Abstract

Solution-processed flexible organic optoelectronic devices have great potential as low-cost organic photovoltaics for energy harvesting, and in organic light-emitting diodes as a lighting source. However, a major challenge for improving device performance and stability is the different interfacial characteristics of the hydrophobic organic layers and hydrophilic transparent electrodes, particularly for flexible devices. Surface wetting controlled interfacial engineering can provide a useful method to develop highly efficient flexible organic devices. Here, an unsaturated fatty acid-modified ethoxylated polyethyleneimine organic interfacial layer is designed, which is hydrophobic or hydrophilic on different interfaces. This interlayer results in a power conversion efficiency of 10.57% for rigid and 9.04% for flexible photovoltaic devices. Furthermore, the long-term air storage stability for 250 h is substantially improved, retaining 87.75% efficiency without encapsulation, due to the wettability driven improvement of the optical and electronic properties of the cathode interfacial layer. The performance of organic light emitting diodes also benefitted from the interlayer. This study provides a strategy to simultaneously improve efficiency and stability by controlling the wettability of the interfacial layer.

Similar content being viewed by others

Introduction

Over the past few decades, organic semiconductor optoelectronic devices, such as organic photovoltaics (OPVs) and organic light-emitting diodes (OLEDs) have garnered considerable attention owing to their remarkable intrinsic properties. These properties include solution processability, good mechanical flexibility, and easy and low-cost manufacturing (printing or roll-to-roll fabrication) techniques1,2,3,4,5,6,7. Moreover, with excellent color tunability and free-form design, OPVs and OLEDs show prominent and wide-ranging advantages for commercial applications5,8,9. Recently, OPVs have been reported to exhibit a power conversion efficiency (PCE) of over 18% (non-fullerene acceptor), which set a new landmark for high-performance OPVs to overcome the energy crisis10. On the other hand, OLEDs have achieved vivid RGB (red–green–blue) color and high-brightness white light. These OLEDs have already been commercialized in the display and lighting market7.

For developing integrated photovoltaics and large-sized, yet lightweight, flexible displays, the flexibility of OPVs and OLEDs is highly desirable. Generally, polyethylene naphthalate (PEN) and polyethylene terephthalate (PET) are used as substrates for fabricating flexible optoelectronic devices. However, these substrates become unstable when thermally annealed over 120 °C for PEN and 78 °C for PET7,11,12. Thus, the room temperature fabrication process is strongly preferable for developing flexible optoelectronic devices. However, flexible devices, particularly those with inverted structures, still underperform as compared to the rigid devices. The electron transport or material properties of the electron injection layer are important for extracting or injecting electrons while blocking hole transport, which is more effective when using rigid substrates or high-temperature manufacturing processes.

Metal oxides, such as zinc oxide (ZnO), tin oxide (SnO2), and titanium oxide (TiO2), have a wide bandgap, high electron mobility, and environment-friendly characteristics. As a result, they are commonly used to fabricate highly efficient optoelectronic devices13,14,15,16,17,18,19,20. However, ZnO, SnO2, and TiO2 interfacial layers are commonly fabricated using a high-temperature annealing process, which is not suitable for developing flexible optoelectronic devices. Thus, to improve the performance of the OPVs and OLEDs, many researchers have employed organic cathode interfacial layers (CILs) of different materials, such as Poly [(9,9-bis(3’-(N, N-dimethylamino)propyl)-2,7-fluorene)-alt-2,7-(9,9–dioctylfluorene)] (PFN) and its derivate (PFN-V and PFN-Br) or polyfluorene derivative (WPF-Oxy-F) and Poly[(9, 9-bis (6′-diethoxylphosphorylhexyl) fluorene)] (PF-EP)21,22,23,24,25. Among these materials, polyethylenimine 80% ethoxylated (PEIE), a low-cost commercial polyelectrolyte, has been extensively used for fabricating flexible optoelectronic devices. This is because PEIE can perform well even without thermal annealing treatment owing to its excellent mechanical flexibility14,26,27,28,29. The aliphatic amine groups that are present in the PEIE can align the permanent dipole at the indium tin oxide (ITO)/photoactive layer interface. This alignment lowers the electron injection barrier to reduce the trap-assisted recombination26,28,29. Nevertheless, the nonconjugated PEIE, which is an electrical insulator, weakens the charge extraction or injection of the substrate material. In addition, the hydrophilic tail of PEIE deteriorates the long-term device stability28,30 and prevents the uniform deposition of the organic active layer on the PEIE treated ITO substrate31. Thus, the structural engineering or modification of the PEIE molecule is crucial to improve its capability as the interfacial layer for the development of flexible optoelectronic devices. To improve the performance of OPV devices based on PEIE CILs, many studies have been attempted. For example, Zhang et al. modified the PEIE by a simple quaternization reaction between PEIE and 1,8-diiodooctane (DIO) to improve the thickness dependency30. Moreover, Zhang et al. also reported two nonconjugated polymers PEIE-DBO and PEIE-DCO developed by quaternization of PEIE with 1,8 dibromooctane (DBO) or 1,8 dichlorooctane (DCO) to improve electron mobility and conductivity32. The PEIE doped by tetraalkylammonium salts also was developed to further reduce the WF by a combination of the alignment of the permanent dipole of PEIE and ionic electric polarization along the depth direction on electrodes33. However, from the reported studies, the wetting properties at the electrode/active layer interface is not yet intensely investigated.

In this study, we demonstrated highly efficient flexible OPV and OLED devices using modified PEIE CILs with different hydrophilicity on both sides of the layer. The different hydrophilicity of the CILs can adjust the heterogeneous bifacial interlayer properties between the organic active layer and transparent conducting ITO electrode. A novel Janus PEIE CIL was prepared by adding hydrophobic organic molecules, such as fatty acids in the PEIE. Fatty acids consist of a polar head, –COOH, and chains of an uncharged, nonpolar tail, which are hydrophobic in nature. The polar head of the fatty acid simply reacted with the hydroxyl group of PEIE and/or created bonds with the ITO surface by acting as an anchoring group. The long hydrophobic chain of the fatty acid partially exposed the top surface of the PEIE CIL and transformed it into a hydrophobic surface. In addition, the opto-electrical characteristics, such as electrical conductivity, band gap, and dipole moment were also improved.

