (2012). https://doi.org/10.1038/srep00612

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep00612

This article is cited by

-

Recent progress in developing advanced membranes for emulsified oil/water separation

NPG Asia Materials (2014)

-

Fabrication of flexible α-MnO2 nanowire membranes with superior mechanical strength

Chinese Science Bulletin (2014)

-

Nanowire Membrane-based Nanothermite: towards Processable and Tunable Interfacial Diffusion for Solid State Reactions

Scientific Reports (2013)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.