Abstract

Black-colored (α, γ-phase) CsPbI3 perovskites have a small bandgap and excellent absorption properties in the visible light regime, making them attractive for solar cells. However, their long-term stability in ambient conditions is limited. Here, we demonstrate a strategy to improve structural and electrical long-term stability in γ-CsPbI3 by the use of an ultraviolet-curable polyethylene glycol dimethacrylate (PEGDMA) polymer network. Oxygen lone pair electrons from the PEGDMA are found to capture Cs+ and Pb2+ cations, improving crystal growth of γ-CsPbI3 around PEGDMA. In addition, the PEGDMA polymer network strongly contributes to maintaining the black phase of γ-CsPbI3 for more than 35 days in air, and an optimized perovskite film retained ~90% of its initial electrical properties under red, green, and blue light irradiation.

Similar content being viewed by others

Introduction

Halide perovskites are considered as the next-generation optoelectronic materials because of their excellent optoelectronic properties owing to inherent direct band gaps, high absorption coefficients, long exciton diffusion lengths, and low-cost solution process availabilities1,2,3. Among them, organic–inorganic hybrid perovskites in which organic cations such as methylammonium4,5 or formamidinium6,7 are applied to the position A of ABX3 structure have been preferentially studied for realizing a cubic structure by satisfying the Goldschmidt tolerance factor (0.81 < t < 1.1, t = (rA + rX)/√2(rB + rX), where rA, rB, and rX are the ionic sizes of A, B, and X, respectively)8,9. However, due to the inherent volatility problems of the organic cations10,11, all-inorganic perovskite (CsPbX3, X = I, Br, Cl) which replaced the organic cation with cesium is drawing attention recently12,13,14,15,16,17. Particularly, in the case of CsPbI3 in which the iodine is in the X position, it is intensively studied as a visible light detection material because it can effectively absorb the entire visible light18,19,20.

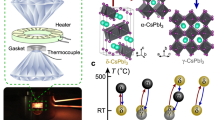

In general, cubic α-CsPbI3 (black phase) has a suitable low bandgap (~1.70 eV) that can effectively absorb the visible region. Unfortunately, α-CsPbI3 is unstable below 330 °C and undergoes rapid phase transition to undesirable large bandgap (~2.80 eV) orthorhombic δ-CsPbI3 (yellow phase) at the room temperature21. Recently, adding hydroiodic acid (HI) enables lower formation energy of perovskite that is to realize relatively stable orthorhombic γ-CsPbI3 (~1.69 eV, black phase) in a low-temperature process at about 100 °C22,23,24. However, there is still a challenge of phase transition occurrence to δ-CsPbI3 upon prolonged exposure of γ-CsPbI3 to ambient conditions.

To secure the long-term stability of the black phase CsPbI3 under ambient conditions, two approaches have been developed: partial substitution of anion or cation25,26,27,28, and surface passivation using organic additives29,30,31,32. One of the partial substitution methods, CsPbInBr3−n implemented by partially replacing bromide at the iodide position possesses a wider bandgap than α and γ-CsPbI3, thereby it is a compromise way which is difficult to effectively absorb visible light25. The surface passivation method using organic additives, another approach to achieving improved stability, deteriorates the electrical properties of perovskite due to excess additives (10–70 wt%29) for realizing long-term stable black phase CsPbI3.The above methods obviously provide a roadmap for CsPbI3 to stabilize the black phase in the long-term, but still contain the issues of bandgap widening and electrical properties deterioration.

Herein, we propose a robust strategy by employing infinitesimal (≤3 wt%) ultraviolet (UV)-curable polyethylene glycol dimethacrylate (PEGDMA) to ensure the structural and electrical long-term stability of the γ-CsPbI3 under ambient conditions. Oxygen lone-pair electrons of the PEGDMA capture Cs+ and Pb2+ cations and considerably improve the crystal growth of γ-CsPbI3 around PEGDMA. In addition, polymer network of PEGDMA processed by UV exposure strongly contributes to maintaining the γ-CsPbI3 structure tight for more than 35 days in ambient conditions. To evaluate the photo-electronic properties, two-terminal photoresistors were fabricated and evaluated, the optimized UV-cured γ-CsPbI3 (3 wt% PEGDMA) film showed that ~90% of the initial electrical values responding to red, green, and blue lights, were stably maintained even after 35 days in the ambient conditions.