In general, two groups of fatty acids exist: saturated fatty acids (SFA) and unsaturated fatty acids (UFA). In this study, PEIE was modified using saturated stearic acid and unsaturated linoleic acid with an equal number of carbon atoms, which are denoted as SA-PEIE and LA-PEIE, respectively. The LA-PEIE based flexible OPV and OLED devices have excellent properties, which are superior to those of the pristine PEIE, and ZnO CILs. These properties particularly include: (i) the interfacial charge transport, (ii) device stability under ambient conditions, and (iii) mechanical durability of the device during bending tests. The OPV devices that used LA-PEIE as the CILs and PTB7‐Th: PC70BM bulk‐heterojunction as the active layers achieved a remarkably high PCE of 10.57% (flexible OPVs achieved 9.04% of PCE), whereas the devices that used the pristine PEIE CIL achieved a PCE of 9.30% (flexible OPVs achieved 7.87% PCE). To the best of our knowledge, these results indicate the highest achieved PCEs for the widely studied PTB7‐Th: PC70BM devices with polyelectrolyte CILs.

Results

Optoelectronic properties and morphology of CILs

To study the optoelectronic properties and morphology of the CILs, we compare the transmittance spectra of bare glass, ITO glass, and ITO PEN substrates (see Supplementary Fig. S2a). The high absorption of the ITO PEN in the ultraviolet (UV) region is due to the naphthalene rings in the PEN main chain30. The transmittance spectra of the ZnO, PEIE, and LA-PEIE films that are deposited on ITO glass substrates are shown in Supplementary Fig. S2b. Both PEIE and LA-PEIE films exhibit similar light transmittance characteristics. Surface roughness and organic hydrophobicity are the prerequisites for fabricating superhydrophobic surfaces. Low surface energy and texture with nano- or micro-texturing alter the surface characteristics and turn the surface hydrophobic. The surface morphologies of the CILs were observed via atomic force microscopy (AFM). The corresponding AFM images are shown in Fig. 1b, c. The surface (0.48 nm, which is a root mean square (rms) value) of the LA-PEIE film is smoother than that of the PEIE film (0.75 nm rms). A smoother surface helps in a seamless transition from the CILs to active layers without defects, allowing for better charge extraction34,35,36. Several reports mentioned that CILs with textured rough surfaces (nanowires, nanowall, and ripples) are a more suitable architecture for enhancing the electrical and mechanical properties of the interface between the CILs and the active layer37,38,39. A stronger hydrophobicity is expected on the rough surface of the PEIE film (Fig. 1b, c). However, a higher hydrophobicity is observed on the smooth LA-PEIE film surface (Fig. 1d, e), which was previously treated by a linoleic fatty acid. The addition of LA increased the contact angle; the contact angle of LA-PEIE (58.62°) is higher than that of the PEIE (25.85°). The improved hydrophobicity of the LA-PEIE film is a consequence of the formation of the hydrophobic tail of LA on the top surface of the PEIE layers. This improvement in the hydrophobicity is confirmed by performing Fourier transform infrared spectroscopy (FTIR) of the films (Fig. 1f). For both PEIE and LA-PEIE samples, the absorption peaks at 1047 and 1460 cm−1 can be attributed to C–N and C–O bonds, respectively. The carboxylic group (C=O) and C=C are observed respectively at 1659 and 1565 cm−1, which indicates that LA is well incorporated with PEIE. The absorption of O–H is observed in the range of 3200–3500 cm−1. In this range, the decrease in absorption by the O–H bond in LA-PEIE indicates a decrease in the number of OH hydrophilic sites. These results are further confirmed by the Raman spectra (Supplementary Fig. S10). The C=O and C=C bonds indicating the incorporation of LA with PEIE are observed at 1697 and 1648 cm−140,41,42,43 Furthermore, the intensity of peak corresponding to O–H bending is observed decreased. It implies that the concentration of the hydroxyl group in PEIE is decreased after the incorporation of LA42,44,45. The hydrophilic sites of PEIE can easily react with the OH groups in the fatty acids. This suggests that most of the fatty acid hydrophobic chains are located on one side of the LA-PEIE film, depending on the surface condition of the substrate, while the hydrophilic hydroxyl chains are located on the other side. In this manner, the incorporation of organic hydrophobic molecules (fatty acids) into PEIE can create a bifacial interface that is hydrophilic at the bottom surface facing the ITO layer and hydrophobic at the top surface facing the photoactive layer. The bifacial property of the LA-PEIE CIL also increases the contact angle and strength of the induced surface dipoles. Thus, compared to the PEIE CILs, the photoactive layer can be coated more uniformly on the LA-PEIE CILs, thereby improving the adhesion of the LA-PEIE with the photoactive layer when spin-coated using a hydrophobic chlorobenzene solvent31, as illustrated in Fig. 1a. The excessive phase separation and aggregated PC70BM occurred when the photoactive layer was coated on the PEIE with a hydrophilic surface, resulting in poor device performance (Supplementary Fig. S3a). Meanwhile, the photoactive layer coated on the hydrophobic surface of LA-PEIE has lower roughness (Supplementary Fig. S3b), indicating a better morphology of D/A photoactive materials. Therefore, the bifacial LA-PEIE CILs can improve the performance of flexible optoelectronic devices.

a Schematic of the mechanism of PEIE and LA-PEIE CILs. b, c AFM images of PEIE and LA-PEIE CILs with rms of 0.75 and 0.48 nm, respectively. d, e Contact angle images of PEIE (θ = 25.85o) and LA-PEIE (θ = 58.62o). f Fourier transform infrared spectroscopy (FTIR) spectra of PEIE (blue line) and LA-PEIE CILs (red line).

