Abstract

Organs-on-chips (OoCs) are systems containing engineered or natural miniature tissues grown inside microfluidic chips. To better mimic human physiology, the chips are designed to control cell microenvironments and maintain tissue-specific functions. Combining advances in tissue engineering and microfabrication, OoCs have gained interest as a next-generation experimental platform to investigate human pathophysiology and the effect of therapeutics in the body. There are as many examples of OoCs as there are applications, making it difficult for new researchers to understand what makes one OoC more suited to an application than another. This Primer is intended to give an introduction to the aspects of OoC that need to be considered when developing an application-specific OoC. The Primer covers guiding principles and considerations to design, fabricate and operate an OoC, as well as subsequent assaying techniques to extract biological information from OoC devices. Alongside this is a discussion of current and future applications of OoC technology, to inform design and operational decisions during the implementation of OoC systems.

Similar content being viewed by others

Introduction

The organ-on-a-chip (OoC) is an intriguing scientific and technological development in which biology is coupled with microtechnology1,2 to mimic key aspects of human physiology. The chip takes the form of a microfluidic device containing networks of hair-fine microchannels for guiding and manipulating minute volumes (picolitres up to millilitres) of solution3,4,5. The organ is a more relatable term that refers to the miniature tissues grown and residing in the microfluidic chips, which can recapitulate one or more tissue-specific functions. Although they are much simpler than native tissues and organs, scientists have discovered that these systems can often serve as effective mimics of human physiology and disease. OoCs comprise advanced in vitro technology that enables experimentation with biological cells and tissues outside the body. This is achieved by containing them inside vessels conditioned to sustain a reasonable semblance of the in vivo environment, from a biochemical and physical point of view. Working on the microscale lends a unique opportunity to attain a higher level of control over the microenvironment that ensures tissue life support, as well as a means to directly observe cell and tissue behaviour.

The OoC is a relatively recent addition to the toolbox of model biological systems available to life science researchers to probe aspects of human pathophysiology and disease. These systems cover a spectrum of physiological relevance, with 2D cell cultures the least relevant, followed in increasing order by 3D cell cultures, organoids and OoCs. Unsurprisingly, the use of model organisms such as mice and Drosophila physiologically exceeds engineered tissue approaches6,7. While biological complexity increases with physiological relevance in model organisms, this unfortunately leads to increased experimental difficulty. In vivo physiological processes are, in many ways, the least accessible to direct investigation in mice, humans and other mammals, despite significant advances in in vivo imaging. However, 2D and 3D cell cultures, such as spheroids and stem cell-derived organoids, sacrifice some aspects of in vivo relevance to facilitate experimentation. The OoC may be regarded as a bridging technology, offering the ability to work with complex cell cultures, while providing better engineered microenvironments to maximize the model.

Following on from early concepts, including animal-on-a-chip8, body-on-a-chip9 and breathing lung-on-a-chip10, research in the OoC and microphysiological systems fields has grown exponentially; evidenced by numerous excellent reviews published recently1,2,11. Recognition of OoC technology now extends far beyond university laboratories, driven by a need to better understand the human physiology underlying health and disease, and to find new approaches to improve the human condition. The World Economic Forum, for instance, selected the OoC as one of the top ten emerging technologies in 2016 (ref.12). This indicates that there is a strong need for human-like testing systems in the pharmaceutical industry and also a maturity of the OoC technologies to build them. Similarly, cosmetic, food and chemical industries stand to benefit enormously from OoC technologies for both production and testing, as society seeks humanized in vitro alternatives to animal testing.

OoC technology has benefited from converging advances in tissue engineering and microfabrication. Cell and tissue engineering have progressed from primitive 2D monocultures to complex 3D co-culture systems. Much emphasis has been placed on cellular microenvironment and geometrical arrangement, which enables cell manipulation to achieve cell polarization13,14,15, direct cell–cell interaction16,17 and propagation of chemical and electrical signalling18,19,20. Besides more advanced cell lines21, handling of primary cell sources and integrating them into artificial structures to promote organ-like functions has become more robust and reliable22,23. The emergence of induced pluripotent stem cell (iPSC) technology promises personalization of OoCs, as patient-specific cells can be differentiated from iPSCs obtained from individual donors and incorporated into the OoCs24,25,26. This allows study of disease phenotypes and drug responses in a patient-specific manner27.

The second driving force behind OoC success has been microsystems technology, the umbrella term for fabrication processes borrowed from integrated circuit industry. This approach uses lithographic pattern transfer to create structures in the nanometre and micrometre range28,29. Milestones in the development of OoCs are coupled with key technological developments in microsystems technology (Box 1). First used in analytical chemistry to engineer laboratory-on-a-chip devices3,30,31,32, microsystems technology has driven the development of both microfluidic and miniaturized actuator and sensing capabilities of OoCs. This has resulted in a shift to how in vitro bioreactor and cell biological systems are designed33,34, operated35,36,37,38,39 and monitored38,40,41. Gone are the typical flat polystyrene (PS) surfaces of the well plate or Petri dish. In vitro organ function can now be observed in chips individualized for the organ of interest. The chips are tailored to replicate cellular and extracellular features of the organ that can respond to biochemical and physical cues to maintain and simulate organ function. Crucially, OoC systems enable multi-parametric read-outs of organ function, providing a window into the integrated biology of humans and animals.

OoC technologies have advanced and matured substantially and it is predicted that interest will continue to grow in the coming years. However, for those new to the field, it may seem as if there are at least as many examples of OoCs in the literature as there are applications. Deciding where to start may be daunting. This Primer is designed to introduce the aspects of OoCs that need to be considered when developing an experiment. Important inventions over the past two decades are summarized, with the goal of illustrating how these have advanced the field. The Primer covers guiding principles and considerations to design, fabricate and operate an OoC as well as subsequent assaying techniques to extract biological information. Also included is a discussion of applications for OoC technology.

Experimentation

OoCs are designed to provide a suitably in vivo-like environment to guide a collection of cells to assemble into a 3D tissue capable of replicating one or more organ-level functions or to culture organotypic tissue to retain function. This section gives an overview of choices and considerations when designing an OoC tailored to a particular in vitro tissue experiment. OoC development should be guided by its context of use, which is related to the application area it will be used for, and defines the expected data42,43. The considerations, strategies and equipment needed for any general OoC experiment are reviewed in the order they present themselves when setting up a new experiment (Fig. 1). Finally, several case studies of single-organ and multi-organ OoCs provide insight into the development of these systems for specific applications in drug research.

a | Design and conceptualization of the organ-on-a-chip (OoC) system need to factor in number of organ models, how they are communicating and culture configuration of each organ model. b | Materials and fabrication technique need to be selected for construction of the OoC device, depending on scale, read-out functionality and feature resolution required. Sterilization and surface modification are tied to material choices. c | Choice of cell sources (primary, immortalized, stem cell-derived) will need to balance between biological functionality and practical operability of device. d | Finally, OoC system will be operated with peripheral equipment including pumps, incubators, sensors and microscopes to properly maintain, stimulate and monitor cells inside the OoC system. ECM, extracellular matrix; TEER, transepithelial electrical resistance.

