Abstract

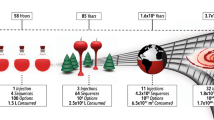

Understanding polymerization reactions has challenges relating to the complexity of the systems, the hazards associated with the reagents, the environmental footprint of the operations and the highly nonlinear topologies of reaction spaces. In this work, we aim to present a new methodology for studying polymerization reactions using machine-learning-assisted automated microchemical reactors. A custom-designed rapidly prototyped microreactor is used in conjunction with automation and in situ infrared thermography for efficient, high-speed experimentation to map the reaction space of a zirconocene polymerization catalyst and obtain fundamental kinetic parameters. Chemical waste is decreased by two orders of magnitude and catalytic discovery is reduced from weeks to hours. Bayesian regularization backpropagation is used in conjunction with kinetic modelling to understand the reaction space and resultant technoeconomic topology. Here, we show that efficient microfluidic technology can be coupled with machine-learning algorithms to obtain high-fidelity datasets on a complex chemical reaction.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The datasets generated and/or analysed during the current study are available in the Zenodo repository, http://doi.org/110.5281/zenodo.3706730[50].

Code availability

The code used for data analysis in the current study is publicly available in the Zenodo repository, http://doi.org/110.5281/zenodo.3706730[50]. The code used for experimental control is available in the Zenodo repository, http://doi.org/zenodo.3706734[51]. This code is not publicly available due to inclusion of third party code but is available upon reasonable request from the corresponding author.

References

Brintzinger, H. H., Fischer, D., Mülhaupt, R., Rieger, B. & Waymouth, R. M. Stereospecific olefin polymerization with chiral metallocene catalysts. Angew. Chem. Int. Ed. 34, 1143–1170 (1995).

Shamiri, A. et al. The influence of Ziegler–Natta and metallocene catalysts on polyolefin structure, properties and processing ability. Materials 7, 5069–5108 (2014).

Kaminsky, W. Highly active metallocene catalysts for olefin polymerization. J. Chem. Soc. Dalton Trans. 1998, 1413–1418 (1998).

Sinclair, K. B. Future trends in polyolefin materials. Macromol. Symp. 173, 237–261 (2001).

Plastics and Polymers Global Market Briefing 2018 (The Business Research Company, 2018).

Sumerin, V. & Thorman, J. Ziegler–Natta catalyst and preparation thereof. US patent 10,118,977 (2018).

Kesti, M. R., Coates, G. W. & Waymouth, R. M. Homogeneous Ziegler–Natta polymerization of functionalized monomers catalyzed by cationic group IV metallocenes. J. Am. Chem. Soc. 114, 9679–9680 (1992).

Society of the Plastics Industry, US Department of Energy Improving Energy Efficiency at US Plastics Manufacturing Plants 40 (US DOE, 2005).

Worrell, E., Bernstein, L., Roy, J., Price, L. & Harnisch, J. Industrial energy efficiency and climate change mitigation. Energy Efficiency 2, 109–123 (2009).

Khripko, D., Schlüter, B. A., Rommel, B., Rosano, M. & Hesselbach, J. Energy demand and efficiency measures in polymer processing: comparison between temperate and Mediterranean operating plants. Int. J. Energy Environ. Eng. 7, 225–233 (2016).

Sinn, H. & Kaminsky, W. Ziegler–Natta catalysis. Adv. Organomet. Chem. 18, 99–149 (1980).

Chien, J. C. W. & Wang, B.-P. Metallocene–methylaluminoxane catalysts for olefin polymerizations. IV. Active site determinations and limitation of the 14CO radiolabeling technique. J. Polym. Sci. A 27, 1539–1557 (1989).

Kaminsky, W. (ed.) Metalorganic Catalysts for Synthesis and Polymerization (Springer, 2011).

Rieger, B., Jany, G., Steimann, M. & Fawzi, R. Synthesis of ethylene bridged biscyclopentadiene ligand precursor compounds and some of their ansa-zirconocene derivatives chiral epoxides: a synthetic strategy of high variability. Z. Naturforsch. B Chem. Sci. 49, 451–458 (1994).

Kolthammer, B. W. S., Mangold, D. J. & Gifford, D. R. Polymerization kinetics of octene-1 catalyzed by metallocene methylaluminoxane investigated with attenuated total reflectance Fourier transform infrared (ATR-FT-IR) spectroscopy. J. Polym. Sci. A 30, 1017–1026 (1992).