Results and discussion

Feasibility of long-term stable perovskite CsPbI3 by UV-curable polymer network

Figure 1 shows the feasibility of long-term stabilized black phase CsPbI3 under ambient conditions when UV is irradiated to thin film prepared by the spin coating method with CsPbI3 precursor solution containing a small amount of PEGDMA with photo-initiator (2-hydroxy-2-methylpropiophenone; HMPP). The reference CsPbI3, and the CsPbI3 with or without UV-curing after the addition of PEGDMA showed absorbance peaks from ~730 nm in the fresh state (Fig. 1a). As a result of recalculating the UV–vis spectroscopy analysis data and deriving the Tauc’s plot, the optical bandgap of reference CsPbI3 is 1.72 eV, and the CsPbI3 with or without UV-curing after the addition of PEGDMA are 1.69 eV, all samples exhibit black color to the naked eye (Fig. 1c). After the above three CsPbI3 samples were left in the air for 5 days, CsPbI3 with or without UV-curing after adding PEGDMA maintained an optical bandgap of 1.69 eV. However, in the case of the reference CsPbI3 without PEGDMA, an undesirable phase transition (yellow colored) occurred, which means that the optical bandgap derived to 2.82 eV. Even adding PEGDMA, the CsPbI3 that did not undergo UV irradiation maintained a bandgap of 1.69 eV, but the phase transition is progressing slowly, and it shows slightly brown to the naked eye after 5 days (Fig. 1b, d). However, the CsPbI3 with UV-curing after the addition of PEGDMA stably maintained a bandgap of 1.69 eV and the color of black even after 5 days. These results indicate that the UV-cured PEGDMA network is a direct clue to keeping the perovskite’s lattice structure firmly under atmospheric conditions. Using attenuated total reflection Fourier transform infrared (ATR-FTIR) spectroscopy, we measured the IR absorbance of PEGDMA containing photo-initiator before and after UV irradiation to perform a qualitative investigation for the conversion of C=C double bonds in the methacrylate group of PEGDMA (Fig. 1e). Each PEGDMA has two methacrylate end groups, which, when exposed with UV, react with four other methacrylate groups through radical polymerization by HMPP to make a covalent bond, and the PEGDMA forms a cross-linked network (Supplementary Fig. 1)33. When no UV irradiation was applied after HMPP was added to PEGDMA, the inherent C=C double bond peak of PEGDMA was clearly maintained and even matched exactly with all the intrinsic peaks of PEGDMA. This means that HMPP does not have any influence on the PEGDMA molecular structure when UV is not irradiated. However, when UV lights were irradiated after HMPP was added to PEGDMA, the C=C peak of the methacrylate group of PEGDMA disappeared. In addition, as the C=C peak at 1637 cm−1 disappeared, the C=O peak was blue-shifted from 1716 to 1722 cm−1 due to the C=C double bond being converted to a C–C single bond, so that is clear evidence the PEGDMA with HMPP was fully UV-cured34. Through the XRD analysis, with the fresh state, the reference CsPbI3, the CsPbI3 with or without UV-curing after the addition of PEGDMA showed Bragg peaks at 14.16°, 14.33°, 28.54°, and 28.89°, which corresponded to the (200), (100), (400), and (220) planes of the orthorhombic γ-CsPbI3 (Pbnm space group) crystallites, respectively20,23. However, after exposure to ambient conditions for 7 days, the only CsPbI3 with UV-cured PEGDMA network maintained stably the black γ-CsPbI3 phase (Fig. 1g).

a, b The UV–vis spectrum of the reference CsPbI3, and CsPbI3 with or without UV-curing after the addition of PEGDMA, at the fresh state (a), and after 5 days left in the ambient conditions (b). c, d Tauc’s plot derived from the UV–vis spectroscopy analysis data of the fresh state (c), and after 5 days left in the ambient conditions (d). Inset: photographic images of the reference CsPbI3, and CsPbI3 with or without UV-curing after the addition of PEGDMA. e ATR-FTIR spectroscopy analysis to investigate qualitatively for the conversion of C=C double bonds in the methacrylate group of PEGDMA whether UV irradiation. f, g XRD patterns of the reference CsPbI3, and CsPbI3 with or without UV-curing after the addition of PEGDMA, at the fresh state (f), and after 7 days left in the ambient conditions (g). Asterisk (*): HPbI3+x20.