Device performance of ITO/glass-based OPVs

To determine the dependency of device efficiency on the hydrophobic characteristics of the PEIE CILs, we fabricated devices with different LA concentrations. The variation of the performance of a rigid OPV device with the contact angle owing to the LA concentration and its effect are shown in Supplementary Fig. S3c and tabulated in Supplementary Table S1. As expected, the device performance is strongly affected by the hydrophobicity based interfacial characteristics. As we increased the LA concentration, the PCE of the OPVs increased to a certain value with enhanced hydrophobicity and then decreased (see Supplementary Fig. S3d). The decreased PCE can be interpreted as the nonconducting effect of the excessive amount of the LA hydrophobic chain. The current density–voltage (J–V) curve and external quantum efficiency (EQE) of the best OPV on a rigid substrate are shown for each CIL in Fig. 2a, b. In addition, the photovoltaic properties of each device are summarized in Table 1. The ZnO CILs exhibited a higher PCE (9.46%) as compared to the PEIE CIL, mainly because of the higher fill factor (FF) of the ZnO CILs. The OPV with LA-PEIE CIL outperformed the OPVs with other CILs and showed the highest PCE (10.57%), FF (0.68), open-circuit voltage (VOC) (0.82 V), and short circuit current density (JSC) (19.33 mA cm−2). These results show that the LA-PEIE CIL can be much better than the conventional metal-oxide-based CILs, which are formed and annealed at high temperatures. Remarkably, to the best of our knowledge, the PCE of our devices with LA-PEIE CILs is one of the highest values recorded thus far among the widely studied PTB7‐Th:PC70BM active layer with functional polymer-based CILs (see Supplementary Table S3). Interestingly, as shown in Supplementary Fig. S4c and Supplementary Table S2, the PEIE modified by UFA (i.e., LA) showed an enhanced performance than the PEIE modified by SFA (i.e., stearic acid). LA has a melting point (−5 °C) that is considerably lower than that of the stearic acid (69.6 °C) having the same number of carbon atoms. The chemical structures of SFA and UFA, represented by stearic acid and LA, are shown in Supplementary Fig. S4a. This result implies that the lower melting point fatty acids are favorable for fabricating room-temperature processed organic devices. Besides, the conjugated chains in LA lead to form higher dipole moment compared to SA. The calculated dipole moments for LA and SA are 1.61 and 1.48 D, respectively. Thus, the reinforced dipole moment of LA-PEIE is higher than those of SA-PEIE as illustrated in Supplementary Fig. S4b.To gain deeper insights into the improved FF and JSC, the OPV devices were analyzed under dark conditions (Fig. 2c). The parameters extracted from the dark J–V are tabulated in Supplementary Table S5. The shunt resistance (RSH) plays an important role in controlling the leakage currents and FF22,46. In the region −2 to 0 V, the leakage currents of the reverse-biased LA-PEIE (RSH of 5.35 × 105 Ω cm2) devices are remarkably suppressed as compared to the PEIE (RSH of 5.94 × 104 Ω cm2). In the region beyond 1 V, an improvement in the injection currents of the LA-PEIE device is also noticed. This implies an improved electron extraction from the active layer47. In contrast, the PEIE shows a poor injection current compared to LA-PEIE devices. Moreover, upon the incorporation of LA to PEIE, the ideality factor (n) decreases from 1.42 to 1.27, indicating suppressed carrier recombination which leads to the improvement in FF.

a Current density–voltage characteristics, b EQE spectra, and c dark J–V of various CILs. d [hv ln(1−EQE)]2 vs hv curve of PEIE (blue line) and LA-PEIE (red line) with Tauc plot. The straight-black line represents the extrapolation. e UPS spectra of ZnO (black line), PEIE (blue line) and LA-PEIE (red line) on ITO substrates. f Energy level diagram of an OPV device with the structure of ITO/LA-PEIE/PTB7-th:PC70BM/MoOx/Ag.

The difference in the VOC of the PEIE and LA-PEIE devices should also be assessed by the energy loss mechanism. Assuming that energy loss (ELoss) or VOC loss is defined by the difference between the bandgap (Eg) and actual VOC, Eg of 1.65 and 1.64 eV for PEIE and LA-PEIE, respectively, are obtained with a Tauc plot, as shown in Fig. 2d. Notably, the VOC loss (Eg/q-VOC) of the LA-PEIE is only 0.82 V, which is 0.04 V lower than that of the PEIE (0.86 V). This lower energy loss indicates a reduced interfacial area for recombination in the LA-PEIE devices. The modification of PEIE with LA shifted its work function (WF) from 4.4 to 4.1 eV as shown in Fig. 2e, because the induced surface dipoles at the photoactive layer/cathode interface lower the electrostatic potential at the interface, which is evident from the energy band diagram (Fig. 2f). The low WF and enhanced interfacial dipoles of the LA-PEIE devices can also improve the quality of electrical contact by forming an Ohmic contact with the fullerene acceptor48,49. For comparison, the WF of ZnO is also presented (4.3 eV). The better photoactive layer morphology of the LA-PEIE owing to its better affinity at the cathode/photoactive layer interface also aids in reducing the energy loss50,51. In contrast, the PEIE device has a higher energy barrier to the lowest unoccupied molecular orbital (LUMO) acceptor, which enhances the surface recombination and decreases the electric field, thereby reducing JSC and VOC52.

Charge carrier recombination dynamics

To elucidate the charge recombination kinetics in the OPV devices: (i) the illuminated J–V characteristics were analyzed as a function of light intensity, and (ii) electrochemical impedance spectroscopy (EIS) was performed. The J–V curves at different light intensities were measured and compared, as shown in Supplementary Fig. S5a–c, for ZnO, PEIE, and LA-PEIE CILs. The PCE of OPV devices monotonically increases with lower light intensity, particularly for the LA-PEIE device (see Supplementary Fig. S5d). The power law relates the JSC to the light intensity as JSC ∝ Iα, where I is the light intensity and the exponent α indicates bimolecular recombination coefficient. Therefore, α~1 implies a smaller recombination loss. In Fig. 3a, the α values are 0.94, 0.92, and 0.95 for the OPV devices with ZnO, PEIE, and LA-PEIE CIL, respectively. Moreover, VOC can be represented as follows:

where kB, T, and q are the Boltzmann constant, temperature, and elemental charge, respectively; n and C represent the ideality factor and a constant, respectively. The ideality factor n is extracted from the slope of (1), giving 1.31, 1.56, and 1.18 for the ZnO, PEIE, and LA-PEIE CIL, respectively, as shown in Fig. 3b. These results signify that the OPV with LA-PEIE CIL has the lowest trap-assisted recombination due to the enhanced internal electric field and improved photoactive layer quality38,39,46,47,48,49. The large difference in FF (Fig. 3c) at low light intensities can be ascribed to RSH and trap-assisted recombination, which shows charge transport supporting capability of the LA-PEIE CIL53,54. Moreover, the higher VOC and FF of the LA-PEIE CIL at low light intensity can be beneficial for indoor applications under low-light intensity55,56.

The interfacial charge transport properties of the OPVs can be easily determined via EIS. The OPV can be modeled with an equivalent circuit of an internal series resistance (RS), a charge transport resistance (RCT), and a constant phase element (CPE) represents nonideal capacitor defined by interface capacitor (CPE-T) and ideal capacitor (CPE-P)57 as shown in the inset of Fig. 3d. The parameters obtained from the fitting of the Nyquist plot of EIS are summarized in Supplementary Table S4. In the Nyquist plot, the radius of the low-frequency semicircle represents the resistance of the CIL. Thus, it can be inferred that a better carrier transport leads to a smaller value of RCT58. Figure 3d shows that LA-PEIE has the best charge transport properties for the interlayers of OPVs, with the RCT of 105.7 Ω cm2. Besides, the LA-PEIE also exhibits the smallest RS value (13.75 Ω), indicating less recombination loss at the photoactive layer/cathode interface, leading to an increase in the FF and JSC of the devices59,60,61,62. The higher RS value of 19.97 Ω and higher RCT (151.8 Ω cm2) for the PEIE CIL implies that the generated charges can accumulate at the photoactive layer/cathode interface owing to the large mismatch between the energy levels of the photoactive layer and ITO substrate63,64,65. Since our photoactive layer is very thin (~110 nm), the recombination capacitance becomes large. Therefore, the characteristic frequency of the high-frequency circle in the Nyquist plot approaches that of the low-frequency one, owing to which it is not observed separately. The time-resolved photoluminescence (TRPL) decay characterization for the PTB7-th:PC70BM active layer deposited on various CILs were carried out to study the charge extraction. Supplementary Fig. S11 shows the TRPL curve (with an excitation at 405 nm and emission at 745 nm). The PL decay time and amplitudes are fitted and estimated using the double exponential function (Eq. (2)).

where τ1 and τ2 are the fast and the slow decay times, respectively; A1 and A2 are the pre-exponential constants or decay amplitudes; C is a constant for the baseline offset66. The fitted parameters are tabulated in Supplementary Table S9. The τave is calculated by using Eq. (3).

