Abstract

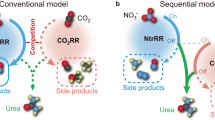

To reduce anthropogenic carbon dioxide (CO2) emissions, it is desirable to develop reactions that can efficiently convert low concentrations of CO2, present in exhaust gases and ambient air, into industrially important chemicals, without involving any expensive separation, concentration, compression, and purification processes. Here, we present an efficient method for synthesizing urea derivatives from alkyl ammonium carbamates. The carbamates can be easily obtained from low concentrations of CO2 as present in ambient air or simulated exhaust gas. Reaction of alkyl ammonium carbamates with 1,3-dimethyl-2-imidazolidinone solvent in the presence of a titanium complex catalyst inside a sealed vessel produces urea derivatives in high yields. This reaction is suitable for synthesizing ethylene urea, an industrially important chemical, as well as various cyclic and acyclic urea derivatives. Using this methodology, we also show the synthesis of urea derivatives directly from low concentration of CO2 sources in a one-pot manner.

Similar content being viewed by others

Introduction

Climate change due to emission of greenhouse gases is one of the most pressing challenges globally. Among the greenhouse gases, carbon dioxide (CO2) emission due to human activities has been considered the main cause of global warming1. Therefore, it is desirable to develop technologies for CO2 capture, storage, and utilization (CCSU) from exhaust gases and, if possible, air, for reducing CO2 in the atmosphere2,3,4,5,6. The method for capturing CO2 directly from ambient air is called direct air capture (DAC)7,8,9,10. In the field of classical organic synthesis, CO2 has been extensively utilized as an abundant, low-toxicity, and low-cost C1 building block11,12,13,14,15,16. However, these reactions require highly pure CO2, often under high pressure. In other words, these reactions cannot be realized using low concentrations of CO2 directly and require prior steps, such as concentration, compression, and purification, which involve high costs. Owing to the high costs involved, organic syntheses using CO2 are considered reasonable only for high value-added chemicals, such as pharmaceuticals at CCSU. Thus, new methods that do not require high-CO2 concentrations, compression, or purification must be developed for CCSU to synthesize a wide range of chemical products. The DAC method has been utilized by Yoshida et al. and Inagaki et al. independently for the synthesis of oxazolidinone derivatives from CO2 in air and propargylamine derivatives17,18,19. However, in order to reduce CO2 emissions, core chemicals that are handled in large quantities must be synthesized, using inexpensive raw materials and low concentrations of CO2. In this regard, the abovementioned reactions use expensive raw materials, and the products formed are not core chemicals.

Urea derivatives (R2N(CO)NR2) are used as solvents, medicines, and fertilizers20,21,22. In particular, ethylene urea, a cyclic urea derivative, is a relatively high value-added core chemical (ca. 10 USD/kg in 2018) with a large market (ca. 12,000 t/year in 2018). It is used in paints and as a fabric finishing agent and raw material for agrochemicals20,23. Synthesis of urea derivatives has been performed using CO2 as a raw material. Reactions of amines with high-pressure CO2 in the presence of catalysts, such as cesium hydroxide24, cerium oxide25,26, organic bases27, and inorganic bases28 have been reported. Recently, the synthesis of urea derivatives from amines and atmospheric CO2, with an equivalent amount of phosphine and trichloroisocyanuric acid as a sacrificial reagent, has also been reported29. These studies are, of course, important as they provide methods for utilizing less reactive CO2 as a C1 building block. However, not all such studies contribute to the reduction of CO2 emission, since the reactions require high-purity CO2 either under high-pressure or in the presence of sacrificial reagents.

Considering the above facts, we inferred that the development of a reaction to synthesize urea derivatives from low concentrations of CO2, without the need for CO2 concentration, compression, and purification, could be a useful method for reducing CO2 emissions, while maintaining market competitiveness. Alkyl ammonium carbamates are well-known intermediates in the synthesis of urea derivatives from CO2 and amines24,25,26,27,28,29, and are also extensively studied in the field of CO2 capture2,3,4,5,6,7,8,9,10,30. Thus, we focused on utilizing alkyl ammonium carbamates, which are 1:2 adducts of CO2 and amines, as intermediates for the synthesis of urea derivatives from low concentrations of CO2. Since alkyl ammonium carbamates reversibly decompose into CO2 and amine when heated, they are utilized as a mediator for capturing and concentrating CO2 from exhaust gases released from major high-CO2 outlets, such as thermal power plants, cement industries, and gas refineries.