A conceivable mechanism for the introduction of the PEGDMA UV-curing strategy to improve the long-term stability of CsPbI3 is proposed in Fig. 2. In a previous study, Li et al.30 reported that the electronegative acylamino group of the poly-vinylpyrrolidone (PVP) molecule attracts the cation of the CsPbI3 precursor to help the CsPbI3 nucleus formation and growth from the vicinity of the PVP molecule. Similarly, the acrylate group of PEGDMA also exhibits electronegative properties. The rich oxygen lone pair electrons of the acrylate group effectively attract Cs+ and Pb2+ cations in the precursor solution to induce CsPbI3 nuclei formation and crystal growth from the PEGDMA molecular backbone chain. The PEGDMA molecules prevent the aggregation of perovskite crystals grown in the precursor solution due to the intermolecular rejection effect30,32 of each other and help to form a stable colloid (Fig. 2a). After the spin-coating process, the CsPbI3 with PEGDMA annealed at 90 °C for 5 min and exposed UV for 5 s immediately before cooling, which induces to photopolymerization between PEGDMAs, thus CsPbI3 crystals in the thin film were fixed more compactly without any extra byproducts (Fig. 2b). Therefore, the PEGDMA induces CsPbI3 nuclei formation and crystal growth from the PEGDMA molecular backbone chain, the γ-CsPbI3 structure, which is tightly fixed by the UV-cured PEGDMA polymer network, can maintain the robust γ-phase under ambient conditions (Fig. 2c).

a Step 1: Induced CsPbI3 nuclei formation and crystal growth from the PEGDMA molecular backbone chain by the PEGDMA’s oxygen lone pair electrons in the precursor solution. b Step 2: UV-curing process immediately before cooling, on the spin-coated and annealed CsPbI3 after the addition of PEGDMA. UV irradiation: 365 nm, 400 mW cm−2 for 5 s. c Step 3: Establishment of the robust γ-CspbI3 with the UV-cured PEGDMA polymer network.

The correlation between PEGDMA content and black γ-CsPbI3 optical long-term stability

We investigated in-depth the effect of the content of UV-cured PEGDMA polymer network inside CsPbI3 thin film on the atmospheric stability of γ-CsPbI3. Figure 3 shows the effect on the optical long-term stability of γ-CsPbI3 by splitting the PEGDMA content added to the CsPbI3 precursor solution into 0, 0.5, 1, 3, and 5 wt%, respectively. For convenience, the group of γ-CsPbI3 thin-film samples with adding different wt% of PEGDMA cured by UV after spin coating are briefly referred to as γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA), respectively. Figure 3a–e is the result of accumulating UV-vis absorbance spectra while exposing γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) to the ambient conditions for 35 days. The variation of an optical property of γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) for 35 days were measured at ambient conditions with 20.50 ± 1.10 °C for temperature and 26.81 ± 2.56% for relative humidity, respectively (Supplementary Fig. 2 and Supplementary Tables 1 and 2). The achromatic lines (black and gray) indicate the date of which the perovskite represents a stable black phase, and the chromatic lines (from red to yellow) indicate the date at which the perovskite can no longer maintain the black phase. The γ-CsPbI3 (0 wt% PEGDMA) was rapidly changed to δ-CsPbI3 as the phase transition began 3 days after exposure to the ambient conditions, but γ-CsPbI3 (0.5, 1, 3, and 5 wt% PEGDMA) were kept stable black phase in the long term as the PEGDMA content increased. Especially, both γ-CsPbI3 (3 wt% PEGDMA) and γ-CsPbI3 (5 wt% PEGDMA), even after 35 days after exposure to the ambient conditions, the absorbance peak was stably observed at ~730 nm, and the spectrum change was almost negligible. Interestingly, as the PEGDMA content increased, the absorbance peak intensity at the 720 nm position of all fresh γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) follows a linear relationship with the PEGDMA content (Supplementary Fig. 3). This means that PEGDMA directly affects the growth of perovskite grain, and this tendency is clearly confirmed through the field emission scanning electron microscopy (FE-SEM) images in Fig. 3f.

a–e Accumulated UV–vis absorbance spectra while exposing γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) to the ambient conditions for 35 days. f FE-SEM top view images of γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA). Scale bar: 2 μm. g Time-dependent photographic results obtained by observing the optical color change of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) thin films during 35 days in ambient conditions. The red square box represents the limitation of γ-phase stability that begins to transition from the γ-phase to the δ-phase. h–k XPS analysis on the fresh γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) at full range (h), Pb 4 f (i), I 3d (j), and Cs 3d (k).