Conceptualization and design

Single-organ systems often achieve a high degree of biological authenticity, allowing evaluation of the response of a specific organ to a compound or mixture of compounds. Multi-organ systems provide a framework to examine the potential interaction of one organ with at least one other, principally through the exchange of metabolites or soluble signalling molecules. Both single-OoC and multi-OoC systems are often referred to as microphysiological systems, as they are designed to model features of human or animal biology within a microscale culture44. Multi-OoC systems, which model the physiological systemic response in the body, are commonly referred to as body-on-a-chip35. The choice of a single-organ or multi-organ system depends on the desired functionalities needed for the system to be a good model of the physiological processes. The degree of complexity should be kept to the minimum required to represent the biological application without introducing unnecessary factors that make the system difficult to use and analyse. Multi-organ systems tend to involve more complex engineering design than single-organ systems. This allows control of the transport and distribution of culture media between the individual organs. Consequently, there is a trend in the OoC systems that have been developed, where single-OoCs are more biologically detailed models of an organ whereas multi-OoCs use less detailed organ models and focus on the systemic interactions between organs35.

The next design consideration is to decide the approach for forming functional tissues within the OoC. In a top-down or organotypic approach, a primary tissue — for example, an organ slice from a biopsy — or engineered tissue — such as a preformed organoid — is incorporated into the OoC system. In a bottom-up approach, isolated cells from primary, immortalized lines or stem cell-derived sources are cultured inside an a priori empty microfluidic environment, which supports the remodelling of the cells into a functional neo-tissue. The selected strategy informs the design of the OoC architectures. This serves a dual purpose of organizing and supporting cells within the OoC in a specific cell culture configuration, as well as routing fluids, such as the culture medium, to connect tissue components in a manner that reflects their connectivity in vivo. Although there are many variations of OoC device architectures, they can generally be divided into two classes, based on the organ system they create. The first comprises solid organ chips, where cells are cultured as 3D tissue masses that can interact with one another and the culture medium in a defined manner. Examples of this architecture type include micro-pillar and microwell arrays that are often used in liver (Fig. 1), tumour, cardiac and adipose OoCs11,45. The second class contains barrier tissue chips, where the device architecture supports the cells to form a natural barrier between fluid compartments. This allows selective transport processes across the barrier to be studied. These architectures are typically found in gut, lung and skin OoCs (Fig. 1). The choices for either architecture and the culture strategy depend on the final functionality of the OoC46.

Material selection and fabrication

The choice of material depends on numerous factors, including the functionality of the final device, microfabrication strategy, read-outs and biocompatibility. A typical OoC device consists of various material combinations to build the final device. Amongst the most commonly used materials are silicone rubber, such as poly(dimethylsiloxane) (PDMS); glass; and thermoplastics such as PS, poly(methyl methacrylate) (PMMA), polycarbonate (PC) or cyclic olefin copolymer (COC). However, there is no perfect standard material, as different materials have their advantages and disadvantages (Table 1). Decisions regarding material choice are often a compromise between desired functionality, access to fabrication facilities and development stage of the product (Supplementary Fig. 1). Glass is robust and inert, but expensive and requires advanced processing facilities. Silicon allows fabrication of intricate nanostructures to form on-chip sensors or barrier gratings, although this is expensive and laborious due to the need for clean-room facilities. Moreover, it is not transparent, presenting compatibility issues with conventional inverted microscopes. Thermoplastics ensure transparency and are easy to mass-produce, but are challenging when creating complex designs at the prototyping phase. Currently, PDMS is the most widely used material for development of OoC devices because devices with high-resolution microstructures and nanostructures can be easily produced by replica moulding in PDMS from microfabricated templates. PDMS is ideal for biological applications due to its biocompatibility, optical transparency and gas permeability. Furthermore, the elasticity of PDMS has been exploited to apply mechanical stimulation to cells10. Recently, breakthrough technology has been proposed that enables high-speed and high-quality PDMS 3D processing through laser pyrolysis47. However, this material is known to adsorb and absorb a wide range of (bio)chemicals, which may influence experimental results, especially for drug testing applications48,49.

PS is one of the alternatives often seen in standard cell culture tools, such as tissue culture flasks and multiwell plates, as well as newly developed OoCs50,51. What is noteworthy is that production yield, which is one of the obstacles of the existing OoC fabrication method, can be solved by mass production through injection moulding, whereas single prototypes are made by micro-milling. This productivity can provide a route to efficient OoC-based high-throughput screening that allows automated testing of a large number of drug compounds for a specific biological target. Injection moulding is not suitable for OoC models having complex designs and functional features such as stretching. The fabrication method should thus be adopted considering the experimental purpose.

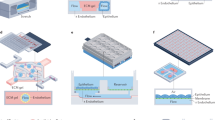

Meanwhile, as 3D printing technology advances, some groups have reported OoC models generated by 3D printing (or additive manufacturing)52. This method quickly and accurately creates complex 3D structures that have been difficult to create with the other methods mentioned so far. The use of 3D-printed microfluidic devices for OoC applications is currently limited by inadequate optical transparency, as resin formulations and post-processing steps are not yet optimized for this property. In addition, the biocompatibility of 3D-printed resins also needs to be verified. Nonetheless, OoC technology has reached a point where effective fabrication methods can be adopted through material selection based on experimental purposes (Fig. 2). Various options have been presented, including etched microchannel configuration via PDMS-based soft lithography, production of complex structures via 3D printing and plastic-based OoC mass production via injection moulding.

a,b | With biological compatibility and tunable mechanical properties, poly(dimethylsiloxane) (PDMS) is fabricated using soft lithography to develop an elaborate microstructure323 (part a) or 3D rapid prototyping by laser processing47 (part b). c | Integrated device fabrication with gold- or platinum-deposited substrate such as an electrode array324. d | For large-scale experiments such as high-throughput screening, plastic-based injection moulding could be selected50,51. e,f | For rapid prototyping with a high degree of design freedom, resin-based (part e) or hydrogel-based (part f) 3D printing is available325,326. HCS, high-content screening.

Sterilization

OoC devices differ from conventional cell culture platforms (such as multiwell plates) due to their 3D architectures and the materials from which they are fabricated, as highlighted by a previous review53. However, performing cell culture in OoC devices shares similar requirements with conventional platforms. Sterility of the OoC devices must therefore be ensured to avoid microbial contamination, including in the various microfluidic components that will be used to set up the entire OoC system. The variation in materials used in OoC devices and microfluidic components requires additional precaution in choosing the appropriate sterilization methods to prevent component damage. Inappropriate use of sterilization methods may cause damage to the OoC devices and microfluidic components, resulting in undesirable leaks during system assembly. Many common plastics such as PMMA and PC may not be suitable for conventional autoclave sterilization due to their low thermal resistance. Other methods of sterilization, such as UV or ethanol treatment, are often employed in the laboratory setting, although these methods should be used with caution. UV penetration may be limited by the material’s opacity and ability to absorb the germicidal UV rays. Ethanol soaking is not compatible with some materials, such as PMMA, as they may be partially dissolved. Ethanol can also be absorbed into PDMS devices if soaked for extended periods of time (longer than overnight), which can adversely affect cells when it is subsequently leached out. Gamma irradiation and ethylene oxide treatment should be the preferred sterilization options in industrial or clinical settings.

Surface treatment

Treatment of device surfaces that come into contact with cells may be necessary to ensure biocompatibility or enhance cell adhesion. In 3D spheroid or organoid cultures, treatment with pluronic acid is often adopted to passivate the chip surface to prevent undesirable spheroid or organoid dissociation via potential cell attachment. This is crucial, as loss of the 3D tissue architecture may cause a concomitant loss in physiological organ function54. On the other hand, protein and extracellular matrix (ECM) coatings may be used if we wish to promote cell attachment to the chip substrate. These coatings are a must for the formation of attached, confluent monolayers of cells needed to emulate the intestinal epithelium in the gut14,55, for instance, or the endothelium in blood–brain barrier (BBB) OoCs56,57,58. To create higher-fidelity (patho)physiological models, tissue-specific and disease-specific matrices may be used, for example to induce crypt-like structures in gut-on-a-chip devices59,60. These can include complex biomatrices such as Matrigel, or simpler biomatrices derived from fibrin or collagen. Cells can be mixed with the liquid precursor of these biomatrices, which can be subsequently loaded into the OoC device and allowed to polymerize into a gel. Some organs such as the liver and skin require a 3D microenvironment in order to attain physiological function, and hence biomatrices can serve as a useful scaffold for cells to remodel into a 3D structure. Biomatrices may also be essential for maintenance or differentiation of certain cell types. For example, Matrigel has been found to promote neuronal maintenance and differentiation in neural stem cells61, whereas culturing of myoblasts within a suspended overhanging fibrin-based gel promoted myogenic differentiation62.