The TRPL spectrum of the PTB7-th:PC70BM on the LA-PEIE shows a decay time of 0.53 ns, which is smaller than the decay time of 1.08 ns of the pristine PEIE. Compared with the PEIE, the shorter decay time of the LA-PEIE-based implies that the electron extraction at the LA-PEIE/active layer interface is more efficient than that at the PEIE/active layer interface67,68,69. The improved charge extraction characteristic is confirmed via photoconductive atomic force microscopy. The illumination intensity-dependent photocurrent and mapped images of the PEIE and LA-PEIE CILs on the ITO glass substrates are shown in Supplementary Fig. S6a, b, and the average local photocurrents are given in Supplementary Table S6. The average of photocurrent with respect to light intensity is illustrated in Supplementary Fig. S6c. The LA-PEIE CIL exhibited higher local photocurrents under all illuminations compared to the PEIE CIL, implying that LA-PEIE is more efficient in charge extraction at the cathode interface.

Estimating optical loss in CILs

The drastically enhanced device characteristics due to the modification of PEIE CIL, particularly the value of JSC, cannot be fully understood by the improved electrical properties, such as reduced charge recombination, increased charge extraction, and energy balance. In addition, the optical properties of the PEIE and LA-PEIE CIL were further investigated using the scattering matrix method, as shown in Fig. 4, although it was mentioned earlier that the optical transmittances of the two samples were almost identical. The transmittance and reflectance were measured for the single layer of the PEIE (50 nm), LA-PEIE (50 nm), and photoactive layer (110 nm) on a glass substrate, and the optical parameters (refractive index, n and extinction coefficient, k) of each layer were extracted, as shown in Fig. 4a. As can be seen, the k curve of the LA-PEIE is formed below that of the PEIE, an observation that is consistent with the bandgap energy of each layer obtained with the Tauc plots in Fig. 2d. Using the optical parameters, optical simulation of the OPVs were performed with the structure of glass/ITO (150 nm)/PEIE or LA-PEIE (5 nm)/photoactive (110)/MoO (5 nm)/Ag. In Fig. 4b, the EQE of the OPV with the LA-PEIE CIL is slightly higher than that with the PEIE CIL, while the reflectance (Fig. 4c) of the two OPVs is almost the same. This is because the optical loss in the LA-PEIE is lower than that in the PEIE, as seen from Fig. 4d. The optical simulation clearly shows that LA-PEIE can act as a molecular optical spacer and results in a higher JSC, as opposed to its counterparts. The combined optical and electrical improvements that are caused by the multifunctional fatty acid-modified PEIE increase the PCE. This occurrence happens when the dipoles are aligned with the electric field, it can vibrate the dipoles and impede the electric field, which is observed as an optical loss. In comparison with the disordered dipoles of the PEIE, most dipoles of the LA-PEIE are relatively well aligned normal to the surface (or aligned with the propagation direction of light)70. It is observed that the optical loss of the LA-PEIE is lower than that of the PEIE in Fig. 4d. Generally, metal oxides such as ZnO and TiOx are used as optical and mechanical spacers; however, these metal oxides are not used in flexible electronic devices71,72,73. Thus, it is meaningful to design organic interfacial materials with wettability driven adjustable optical and electrical characteristics for developing flexible electronic devices.

Photovoltaic performance of flexible OPVs

To understand the applicability of various CILs in flexible OPVs, flexible OPV devices with an inverted structure were fabricated with PTB7-Th:PC70BM photoactive layer. As shown in Fig. 5a and Table 1, the LA-PEIE-based flexible device achieved a PCE of 9.04% with a VOC of 0.80 V, JSC of 16.99 mA cm−2, and FF of 0.66. These values are superior to those of the ZnO and PEIE flexible devices, which showed a PCE of 6.41% (VOC: 0.79 V, JSC: 15.28 mA cm−2, and FF: 0.53) and 7.87% (VOC: 0.76 V, JSC: 15.53 mA cm−2, and FF: 0.64), respectively. Here, the S-shaped behavior of the ZnO CIL OPV device indicates the non-compatibility of metal oxide CILs with flexible substrates. Organic CILs, especially bifacial interlayer-designed organic CILs, play a highly decisive role in flexible OPVs. The EQE spectra of the flexible devices are shown in Fig. 5b. The flexible devices have low EQE values in the UV region owing to the UV light absorption characteristic of the PEN substrate.

a Current density–voltage characteristics, b EQE spectra, c normalized PCE of 200 bending cycles with respect to substrate bending radius, and d normalized stability graph of flexible OPVs with ZnO (black line, solid circles), PEIE (blue line, solid square), and LA-PEIE (red line, solid triangles) CILs.

Bending and air-storage stability test of flexible OPVs

The interfacial contact can also influence the mechanical stability of flexible OPVs. Figure 5c shows the PCE of the flexible OPVs with ZnO, PEIE, and LA-PEIE CILs that were measured after the bending test for up to 200 cycles with different bending radii. The OPV with the LA-PEIE CIL was maintained at 95.83% of its initial PCE value, which was higher than that (82.21%) of the device with PEIE CIL; however, the performance of the OPV with the ZnO CIL severely deteriorated, even at a bending radius of 0.75 cm. The degradation by bending the device is believed to increase the sheet resistance due to the cracks on the ITO substrate and delamination of the photoactive layer/ITO74,75,76. In addition, when the flexible OPVs were exposed to air without any encapsulation, the ones with LA-PEIE CIL exhibited superior stability (Fig. 5d). The other parameters are shown in Supplementary Fig. S7a–c. The LA-PEIE device retained 87.75% of its initial PCE after 10 days; however, the PCE of the ZnO and PEIE devices decreased to 38.80% and 77.43% of their initial values, respectively. The decrease in PCE is mainly influenced by a decrease in FF. The modification of PEIE by the LA hydrophobic molecule is believed to improve the adhesion of the active layer for effectively preventing the penetration of moisture to the gap between the photoactive layer and cathode of the device.