In this study, we have developed an efficient method for the synthesis and isolation of alkyl ammonium carbamates from aliphatic amines and low concentrations of CO2, including CO2 from ambient air. Using these synthesized alkyl ammonium carbamates, we have developed a method for the catalyzed synthesis of various important urea derivatives, such as ethylene urea. Most importantly, this method does not require separate steps for CO2 concentration, compression, and purification and hence, is expected to be an efficient and cost-effective strategy for reducing CO2 emissions.

Results and discussion

Synthesis of alkyl ammonium carbamates from low concentrations of CO2

Inagaki et al. have reported the DAC of CO2 to produce alkyl ammonium carbamates by exposing benzylamine and its analogs in ambient air for 1 week30. However, the efficiency of formation and the isolation methods for alkyl ammonium carbamates under various CO2 concentrations have not been discussed. Therefore, we investigated the efficiency of alkyl ammonium carbamate formation as a function of CO2 concentration, using ethylenediamine, the raw material for ethylene urea, as a model compound (Fig. 1). The experiment was conducted by bubbling pure CO2 gas or CO2/N2 mixed gas (50 or 15 vol% CO2) at a flow rate of 50 mL/min into 50 mL EtOH solution of ethylenediamine (20 mmol). Efficiency of alkyl ammonium carbamate (1a) formation was estimated based on the conversion rate of ethylenediamine, which was calculated from the 1H NMR spectra, using mesitylene as an internal standard. When pure CO2 gas was used, 97% ethylenediamine was converted after 10 min of bubbling (Fig. 1, red curve). When CO2/N2 mixed gas was bubbled, it took 20 min for 50 vol% CO2 (Fig. 1, green curve) and 70 min for 15 vol% CO2 (Fig. 1, blue curve) to consume ~97% ethylenediamine. In other words, although the rate of carbamate formation depended on the CO2 concentration, the carbamate could be obtained in high yields even with a low concentration of CO2 if the reaction time was prolonged. Since 1a precipitates in EtOH as a white powder after bubbling CO2-containing gases, it could be easily separated by filtration. The isolated yields of 1a from various CO2 sources are summarized in Table 1. The isolated yields of 1a from both pure CO2 and 15 vol% CO2 were high (93–96%) if the reaction was prolonged (Table 1, entries 1 and 2). This volume percent of CO2 (15 vol%) is approximately same as the CO2 concentration in exhaust gases of industrial plants, such as thermal power plants, cement plants, petroleum refinery, and steel mills, and CO2 emissions from these sources have raised concerns worldwide. Although the exhaust gases from industrial plants contain various compounds, such as water, CO, H2, SOx, and NOx, we expect most of these impurities to be easily removed by precipitation and filtration in our method for the synthesis of 1a. In fact, when the same experiment was conducted using simulated exhaust gas (CO2: 15 vol%, N2: 85 vol%, CO: 300 p.p.m., NO2: 500 p.p.m., SO2: 500 p.p.m.; the content of each component was determined according to the recent report by Kuznetsov et al.31), the yield of 1a was almost as high as that obtained when 15% CO2 gas was used (92%, Table 1, entry 3). Therefore, the method for synthesizing 1a developed in this study should be effective in utilizing CO2 of exhaust gases from industrial plants. Furthermore, since ethylenediamine reacts with CO2 in ambient air (0.04 vol%), 1a can also be synthesized by DAC. In fact, 1a could be isolated in 45% yield by exposing ethylenediamine to ambient air for 1 week (Table 1, entry 4). The reaction of amine with CO2 is known to yield water-incorporated ammonium carbonate salts, depending on the reaction conditions30. However, elemental analysis showed that anhydrous alkyl ammonium carbamate 1a could be obtained selectively from each CO2 source by our method, even when undried EtOH was used. In addition, the alkyl ammonium carbamates synthesized using various CO2 source were of comparable quality, as no significant differences were observed in the 1H and 13C NMR spectra and elemental analysis (Supplementary Figs. 1–3 and Supplementary Table 1). Since 1a was only soluble in water, the NMR spectra was acquired in D2O; however, some amount of 1a reacted with D2O to form a deuterated ammonium bicarbonate salt (Supplementary Figs. 1–3 for details). Therefore, the purity of 1a can be confirmed only by elemental analysis.

a Synthesis of 1a from ethylenediamine by bubbling various concentrations of CO2. Reaction conditions: ethylenediamine (1.2 g, 20 mmol), EtOH (50 mL), gas flow rate (50 mL/min). b Plot of the conversion rate of ethylenediamine as a function of bubbling time of pure CO2 gas and CO2/N2 mixed gases: red curve: pure CO2, green curve: CO2/N2 = 50:50 (v/v), and blue curve: CO2/N2: 15:85 (v/v). Conversions of ethylenediamine were calculated from 1H NMR spectra using mesitylene as an internal standard.