Figure 3g shows the time-dependent photographic results obtained by observing the optical color change of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) thin films, which were continuously exposed to the ambient conditions. The red square box represents the limitation of γ-phase stability that begins to transition from the γ-phase to the δ-phase, which perfectly matches the UV–vis spectral trend of Fig. 3a–e. The XPS analysis was performed on the fresh γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) to confirm the CsPbI3 lattice binding energy varying with PEGDMA content (Fig. 3h–k). In the case of pure γ-CsPbI3 (0 wt% PEGDMA), the Cs 3d spectra show two peaks at 723.5 and 737.2 eV corresponding to the binding energies of Cs 3d5/2 and Cs 3d3/2, respectively. The Pb 4f spectra show two peaks at 137.6 and 142.5 eV corresponding to the binding energies of Pb 4f7/2 and Pb 4f5/2, and the spectra of I 3d also exhibit two peaks at 618 and 629.3 eV corresponding to I 3d5/2 and I 3d3/2, respectively. However, in cases of γ-CsPbI3 (0.5, 1, 3, and 5 wt% PEGDMA), as the PEGDMA content increases, Cs 3d and Pb 4f binding energy were significantly lowered by 0.7 eV, and I 3d was also slightly shifted to the low binding energy. This tendency indicates that the PEGDMA content increases, the oxygen lone pair sites also increase linearly, so the binding energy of Cs 3d and Pb 4f peaks are lowered by causing a stronger interaction between the cations of the γ-CsPbI3 and oxygen lone pairs of PEGDMA. Since the binding energy of Cs+ and Pb2+ ions forming the γ-CsPbI3 lattice was lowered, the anion I 3d peaks was also shifted slightly to the lower binding energy as a side effect. As a result of XPS analysis, it was confirmed that effective Coulombic interactions exist between the oxygen lone pairs and the Cs+, Pb2+ cations inside the CsPbI3 thin film. We performed dynamic light scattering (DLS) analysis to determine whether these Coulombic interactions originated from the PEGDMA added CsPbI3 precursor solution (Supplementary Fig. 4).

Through the DLS analysis, the colloid size of the CsPbI3 (0 wt% PEGDMA) precursor solution was confirmed that the solution contained the monodispersed CsPbI3 colloids which have a diameter of 1.32 nm. However, as the content of PEGDMA increases from 0.5 to 5 wt%, an additional satellite peak was observed, unlike the CsPbI3 (0 wt% PEGDMA) solution. As the content of PEGDMA increases, the intensity of the reference CsPbI3 colloid peak gradually decreased; on the contrary, the intensity of the satellite peak increased with the corresponding colloid size also increased to 173.09, 428.47, 614.62, and 1319.97 nm, respectively. The fact that the observed colloid size is clearly distinguished as the amount of added PEGDMA increases does mean that PEGDMA induces CsPbI3 nucleation and directly affects crystal growth. Obviously, DLS analysis only provided information on the colloid size distribution trend in the liquid phase, therefore, another method for analyzing the grain size of perovskite thin film (solid phase) has considered. We counted the perovskite grain size distribution in the solid phase using the Image J program based on the FE-SEM image (Supplementary Fig. 5 and Supplementary Table 3). Each γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) FE-SEM image was used to measure the areas of grains within the same area (610,000 nm2) and counted by 800 nm2 size section. The average grain size of γ-CsPbI3 (0 wt% PEGDMA) was 2131.95 ± 989.17 nm2, and as the PEGDMA content increased, the γ-CsPbI3 grain size tended to increase. This trend was effective until γ-CsPbI3 (5 wt% PEGDMA), which grain size measured 7824.19 ± 4255.89 nm2. This result indicates that the colloid size distribution result through DLS analysis of perovskite precursor solution (liquid phase) is directly related to the grain size inside the fabricated thin film (solid phase). Therefore, XPS, DLS, and Image J analysis results provide strong evidence supporting the mechanism of Fig. 2, as it can be seen that oxygen lone pairs of PEGDMA induce CsPbI3 nucleation and crystal growth in the PEGDMA molecular backbone chain from the precursor solution state.