Selection of biological elements

Here, we focus the discussion mainly on the selection of isolated cells because they are more commonly employed in OoCs. The integration of tissue slices into microfluidic devices has been previously reviewed63. There are several criteria when selecting an appropriate cell source that should be considered in the context of the application of the OoC.

Patient specificity

If the OoC is intended to model physiological variations in individuals or specific patient (for example, diseased versus healthy) populations, primary and stem cell-derived cells are both viable options. However, primary cells are often less accessible due to a lack of both availability of donor tissues and well-established protocols for isolating the cells from the tissues with high purity. With the advent of iPSC technology64, patient-derived stem cells become more accessible with minimal invasiveness. iPSCs can be differentiated into various cell lineages, and are particularly useful when one is trying to generate human leukocyte antigen (HLA) or patient-matched tissues in a multi-OoC system65.

Intrinsic functionality of the cells

OoCs often need to recapitulate tissue-specific physiological functions that are essential for their intended application, such as xenobiotic metabolism in the liver, barrier functions for the intestine and skin, and contractility of cardiac and skeletal muscles. Many immortalized cell lines as well as human pluripotent stem cell-derived cells often express a limited subset or fraction of the functional capacity as compared with primary cells66. Although primary cells may possess the full in vivo complement of cellular functions, they often lose their tissue-specific functions rapidly when maintained in vitro67, which may limit the useful time window of the OoC, especially for long-term studies. Primary cells can have inter-donor variability, which may pose a challenge for data reproducibility when not looking at patient-specific responses. Therefore, it is helpful to prioritize the different cellular functions based on the intended application of the OoC when considering different cell sources.

Expansion capacity

Expansion capacity refers to the ability of the cells to undergo proliferation in vitro and directly relates to the number of cells that can be practically generated for seeding into an OoC device. Although microfluidic devices house a minute number of cells (typically in the order of 103–105 cells), their design can influence how many cells are practically needed during the seeding process. This may be limiting for primary cells, which have no or limited doubling capacity before they undergo senescence. Although human iPSCs can be expanded indefinitely, the differentiation and cell harvesting process can result in significant cell loss, capping the number of cells that one can produce in a single batch. On the other hand, when using immortalized cell lines which have high proliferation rates, one needs to consider the minute cell culture volumes present in OoC devices to prevent nutrient depletion as well as occlusion of the fluidic channels by the growing tissue mass.

Supporting cell types

The stromal environment of tissues is composed of supporting cells (such as fibroblasts, pericytes and vasculature) that often contribute to the functionality of the engineered tissue, and play major roles in disease progression. The incorporation of stromal cells into engineered tissues has been shown to modulate cell signalling and structural support via modification and deposition of the ECM, and influence whether a drug treatment will succeed or fail. The stroma is dramatically changed in the context of disease, particularly with respect to systemic diseases such as fibrosis and cancer. Thus, the inclusion of stromal cells and their proper microenvironment can be critical in recapitulating specific tissue functionality and physiological responses that are representative of the in vivo situation.

Functional time window

iPSCs need to be differentiated for 2–3 weeks to mature into specific cell lineages. Primary cells forming barrier tissues, such as the skin, BBB and intestinal epithelium, often require an extended culture period to remodel into cell sheets with well-established cell–cell contacts to have physiological barrier functions68. The device design and operation should be sufficiently robust to cater to long-term cultures (typically a few weeks) if on-chip stem cell differentiation and tissue maturation are considered.

Additional cell considerations for systemic studies

For systemic studies, the presence of a functional circulatory system (blood or surrogate with different cell types) and the immune system may be required. Both are challenging to work with and both elements have been underdeveloped up until now.

Supporting life inside the device

Selection of cell culture medium

For a single-OoC involving only a single cell type, culture medium that was originally formulated for conventional cultures can similarly be adopted. An added complexity for media selection is introduced when generating single/multi-OoCs that involve multiple cell types, each having different nutrient requirements. The optimized co-culture medium must be able to maintain the viability and functional phenotype of each distinct cell population. Once this criterion is satisfied, we can then consider the suitability of the medium in supporting downstream assays without undesired interference. In the optimization of a suitable co-culture medium for OoC applications, many groups have adopted various mixtures of the original culture medium used for each individual cell type with relatively good outcomes. These include multicellular OoC models mimicking adipose tissue69, and also multi-organ OoC models recapitulating liver–kidney interactions70 and liver–adipose–skin–lung interactions71. However, with an increasing number of different cell types being co-cultured, the optimization of a suitable co-culture medium becomes more challenging. Compartmentalization of cells into individual compartments via permeable membranes can circumvent the need for a common co-culture medium, thus allowing for cell-specific media to be supplied to each compartment while still permitting paracrine interactions between the compartments, as shown in OoC devices mimicking the liver72 and skin73. If possible, serum-free media should be considered as sera constitute a large source of variation and may interfere with assays74. Media should be optimized in experiments with the OoC, starting with the most commonly used cell culture medium for non-OoC work with the same cells, such as minimal essential medium (MEM)-based medium for epithelial cell cultures or endothelial cell growth medium (ECGM) for endothelial cells.

Creation of perfusion circuits

Media perfusion is a hallmark of OoC devices, serving as a circulatory system mimic that maintains a concentration gradient for nutrient and waste convective transport. To drive media perfusion through the OoC device, various pumps have been adapted for OoC applications (Supplementary Fig. 2). These include conventional syringe pumps75,76, microvalve-driven actuator pumps77,78 and peristaltic pumps38,79. Alternatively, various groups have also adopted hydrostatic pressure-based pump-free systems to drive perfusion80,81,82. The choice of pumps will greatly depend on whether the culture runs on a one-pass type of perfusion flow or a recirculatory flow configuration. Conventional syringe pumps and pump-free gravity-driven flows typically support one-pass perfusion flows, whereas other pump variants such as peristaltic pumps are amenable to driving recirculatory flow. Recently, however, we have seen the emergence of OoC devices with gravity-driven recirculatory flows, which removes the need for physical pumps, hence minimizing overall system complexity while still mimicking soluble factor crosstalk between multiple organ compartments82,83,84,85,86. The choice for either type of flow and for the flow rate (volume per time) depends on the needs of the organ model and the in vivo situation, including the appropriate level of shear stress induced by flow over a tissue surface.

One-pass flow ensures a stable supply of fresh nutrients, but inter-tissue communication is only possible in one direction (namely downstream). A recirculating flow has the advantage of recirculating signalling molecules, which allows chemical communication between the different elements of a multi-organ device. Recirculation, however, does not allow for continuous replenishment of nutrients, and will lead to an accumulation of waste products. Although OoC systems can be operated for several days without medium exchange, periodic removal of a portion of medium from the OoC with replacement by fresh medium is necessary. This removal has the useful consequence that material is provided for offline analysis. The fraction removed and frequency of removal can be variable24,87. Fluid volume in an OoC is also very limited, particularly in a design that emulates physiologically realistic values of the ratio of blood/interstitial fluid to body mass85. The amount of sample that can be withdrawn is thus small (<100 µl medium per day, even if full replacement is used). Partial fluid replacement is preferred to sustain more physiological conditions, so samples of only 25–50 µl per day may be available for offline analysis in systems emulating realistic fluid to cell ratios.