Synthesis of urea derivatives from alkyl ammonium carbamates

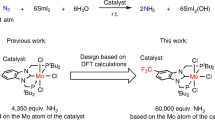

Next, we explored the optimal conditions for the catalytic synthesis of ethylene urea 3a from 1a. Since alkyl ammonium carbamates easily decompose into amines and CO2 upon heating, we performed the reaction inside a sealed vessel that was completely filled with the substrate, catalyst, and solvent, to prevent the release of CO2 from the reaction system. We investigated Lewis acids, such as group 4 metal complexes and tin compounds. These are effective catalysts for CO2 utilization reactions involving dehydration, such as the synthesis of dialkyl carbonates and organic carbamates, using acetals as a regenerable dehydration agent32,33,34. In addition to CsOH, CeO2, DBU, and inorganic bases, which are effective for the synthesis of urea derivatives using high-pressure CO2 (refs. 24,25,26,27,28), the Lewis acid catalysts can be used to synthesize urea derivatives from alkyl ammonium carbamate. As a result, group 4 metal compounds were found to be particularly active (Supplementary Table 2). The most active catalyst was a Ti complex Cp2Ti(OTf)2 (Cp = cyclopentadienyl; OTf = trifluoromethanesulfonate; Table 2, entry 1). When a 10 mL autoclave having a dead volume was used instead of the sealed reaction vessel, the yield of 3a decreased (Table 2, entry 2). Almost quantitative 3a was obtained in 15 h of reaction time (Table 2, entry 3). Optimization of the solvents revealed that the yields were better in 1,3-dimethyl-2-imidazolidinone (DMI) and N-methylpyrrolidone (NMP) than in other polar solvents, such as 2-pyrrolidone, dimethyl formamide, tetrahydrofuran, acetonitrile, and 1,4-dioxane (Table 2, entries 4–9). In order to clarify the dependence of reaction efficiency on the solvents, the reaction was conducted in DMI, NMP, and 1,4-dioxane without any metal catalyst. The reaction proceeded to some extent in the absence of a catalyst when DMI and NMP were used (Table 2, entries 10–12). It was also found that the addition of one equivalent of ethylene urea 3a accelerated the reaction (Table 2, entry 13).

We believe that the solvent and autocatalytic effects discussed above are closely related to the reaction mechanism. The Ti-catalyzed synthesis of urea derivatives from alkyl ammonium carbamate uses a closed vessel with no dead volume, making it difficult to follow the detail of the reaction. Nevertheless, we assumed this reaction to proceed by a mechanism via a metal carbamate, similar to the CeO2-catalyzed synthesis using high-pressure CO2, where the metal center acts as a Lewis acid, as proposed by Tomishige et al. (Fig. 2)25. It should be noted that in the CeO2 catalytic system, dicarbamic acid is formed once due to the presence of a large amount of CO2; however, in the Ti complex catalytic system used in this study, the titanium carbamate complex could be obtained directly because there is no additional CO2 (Fig. 2, step 1). In the CeO2 catalytic system, it is assumed that the oxygen atom in CeO2 acts as a proton acceptor, enabling the nucleophilic attack of the amine and promoting the reaction. On the other hand, in the Ti complex catalytic system, basic solvents such as DMI and NMP assists the proton transfer and acted as temporary proton acceptors, thereby promoting the reaction (Fig. 2, steps 2 and 3). Kim and Lee et al. reported that the addition of ethylene urea stabilized zwitterionic carbamate species via a hydrogen-bonding network during the synthesis of urea derivatives, using inorganic salt catalysts; similar acceleration effects are also expected in our Ti complex catalytic system28. Finally, the Ti complex catalyst would regenerate through the dehydration reaction and subsequent formation of urea derivatives (Fig. 2, steps 4 and 5).