Large-area flexible OPV modules

For practical applications, a large-area device applicability test is crucial. Sub-module-sized OPV devices were fabricated on a 5 × 7 cm2 (9 cells) PEN flexible substrate with an active area of 18.63 cm2 and its device structure is shown in Supplementary Fig. S8a. The J–V curves of flexible OPV sub-modules with PEIE and LA-PEIE CILs are shown in Supplementary Fig. S8b, and the photovoltaic properties are summarized in Supplementary Table S7. The OPV module with LA-PEIE CIL exhibited the highest PCE of 8.31% (FF: 0.59, JSC: 2.04 mA cm−2, and VOC: 6.88 V), while the module with PEIE CIL showed a PCE of 6.41% only (FF: 0.55, JSC: 1.78 mA cm−2 and VOC: 6.51 V). The enhanced performance is more pronounced for all the factors. Based on this, one can strongly argue that fatty acid-modified PEIE is a suitable interfacial material for the realization of flexible and large-area OPV modules.

Device performance of the flexible OLEDs

Finally, to verify the effect of LA-PEIE CIL on the performance of the OLEDs, solution-processed OLEDs were fabricated using ZnO, PEIE, and LA-PEIE CILs. The structure of the fabricated OLED is shown in Supplementary Fig. S9a. The current density–voltage–luminance (J–V–L) characteristics of the OLEDs that were fabricated on flexible substrates with different CILs are shown in Supplementary Figure S9c–e. The devices with LA-PEIE showed higher current densities and luminescence when compared to the reference devices based on PEIE. The LA-PEIE-based OLED exhibited a notably reduced driving voltage (3.2 V at 150 cd m−2) as compared to the PEIE-based OLED (3.4 V at 150 cd m−2). The LA-PEIE CIL forms strong interfacial dipoles at the interface of the emissive layers and cathodes. The presence of these dipoles can reduce the electron injection barrier at the interface and enhance the electron injection property, which returns to a low on-set voltage. Moreover, LA-PEIE creates hydrophobic interactions that are favorable for coating the emissive layer uniformly to ensure improved contact at the interface. Therefore, the highest current efficiency (CE) and power efficiency (PE) for the luminescence were obtained for the flexible OLED with the LA-PEIE CIL, as shown in Supplementary Fig. S9b and Supplementary Table S8. The maximum CE and PE were 10.21 cd A−1 and 8.47 lm W−1, respectively. The excellent charge injection characteristic of the LA-PEIE CIL contributed towards making the LA-PEIE-based OLED superior to the other CIL-based OLEDs. The previously mentioned distinguishing features of the LA-PEIE CIL allow the fabrication of low-cost, long-lived, large area, and highly efficient solution-processed OLEDs with the conventional device architecture. Owing to such excellent features, these solution-processed OLEDs can be employed to develop organic electronics.

Discussion

One of the major problems in solution-processed organic devices is the different wetting properties between the hydrophobic active layer and hydrophilic interfacial layer. This difference constitutes the poor interfacial properties between the active layer and interfacial layer, resulting in poor device performance and stability. In this study, we used a hydrophobic fatty acid to modify the interfacial properties at the active layer/interfacial layer interface. According to the contact angle analysis, the LA-PEIE CIL became hydrophilic at the bottom surface facing the ITO layer and hydrophobic at the top surface facing the photoactive layer. By controlling the interfacial properties, the charge extraction can be improved and the carrier recombination can be suppressed, resulting in improved VOC, JSC, and FF. Moreover, the optical loss related to the alignment of the electric field is unexpectedly slightly decreased after the inclusion of fatty acid to PEIE, which further improves the JSC. When the LA-PEIE was used as a CIL of the OPV, the charge extraction was remarkably improved and the device with LA-PEIE achieved a PCE ~14% higher than that of the reference device with pristine PEIE. The OPV device using the LA-PEIE CIL and PTB7‐Th:PC70BM active layer achieved a remarkably high PCE of 10.57% (flexible OPV showed 9.04% PCE), whereas the device using the pristine PEIE CIL had a PCE of 9.30% (flexible OPV showed 7.87% PCE). To the best of our knowledge, this result is one of the highest PCEs that has been achieved in the widely studied PTB7‐Th:PC70BM devices with polyelectrolyte CILs. We also showed that improved charge extraction is mainly attributed to the decreased recombination at the photoactive/cathode interfacial layers. Better WF alignment of LA-PEIE to the LUMO levels of PC70BM also reinforced the improved device performance owing to the lowered energy barrier. Moreover, both the stability and mechanical robustness of the OPV were also improved. When LA-PEIE was used for an electron injection layer of the OLED device, the maximum CE (9.68 cd/A) and PE (9.88 lm/W) were achieved. These distinguishing features of the LA-PEIE IL allow the fabrication of low-cost, long-lived, large-area, and efficient optoelectronic organic devices, even in solution processes with conventional device architectures. Consequently, these unique features can broaden the field of application of organic electronics, including flexible products.

Methods

Materials

PEIE, ethanol, methanol, chlorobenzene, and DIO were purchased from Sigma-Aldrich. Linoleic acid (Merck KGaA), PTB7-Th (1-materials), PC70BM (Merck KGaA), PEDOT:PSS (AI4083, Heraeus), and (PDY-132, Merck KGaA) were purchased commercially. All the materials were used without any further purification.

Solar cell fabrication

The chemical structures of the materials that were used in this study are shown in Supplementary Fig. S1. PEIE and LA-PEIE solutions were prepared by dissolving PEIE (20 mg) in ethanol (10 mL). For LA-PEIE, the linoleic acid solution, dissolved in methanol, was added to the PEIE solution and stirred overnight. Before using, PEIE and LA-PEIE were filtered through a 0.5 μm polyvinylidene fluoride filter. The active layer solution was prepared by dissolving PTB7-Th (10 mg mL−1) and PC70BM (18 mg mL−1) in chlorobenzene (0.97 mL) and 1,8-diiodooctane (0.03 mL). The solution was stirred overnight at 70 °C, and then the solution was filtered using a 0.45 μm polytetrafluoroethylene filter. The patterned ITO/glass substrates were cleaned sequentially with deionized water, acetone, and isopropanol for 10 min each. Patterned ITO or PEN substrates were used without the cleaning process. The ITO substrates were treated with UV–ozone plasma for 1000 s and transferred to an Ar-filled glove box. The ultra-thin PEIE and LA-PEIE CIL were spin-coated using 100 μL of PEIE or LA-PEIE solution on the ITO substrates at 2000 rpm for 60 s (the thickness of PEIE and LA-PEIE is ~5 nm). These devices were dried at room temperature for 15 min. The active layer was spin-coated using a blend solution at 2000 rpm for 40 s and then dried for 3 h. The methanol treatment was performed at 2000 rpm for 40 s to remove the DIO in the photoactive layer. Finally, MoO3 (7 nm) and Ag (100 nm) were thermally evaporated in a vacuum chamber (chamber pressure <4 × 10−6 Pa) through a shadow metal mask; an active area of 0.125 cm2 was defined by the overlap of the cathode and anode.

