Key Points

-

Describes the two commonly used materials for relining removable prostheses.

-

Informs the reader regarding the advantages and disadvantages of acrylic-based resilient lining materials and silicone-based resilient lining materials.

-

Introduces a new combination technique for relining removable prostheses.

Abstract

The two major types of resilient lining material include acrylic based lining material and silicone based lining material. Both these materials have few inherent disadvantages associated with them. A technique for overcoming the disadvantages of both the acrylic and silicone based lining materials by using them in a combination is presented in this article.

Similar content being viewed by others

Introduction

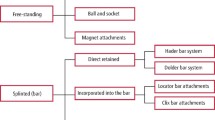

Resilient liners are an integral part of modern prosthodontics. They function as shock absorbers and are indicated for edentulous patients with sharp or atrophied alveolar ridges, thin atrophic mucosa with insufficient tolerance to the load transmitted by the dentures or who experience pain at nerve ending locations; Also indicated in cases of the formation of recurrent sore spots under the dentures, in cases in which the denture exhibits poor retention, for improving the function and feel of obturator and immediate dental prostheses, rehabilitating oral tissues before new dental prostheses fabrication, and maintaining support and stability of a transitional prostheses during the healing phase of implants.1,2,3,4,5 These materials may be indicated for weeks, months or years.5Two major categories of available resilient lining materials include acrylic-based resilient liners (ABRLs) and silicone-based resilient liners (SBRLs)5; each may be chemically activated or heat activated.6

Composed of poly methyl methacrylate or poly ethyl methacrylate, acrylic-based resilient liners chemically bond to methacrylate resins.7 This bond allows ABRLs to adhere to methacrylate denture bases as well as to itself, permitting incremental application. Slight alterations in the powder–liquid ratio allows control of material viscosity to facilitate the needs of varying clinical condition. However, sorption and solubility rates of ABRLs decrease their longevity and colour stability (due to the loss of plasticiser and other soluble materials into the water and water absorption by the polymer)8,9,10 while increasing the bacterial biofilm formation.5 Most ABRLs are therefore applied as interim liners (used for a maximum of 2-4 weeks) in spite of their superior elasticity as they harden at a faster rate compared to the silicone liners.10 Removing, replacing and finishing the liner is a time intensive and a costly task, especially when multiple layers of liner are required to bring the prosthesis to full contour and/or greater thickness of lining material is desired.

SBRLs are dispensed as both, a single component system and a dual component system.11,12 A chemical bond does not occur between silicone and the denture base unless an adhesive is applied between them.11 While dispensing SBRLs may be easier and result in consistent viscosity of the material, their use is limited where incremental application may be required or change in viscosity may be needed. However, SBRLs remain a desirable material due to material longevity, sorption and solubility rate, colour stability and decreased biofilm formation as compared with ABRLs.5

Authors propose that the resilient acrylic lining material can be used in combination with the resilient silicone lining material. The acrylic lining material is applied first as it bonds to the denture base. Subsequent layers of acrylic based lining material is applied until the desired border contours are achieved. A layer of resilient silicone lining material is applied over the primed ABRL to improve surface quality, sorption, and solubility, resulting in less frequent maintenance intervals. This technique is especially indicated when the tissue contours are difficult to achieve in one application for a transitional prosthesis requiring extended wear. This article describes a novel technique of relining the mandibular denture for a patient with collapsed occlusal vertical dimension (OVD).