To determine the optimum reaction temperature, the reaction was conducted at various temperatures under the conditions corresponding to entry 3 in Table 2, and the yields at each temperature were plotted as a function of the reaction time (Fig. 3). The yield reached 99% within 15 h at temperatures >170 °C. The reaction was first order with respect to the concentration of 1a, and the activation energy calculated from the Arrhenius plot was 144 kJ/mol. Based on the above experimental results and kinetic analysis, 10 mmol of 1a, 2 mol% of Cp2Ti(OTf)2 as a catalyst, and a temperature of 170 °C were determined to be the optimal reaction conditions. In addition, DMI was determined to be the best solvent as it is stable against acids and bases at high temperatures. No ethylene urea was formed when ethylenediamine was heated with 2 mol% of Cp2Ti(OTf)2 in DMI, confirming that DMI was not a carbonyl source. Under these conditions, 3a was obtained in 99% NMR yield in 24 h, and simple distillation following this allowed the isolation of 3a in 82% yield (Table 2, entry 14).

Following the determination of the optimal reaction conditions, we investigated the substrate scope (Fig. 4). Initially, we investigated the synthesis and isolation of various alkyl ammonium carbamates from the corresponding amines and CO2, which are commonly used in the conventional synthesis of urea derivatives, using the method for the synthesis of 1a from ethylenediamine and CO2 (refs. 24,25,26,27,28,29). The reaction was conducted using EtOH or n-hexane as the solvent, depending on the solubility of the alkyl ammonium carbamates. Depending on the type of amine, intramolecular salts 1b–1g or intermolecular salts 2a–2d were obtained in 72–97% yields (see Supplementary Methods for further details). Elemental analysis of the solid alkyl ammonium carbamates, except 1b, obtained by our method suggested that they were composed only of the corresponding amines and CO2. The composition of 1b was different from those of the other compounds probably due to the adsorption of small amounts of water and nitrogen gas. We shall assume that 1b has an ideal composition and discuss it in the following sections, since 1b is treated only as an intermediate raw material in this reaction. Urea derivative 3b could also be synthesized in high yields when 1b, with impurities such as water, was used. Compounds 3c and 3d with fused ring structures derived from 1c and 1d were synthesized, respectively, from the cis- and trans-isomers of 1,2-cyclohexyl diamine 3c, with relatively close distances between the two nitrogen atoms. While 3c was obtained in a high yield (82%), 3d, with relatively large distances between the two nitrogen atoms, was obtained in a relatively low yield (62%). When 10 mmol of 1d was used, large amounts of insoluble white precipitate were formed. These were probably polyurea precipitates that were formed through an intermolecular reaction. Hence, it was necessary to lower the amount of 1d to 2 mmol and increase the amount of catalyst to 10 mol% for the synthesis of 3d. On the other hand, urea derivative 3e was obtained in high yield (79%) even when 1e, in which the carbon chain is longer than that in 1a–1d, was used. Our method is also applicable to the synthesis of alkyl ammonium carbamates 1f and 1g derived from secondary diamines. The corresponding N,N′-disubstituted cyclic urea derivatives 3f and 3g can be obtained in relatively high isolated yields with 10 mol% of the catalyst (64% and 65%, respectively). Acyclic urea derivatives can also be synthesized from monoamine-derived alkyl ammonium carbamates, although the efficiency is slightly lower than that of the synthesis of cyclic urea derivatives. Alkyl ammonium carbamates 2a and 2b derived from linear primary amines gave corresponding urea derivatives 4a and 4b in moderate isolated yields (48% and 52%, respectively), when the reaction time was extended to 48 h, and 2 mmol of alkyl ammonium carbamates and 10 mol% of the catalyst were used. On the other hand, alkyl ammonium carbamate 2c afforded corresponding urea derivative 4c in low yield (13%), probably due to steric hindrance of the two cyclohexyl groups. Interestingly, the intermolecular alkyl ammonium carbamates 2d derived from 2-aminobenzylamine gave N-aryl-N′-alkyl cyclic urea derivative 3h in quantitative yield, unlike the case of monoamine-derived 2a–2c. As mentioned above, our method can be applied to the synthesis of various alkyl ammonium carbamates, and all the urea derivatives can be easily isolated upon solvent removal and simple distillation. This method is particularly suitable for the synthesis of cyclic urea derivatives. In addition, even when alkyl ammonium carbamate 1a, derived from CO2 in ambient air or 15 vol% CO2, was used as the raw material, urea derivative 3a could be synthesized in the same high yield (99% NMR yield) as that obtained, using 1a derived from pure CO2.