Besides the use of pump/gravity-driven perfusion flows to drive organ OoC interactions, another method adopted is the transfer of conditioned medium from one single-OoC (such as the liver) to another single-OoC (such as the kidney) in a sequential manner88,89. This is known as functional coupling of OoCs88, whereas the perfusion methods described above with direct interactions between OoC modules are known as physical coupling of OoCs. Functional coupling does away with the technical challenge of incorporating pumps or means of creating gravity-driven flow, and the need for interconnections between different OoC modules. However, it should be noted that functional coupling may not be useful when monitoring real-time crosstalk interactions between OoC modules, such as the gut–liver axis. Furthermore, certain cell-secreted factors may need to be continuously concentrated due to their highly degradable nature90. As such, the transfer of conditioned medium from one OoC to another may result in the loss of an effective amount of these cell-secreted factors, with remaining numbers of factors insufficient to elicit a response in the target OoC. Physical coupling would be more appropriate in the scenarios mentioned above.

Control of the cell microenvironment

Cells interact with soluble factors, the ECM and neighbouring cells in a 3D milieu with specific physico-chemical properties. This is collectively known as the cell microenvironment, which must be carefully controlled in the OoC system for cells to function properly. As compared with conventional bulk cell culture systems, OoC systems offer more precise control over the cell microenvironment because the geometries of the culture chamber and the associated physical and chemical phenomena of fluids are defined with microscale resolution (in the order of 101–102 µm).

The unique physics of microfluidics results in fundamental differences between microfluidic-based and conventional static cell cultures. Common phenomena observed in conventional macroscale cell cultures, such as bubble formation, evaporation and nutrient depletion, are exacerbated by the microscale volumes and material choices of OoCs, and can dramatically alter osmolality, pH and nutrient availability. It is critical to have a working knowledge of how various physical forces and mass transport phenomena at the microscale influence the presentation of various biochemical and mechanical cues, such as cytokines and shear stress, respectively. Dimensionless numbers expressing the relative dominance of competing physical phenomena that are relevant to microenvironmental control include the Reynolds number (Re; inertial/viscous forces), Péclet number (Pe; convective/diffusive transport) and Damköhler number (Da; diffusion/reaction timescales). Their links to various environmental factors, such as shear stress and soluble factor signalling, have been previously explained91. For instance, the Da of critical biochemical factors, such as growth factors and glucose, in cell cultures can be used to estimate the effective culture time in an OoC device. Owing to the smaller dimensions of OoCs compared with conventional well plates, the Da of biochemical factors is much smaller, implying that their reaction time dominates over diffusion time. Consequently, in a static diffusion-dominated OoC, the time interval between medium change is often shorter than that of the macroscale culture system, and can be scaled based on the relative change in channel height, h, and the known effective culture time of the macroscale culture system91. Perfusing the OoC at flow rates such that the Pe to Da ratio is high (≫1) ensures sufficient convective delivery of these biochemical factors without limiting cell uptake92,93.

Microfluidic control of environmental factors is often coupled. For example, the fluid shear stress and mass transport regime of soluble factors are both functions of flow velocity, which means changing the perfusion flow rate of an OoC can alter both shear stress magnitude and soluble signalling at the same time. Dimensionless numbers can be used to guide device dimensions and operating parameters to selectively keep one environmental factor constant (at least from the biological perspective that there are minimal effects on cells) while varying another. For example, when operating a multiplexed device to examine effects of different shear stress magnitudes on cells, the Pe can be used to ensure that all of the cells are in the convective mass transport zone (Pe > 1). This would help decouple effects of shear stress from autocrine soluble signalling as secreted factors would be washed away. Conversely, when trying to study the effects of secreted autocrine or paracrine factors, it may be preferable to operate at flow rates where all cells are subjected to shear stresses below a set threshold. This is particularly important to prevent detrimental effects on shear-sensitive cells, such as embryonic stem cells (<10–3 dynes cm–2)92, primary neurons (<10–3 dynes cm–2)94 and hepatocytes (<10–1 dynes cm–2)95,96. On the other hand, cells that experience shear stress physiologically have been reported to exhibit enhanced differentiated cell phenotypes and functions over a certain optimal range of shear stress magnitudes, as exemplified by intestinal epithelial cells (~10–2 dynes cm–2)97,98, airway epithelial cells (5 × 10–1 dynes cm–2)99,100, bone cells (10–1–101 dynes cm–2)100 and cardiovascular cells (100–101 dynes cm–2)100,101.

Care must be taken to ensure proper equilibration of culture medium with the gaseous environment. The gaseous composition of the air is important for maintaining proper oxygen concentration and physiological pH (7.0–7.4). Depending on the needs of the OoC, oxygen may be kept at atmospheric levels (21%), lowered or removed to recreate hypoxic (<10%)102 to anaerobic systems, or increased to improve oxygenation of tissue sections. Most conventional cell culture media (such as DMEM or RPMI 1640) are formulated with bicarbonate buffers, which yield a physiological pH of 7.0–7.4 only when equilibrated with 5% carbon dioxide. Hence, 5% carbon dioxide is typically used in conventional cell culture incubators. If the OoC is operated outside a conventional incubator, such as on a heating block or transparent indium–tin oxide heaters under atmospheric conditions, the medium pH can be maintained by the addition of HEPES buffer103 or pre-equilibrating the medium in a 5% carbon dioxide environment, first, before delivery into the OoC device34. Cells grown in OoCs may have a different baseline function from those grown in conventional cell culture grown on tissue culture plastics. Therefore, one needs to be careful when attributing differences observed between OoCs and conventional cell culture to the specific environmental cue being applied through the microfluidic device.

Monitoring OoC status

Different read-out options and controls are necessary to monitor the status of the OoC during culturing and experimentation. The most common control is visual microscopic inspection of the OoC to regularly check whether the cells or tissue sections are normal in appearance (size, number, shape and so on) and there are no abnormalities (such as air bubbles or microbial contaminations) that will lead to device failure. Air bubbles may arise during device operation, such as upon connecting a new syringe with medium. This is undesirable as moving air bubbles can be destructive to cells in the microchannels by the interfacial force they exert. Ideally, air bubble formation should therefore be avoided by carefully connecting the tubing and forcing the air out before cells are introduced. In the presence of an air bubble, if the bubble is not obstructing the medium perfusion flow and cells are protected from direct bubble interaction (such as when cells are trapped in hydrogel/micro-pillar arrays), it is better to leave the air bubbles and allow them to dissolve into the medium or diffuse through the chip if the chip is gas permeable. However, if there is a high likelihood that the air bubbles will come into direct contact with the cells or block medium perfusion flow, flushing out the bubble may be essential to preserve the experimental set-up. When attempting to flush out air bubbles, extra care has to be taken to not dislodge the cells or break the chip’s seal with the large forces required to extract the air bubbles. Engineering controls such as the implementation of an on-chip or external bubble trap ahead of the cell culture chamber can also greatly eliminate the risk of air bubbles directly interacting with the cells. Other flow obstructions may be caused by fibres or accumulated debris, which can generally not be solved when cells are already present; the experiment can then continue if the obstruction is not in an essential place, or aborted if it is blocking an essential flow. Microbial contaminations are indicated by the presence of bacteria or yeasts inside the microchannel and always result in the termination of the experiment.