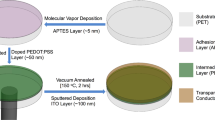

OLED device fabrication

LA-PEIE was also incorporated into the flexible OLED structure of ITO/PEDOT:PSS/Super Yellow/LA-PEIE/Al as an electron injection layer. All the fabrication processes of the solution-processed OLEDs were performed in a nitrogen-filled glove box. PEDOT:PSS mixed with IPA (1:5 by volume) was spin-coated onto the ITO substrate at 3000 rpm for 30 s, followed by annealing at 120 °C for 10 min; the thickness of PEDOT:PSS was ~30 nm. The polymeric emitter, Super Yellow, was dissolved in toluene at a concentration of 5 mg mL−1. The emissive layer (thickness ~100 nm) was spin-coated onto the PEDOT:PSS film at 1500 rpm and annealed at 100 °C for 5 min. PEIE and LA-PEIE solutions were subsequently deposited at 5000 rpm. Finally, a thin layer of LiF (1 nm) and aluminum (100 nm) was thermally evaporated in a high-vacuum chamber. The active area of the device was ~6 mm2. For comparison, ZnO CIL was also used as a reference to determine the effect of metal oxide on the device performance of both rigid and flexible OPVs and OLEDs.

Measurements and characterization

The J–V curves were measured using a Keithley 2400 A under a calibrated AM 1.5 G simulated illumination of 100 mW cm−2 in ambient air. The light intensity was calibrated using a standard Si photodiode detector with a KG-5 filter (Newport Co., Oriel 91150V). The EQE was measured in a wavelength range of 300–850 nm via an EQE measurement system (Newport Co., Oriel IQE-200™ system). The optical transmittance was measured with an ultraviolet-visible (UV–Vis) spectrometer (Varian, Cary5000). The surface morphology of the cathode buffer layer films was observed by AFM (Park system, Park NX10 AFM). Photocurrent mapping images were obtained using photoconductive AFM (Seiko, E-Sweep SI-DF3-R) with a halogen lamp as the light source. The surface contact angle (wetting behavior) was measured with water as the test media using a contact angle analyzer (SEO, Phoenix-300). FTIR (Varian, Scimitar Series FTS-2000) was also performed in the region from 4000 to 500 cm−1 to analyze the bonding structure of the CIL materials. The Raman spectra were measured by using Jasco NRS-3000 (Jasco, NRS-3000 series) with laser wavelength 532 nm. The WFs of the PEIE and LA-PEIE layers were obtained from the onsets of the secondary cut-off region (Ecut-off) by using UV photoelectron spectroscopy (Thermo Scientific, Multilab-2000). AC impedance spectroscopy was carried out using an impedance analyzer compact state electrochemical interface (IVIUM Technologies) in the frequency range from 1 kHz to 1 MHz, where the applied bias voltage was set to a value close to VOC of the device under AM 1.5 G illumination. The J–V–L characteristics of the OLEDs were measured with a source measure unit (Keithley 2401) and a spectroradiometer (Otsuka Electronics, HS-1000). Time-resolved photoluminescence (PL) decay transients were measured at 745 nm with a 405 nm light pulse. The dipole moments of SA and LA were simulated based on the adopted basis Newton–Raphson method within Millsian software (Millsian, Inc).

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Kippelen, B. & Brédas, J.-L. Organic photovoltaics. Energy Environ. Sci. 2, 251 (2009).

Xia, Y., Xu, X. & Inganäs, O. Photovoltage loss in semi-transparent organic photovoltaic devices. Org. Electron. 74, 37–40 (2019).

Krebs, F. C., Tromholt, T. & Jørgensen, M. Upscaling of polymer solar cell fabrication using full roll-to-roll processing. Nanoscale 2, 873–886 (2010).

Ma, X. et al. Simultaneously improved efficiency and average visible transmittance of semitransparent polymer solar cells with two ultra-narrow bandgap nonfullerene acceptors. J. Mater. Chem. A 6, 21485–21492 (2018).

Salehi, A., Fu, X., Shin, D.-H. & So, F. Recent advances in OLED optical design. Adv. Funct. Mater. 29, 1808803 (2019).

Tao, J. et al. Highly transparent, highly thermally stable nanocellulose/polymer hybrid substrates for flexible OLED devices. ACS Appl. Mater. Interfaces 12, 9701–9709 (2020).

MacDonald, W. A. et al. Latest advances in substrates for flexible electronics. J. Soc. Inf. Disp. 15, 1075–1083 (2007).

Cui, Y. et al. Efficient semitransparent organic solar cells with tunable color enabled by an ultralow-bandgap nonfullerene acceptor. Adv. Mater. 29, 1527–1538 (2017).

Lee, H. et al. Color-tunable organic light-emitting diodes with vertically stacked blue, green, and red colors for lighting and display applications. Opt. Express 26, 18351–18361 (2018).

Liu, Q. et al. 18% Efficiency organic solar cells. Sci. Bull. 65, 272–275 (2020).

Fonrodona, M. et al. PEN as substrate for new solar cell technologies. Sol. Energy Mater. Sol. Cells 89, 37–47 (2005).

Lee, U. J. et al. Surface interpenetration between conducting polymer and PET substrate for mechanically reinforced ITO-free flexible organic solar cells. Sol. Energy Mater. Sol. Cells 108, 50–56 (2013).

Huang, J., Yin, Z. & Zheng, Q. Applications of ZnO in organic and hybrid solar cells. Energy Environ. Sci. 4, 3861–3877 (2011).

Xiong, S. et al. 12.5% flexible nonfullerene solar cells by passivating the chemical interaction between the active layer and polymer interfacial layer. Adv. Mater. 31, 1806616 (2019).

Kumar, M. H. et al. Flexible, low-temperature, solution processed ZnO-based perovskite solid state solar cells. Chem. Commun. 49, 11089 (2013).

Qiu, X. et al. Efficient, stable and flexible perovskite solar cells using two-step solution-processed SnO2 layers as electron-transport-material. Org. Electron. 58, 126–132 (2018).