Charpentier, P. A., Zhu, S., Hamielec, A. E. & Brook, M. A. Continuous solution polymerization of ethylene using metallocene catalyst system, zirconocene dichloride/methylaluminoxane/trimethylaluminum. Ind. Eng. Chem. Res. 36, 5074–5082 (1997).

D’Agnillo, L., Soares, J. B. P. & Penlidis, A. Effect of operating conditions on the molecular weight distribution of polyethylene synthesized by soluble metallocene/methylaluminoxane catalysts. Macromol. Chem. Phys. 199, 955–962 (1998).

Martínez, S., Cruz, V. L., Ramos, J. & Martínez-Salazar, J. Polymerization activity prediction of zirconocene single-site catalysts using 3D quantitative structure-activity relationship modeling. Organometallics 31, 1673–1679 (2012).

Moscato, B. M., Zhu, B. & Landis, C. R. GPC and ESI-MS analysis of labeled poly(1-hexene): rapid determination of initiated site counts during catalytic alkene polymerization reactions. J. Am. Chem. Soc. 132, 14352–14354 (2010).

Santos, L. S. & Metzger, J. O. Study of homogeneously catalyzed Ziegler–Natta polymerization of ethene by ESI-MS. Angew. Chem. Int. Ed. 45, 977–981 (2006).

Silveira, F., De Sá, D. S., Da Rocha, Z. N. & Dos Santos, J. H. Z. Metallocene combinations in ethylene polymerization: a cyclic and differential pulse voltammetry study. Macromol. React. Eng. 2, 253–264 (2008).

Moscato, B. M., Zhu, B. & Landis, C. R. Mechanistic investigations into the behavior of a labeled zirconocene polymerization catalyst. Organometallics 31, 2097–2107 (2012).

Gonzalez-Ruiz, R. A., Quevedo-Sanchez, B., Laurence, R. L., Henson, M. A. & Bryan Coughlin, E. Kinetic modeling of slurry propylene polymerization using rac-ET(Ind)2ZrCl2/MAO. AIChE J. 52, 1824–1835 (2006).

Christianson, M. D., Tan, E. H. P. & Landis, C. R. Stopped-flow NMR: determining the kinetics of [rac-(C2H4(1-indenyl)2)ZrMe][MeB(C6F5)3]-catalyze dpolymerization of 1-hexene by direct observation. J. Am. Chem. Soc. 132, 11461–11463 (2010).

Rubens, M., Vrijsen, J. H., Laun, J. & Junkers, T. Precise polymer synthesis by autonomous self-optimizing flow reactors. Angew. Chem. Int. Ed. 58, 3183–3187 (2019).

Knox, S. T. & Warren, N. J. Enabling technologies in polymer synthesis: accessing a new design space for advanced polymer materials. React. Chem. Eng. 5, 405–423 (2020).

Kaminsky, W. Zirconocene catalysts for olefin polymerization. Catal. Today 20, 257–271 (1994).

Jensen, K. F. Flow chemistry—microreaction technology comes of age. AIChE J. 63, 858–869 (2017).

Heider, P. L. et al. Development of a multi-step synthesis and workup sequence for an integrated, continuous manufacturing process of a pharmaceutical. Org. Process Res. Dev. 18, 402–409 (2014).

Hartman, R. L., Naber, J. R., Buchwald, S. L. & Jensen, K. F. Multistep microchemical synthesis enabled by microfluidic distillation. Angew. Chem. Int. Ed. 49, 899–903 (2010).

Kim, J. O. et al. A monolithic and flexible fluoropolymer film microreactor for organic synthesis applications. Lab Chip 14, 4270–4276 (2014).

Hu, C., Morris, J. E. & Hartman, R. L. Microfluidic investigation of the deposition of asphaltenes in porous media. Lab Chip 14, 2014–2022 (2014).

Rizkin, B. A., Popovic, F. G. & Hartman, R. L. Spectroscopic microreactors for heterogeneous catalysis. J. Vac. Sci. Technol. A 37, 050801 (2019).

Gromski, P. S., Granda, J. M. & Cronin, L. Universal chemical synthesis and discovery with ‘The Chemputer’. Trends Chem. 1–9 (2019); https://doi.org/10.1016/j.trechm.2019.07.004

Coley, C. W. et al. A robotic platform for flow synthesis of organic compounds informed by AI planning. Science 365, eaax1566 (2019).

Theurkauff, G., Bondon, A., Dorcet, V., Carpentier, J. F. & Kirillov, E. Heterobi- and -trimetallic ion pairs of zirconocene-based isoselective olefin polymerization catalysts with AlMe3. Angew. Chem. Int. Ed. 54, 6343–6346 (2015).