Case studies

Here, we provide insight into the development of single-organ and multi-organ OoC systems for specific applications, with a special emphasis on OoCs for drug research including absorption, distribution, metabolism, excretion and toxicology (ADME-Tox). We discuss conceptualization and design, material selection and fabrication, selection of biological elements and supporting life inside the device. The examples considered in this section exhibit evolution in their designs that are commensurate with advances in both microfabrication and biological models over the past decade. Once one or multiple research questions have been formulated, these can be translated into a list of functional requirements and technical specifications that guide the construction and implementation of the OoC system.

The desired functionalities of the system should be leading in its design. The first decision is between a single-organ or multi-organ system. Single-organ systems tend to be more suited to study specific tissue and organ functions, without having the complexity of other organ systems involved. Multi-organ systems are more suited to study interactions between different organ compartments, such as when the functions of one organ affect the functioning of another organ. We use drug absorption through the intestinal epithelium as an example of a single-organ system, and highlight different multi-organ systems investigating the metabolism of a drug in the liver and its subsequent therapeutic or toxic effects in other target organs.

Single-organ OoC systems

Intestinal absorption of orally administered drugs is commonly evaluated in Transwell assays, where a layer of intestinal epithelial cells is cultured on a permeable insert placed in one of the wells of a cell culture plate. These intestinal cells act as the barrier between the top compartment (mimicking the gut lumen) and the bottom compartment (mimicking the bloodstream); drug absorption can be measured over time by analysing samples taken from both compartments. This intestinal absorption process has been translated into a microfluidic format104 (Fig. 3A).

A | Gut-on-a-chip device for drug absorption studies104: Transwell cell culture insert that was the inspiration for this gut-on-a-chip (part Aa); and flowing microsystem, with uptake of drug molecules from apical channel and transport into basolateral channel (part Ab). B | Reconfigurable multi-organ-on-a-chip (OoC): includes four, seven or ten different organ models that can interact with one another via microchannels107 (part Ba); and various layers of device, including all connections for cell culture media and pneumatic channels to actuate integrated micropumps (part Bb). C | Multi-OoC developed consisting of several OoC compartments together in one device108: all microchannels and chambers filled with green dye for visualization (part Ca); and elements (1, liver chamber; 2 and 4, heart chamber with cantilevers and microelectrode arrays; 3, vulva cancer chamber; 5, breast cancer chamber) contained in device, as well as medium access ports and integrated read-out structures (part Cb). IV, intravenous; MPS, microphysiological system. Parts Aa and Ab adapted from ref.104, Springer Nature Limited. Parts Ba and Bb adapted from ref.107, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/). Parts Ca and Cb adapted with permission from ref.108, AAAS.

The barrier consisting of intestinal cells grown on a porous membrane was retained, but replaced the static top and bottom compartments of the Transwell with microchannels containing a dynamic flow of cell medium (conceptualization and design). PDMS was used because it is a transparent, biocompatible and mouldable silicone rubber, with moulds produced by photolithography, and the membrane was pretreated with a collagen surface coating to improve cell adhesion (material selection and fabrication). Caco-2 cells, the gold-standard cell line for drug absorption studies, were cultured inside the microchannel; these cells lack many other functions that intestinal epithelial cells have, but they are very suitable for absorption studies (selection of biological elements). The intestinal OoCs were kept in an incubator, with the cell medium provided by two syringe pumps without recirculation (supporting life inside the device). The device was inspected by optical microscopy, and the permeability of model drugs was monitored using high-performance liquid chromatography and fluorescence-based assays with samples of the OoC effluent.

A more complex intestinal single-organ OoC was developed to address whether enteric coronavirus infections could be modelled in an OoC format, including the testing of antiviral drugs105. The process of viral infection is far more complex, and requires multiple different organ functions, including immune components, to be present. A similar two-channel OoC as above was used, based on a porous membrane, but with the inclusion of more biological functionalities such as the barrier function of both the intestinal epithelium and the blood vessel wall, as well as an immune component (conceptualization and design). The OoC consisted of stretchable silicone rubber with two channels and a permeable membrane, pretreated with collagen and Matrigel. The stretchability of the membrane was exploited to actuate peristalsis-like motions of the tissue (material selection and fabrication). Intestinal organoids were cultured from patient biopsy samples. Endothelial cells were cultured on the other side of the membrane, to include the functions of intestinal blood vessels. Peripheral blood mononuclear cells were isolated from patient blood and inserted into the bottom microchannel of the device to act as blood vessels (selection of biological elements). All incubation conditions, including flows and cyclic stretching, were controlled by a commercially available apparatus (supporting life inside the device). Various different read-outs, including on-chip fluorescent staining and offline gene analysis, were used to assess enteric viral infections in a single-OoC format.

Multi-organ OoC systems

A first multiple-organ system on a chip was designed to mimic systemic distribution of, and toxicity response to, the compound naphthalene106. The device contained a combination of four compartments representing the lung, liver, fat and other tissues. The dimensions of the tissue compartments and microchannels connecting them were specifically designed to mimic systemic blood flow distribution and residence times in the respective organs; after passing through the lung, fluid flow was volumetrically distributed to the fat (9%), liver (25%) and other tissue (66%) compartments. The study was focused on mimicking the toxicity of naphthalene metabolites, generated by the liver, on lung cells. The different compartments, therefore, had essential interconnections in the form of microchannels that allowed the distribution and metabolism of these compounds (conceptualization and design). The device was assembled from etched silicon and machined PMMA, which yielded very well-defined channels. These materials allowed for optical inspection of the compartments on the chip (material selection and fabrication). The lung and the liver compartments contained rat cell lines, whereas the fat and other tissue compartments remained cell-free, thereby not participating in the biological response but serving to better emulate the proportion of drugs distributed to the biologically active liver and lung compartments (selection of biological elements). Peristaltic pumps were used to recirculate media through the different organ compartments (supporting life inside the device). The distribution, metabolism and toxicology of compounds could be studied with this device. The introduction of a flow component into conventionally static cell culture models allowed the study of inter-organ interactions, which would not have been possible in a non-OoC format. However, extrapolation from this miniaturized rat-based system to humans remained difficult. Today, it has become possible to use human organoids or spheroids, or even simpler cell lines of human origin, in this type of experiment to eliminate the need to take species differences into account.

A different approach for a multi-OoC for drug metabolism was developed later, aimed at developing a physiologically relevant multi-organ system for drug discovery107 (Fig. 3B). This system included four, seven or ten organ models, which were coupled with integrated fluidic circuitry to study organ interactions (conceptualization and design). This integrated device was fabricated with easier to process polysulfone and polyurethane, with integrated air pressure-controlled valves as built-in pumps to recirculate media in a more controllable fashion (material selection and fabrication). The organs modelled were of human origin (primary cells, from cell lines and iPSC-derived cells) and included the kidney, muscle, liver and gut, amongst others (selection of biological elements). The pumping system was incorporated into the final device, requiring only external air pressure to regulate the valves by software (supporting life inside the device). The drug diclofenac was administered to the gut section of this system, where it was absorbed and, subsequently, distributed among the other organ models. The complexity that this system allowed was necessary to answer a more complex scientific question, but was met with an increase in the complexity of the peripheral system, with various pieces of supporting equipment required (including a 36-channel pressure/vacuum controller). This added complexity leads to additional costs for setting up the system, and a large laboratory footprint for a miniaturized system.

Another, different, approach for a multi-OoC was reported for the efficacy and toxicity testing of various anticancer agents108 (Fig. 3C). This system contained a reconfigurable design with multiple organs, including solid tumour-derived cells and leukaemia to study effects of the anticancer agents on their target as well as toxic effects on other organs (conceptualization and design). The system was composed of PDMS, glass and plastics, and so was easily fabricated (material selection and fabrication). Cancer cell lines modelling various malignant conditions were cultured in the OoC, similar to other systems (selection of biological elements). The device was pumpless, and hence more user-friendly as it required fewer supporting machines (supporting life inside the device). The entire device was placed on a rocking shaker for gravity-induced recirculating flows, thereby greatly reducing its laboratory footprint. A system such as this is more suited for biological applications, with less emphasis on the exact manipulations of individual microchannels in the device.