Al-hashimi, M. K., Kadem, B. Y. & Hassan, A. K. Rutile TiO2 films as electron transport layer in inverted organic solar cell. J. Mater. Sci. Mater. Electron 29, 7152–7160 (2018).

Nho, S. et al. Highly efficient inverted bulk-heterojunction solar cells with a gradiently-doped ZnO layer. Energy Environ. Sci. 9, 240–246 (2016).

Wu, Z., Yu, H., Shi, S. & Li, Y. Bismuth oxysulfide modified ZnO nanorod arrays as an efficient electron transport layer for inverted polymer solar cells. J. Mater. Chem. A 7, 14776–14789 (2019).

Huang, X., Yu, H., Shi, S. & Huang, C. Improving the performance of inverted polymer solar cells by the efficiently doping and modification of electron transport layer-ZnO. Org. Electron. 65, 311–320 (2019).

He, Z. et al. Largely enhanced efficiency with a PFN/Al bilayer cathode in high efficiency bulk heterojunction photovoltaic cells with a low bandgap polycarbazole donor. Adv. Mater. 23, 3086–3089 (2011).

Zhao, Y. et al. Enhanced charge collection in polymer photovoltaic cells by using an ethanol-soluble conjugated polyfluorene as cathode buffer layer. Sol. Energy Mater. Sol. Cells 93, 604–608 (2009).

Na, S.-I., Oh, S.-H., Kim, S.-S. & Kim, D.-Y. Efficient organic solar cells with polyfluorene derivatives as a cathode interfacial layer. Org. Electron. 10, 496–500 (2009).

Lozano-Hernández, L. A. et al. Structurally simple OLEDs based on a new fluorinated poly(oxindolylidenearylene). Dye. Pigment. 173, 107989 (2020).

Wu, Y., Liu, Y., Emrick, T. & Russell, T. P. Polymer design to promote low work function surfaces in organic electronics. Prog. Polym. Sci. 103, 101222 (2020).

Zhou, Y. et al. A universal method to produce low-work function electrodes for organic electronics. Science (80-.) 336, 327–332 (2012).

Yu, H., Huang, X. & Huang, C. PEIE doped ZnO as a tunable cathode interlayer for efficient polymer solar cells. Appl. Surf. Sci. 470, 318–330 (2019).

Yeo, J.-S. et al. In-depth considerations for better polyelectrolytes as interfacial materials in polymer solar cells. Nano Energy 21, 26–38 (2016).

Kim, Y.-H. et al. Polyethylene imine as an ideal interlayer for highly efficient inverted polymer light-emitting diodes. Adv. Funct. Mater. 24, 3808–3814 (2014).

Zhang, Z. et al. Polymer with a 3D conductive network: a thickness-insensitive electron transport layer for inverted polymer solar cells. J. Mater. Chem. A 6, 12969–12973 (2018).

Borse, K., Sharma, R., Gupta, D. & Yella, A. Interface engineering through electron transport layer modification for high efficiency organic solar cells. RSC Adv. 8, 5984–5991 (2018).

Zhang, Z. et al. Non-conjugated polymers as thickness-insensitive electron transport materials in high-performance inverted organic solar cells. J. Energy Chem. 47, 196–202 (2020).

Ohisa, S., Suzuki, M., Chiba, T. & Kido, J. Doping of tetraalkylammonium salts in polyethylenimine ethoxylated for efficient electron injection layers in solution-processed organic light-emitting devices. ACS Appl. Mater. Interfaces 11, 25351–25357 (2019).

Kang, Q. et al. A printable organic cathode interlayer enables over 13% efficiency for 1-cm2 organic solar cells. Joule 3, 227–239 (2019).

Ma, Z. et al. Influences of surface roughness of ZnO electron transport layer on the photovoltaic performance of organic inverted solar cells. J. Phys. Chem. C 116, 24462–24468 (2012).

Wang, Z. et al. Urea-doped ZnO films as the electron transport layer for high efficiency inverted polymer solar cells. Front. Chem. 6, 398 (2018).

Xiao, B., Wu, H. & Cao, Y. Solution-processed cathode interfacial layer materials for high-efficiency polymer solar cells. Mater. Today 18, 385–394 (2015).

Lim, D. C. et al. Spontaneous formation of nanoripples on the surface of ZnO thin films as hole-blocking layer of inverted organic solar cells. Sol. Energy Mater. Sol. Cells 95, 3036–3040 (2011).

Yuan, K., Chen, L., Li, F. & Chen, Y. Nanostructured hybrid ZnO@CdS nanowalls grown in situ for inverted polymer solar cells. J. Mater. Chem. C 2, 1018–1027 (2014).

Chang, C.-Y., Tsai, B.-C., Lin, M.-Z., Huang, Y.-C. & Tsao, C.-S. An integrated approach towards the fabrication of highly efficient and long-term stable perovskite nanowire solar cells. J. Mater. Chem. A 5, 22824–22833 (2017).

Rana, V., Cañamares, M. V., Kubic, T., Leona, M. & Lombardi, J. R. Surface-enhanced Raman spectroscopy for trace identification of controlled substances: morphine, codeine, and hydrocodone. J. Forensic Sci. 56, 200–207 (2011).

Wang, M., Shi, G., Zhu, Y., Wang, Y. & Ma, W. Au-decorated dragonfly wing bioscaffold arrays as flexible surface-enhanced Raman scattering (SERS) substrate for simultaneous determination of pesticide residues. Nanomaterials 8, 289 (2018).

Ghazvini, M. S., Pulletikurthi, G., Lahiri, A. & Endres, F. Electrochemical and spectroscopic studies of zinc acetate in 1-ethyl-3-methylimidazolium acetate for zinc electrodeposition. ChemElectroChem 3, 598–604 (2016).

Tu, J.-S., Perevedentseva, E., Chung, P.-H. & Cheng, C.-L. Size-dependent surface CO stretching frequency investigations on nanodiamond particles. J. Chem. Phys. 125, 174713 (2006).

Petit, T. et al. Unusual water hydrogen bond network around hydrogenated nanodiamonds. J. Phys. Chem. C 121, 5185–5194 (2017).

Selvarajan, P. et al. Potential of Raman spectroscopy towards understanding structures of carbon-based materials and perovskites. Emergent Mater. 2, 417–439 (2019).

Proctor, C. M. & Nguyen, T.-Q. Effect of leakage current and shunt resistance on the light intensity dependence of organic solar cells. Appl. Phys. Lett. 106, 83301 (2015).

Cai, Y. et al. Novel nonconjugated polymer as cathode buffer layer for efficient organic solar cells. ACS Appl. Mater. Interfaces 10, 24082–24089 (2018).