Song, F., Cannon, R. D. & Bochmann, M. Zirconocene-catalyzed propene polymerization: a quenched-flow kinetic study. J. Am. Chem. Soc. 125, 7641–7653 (2003).

Christopher, J. N., Diamond, G. M., Jordan, R. F. & Petersen, J. L. Synthesis, structure and reactivity of rac-Me2Si(indenyl)2Zr(NMe2)2. Organometallics 15, 4038–4044 (1996).

Lenton, T. N. et al. Formation of trivalent zirconocene complexes from ansa-zirconocene-based olefin-polymerization precatalysts: an EPR- and NMR-spectroscopic study. J. Am. Chem. Soc. 135, 10710–10719 (2013).

Ning, Y., Cooney, M. J. & Chen, E. Y. X. Polymerization of MMA by oscillating zirconocene catalysts, diastereomeric zirconocene mixtures, and diastereospecific metallocene pairs. J. Organomet. Chem. 690, 6263–6270 (2005).

Bochmann, M., Cannon, R. D. & Song, F. Kinetic and mechanism of alkene polymerization. Kinet. Catal. 47, 160–169 (2006).

Song, F., Hannant, M. D., Cannon, R. D. & Bochmann, M. Zirconocene-catalysed propene polymerisation: kinetics, mechanism and the role of the anion. Macromol. Symp. 213, 173–185 (2004).

Su, Y., Song, Y. & Xiang, L. Continuous-flow microreactors for polymer synthesis: engineering principles and applications. Top. Curr. Chem. 376, 44 (2018).

Zhang, J. S., Zhang, C. Y., Liu, G. T. & Luo, G. S. Measuring enthalpy of fast exothermal reaction with infrared thermography in a microreactor. Chem. Eng. J. 295, 384–390 (2016).

Hany, C., Lebrun, H., Pradere, C., Toutain, J. & Batsale, J. C. Thermal analysis of chemical reaction with a continuous microfluidic calorimeter. Chem. Eng. J. 160, 814–822 (2010).

Pradere, C., Joanicot, M., Batsale, J.-C., Toutain, J. & Gourdon, C. Processing of temperature field in chemical microreactors with infrared thermography. Quant. Infrared Thermogr. J. 3, 117–135 (2007).

Terms, F. Heat of polymerization. Polym. Rev. 3, 339–356 (1969).

Rizkin, B. A. & Hartman, R. L. Supervised machine learning for prediction of zirconocene-catalyzed α-olefin polymerization. Chem. Eng. Sci. 210, 115224 (2019).

Iooss, B. & Lemaître, P. A review on global sensitivity analysis methods. Uncertain. Manag. Simulation-Optimization Complex Syst. Algorithms Appl. 59, 101–122 (2015).

Rizkin, B. A., Shkolnik, A. S., Ferraro N. J. & Hartman R. L. Combining automated microfluidic experimentation with machine learning for efficient polymerization design. Zenodo https://doi.org/10.5281/zenodo.3706730 (2020).

Rizkin, B. A., Shkolnik, A. S., Ferraro N. J. & Hartman R. L. Combining automated microfluidic experimentation with machine learning for efficient polymerization design, control code. Zenodo https://doi.org/10.5281/zenodo.3706734 (2020).

Acknowledgements

This material is based on work supported by the National Science Foundation under grant no. CBET-1701393. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

Author information

Authors and Affiliations

Contributions

Conceptualization was provided by R.L.H., data curation by B.A.R., formal analysis by B.A.R. and A.S.S., funding acquisition by R.L.H., investigation by B.A.R. and A.S.S., methodology by B.A.R. and N.J.F., project administration by B.A.R. and R.L.H., resources by R.L.H., software by B.A.R., A.S.S. and N.J.F., supervision by R.L.H., validation by B.A.R. and A.S.S., visualization by B.A.R., A.S.S. and R.L.H., writing of the original draft by B.A.R. and A.S.S. and review and editing by R.L.H.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary methods, Figs. 1–5, Tables 1 and 2, discussion and analysis.

Rights and permissions

About this article

Cite this article

Rizkin, B.A., Shkolnik, A.S., Ferraro, N.J. et al. Combining automated microfluidic experimentation with machine learning for efficient polymerization design. Nat Mach Intell 2, 200–209 (2020). https://doi.org/10.1038/s42256-020-0166-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s42256-020-0166-5

This article is cited by

-

Applied machine learning as a driver for polymeric biomaterials design

Nature Communications (2023)

-

Machine learning-assisted systematical polymerization planning: case studies on reversible-deactivation radical polymerization

Science China Chemistry (2021)