Photo-electrical properties and phase stabilities according to variation of the PEGDMA polymer network content in γ-CsPbI3

To confirm the applicability of γ-CsPbI3 with PEGDMA polymer network as a light detecting material, 2-terminal lateral photoresistors with channel length and width of 120, 1000 µm, respectively, were fabricated in Au/γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA)/Au structure. Figure 4 shows the electrical properties of photoresistors under irradiation of 0.4 mW cm−2 of red (635 nm), green (532 nm), and blue (450 nm) LED light sources. Figure 4a–e represents the photoresponse I–V characteristics of photoresistors including γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA). As the PEGDMA content increased, the dark current of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) device decreased. The dark current of the γ-CsPbI3 (0 wt% PEGDMA) device showed a relatively large value of 8.0 × 10−10 A, while the γ-CsPbI3 (5 wt% PEGDMA) device slightly decreased by 6.47 × 10−11 A. Since PEGDMA exhibits electrical insulating properties, the dark current tends to decrease as the amount of added PEGDMA increases. On the other hand, when red, green, and blue light was irradiated, the photocurrent of photoresistors including the γ-CsPbI3 (0, 0.5, 1, and 3 wt% PEGDMA) tended to increase as the increment of PEGDMA content from 0 to 3 wt%. As mentioned in Fig. 3f and Supplementary Fig. 4, the increment of PEGDMA content attributes to the large growth of perovskite grains and within such large grains, photo-generated charge carriers generally exhibit a longer mean free-path which would yield a higher photocurrent. However, the photocurrent of γ-CsPbI3 (5 wt% PEGDMA) did not follow the above trend. Since the γ-CsPbI3 grains, irregularly overgrown when 5 wt% PEGDMA was added, the film shows poor roughness which hinders the charge carrier transport from the CsPbI3 to the electrodes. In addition, the 5 wt% PEGDMA-added film suppresses the generation of effective photocurrent because it contains a large number of pinholes that cause scattering of photogenerated charge carriers (Fig. 3f). As a result of measuring the I–V curve after continuously exposing these devices to the ambient conditions for 35 days, γ-CsPbI3 (3 wt% PEGDMA) device showed ~90% of the photoelectrical performance compared to the initial state (Supplementary Fig. 6 and Supplementary Table 4). Figure 4f, g shows the comparison of additional optical response parameters between as-prepared and after 35 days of Au/γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA)/Au photoresistors. To determine whether CsPbI3 with UV-cured PEGDMA network continuously maintains the black phase and the photoelectric properties, we tested the response of the photoresistor on red-colored (635 nm) light in cases of fresh and after 35 days, respectively (Table 1). The γ-CsPbI3 (3 wt% PEGDMA) device showed stable photoresponse characteristics in light of 635 nm as well as 450 and 532 nm even after exposure to ambient conditions for 35 days. The initial Jphoto/Jdark of the γ-CsPbI3 (3 wt% PEGDMA) device for 635 nm light is 9.07 × 102, and the Jphoto/Jdark after 35 days is 7.55 × 102. Initial responsivity (R) is 0.122 A W−1, and the responsivity after 35 days is 0.0974 A W−1. In addition, normalized detectivity (D*) showed a value of 7.56 × 1011 Jones after 35 days from the initial value of 9.30 × 1011 Jones. The initial value of the external quantum efficiency (EQE) is 23.8%, and the EQE after 35 days still retains 19%, which shows excellent electrical long-term stability.

a–e Photoresponse I–V characteristics of photoresistors including fresh γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA), under irradiation of 0.4 mW cm−2 of red (635 nm), green (532 nm), and blue (450 nm) LED light sources. f, g The comparison of additional optical response parameters between as-prepared and after 35 days of Au/γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA)/Au photoresistors. Unit of the parameters: EQE(%), Jphoto/Jdark, R (A W−1), D* (Jones).

Furthermore, to evaluate the repetitive driving stability of the optimized γ-CsPbI3 (3 wt% PEGDMA) photoresistor, we measured the time-resolved photoresponse and transient response time (Fig. 5). Photocurrent–time response was measured at 40 V applied bias in the dark and under illumination using the LEDs at 635, 532, 450 nm with fixed light intensity (Pin = 0.4 mW cm−2) and frequency (1 Hz) (Fig. 5a, b, d, e). Unlike the reference γ-CsPbI3 (Fig. 5a, b), the γ-CsPbI3 (3 wt% PEGDMA) photoresistor showed stable and consistent repetitive driving characteristics not only the fresh state but also after 35 days, and the photocurrent values were also matched with Fig. 4d and Supplementary Fig. 6d. In addition, rise times in response to red, green, and blue light of fresh γ-CsPbI3 (3 wt% PEGDMA) were 65.1, 66.0, and 66.4 ms, and fall times were 66.8, 66.8, and 66.7 ms, respectively. Even after 35 days exposed in the ambient conditions, it shows an excellent fast response time that did not change much from the rise and fall time values of the initial device (Fig. 5c, f).