Brabec, C. J. et al. Origin of the open circuit voltage of plastic solar cells. Adv. Funct. Mater. 11, 374–380 (2001).

Mihailetchi, V. D., Blom, P. W. M., Hummelen, J. C. & Rispens, M. T. Cathode dependence of the open-circuit voltage of polymer:fullerene bulk heterojunction solar cells. J. Appl. Phys. 94, 6849–6854 (2003).

Tang, Z. et al. Relating open-circuit voltage losses to the active layer morphology and contact selectivity in organic solar cells. J. Mater. Chem. A 6, 12574–12581 (2018).

Menke, S. M., Ran, N. A., Bazan, G. C. & Friend, R. H. Understanding energy loss in organic solar cells: toward a new efficiency regime. Joule 2, 25–35 (2018).

Proctor, C. M., Kuik, M. & Nguyen, T.-Q. Charge carrier recombination in organic solar cells. Prog. Polym. Sci. 38, 1941–1960 (2013).

Sherkar, T. S., Momblona, C., Gil-Escrig, L., Bolink, H. J. & Koster, L. J. A. Improving perovskite solar cells: insights from a validated device model. Adv. Energy Mater. 7, 1602432 (2017).

Jahandar, M. et al. High-performance CH3NH3PbI3-inverted planar perovskite solar cells with fill factor over 83% via excess organic/inorganic halide. ACS Appl. Mater. Interfaces 9, 35871–35879 (2017).

Cojocaru, L. et al. Determination of unique power conversion efficiency of solar cell showing hysteresis in the I-V curve under various light intensities. Sci. Rep. 7, 11790 (2017).

Cowan, S. R., Roy, A. & Heeger, A. J. Recombination in polymer-fullerene bulk heterojunction solar cells. Phys. Rev. B 82, 245207 (2010).

Zhou, P. et al. Nonconjugated polymer poly(vinylpyrrolidone) as an efficient interlayer promoting electron transport for perovskite solar cells. ACS Appl. Mater. Interfaces 9, 32957–32964 (2017).

Pockett, A., Lee, H. K. H., Coles, B. L., Tsoi, W. C. & Carnie, M. J. A combined transient photovoltage and impedance spectroscopy approach for a comprehensive study of interlayer degradation in non-fullerene acceptor organic solar cells. Nanoscale 11, 10872–10883 (2019).

Li, Z. et al. Impedance investigation of the highly efficient polymer solar cells with composite CuBr2/MoO3 hole transport layer. Phys. Chem. Chem. Phys. 19, 20839–20846 (2017).

von Hauff, E. Impedance spectroscopy for emerging photovoltaics. J. Phys. Chem. C 123, 11329–11346 (2019).

Rasool, S. et al. Amine-based interfacial engineering in solution-processed organic and perovskite solar cells. ACS Appl. Mater. Interfaces 11, 16785–16794 (2019).

Kim, S. et al. The role of cation and anion dopant incorporated into a ZnO electron transporting layer for polymer bulk heterojunction solar cells. RSC Adv. 9, 37714–37723 (2019).

Wetzelaer, G.-J. A. H., Koster, L. J. A. & Blom, P. W. M. Bimolecular and trap-assisted recombination in organic bulk heterojunction solar cells. Org. Photovolt. 343–376, https://doi.org/10.1002/9783527656912.ch11 (2014).

Lee, J.-H. et al. Reinforcing the built-in field for efficient charge collection in polymer solar cells. Adv. Funct. Mater. 28, 1705079 (2018).

Sundqvist, A., Sandberg, O. J., Nyman, M., Smått, J.-H. & Österbacka, R. Origin of the S-shaped JV curve and the light-soaking issue in inverted organic solar cells. Adv. Energy Mater. 6, 1502265 (2016).

Cai, Q. et al. Enhancing efficiency of planar structure perovskite solar cells using Sn-doped TiO2 as electron transport layer at low temperature. Electrochim. Acta 261, 227–235 (2018).

Zhong, D. et al. Synthesis of oriented TiO2 nanocones with fast charge transfer for perovskite solar cells. Nano Energy 11, 409–418 (2015).

Tian, C. et al. A C60 modification layer using a scalable deposition technology for efficient printable mesoscopic perovskite solar cells. Sol. RRL 2, 1800174 (2018).

Baloch, A. A. B. et al. Analysis of photocarrier dynamics at interfaces in perovskite solar cells by time-resolved photoluminescence. J. Phys. Chem. C 122, 26805–26815 (2018).

Rosell, F. I. & Boxer, S. G. Polarized absorption spectra of green fluorescent protein single crystals: transition dipole moment directions. Biochemistry 42, 177–183 (2003).

Park, S. H. et al. Bulk heterojunction solar cells with internal quantum efficiency approaching 100%. Nat. Photonics 3, 297–302 (2009).

Lee, J. K. et al. Efficacy of TiOx optical spacer in bulk-heterojunction solar cells processed with 1,8-octanedithiol. Appl. Phys. Lett. 92, 243308 (2008).

Kyaw, A. K. K. et al. Improved light harvesting and improved efficiency by insertion of an optical spacer (ZnO) in solution-processed small-molecule solar cells. Nano Lett. 13, 3796–3801 (2013).

Li, Y., Xu, G., Cui, C. & Li, Y. Flexible and semitransparent organic solar cells. Adv. Energy Mater. 1701791 (2018).

Hashemi, S. A., Ramakrishna, S. & Aberle, A. G. Recent progress in flexible–wearable solar cells for self-powered electronic devices. Energy Environ. Sci. 13, 685–743 (2020).

Acknowledgements

This research was supported by Korea Institute of Materials Science (KIMS, No. PNK7660), Korea Institute of Energy Technology Evaluation and Planning (KETEP, No. 2018201010636A) and the National Research Foundation of Korea (NRF 2020M3H4A3081820).

Author information

Authors and Affiliations

Contributions

S.K., and A.P., contributed equally to this work. D.C.L., conceived the idea. M.J., and D.C.L., designed the experiment. S.K., conducted most of the OPV device fabrications and characterizations. A.P., fabricated the large-area OPV devices, conducted charge carrier recombination analysis and stability test. J.W.H., J.H.K., and Y.H.K., carried out the OLED device and characterization. Y.K., and M.S., design and conduct the simulations. J.H., conducted the film morphology. S.C., carried out spectroscopy measurements. M.S., Y.H.K., M.J., and D.C.L., wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Primary handling editor: John Plummer

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kim, S., Prasetio, A., Han, J.W. et al. Enhanced flexible optoelectronic devices by controlling the wettability of an organic bifacial interlayer. Commun Mater 2, 26 (2021). https://doi.org/10.1038/s43246-021-00131-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-021-00131-4