In general, the use of single-OoCs has two phases. In the first — preparatory — phase, biological elements such as cells or organoids are introduced in the microchannels of the device. These living elements need time in order to settle properly in the device. They may need time to proliferate to confluency in the microchannels (such as in the case of a barrier model), or for cell differentiation into the cell types that occur in a particular organ in vivo. In the second — experimentation — phase, the device has matured enough in terms of physiological relevance and functionality to be used in experimentation. Multi-OoC systems have the same two operational phases. The different single-OoC compartments are usually cultured separately in the first phase. When each of the single-OoCs has reached the required level of maturation (which is dictated by the desired functionality), the single-OoCs can be combined into an interconnected multi-OoC with a common cell culture medium. After combining all of the required elements in one multi-OoC device in a sustainable fashion, the multi-OoC system may be used for experimentation.

Results

OoC systems are complex and entail significant effort, often with long experimental times (up to 28 days). Being able to collect maximal information is important and requires a combination of offline and in situ analysis (Fig. 4). When evaluating read-outs, it is important to consider the timescale of measurement versus the physiological timescale (which can be seconds to days), the required spatial resolution on a system level and organ level, and whether the measurement is quantitative or qualitative. Measurements that are on the same timescale as the physiological response are critical. For instance, a change in cardiac conduction velocity can be measured in seconds, whereas changes in cell viability, if they occur at all, may take many hours. For example, resolving the propagation of action potentials in neural networks not only requires sub-millisecond recording but also a dense array of sensing points. Ideally, the read-outs can be related to a relevant biological or clinical end point. In vitro to in vivo extrapolation is key to understanding the mechanism of action of a drug or chemical on the body. Also, multi-organ systems monitored simultaneously with various organ-specific and local read-outs can lead directly to mechanistic insights of the whole-body response and organ resolution. In particular for drug development, it allows the measurement of not only the response of the target organ (the efficacy) but also side effects on other organs (the toxicity)35.

A | In situ measurements during operation of a recirculating organ-on-a-chip (OoC) system allow for near real-time assessment of cell states and functionality: integrated electrodes and cantilevers in OoC devices can be configured to measure various electromechanical signals indicative of transepithelial electrical resistance (TEER)127, electrophysiological signals using microelectrode arrays (MEAs)133 and cell/tissue contractility using cantilevers327 (part Aa); integrated biochemical sensors in the OoC device can provide online measurement of various soluble analytes, such as secreted proteins via immunosensors328 and dissolved oxygen329 (part Ab); sampling of recirculating medium can be used for offline measurement of soluble biomarkers using assay kits or liquid chromatography/mass spectrometry (LC/MS) (part Ac); and device can be coupled to an optical set-up for live-cell imaging to track cell functions such as migration330 (part Ad). B | End point measurements are often used to interrogate cell states at transcriptome and protein levels: expression of specific biomarkers can be imaged by immunohistochemical and/or cytochemical techniques (part Ba); and cells or tissues in the OoC device can be lysed and further processed for transcriptional and protein expression analysis (part Bb). NGS, next-generation sequencing. Part Aa adapted with permission from ref.127, RSC, ref.133, Elsevier, and ref.327, Elsevier. Part Ad adapted with permission from ref.330, PNAS.

Offline, online and in situ analysis

To profile OoC homeostasis and response to externally applied chemical or physical stimuli, the intermittent measurement of multiple compounds simultaneously is highly desirable. Offline high-performance liquid chromatography/mass spectrometry (HPLC/MS) or multiplexed (bead-based) protein-binding/DNA-binding assays often remain the most practical techniques in this regard, as both allow measurement of a wide range of different chemicals at the same time, of which many are responsive biomarkers. Both offline approaches can be performed in microlitre volumes of sample, which are compatible with the flow rates commonly used in one-pass perfusion, or removed periodically from recirculating medium circuits. Various commercial assay kits can be used as an alternative for selected biomarkers (such as albumin, lactate dehydrogenase, alanine aminotransferase, aspartate aminotransferase and urea, for liver systems), although possible interference due to medium components (particularly serum) must be carefully considered. In very low-volume systems, the number of measurements that can be made with such kits is quite limited, although new microarray techniques allow use of very low volumes (<5 µl) and parallelization of measurements (cell health assays).

Online or in situ measurements of the supernatant can offer measurements of nutrients and metabolites with minimal time delays. Small sensors are typically used, based on optical detection exploiting dyes109. In situ measurement of dissolved oxygen in OoCs has been reviewed in detail110,111,112. Dissolved oxygen is a key parameter in metabolism, especially in terms of CYP450 activity in the liver113,114,115. Dissolved oxygen and pH can both be measured using microprobes or pH-sensitive patches9. Optical detection requires the use of microscopy or optical fibres; automated techniques to reduce time and labour have been suggested116,117. Some analytes such as glucose and lactate can be measured by using electrochemical enzyme-based biosensors41,118. These online, near continuous measurements are desirable as periodic measurements may miss important fluctuations in response. If sensors or patches are integrated as arrays at close distance or in direct contact with tissues structures, analyte concentrations can be spatially resolved.

Measuring cell phenotype and function

Although biomarkers provide important biological insights into the body’s response to drugs, cosmetics, food ingredients and environmental exposure to chemicals, it is often the functional tissue response that may be the most informative. Ideally, the functional measurements are non-destructive and readily adapted to in situ analysis, particularly in systems with continuous recirculation of medium over extended periods (such as 28 days). These measurements should also provide rapid insights into responses — often within minutes — in order to achieve relatively high temporal resolution with respect to the timescale of the functions being monitored.

End point analyses

Although highly informative when it comes to cell status, gene and protein analyses in OoCs are difficult to do online, and may require that the device be dismantled to perform end point histology, lytic assays, transcriptomics and even cell viability assays119,120. A chip design concept that allows easy removal of tissues with no detrimental effect on tissue structure and morphology becomes essential in order to obtain representative results as well as maintain spatial organization of the cells in the tissue. Analysis of circulating cells such as immune cells and tumour cells can be done using medium samples taken from OoC devices121. However, many microfluidic devices can destroy circulating cells during experiments, so it is essential that the fluid dynamics be considered during device design. In other cases, cells have to be removed from the tissues in the device. Techniques to remove cells without damage do exist, but can be difficult to implement, requiring expertise to perform. For effective quantification, removal of all of the cells may be important so as not to bias the results.

Microscopy and high-content imaging

Microscopy and high-content imaging are among the most widespread analytical methods in cell biology, and thus also the most common measurement of cell and tissue function is visual inspection in OoC devices. Most OoC devices are constructed from optically transparent materials, such as glass, PDMS and thermoplastics, and can be constructed to fall within the imaging depth of conventional epifluorescence or confocal microscopes. It is thus possible to perform in situ staining of the cells and tissues in-chip with fluorescent stains or antibodies to assess cell viability or expression of specific biomarkers, by using the microfluidic function of the OoC to deliver the necessary reagents122.