Reaction conditions: alkyl ammonium carbamate (10 mmol), Cp2Ti(OTf)2 (0.04 mmol), DMI (4.5 mL), and 5 mL sealed reaction vessel. Values in parentheses indicate isolated yields. aTentative isolated yield if pure 1b was used. b8 mmol of 1c and 4 mL of DMI were used. c2 mmol of alkyl ammonium carbamates and 10 mol% of Cp2Ti(OTf)2 were used for 15 h. dNMR yield could not be determined due to low solubility. e1,4-dioxane was used as the solvent instead of DMI for 24 h. f2 mmol of alkyl ammonium carbamate and 10 mol% of Cp2Ti(OTf)2 were used for 48 h. g4.6 mmol of 2d and 4 mL of DMI were used.

In addition, we investigated the one-pot synthesis of urea derivatives from low concentrations of CO2 (Fig. 5). To ethylenediamine (2.0 mmol) dissolved in DMI (2 mL; reaction solvent) in a 5 ml reaction vessel, 15 vol% CO2 was blown at 20 mL/min for 1 h. Then, 10 mol% of Cp2Ti(OTf)2 and DMI (2.5 mL) were added, and the reaction vessel was sealed. After heating at 170 °C for 24 h, ethylene urea 3a was obtained in 80% yield. This one-pot method can be applied to the synthesis of other urea derivatives. Using this one-pot method, urea derivatives 3b, 3c, and 3g, which had particularly good yields in the stepwise synthesis, were obtained in relatively high yields (71%, 76%, and 53%, respectively).

Conclusion

In this study, a method for the Cp2Ti(OTf)2-catalyzed synthesis of urea derivatives from alkyl ammonium carbamates, which can be obtained from low concentrations of CO2, including those in exhaust gases and ambient air, was developed. The various alkyl ammonium carbamates could be readily synthesized and isolated in high yields by exposing the corresponding amines in appropriate solvents to CO2/N2 (v:v = 15:85) mixed gases, in which the CO2 concentration is almost equivalent to that in the exhaust gas of a thermal power plant. In addition, alkyl ammonium carbamate could be synthesized from ethylenediamine, using simulated exhaust gas and ambient air as a CO2 source. Moreover, quality of the obtained alkyl ammonium carbamates was same, regardless of the CO2 source. Our method was applicable to the synthesis of various other urea derivatives and particularly suitable for the synthesis of cyclic urea derivatives, such as ethylene urea, which has a high commercial value. Synergistic effect of the Ti catalyst, solvent (DMI), and the product (urea derivative) rendered the reaction highly efficient. Furthermore, we found that the urea derivatives could be synthesized from low concentrations of CO2 and amines via alkyl ammonium carbamates in a one-pot manner, using DMI as a solvent.

This method for the synthesis of urea derivatives can be used to obtain useful chemicals from low concentrations of CO2, without the need for expensive and energy-intensive processes of concentrating, compressing, and purifying CO2. Moreover, since carbamate can be purified by bubbling low concentrations of CO2 into the solvent, followed by filtration of the solid, this method has potential applications in utilizing exhaust gases containing various impurities. Therefore, we believe that our method for the synthesis of urea derivatives will aid in reducing CO2 emissions by effectively using the CO2 in ambient air and exhaust gases as a raw material.

Methods

General procedure

For synthesizing urea derivatives, alkyl ammonium carbamates (10.0 mmol), Cp2Ti(OTf)2 (2 mol%), and DMI (4.5 mL) were added to a 5 mL autoclave reactor vessel and completely shielded with a stainless plate gasket. The vessel was dropped in a heated oil bath, and the reaction solution was stirred at 170 °C for 24 h. After the reaction reached completion, the vessel was removed from the oil bath and cooled to room temperature. The reaction mixture was extracted with MeOH (ca. 20 mL), and then 1,3,5-trimethylebenzene (ca. 100 mg) was added as an internal standard for 1H NMR measurements to determine the NMR yield. After recording the 1H NMR spectrum, MeOH was removed under reduced pressure using an evaporator. Then, components other than the target compound were roughly eliminated using a Kugelrohr apparatus. The obtained solid was washed with Et2O/n-hexane and dried under reduced pressure at 50 °C to afford urea derivatives as a white solid. Full experimental details for all the alkyl ammonium carbamates and urea derivatives are provided in the Supplementary Methods and Supplementary Figs. 4–26.