a, b Photocurrent–time responses of the reference γ-CsPbI3 photoresistor at fresh state (a) and after 35 days (b) at 40 V applied bias. c, f The transient response time of the γ-CsPbI3 (3 wt% PEGDMA) photoresistor at fresh state (c) and after 35 days (f). d, e Photocurrent–time responses of the γ-CsPbI3 (3 wt% PEGDMA) photoresistor at fresh state (d) and after 35 days (e). Photocurrent–time response was measured at 40 V applied bias in the dark and under illumination using the LEDs at 635, 532, 450 nm with fixed light intensity (Pin = 0.4 mW cm−2) and frequency (1 Hz). The transient response time was measured at the 10th period during the 2 Hz, 50% duty cycle with fixed light intensity (Pin = 0.4 mW cm−2).

Conclusion

In summary, we suggest a robust strategy to ensure the structural, electrical long-term stability of γ-CsPbI3 under ambient conditions by employing the infinitesimal amount (≤3 wt%) of UV-curable PEGDMA. The electronegative oxygen lone pairs of the PEGDMA attract Cs+ and Pb2+ cations from the CsPbI3 precursor solution, which induce effective CsPbI3 nucleation and growth from the PEGDMA backbone chain. In addition, the PEGDMA (Mn ≈ 330) has short chain lengths with four repeating units, resulting in a dense network by the UV-curing, which acts to hold CsPbI3 tightly, thus it is possible to suppress the additional distortion of the γ-CsPbI3 lattice. The PEGDMA polymer network formed by UV irradiation inside the γ-CsPbI3 thin-film clearly contributed to maintaining a considerably stable black phase even when exposed to ambient conditions for 35 days. To evaluate the electrical long-term stability of the γ-CsPbI3 thin-film employing with the PEGDMA polymer network, 2-terminal lateral photoresistors of Au/γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA)/Au structure were fabricated, and the photoresistor including optimized UV-cured γ-CsPbI3 (3 wt% PEGDMA) showed that ~90% of the initial electrical values were retained responding to red, green, and blue light even after 35 days in the ambient conditions. Consequently, despite the addition of a small amount of UV-cured PEGDMA network into the γ-CsPbI3, the γ-CsPbI3’s photoelectric parameters and light response speed remain robust even after prolonged exposure to ambient conditions. Therefore, applying an infinitesimal UV-curable polymer network with electronegative lone pair electrons to perovskite is an innovative strategy that can contribute effectively to long-term optical and electrical stability. It also indicates that this strategy can be applied not only to γ-CsPbI3 but also to various halide perovskite materials.

Methods

Preparation of CsPbI3 precursor solution containing a small amount of PEGDMA

The CsPbI3 precursor solution was prepared by dissolving 0.48 M of cesium iodide (CsI, 99.999%, Sigma Aldrich) and lead iodide (PbI2, 99%, Sigma Aldrich) in the mixed solvent of 2 mL of anhydrous N, N-dimethylformamide (DMF, 99.8%) and 72 μL of HI (57 wt% in H2O, Sigma Aldrich) and stirred vigorously at 700 rpm over 12 h24. PEGDMA:HMPP mixture with 1 wt% of 2-hydroxy-2-methylpropiophenone (HMPP, 97%, Sigma Aldrich) added to poly(ethylene glycol) dimethacrylate (PEGDMA, Mn ≈330, Sigma Aldrich) as a photoinitiator was added to the prepared CsPbI3 precursor solution as 0, 0.5, 1, 3, 5 wt% of the total amount of CsI and PbI2. Then stirred vigorously at 700 rpm over 6 h.