Technique

-

1

Evaluate extensions of the mandibular denture borders and occlusion, and correct over extended borders and/or occlusal interferences, as deemed necessary

-

2

Assess the occlusal vertical dimension (OVD) with the existing prosthesis using a measuring instrument (Ruler, Boley gauge). If the OVD is less than optimal, it can be increased up to a maximum of 3-4 mm with the reline procedure. If more than 4 mm increase in OVD is desired, the denture should be remade

-

3

Dentures are usually not maintained and need to be cleaned thoroughly before beginning any procedure (Fig. 1). Clean the denture and disinfect it by immersing it in 10% bleach solution for 30 minutes

-

4

Relieve the undercuts on intaglio surface with standard laboratory rotary instruments

-

5

Apply a suitable separating agent (Vaseline, masking tape) on the polished and the occlusal surface of the denture

-

6

Appropriately mix an acrylic based resilient lining material as per the manufacturer's instructions, evenly apply it on the intaglio surface of the denture and place the denture in the oral cavity

-

7

Guide the patient in centric closure until occlusal contacts are established and reverify the OVD. Ensure that the OVD is 1-2 mm lesser than the desired OVD

-

8

Perform border moulding movements for the patient to develop the physiological contours and extensions of the denture

-

9

After initial polymerisation of the acrylic based resilient lining material, remove it from the mouth and evaluate its accuracy

-

10

Trim the excess material with sharp scissors. Repeat the procedure as necessary to develop appropriate contours and border extensions (Fig. 2)

-

11

Next, apply a suitable silicone adhesive to the acrylic based resilient lining.

-

12

Spread and apply an even layer of silicone based resilient lining material on the surface of the ABRL, and place the denture in the oral cavity

-

13

Guide the patient in centric closure until occlusal contacts are established and ensure that the OVD has been reestablished as desired

-

14

Perform the border molding movements for the patient to develop the physiological contours and extensions of the denture

-

15

After initial polymerisation of the silicone soft reline material remove it from the mouth and evaluate its accuracy. Trim the excess with sharp scissors (Fig. 3)

-

16

This patient was recalled at two weeks (Fig. 4) and nine weeks (Fig. 5) to verify the fit of the denture and to ensure that the dual material liner was resilient and it did not debond from the denture. Patient was pleased with the fit, form and function of the relined prosthesis.

Discussion

The following properties are desired of resilient liners: long term softness, good bond strength, minimal sorption of oral fluids and minimal release of products, colour stability and resistance to biofilm formation.13 ABRLs display excellent viscoelastic behaviour and cushioning effect. And permit slight alterations in viscosity and incremental applications. But these materials are not durable over an extended period.5,11 A complex reline with acrylic liners may require 3-4 applications of acrylic based resilient lining material, each requiring about ten minutes to develop accurate contours of the intaglio surface and optimal extensions of the denture borders. Repeating this procedure every two weeks for an extended period can be a time consuming and costly obligation to the clinician and the patient. Maintenance intervals may be shortened for patients prone to poor hygiene and dry mouth. Some patients, especially in the geriatric population, may not be able to commit to frequent appointments due to health or transportation issues.

Many techniques for increasing the longevity of ABRLs have been published they include: application of surface coatings and/or modification of the mixing or the polymerisation processes.14,15,16 However, clinical studies need to be conducted to assess the validity and effectiveness of these procedures. Unfortunately, treatment materials are often chosen based on cost and convenience to the clinician. SBRLs may be chosen because of ease of dispensing, application and removal. Inaccurate contours and extensions, voids or poor adaptation of silicone liners may be tolerated because repairs are not possible without starting over.

Acrylic resins used for chairside reline procedures belong to chemically activated induction systems. As per Phillips17 when two reactants are mixed together they undergo a chemical reaction, to generate free radicals. A terminated reaction of an acrylic denture base can be reactivated to bond to an ABRL. However, polymerisation of the SBRL occurs by step growth. No chemical bond occurs between an acrylic denture base and a SBRL without an intermediary adhesive. The adhesive typically contains a polymeric substance dissolved in a solvent designed to chemically bond to both the acrylic denture and the SBRL18 In this article, the authors assumed that the adhesive would bond to the plasticised acrylic of the ABRL in a similar fashion since both the denture base and the acrylic liners are methacrylate based. However, this should be validated in future laboratory studies.

