Abstract

Hollow nanoclusters are intriguing for bridging the gap between small metal-organic cages and hollow nanoparticles and provide enormous opportunities for functional materials. Rational construction of hollow nanoclusters remains a challenge owing to the poor understanding of their formation pathways and difficulties in obtaining the intermediate structures. Here we report a catalyzed assembly strategy to construct hollow silver–sulfide clusters using a self-releasable carbonate template. The hollow Ag56 cluster and the carbonate-templated Ag33 intermediate are characterized by single-crystal X-ray analysis. Combining this data with a time-dependent UV-Vis spectroscopic investigation, we reveal the catalyst-like behavior of the self-releasable carbonate template and propose the corresponding mechanism. The assembly of hollow clusters using a self-releasable template may provide insight into understanding the formation mechanisms of other hollow nanoclusters and facilitate the design and construction of new hollow nanoclusters.

Similar content being viewed by others

Introduction

Noble metal nanoclusters1,2,3,4 have experienced great advances in the past decade as an important bridge between smaller metal-organic coordination complexes5,6,7 and larger ligand capped nanoparticles8,9, providing enormous opportunities on magnetism1, catalysis4,10,11, luminescent materials12,13,14,15, biomedicine16,17, and molecular sensing15,18. As a prime example, thiolate-protected silver18,19,20,21,22,23, gold3,12,24, and the bimetallic nanoclusters25,26,27 have been studied extensively for understanding their size-dependent evolutions of structures and properties. Because atomically precise nanoclusters have the same monodisperse nature as small coordination molecules1,24, they can be analyzed by single-crystal X-ray crystallography, revealing various sophisticated structures with many kinds of symmetries28,29,30,31. Among these structures, hollow nanoclusters32,33,34,35,36 are particularly intriguing for bridging the gap between small supramolecular cages5,6,7 and hollow nanoparticles37,38, which presents increased structural complexity and may bring more sophisticated functions. However, constructing hollow nanoclusters and precisely determining their structures remain great challenges39,40,41,42, because of the lack of understanding of the formation pathway of nanoclusters28,43,44,45 and the inherent difficulties in getting high-quality single crystals of hollow structures46. To understand the formation mechanism of hollow nanoclusters, it is crucial to track growth kinetics and obtain single-crystal structures of the intermediate clusters. Single crystals of intermediate clusters can be hard to obtain, and other characterization methods, such as advanced mass spectrometry, also could be used to monitor the growth mechanism of nanoclusters and to measure precise intermediate molecular formulas16,17.

Here, we report a catalyzed assembly strategy to construct a hollow silver-sulfide cluster, Ag56S12(StBu)20(Sal)12 (1, HStBu = tert-Butylthiol, H(Sal) = salicylic acid), using a self-releasable anion template. This hollow Ag56 cluster is synthesized from small precursors, whereas a carbonate-templated Ag33 nest-like intermediate is found during the growth of Ag56 cluster. Structures of Ag56 cluster and Ag33 intermediate are characterized by single-crystal X-ray analysis, and the growth kinetics are investigated by time-dependent ultraviolet (UV)–visible (Vis) spectroscopy, revealing the catalyst-like behavior of the self-releasable carbonate template.

Results

Structure of 1

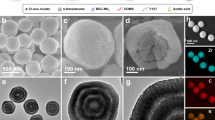

Cluster 1 was synthesized by adding silver salicylate hydrate (Ag(Sal)·H2O, 1.2 mmol) and AgStBu (4.5 mmol) into a mixture of acetonitrile, dichloromethane, and methanol (v/v = 1:1:1). The reaction proceeded at 80 °C for 5 days and was directly reflected by the color change from colorless to yellow and finally to orange. After reaction, orange crystals were obtained and analyzed by single-crystal XRD (Supplementary Table 1), revealing a neutral spherical Ag56S12(StBu)20(Sal)12 structure of 1 (Fig. 1a and Supplementary Fig. 1). Cluster 1 have a core–shell structure containing a [Ag14S12] core (Fig. 1b) and a [Ag42(StBu)20(Sal)12] shell (Fig. 1c).

Structure of 1. a Molecular structure of 1, Ag56S12(StBu)20(Sal)12. b Hollow [Ag14S12] core of 1. c Quasi-fivefold symmetric [Ag42(StBu)20(Sal)12] shell of 1. The [Ag14S12] core and hydrogen atoms have been omitted for clarity in c and the artificial large green sphere shows the inner space occupied by hollow [Ag14S12] core. Color legend: green, Ag (core); magenta, Ag (shell); orange, S2−; yellow, S (thiolate); gray, C; red, O

In the [Ag14S12] core, 14 Ag+ ions form a hollow rhombic dodecahedron, whereas 12 S2– ions are located outside each face of Ag+ rhombic dodecahedron to form an icosahedron. The rhombic dodecahedron@icosahedron geometry of the [Ag14S12] core resembles the [Ag14(C≡CtBu)12Cl] and [Ag14S13] cores in the reported clusters47,48,49. However, all these previously reported clusters encapsulated a guest anion (Cl– or S2–) at the center of [Ag14] rhombic dodecahedron.