Data availability

Data supporting the findings of this study are available within this paper and its Supplementary Information are available from the corresponding author upon reasonable request.

References

Pachauri, R. K. et al. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II, and III to the fifth assessment report of the Intergovernmental Panel on Climate Change (IPCC, 2014).

Leung, D. Y. C., Caramanna, G. & Maroto-Valer, M. M. An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 39, 426–443 (2014).

Bui, M. et al. Carbon capture and storage (CCS): the way forward. Energy Environ. Sci. 11, 1062–1176 (2018).

Hunt, A. J., Sin, E. H. K., Marriott, R. & Clark, J. H. Generation, capture, and utilization of industrial carbon dioxide. ChemSusChem 3, 306–322 (2010).

Markewitz, P. et al. Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy Environ. Sci. 5, 7281–7305 (2012).

Cuéllar-Franca, R. M. & Azapagic, A. Carbon capture, storage and utilisation technologies: a critical analysis and comparison of their life cycle environmental impacts. J. CO2 Util. 9, 82–102 (2015).

Socolow, R. et al. Direct air capture of CO2 with chemicals a technology assessment for the APS panel on public affairs. (Am. Phys. Soc., 2011).

Sanz-Pérez, E. S., Murdock, C. R., Didas, S. A. & Jones, C. W. Direct capture of CO2 from ambient air. Chem. Rev. 116, 11840–11876 (2016).

Fasihi, M., Efimova, O. & Breyer, C. Techno-economic assessment of CO2 direct air capture plants. J. Clean. Prod. 224, 957–980 (2019).

Shi, X. et al. Sorbents for the direct capture of CO2 from ambient air. Angew. Chem. Int. Ed. 59, 6984–7006 (2020).

Aresta, M. Carbon Dioxide as Chemical Feedstock. Carbon Dioxide as A Chemical Feedstock (Wiley, 2010).

Sakakura, T., Choi, J.-C. & Yasuda, H. Transformation of carbon dioxide. Chem. Rev. 107, 2365–2387 (2007).

Mikkelsen, M., Jørgensen, M. & Krebs, F. C. The teraton challenge. A review of fixation and transformation of carbon dioxide. Energy Environ. Sci. 3, 43–81 (2010).

Aresta, M., Dibenedetto, A. & Angelini, A. Catalysis for the valorization of exhaust carbon: from CO2 to chemicals, materials, and fuels. technological use of CO2. Chem. Rev. 114, 1709–1742 (2014).

Liu, Q., Wu, L., Jackstell, R. & Beller, M. Using carbon dioxide as a building block in organic synthesis. Nat. Commun. 6, 5933 (2015).

Klankermayer, J., Wesselbaum, S., Beydoun, K. & Leitner, W. Selective catalytic synthesis using the combination of carbon dioxide and hydrogen: catalytic chess at the interface of energy and chemistry. Angew. Chem. Int. Ed. 55, 7296–7343 (2016).

Yoshida, M., Mizuguchi, T. & Shishido, K. Synthesis of oxazolidinones by efficient fixation of atmospheric CO2 with propargylic amines by using a silver/1,8-diazabicyclo[5.4.0] undec-7-ene (DBU) dual-catalyst system. Chem. A Eur. J. 18, 15578–15581 (2012).

Inagaki, F. et al. Energyless CO2 absorption, generation, and fixation using atmospheric CO2. Chem. Pharm. Bull. 64, 8–13 (2016).

Inagaki, F., Maeda, K., Nakazawa, K. & Mukai, C. Construction of the oxazolidinone framework from propargylamine and CO2 in air at ambient temperature: catalytic effect of a gold complex featuring an L2/Z-type ligand. Eur. J. Org. Chem. 2018, 2972–2976 (2018).

Nitschke, C. & Scherr, G. in Ullmann’s Encyclopedia of Industrial Chemistry 11, 1–9 (Wiley, 2010).

Lam, P. et al. Rational design of potent, bioavailable, nonpeptide cyclic ureas as HIV protease inhibitors. Science 263, 380–384 (1994).