In recent years, microscopy techniques including confocal microscopy and light-sheet microscopy, as well as imaging sample preparation protocols (clearing, staining and so on) and analysis, have been significantly advanced and adapted to deal with complex, 3D multicellular constructs. High-content imaging has the strength to provide both spatial and temporal information of cells and tissue morphology to help researchers untangle disease pathophysiology and assess novel therapies more effectively. Microscopy in OoC systems requires an optical window to the cells, along with a design specification that allows placement and alignment of the OoC on a microscope stage. Successful microscopy requires optimized matching of the tissue model, preparation protocols (fixing, staining, clearing) and microscopy method with the protocol for image and data analysis123. Machine learning algorithms can serve as a powerful tool to aid image and data analysis. An example would be the use of deep learning convolutional neural networks to track invasiveness of tumour spheroids124.

Transepithelial electrical resistance

Transepithelial electrical resistance (TEER) is a commonly used technique to measure the integrity and permeability of any barrier tissue (such as the gastrointestinal tract, the kidney and the BBB). Native barrier tissues in the body have TEER values associated with their function. The tightest barrier is the BBB with values of 1,500–8,000 Ω.cm2 (ref.125), whereas the proximal tube in the kidney has a value of about 70 Ω.cm2 (ref.126). Organ and tissue models should show physiologically accurate values. In some cases, tissue models can give values far greater than physiological values, whereas others fall short of realistic values. The completeness of the model is a determining factor in these situations, especially where the physiological system consists of several cell types and the model uses only a subset of these.

The measurement of TEER values in microscale systems can be done using the Ohm’s law method or impedance spectroscopy, using either microelectrodes integrated into the device during its fabrication127,128,129 or inserted into the device before an experiment129,130. Impedance spectroscopy, when combined with a fitting algorithm, provides a more accurate representation of TEER values than the Ohm’s law method, whereas the Ohm’s law method is easier to apply. Impedance spectroscopy further allows measurement of tissue size and integrity131. For both types of measurement, the electrodes must be placed accurately, and the surface area used in the calculation must be appropriate as a uniform current density must be generated throughout the entire barrier tissue. Applications of TEER to OoC devices have been reviewed previously128,132,133,134.

Microelectrode arrays and cantilevers

Other functional measurements include microelectrode arrays (MEAs) to measure electrical activity in cells and tissues, and cantilevers to measure force generation by cells133,135. The MEA system is much more suitable for application to OoCs than the patch clamp. This method typically relies on a 2D array of cells that allows, using the heart as an example, estimates of conduction velocity, beat frequency and field potential duration as an analogue for the QT interval136. MEAs can be applied to the heart, neuromuscular junctions, skeletal muscle contractions and neuronal systems137,138,139,140. For instance, action potential propagation between presynaptic and postsynaptic chambers connected by microtunnels has been described141. Mechanical forces such as contractile force generation by cells and/or tissues is also critical to many organ functions. They can be measured non-destructively and in near real time by integrating microcantilevers in OoC devices, in which cells are patterned onto silicon cantilevers with optical or electronical detection of their deflection142,143. Meanwhile, a recent study showed that both MEAs and electrodes for TEER measurements can be integrated into chips during their fabrication to achieve multiple functional measurement in a TEER–MEA heart chip144.

The choice of read-outs will depend heavily on the issues to be addressed. Generally speaking, the advantage of most OoC in vitro systems is that they are easier to probe directly than animal models are, irrespective of the analytical approach chosen. OoCs lend themselves to microscopic imaging and small-volume sampling for both offline and online analysis. There has been a remarkable upsurge recently in the availability of small sensors for real-time probing of biological systems. Their application to real-time in situ monitoring of incubation conditions, biomarkers and organ function in OoC has obvious advantages not only for the development of improved OoC but also for the range of experiments that become possible with OoC systems.

Applications

The majority of OoCs are developed with an intended application in mind. In this section, we highlight the various advantageous features of current OoCs for use by commercial organizations interested in testing and predicting compound efficacy and side effects, and biological researchers looking to use OoCs to mimic the complexity of normal or diseased states in humans.

Most OoC prototypes at the pre-commercialization developmental stage generally cannot fulfil the dual purposes of multiplexing and biological complexity simultaneously. As an in vitro system, OoCs also cannot comprehensively capture the entire physiology of an organ or body. Hence, the final commercialized form factor of an OoC system is often informed by the tissue functions and read-outs that are essential for the intended application (Fig. 5). Consequently, one should discern between the necessary and desirable features of an OoC device at different stages of its translational process. This should ideally be done in consultation with the intended end users.

Complexity and form factor of OoCs are dependent on its intended application as illustrated by the liver OoC. Different applications of liver OoC may require varying complexity in culture configuration from hepatocyte monocultures to co-culture with other hepatic cells that better mimic liver physiology. Aa–e | Toxicology testing requires multiplexed arrays for increased throughput. Ba–b | Liver OoCs that mimic liver-bioactivation of drugs or nutraceuticals involved co-culturing liver with the tissue targeted by the drug. Ca–d | Liver disease models often require increased biological complexity with both parenchymal and non-parenchymal cells to recapitulate disease mechanisms. Da–c | Drug pharmacodynamics (PD) and pharmacokinetics (PK) models will include the liver OoC as the metabolizing organ alongside other organs involved in drug absorption, distribution and excretion connected in a recirculating circuit. EBs, embryoid bodies; NAFLD, non-alcoholic fatty liver disease; NASH, non-alcoholic steatohepatitis; PEARL, perfusion array liver system. Part Aa adapted from ref.331, CC BY 3.0 (https://creativecommons.org/licenses/by/3.0/). Part Ab adapted with permission from ref.332, Elsevier. Part Ac adapted from ref.333, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/). Part Ad adapted with permission from ref.334, RSC. Part Ae ©Emulate. Part Ba adapted with permission from ref.77, RSC. Part Bb adapted from ref.335, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/). Part Ca courtesy of InSphero AG, Schlieren. Part Cb adapted with permission from ref.336, Wiley. Part Cc “PhysioMimix™ Liver-on-a-Chip (MPS-LC12) consumable plate”. Part Cd adapted from ref.303, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/). Part Da adapted from ref.337, Springer Nature Limited. Part Db adapted from ref.107, CC BY 4.0 (https://creativecommons.org/licenses/by/4.0/).

Commercial compound testing

Pharmaceutical and chemical compounds

Commercial use of OoC systems has been focused primarily on drug development36,145,146,147. The ability to estimate both efficacy and toxicity for humans in preclinical trials is a huge advantage in allowing a company to choose candidates that have a higher chance of becoming approved drugs. OoC systems can be used throughout preclinical and clinical trials, and coupling OoCs with physiologically based pharmacokinetic (PK) or pharmacodynamic (PD) models offers a rational basis to guide this process37.

The appropriate OoC system changes from relatively simple to increasingly complex due to the different goals of each stage of drug development. Typically, simpler and more highly focused systems that provide relatively high throughput are needed in mid-preclinical trials, whereas multi-organ human-based models are needed towards the end of preclinical trials to predict both efficacy and toxicity. The complexity is not only in the device itself and integrated analytics but also in the complexity of the biological organ module. The majority of OoC companies focus on single-organ modules, although some provide multi-organ systems. Human multi-organ models alone or when coupled with a mathematical model37,148,149,150 have the potential to provide both efficacy and toxicity information on human response in preclinical studies108.

There are numerous issues in terms of scaling data of a multi-organ OoC system to predict human response, including direct scaling, residence time-based scaling, allometric scaling and multifunctional scaling140,151,152,153. Each of these approaches has advantages, although residence-time approaches are the simplest to use. The residence time, defined as the volume of the reactor divided by the total flow rate, is easily applied and controls the degree of conversion of a reactant and formation of metabolites independent of reactor size (which can range from a few microlitres up to tens of thousands of litres). A residence-time approach should be effective if the microphysiological system uses organ chambers sized to be in correct physiological ratios with an appropriate ratio of flow of a blood surrogate to each organ.