This technique provides a method to tackle the most difficult relines with incremental adaptation with ABRLs and still benefit from advantages of the surface characteristics of silicone liners. It is possible that plasticiser leaching is slowed when sealed within the SBRL, hence maintaining accurate contours for a longer period. This technique may provide an alternate option to decrease the debonding of SBRL. Further development of a dual material resilient liner may have a small but important role in dental materials. Randomised controlled trials must be formulated to study the long-term behaviour of the dual liner.

Summary

A combined technique of using both the acrylic-based and the silicone-based soft lining material has been proposed in this article. This technique for overcoming the disadvantages of both the acrylic- and silicone-based lining materials used in combination shows promise to treat specific complex reline cases requiring incremental layering and short recall intervals.

References

Bulad K, Taylor R L, Verran J, McCord J F . Colonization and penetration of denture soft lining materials by Candida albicans. Dent Mater 2004; 20: 167–175.

Mack P J . Denture soft linings: clinical indications. Aust Dent J 1989; 34: 454–458.

El-Hadary A, Drummond J L . Comparative study of water sorption, solubility, and tensile bond strength of two soft lining materials. J Prosthet Dent 2000; 83: 356–361.

Saber-Sheikh K, Clarke R L, Braden M . Viscoelastic properties of some soft lining materials. II Ageing characteristics. Biomaterials 1999; 20: 2055–2062.

Chladek G, Žmudzki J, Kasperski J . Long-term soft denture lining materials. Materials 2014; 7: 5816–5842.

Polyzois G L, Frangou M J . Influence of curing method, sealer, and water storage on the hardness of a soft lining material over time. J Prosthodont 2001; 10: 42–45.

al-Athel M S, Jagger R G . Bond strength of resilient lining materials to various denture base resins. Int J Prosthodont 1996; 9: 167–170.

Gronet P M, Driscoll C F, Hondrum S O . Resiliency of surface-sealed temporary soft denture liners. J Prosthet Dent 1997; 77: 370–374.

Murata H, Kawamura M, Hamada T, Saleh S, Kresnoadi U, Toki K . Dimensional stability and weight changes of tissue conditioners. J Oral Rehabil 2001; 28: 918–923.

Murata H, Hamada T, Toki K, Nikava H . Effect of addition of ethyl alcohol on gelation and viscoelasticity of tissue conditioners. J Oral Rehabil 2001; 28: 48–54.

Rodrigues S, Shenoy V, Shetty T . Resilient liners:a review. J Indian Prosthodont Soc 2013; 13: 155–164.

Kawano F, Dootz E R, Koran A, III, Craig R G . Comparison of bond strength of six soft denture liners to denture base resin. J Prosthet Dent 1992; 62: 368–371.

Mese A, Guzel K G . Effect of storage duration on the hardness and tensile bond strength of siliconeand acrylic resin-based resilient denture liners to a processed denture base acrylic resin. J Prosthet Dent 2008; 99: 153–159.

Gardner L K, Parr G R . Extending the longevity of temporary soft liners with a mono-poly coating. J Prosthet Dent 1988; 59: 71–72.

Nimmo A, Fong B J, Hoover C I, Newbrun E . Vacuum treatment of tissue conditioners. J Prosthet Dent 1985; 54: 814–817.

Corwin J O, Saunders T R . Temporary soft liners: a modified curing technique to extend liner longevity. J Prosthet Dent 1992; 68: 714–715.

Anusavice K J, Shen C, Rawls H R . Phillips' science of dental materials. Prosthetic polymers and resins. 12th ed. pp 474–498. Elsevier Saunders, 2013.

Atsu S, Keskin Y . Effect of silica coating and silane surface treatment on the bond strength of soft denture liner to denture base material. J Appl Oral Sci 2013; 21: 300–306.

Author information

Authors and Affiliations

Corresponding author

Additional information

Refereed Paper

Rights and permissions

About this article

Cite this article

Selecman, A., Ahuja, S. A combination technique for relining removable prostheses. Br Dent J 222, 841–843 (2017). https://doi.org/10.1038/sj.bdj.2017.490

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/sj.bdj.2017.490