Fabrication process of Au/γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA)/Au photoresistors

The prepared CsPbI3 precursor solution containing a small amount of PEGDMA was spin-coated on a bare glass substrate in two steps. First, the spin-coating was performed at 2000 rpm for 25 s, and then spin-coating was immediately performed at 5000 rpm for 35 s. After 5 s of reaching 5000 rpm, the chlorobenzene was directly dropped onto the substrate to quickly remove the DMF solvent35. After the spin-coating process, the CsPbI3 with PEGDMA annealed at 90 °C for 5 min and exposed UV for 5 s immediately before cooling, which induces to photopolymerization between PEGDMAs. LED UV lamp (365 nm, Liim tech) was used as an ultraviolet light source. In this study, all UV-curing processes were performed at 400 mW cm−2 for 5 s and the distance between the light source and substrate was fixed at 15 mm. Finally, 100 nm gold (Au) electrodes were deposited by the thermal evaporator, with a shadow mask with channel length and width of 120, 1000 µm, respectively.

Characterizations of optical and photoelectrical properties

The current-voltage characteristics for all devices were measured in the voltage range −40 to 40 V at room temperature in a dark using the 4155B (Keysight) semiconductor parameter analyzer with the visible light irradiation using LED light sources (STF0A36C, SSC). The optical transmittance and absorbance of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) films are measured using a UV–Vis spectrometer (PerkinElmer Lambda 35). UV-cured PEGDMA structures are confirmed with ATR-FTIR (BRUKER, Alpha) at 4000–600 cm−1 ranges. The crystallinity and morphology of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) films were obtained using FE-SEM (S-4800, Hitachi) and X-ray diffraction (XRD, D8 Advance, Bruker Co.) executed with Cu-Kα radiation (λ = 1.54 Å) at 40 kV and 150 mA (6 kW) with a grazing-incidence mode. X-ray photoelectron spectroscopy (XPS, AXIS SUPRA, Kratos) was used to analyze the chemical properties of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) films. Time-resolved photoresponse and transient response time were measured by B2902A (Keysight) two-channel source meter.

Data availability

The datasets that support all the findings of this study are available from the corresponding author (Y.S. Kim) upon reasonable request.

References

Park, N.-K. Organometal perovskite light absorbers toward a 20% efficiency low-cost solid-state mesoscopic solar cell. J. Phys. Chem. Lett. 4, 2423–2429 (2013).

Xing, G. et al. Long-range balanced electron and hole-transport lengths in organic-inorganic CH3NH3PbI3. Science 342, 344–347 (2013).

Gao, P. et al. Organohalide lead perovskites for photovoltaic applications. Energy Environ. Sci. 7, 2448–2463 (2014).

Hao, F. et al. Lead-free solid-state organic–inorganic halide perovskite solar cells. Nat. Photonics 8, 489–494 (2014).

Dou, L. et al. Solution-processed hybrid perovskite photodetectors with high detectivity. Nat. Commun. 5, 5404 (2014).

Pool, V. L. et al. Thermal engineering of FAPbI3 perovskite material via radiative thermal annealing and in situ XRD. Nat. Commun. 8, 14075 (2017).

Eperon, G. E. et al. Formamidinium lead trihalide: a broadly tunable perovskite for efficient planar heterojunction solar cells. Energy Environ. Sci. 7, 982–988 (2014).

Xu, L. et al. A comprehensive review of doping in perovskite nanocrystals/quantum dots: evolution of structure, electronics, optics, and light-emitting diodes. Mater. Today Nano 6, 100036 (2019).

Bhalla, A. S. et al. The perovskite structure—a review of its role in ceramic science and technology. Mater. Res. Innov. 4, 3–26 (2000).

Conings, B. et al. Intrinsic thermal instability of methylammonium lead trihalide perovskite. Adv. Energy Mater. 5, 1500477 (2015).

Berhe, T. A. et al. Organometal halide perovskite solar cells: degradation and stability. Energy Environ. Sci. 9, 323–356 (2016).

Nam, J. K. et al. Methodologies toward efficient and stable cesium lead halide perovskite-based solar cells. Adv. Sci. https://doi.org/10.1002/advs.201800509 (2018).

Hoffman, J. B. et al. CsPbBr3 solar cells: controlled film growth through layer-by-layer quantum dot deposition. Chem. Mater. 29, 9767–9774 (2017).

Travis, W. et al. On the application of the tolerance factor to inorganic and hybrid halide perovskites: a revised system. Chem. Sci. 7, 4548–4556 (2016).

Sutton, R. J. et al. Bandgap-tunable cesium lead halide perovskites with high thermal stability for efficient solar cells. Adv. Energy Mater. 6, 1502458 (2016).