Biomaterial testing

Many medical treatment modalities rely on the use of biomaterials, including surgical and medical devices (such as catheters, surgical plates, screws or extracorporeal systems), implants and artificial tissue replacements. OoC platforms can be used to study the biocompatibility and efficacy of biomaterials in an environment that is representative of the (patho)physiology of the organ or tissue to be replaced, repaired or regenerated. An important consideration is the integration of various biomaterials into the microfluidic OoC systems for fast and parallelized biocompatibility or biofunctionality testing154,155. Numerous different solutions for facile and versatile integration of biomaterials of various geometries156,157 or bonding strategies have been reported158. Biomaterial samples that have to be integrated into OoC systems require miniaturization, which may be challenging for some material types. Moreover, it is important to prove that the effects observed with miniaturized samples are representative of the situation in the body.

The ability of OoC systems to achieve precise control of environmental factors are of great use for understanding structural–functional relationships of a biomaterial. By controlling the presentation of various cell microenvironmental cues in the OoC, one can conduct a systematic study of how these environmental factors interact with specific biomaterial properties, such as roughness159,160, stiffness161,162, wettability163 and topography164,165,166,167, which in turn regulate cells’ behaviours, such as adhesion, proliferation and differentiation on the biomaterial.

Biological research

Disease modelling

The use of OoC systems for disease modelling enables the investigation of both inherited and acquired disease in a human setting, overcoming inter-species differences that hamper data extrapolation. Specifically, many of the genetic networks implicated in human disease differ substantially between human and murine models, the most common animal model deployed, which greatly limits their utility for disease modelling168. Similarly, the immune systems of mice and humans show significant differences in both innate and adaptive immunity, limiting their use in evaluating immune-related diseases such as multiple sclerosis169. OoC systems provide a human-specific experimental platform to mechanistically study human diseases with complex aetiologies because they can integrate genetic factors (through use of patient-derived or genetically engineered stem cells harbouring the disease-driving genetic mutations or predispositions), environmental factors (such as exposure to drugs or mechanical stresses170 through precise control over the cell microenvironment) and systemic crosstalk with other organ systems, including immune cells and the microbiome (through engineering multi-OoCs with recirculatory flows). There are already some demonstrated examples where OoC systems have been able to demonstrate the importance of interplay between different aetiological factors in the manifestation of clinically relevant disease phenotypes. For example, engineered heart tissues made from diseased cells harbouring a desmoplakin mutation only show clinical arrhythmogenic cardiomyopathy when exposed to dynamic mechanical loading171. Another example demonstrated that the inclusion of regulatory T cells and T helper 17 immune cells and environmental agents (short-chain fatty acids) into a gut–liver multi-OoC could successfully recapitulate paradoxical modulation of inflammatory bowel disease that was dependent on activated CD4+ T cells172.

The development of disease models is of increasing importance for the clinical development of efficacious therapeutics and provides a model for rare diseases where clinical development and trials may be limited by small patient cohorts. Additionally, OoC platforms can enable studies of systemic disease in the human setting for diseases that currently have minimal other models available, including cancer metastasis, inflammation, fibrosis and ageing. It is expected that the inherent complexity of systemic diseases can be mechanistically evaluated to a greater extent as multi-OoC technology continues to advance. To fully attain this, OoC platforms should be developed in a way that enables spatio-temporal tracking of cell and tissue states, modularity to enable multi-tissue studies for systemic diseases, inclusion of functional stromal cell populations that drive disease progression (such as immune cells, fibroblasts and vasculature) and validated disease cell sources. Benchmarking of diseased cells against healthy cells in the same system should serve as a control to interpret the differences in the diseased phenotype from those related to the in vitro setting. Biomarkers of clinical relevance should similarly be evaluated within the OoC platforms, enabling a more direct comparison with the clinical phenotype for enhanced benchmarking of platform utility.

Probing and mimicking the cell microenvironment

Microenvironmental control of cells is a well-established concept in cell biology. OoC systems have been used extensively to manipulate different environmental factors (such as shear stress, autocrine/paracrine soluble factors, cell–cell and cell–ECM interactions) at physiologically relevant length and timescales so as to elucidate their effects on cell phenotypes and functions. This idea is particularly well demonstrated in the context of the stem cell and tumour microenvironments, as evidenced by the number of reviews on these topics173,174,175,176. We cover some of the common design strategies that are used in OoC devices to control and probe the functional roles of biochemical and mechanical environmental factors.

Soluble biochemical factors, such as morphogens and cytokines, can be controlled in OoC systems by manipulating fluid mass transport properties at microscale resolution, and therefore OoC systems offer a more precise method to study the effects of paracrine and autocrine signalling compared with conventional techniques, such as conditioned medium or changing cell density177. By selectively changing channel dimensions and flow velocity, one can tune between diffusion-dominated (Pe < 1) transport, where secreted factors remain in the cell vicinity for binding to receptors, and convection-dominated transport, where secreted factors are removed from the cell vicinity177. Soluble factors can also be applied exogenously to microfluidic cell cultures with spatio-temporal control over the concentrations and compositions that cells are exposed to. This is often accomplished by coupling a convection-based concentration gradient generator178,179 or combinatorial mixer180,181 to the cell culture chambers. Alternatively, static diffusion-based gradients can be applied to shear-sensitive cell types without exposing them to direct flow. This can be achieved by sandwiching a porous matrix between the source and sink reservoirs182 or balancing the pressures between multiple channels that feed into a static chamber where concentration gradients are being established178,179,183.

Devices that are designed to study cell–cell interactions often attempt to control the spatial localization and relative abundance of different cell types using cell patterning184,185,186 or geometrical microstructures (such as microwells) to physically constrain the cells187,188. This allows for better control over the number of interacting partners as well as the spatio-temporal dynamics of the interaction process compared with random co-cultures. Control over cell–cell and cell–ECM interactions becomes coupled when using cell patterning techniques to modulate the number of neighbouring cells because this is reliant on patterning adhesive ECM proteins on the substrates to which the cells then attach. Proper experimental designs to vary cell–cell interactions while maintaining cell–ECM interactions to be consistent, such as uniform coating with a well-defined ECM protein such as fibronectin, can help circumvent this problem. OoC devices for probing cell–ECM interactions aim to modulate either the biochemical composition of the ECM proteins being patterned onto the substrate189 or the substrate’s mechanical properties, such as stiffness or topography. The latter usually involves replacing glass with other materials — such as PDMS or polyacrylamide hydrogel — as the cell culture substrates in the OoC device, whereby the stiffness190,191 or surface topographies192,193 of the substrates can be precisely controlled.

OoC devices are well suited for applying a range of physical environmental stimuli on cells. As fluid flow is inherent in many OoC systems, these systems are used to mimic physiological shear stresses exerted by blood and interstitial fluids. By designing multiplexed channels with varying geometries, one can simultaneously apply shear stress over a range of magnitudes to probe the effects of shear stress on cell proliferation, differentiation and functions119,194,195. Alternatively, fluid shear is used to enhance the functional maturity of microvasculatures in many organotypic tissues. OoC devices can also be designed to apply mechanical tensile or compressive forces to cells for mimicking breathing-induced stretching of the airway, peristalsis-like motions of the gut or contractility of cardiac tissues196. This is often achieved by growing cells on thin flexible PDMS membranes that are incorporated into the OoC device such that they can be flexed cyclically by vacuum or pressure pneumatic actuators. To better recapitulate the electrophysiological functions of neural and cardiac tissues, electrical stimulation has been built into OoC devices by integrating in situ MEAs that are microfabricated as part of the device197 or electrodes that are inserted into the OoC system196.

Single-organ tissue functions

Liver