Li, H.-Q., Lv, P.-C., Yan, T. & Zhu, H.-L. Urea derivatives as anticancer agents. Anticancer. Agents Med. Chem. 9, 471–480 (2009).

Market Research Center. Global and Chinese Ethylene Urea Industry, 2018 Market Research Report (Prof Research, 2018).

Shi, F. et al. Alternatives to phosgene and carbon monoxide: synthesis of symmetric urea derivatives with carbon dioxide in ionic liquids. Angew. Chem. Int. Ed. 42, 3257–3260 (2003).

Tamura, M., Noro, K., Honda, M., Nakagawa, Y. & Tomishige, K. Highly efficient synthesis of cyclic ureas from CO2 and diamines by a pure CeO2 catalyst using a 2-propanol solvent. Green Chem. 15, 1567 (2013).

Tamura, M., Ito, K., Nakagawa, Y. & Tomishige, K. CeO2-catalyzed direct synthesis of dialkylureas from CO2 and amines. J. Catal. 343, 75–85 (2016).

Marchegiani, M. et al. Urea derivatives from carbon dioxide and amines by guanidine catalysis: easy access to imidazolidin-2-ones under solvent-free conditions. J. CO2 Util. 21, 553–561 (2017).

Jin, S. J. et al. Efficient catalytic systems for the carboxylation of diamines to cyclic ureas using ethylene urea as a promoter. Appl. Catal. B Environ. 209, 139–145 (2017).

Ghodsinia, S. S. E. & Akhlaghinia, B. A high-yielding, expeditious, and multicomponent synthesis of urea and carbamate derivatives by using triphenylphosphine/trichloroisocyanuric acid system. Phosphorus Sulfur Silicon Relat. Elem. 191, 1–7 (2016).

Inagaki, F., Matsumoto, C., Iwata, T. & Mukai, C. CO2-selective absorbents in air: reverse lipid bilayer structure forming neutral carbamic acid in water without hydration. J. Am. Chem. Soc. 139, 4639–4642 (2017).

Glushkov, D., Kuznetsov, G. & Paushkina, K. Switching coal-fired thermal power plant to composite fuel for recovering industrial and municipal waste: combustion characteristics, emissions, and economic effect. Energies 13, 259 (2020).

Sakakura, T. et al. Metal-catalyzed dimethyl carbonate synthesis from carbon dioxide and acetals. J. Org. Chem. 64, 4506–4508 (1999).

Kohno, K., Choi, J.-C., Ohshima, Y., Yasuda, H. & Sakakura, T. Synthesis of dimethyl carbonate from carbon dioxide catalyzed by titanium alkoxides with polyether-type ligands. ChemSusChem 1, 186–188 (2008).

Abla, M., Choi, J.-C. & Sakakura, T. Halogen-free process for the conversion of carbon dioxide to urethanes by homogeneous catalysis. Chem. Commun. 2238–2239 (2001).

Acknowledgements

This work was supported by “Uncharted Territory Challenge 2050 (Mitou challenge 2050)” (K.T.) from New Energy and Industrial Technology Development Organization (NEDO)

Author information

Authors and Affiliations

Contributions

K.T., K.M., and J.-C.C. conceived the project and designed the experiments. K.T. and J.-C.C. directed the project. H.K. and K.T. performed the experiments and analyzed the results. H.K., K.T., K.M., and J.-C.C. wrote the manuscript. H.K., K.T., K.M., N.F., K.S., M.U., S.M., S.H., and J.-C.C discussed the results presented in this manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koizumi, H., Takeuchi, K., Matsumoto, K. et al. One-pot catalytic synthesis of urea derivatives from alkyl ammonium carbamates using low concentrations of CO2. Commun Chem 4, 66 (2021). https://doi.org/10.1038/s42004-021-00505-2

Published:

DOI: https://doi.org/10.1038/s42004-021-00505-2

This article is cited by

-

Elastomers mechanically reinforced and toughened with CO2 gas

Communications Materials (2024)

-

Direct synthesis of urea from carbon dioxide and ammonia

Nature Communications (2023)

-

Application of new multi-H-bond catalyst for the preparation of substituted pyridines via a cooperative vinylogous anomeric-based oxidation

Research on Chemical Intermediates (2023)

-

Highly dispersed small Pd nanoparticles on porous P-doped carbon nanospheres for efficient CO2 fixation into cyclic carbonates under solvent-free conditions

Journal of Porous Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.