Liang, J. et al. All-inorganic perovskite solar cells. J. Am. Chem. Soc. 138, 15829–15832 (2016).

Chen, H. et al. Inorganic perovskite solar cells: a rapidly growing field. Sol. RRL 2, 1700188 (2018).

Nam, J. K. et al. Potassium incorporation for enhanced performance and stability of fully inorganic cesium lead halide perovskite solar cells. Nano Lett 17, 2028–2033 (2017).

Swarnkar, A. et al. Quantum dot–induced phase stabilization of a-CsPbI3 perovskite for high-efficiency photovoltaics. Science 354, 92–95 (2016).

Wang, K. et al. All-inorganic cesium lead iodide perovskite solar cells with stabilized efficiency beyond 15%. Nat. Commun. 9, 4544 (2018).

Marronnier, A. et al. Anharmonicity and disorder in the black phases of cesium lead iodide used for stable inorganic perovskite solar cells. ACS Nano 12, 3477–3486 (2018).

Eperon, G. E. et al. Inorganic caesium lead iodide perovskite solar cells. J. Mater. Chem. A 3, 19688 (2015).

Zhao, B. et al. Thermodynamically stable orthorhombic γ‑CsPbI3 thin films for high-performance photovoltaics. J. Am. Chem. Soc. 140, 11716–11725 (2018).

Haque, F. et al. Effects of hydroiodic acid concentration on the properties of CsPbI3 perovskite solar cells. ACS Omega 3, 11937–11944 (2018).

Bao, C. et al. High performance and stable all-inorganic metal halide perovskite-based photodetectors for optical communication applications. Adv. Mater. 30, 1803422 (2018).

Jena, A. K. et al. Stabilization of α‑CsPbI3 in ambient room temperature conditions by incorporating Eu into CsPbI3. Chem. Mater. 30, 6668–6674 (2018).

Zhang, T. et al. Bication lead iodide 2D perovskite component to stabilize inorganic α‑CsPbI3 perovskite phase for high-efficiency solar cells. Sci. Adv. 3, e1700841 (2017).

Hu, Y. et al. Bismuth incorporation stabilized α‑CsPbI3 for fully inorganic perovskite solar cells. ACS Energy Lett 2, 2219–2227 (2017).

Han, B. et al. Stable, efficient red perovskite light‐emitting diodes by (α, δ)‐CsPbI3 phase engineering. Adv. Funct. Mater. 28, 1804285 (2018).

Li, B. et al. Surface passivation engineering strategy to fully-inorganic cubic CsPbI3 perovskites for high-performance solar cells. Nat. Commun. 9, 1076 (2018).

Wang, Q. et al. Stabilizing the α-phase of CsPbI3 perovskite by sulfobetaine zwitterions in one-step spin coating films. Joule 1, 371–382 (2017).

Jeong, B. et al. All-inorganic CsPbI3 perovskite phase-stabilized by poly(ethylene oxide) for red-light-emitting diodes. Adv. Funct. Mater. 28, 1706401 (2018).

Bäckström, S. et al. Tailoring properties of biocompatible PEG-DMA hydrogels with UV light. Mater Sci. Appl. 3, 425–431 (2012).

Hwang, J. W. et al. Gelation and crosslinking characteristics of photopolymerized poly(ethylene glycol) hydrogels. J. Appl. Polym. Sci. 132, 41939 (2015).

Jeon, N. J. et al. Solvent engineering for high-performance inorganic–organic hybrid perovskite solar cells. Nat. Mater. 13, 897–903 (2014).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT, Ministry of Science and ICT)—Basic Science Research Program (No. 2020R1A2B5B03002136) and Nano Material Technology Development Program (No. 2016M3A7B4910458).

Author information

Authors and Affiliations

Contributions

N.-K.C. and H.-J.N. performed the fabrication of the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) films and photoresistors, and the γ-CsPbI3 (0, 0.5, 1, 3, and 5 wt% PEGDMA) film’s optical characteristics were carried out by N.-K.C., H.-J.N., and J.Y. The paper was written through contributions of all authors. The project was planned, directed and supervised by Y.S.K. All authors have given approval to the final version of the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Primary handling editor: John Plummer

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cho, NK., Na, HJ., Yoo, J. et al. Long-term stability in γ-CsPbI3 perovskite via an ultraviolet-curable polymer network. Commun Mater 2, 30 (2021). https://doi.org/10.1038/s43246-021-00134-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-021-00134-1