In the [Ag42(StBu)20(Sal)12] shell, Ag+ ions can be classified into two types: 18 Ag+ ions that are only protected by thiolates, and the other 24 Ag+ ions that are protected by both thiolate and salicylate ligands. The 20 StBu ligands form a dodecahedron and coordinate with Ag+ in μ3 and μ4 bridge binding modes, with the Ag–S bond lengths ranging from 2.419 to 2.944 Å. The 12 Sal ligands form an icosahedron and coordinate with Ag+ in μ2-O,O’ binding mode, with Ag–O bond lengths ranging from 2.257 to 2.357 Å. Therefore, cluster 1 can be resolved as five layers of polyhedral from inner to outer surface: the Ag14 rhombic dodecahedron, the S12 icosahedron, the spherical Ag42 polyhedron, the (StBu)20 dodecahedron and the Sal12 icosahedron. All these polyhedra share a common S6 symmetry axis, making the cluster achiral. In crystal, spherical clusters are packed in the R-3c space group with the S6 axis of the cluster in parallel to the c axis of the unit cell. The diameter of the spherical 1 approximately equals the lattice parameter a (27.1 Å), and the volume of one cluster is 10,436 Å3.

Structure of 2

During the synthesis of 1, we observed an obvious color change from colorless to yellow and finally to orange (Supplementary Fig. 2). Therefore, we speculated that the synthetic pathway of 1 could go through an intermediate stage with the formation of a smaller yellow cluster. By carefully crystallizing the reaction solution at intermediate stage, we obtained a small amount of yellow hexagonal crystals of CO3Ag33S3(StBu)16(Sal)9 (2) concomitantly with orange rhombic crystals of 1. Cluster 2 has a nest-like structure having a C3v-symmetry (Fig. 2 and Supplementary Fig. 3), crystallized in a P-3m1 unit cell. The nest-like structure of 2 is similar to the reported NO3−-templated Ag33 cluster13. However due to the charge difference between CO32− and NO3−, cluster 2 is neutral without any counter-anion outside the cluster. The 33 Ag+ ions in 2 can be identified as two layers: the inner layer contains 9 Ag+ ions (green in Fig. 2), holding the center CO32− anion; and the outer layer contains 24 Ag+ ions (magenta in Fig. 2), which are connected to the inner layer by three S2− ions (orange in Fig. 2) and six StBu ligands (yellow in Fig. 2). The Ag–O bond-length between the center CO32− anion and the Ag+ inner layer was measured as 2.7 Å, which is longer than the 2.3 Å Ag–O bond in Ag2CO350, suggesting the relatively weaker interaction between the central CO32− anion and the Ag+ inner layer. It was surprising that this intermediate 2 contains a CO32− anion template, as no CO32− species was intentionally added into the reaction. We speculated that the CO32− was introduced from the atmospheric carbon dioxide fixation51,52. To confirm the reaction pathway and understand the reaction kinetics, we added a small amount of Ag2CO3 (4% molar ratio to AgStBu) into the previously described reaction for synthesizing 1. Two parallel reactions with and without Ag2CO3 were investigated by time-dependent UV–Vis spectroscopy.

Structure of 2. a Threefold symmetric structure of 2, CO3Ag33S3(StBu)16(Sal)9. b Main structure of 2, the tert-butyl groups and salicylate groups have been omitted for clarity. c Side view of carbonate chemical environment in the nest-like intermediate 2. Color legend: green, Ag (inner); magenta, Ag (outer); orange, S2−; yellow, S (thiolate); gray, C; red, O

Kinetics study

The UV–Vis spectra of the clusters (Fig. 3a) corroborate the observed color change from yellow 2 to orange 1. Compared to the solution of reactants, the smaller 2 shows a peak of absorbance increase at 370 nm, whereas larger 1 shows a wide increase in UV–Vis absorption from 300 to 550 nm (Fig. 3b). Two parallel reactions with and without Ag2CO3 were monitored by UV–Vis spectroscopy at 1 h time intervals. As shown in Fig. 3c, the UV–Vis spectra of the reaction solution without Ag2CO3 increased obviously upon reaction time. By comparing with the initial spectrum, we derived differential spectra for different reaction time (Fig. 3d), showing an increasing peak at 370 nm in the first 4 h, which corresponds to the formation of 2. After 5 h, the differential spectra get broader from 300 to 550 nm with a new increasing peak at 330 nm, corresponding to the formation of 2. For the reaction assisted by Ag2CO3, a similar absorption increase was observed by spectroscopy (Fig. 3e and Supplementary Fig. 4), yet with a higher increasing rate upon reaction time. As shown in Fig. 3f, it took approximately 5 h for UV–Vis spectra to increase for 0.08 at 330 nm without introducing Ag2CO3, however, accelerated by 4% amount of Ag2CO3, it took only 2 h to achieve the similar increase. In fact, the acceleration caused by Ag2CO3 could even be reflected by the considerable difference in the rate of color change observed by bare eyes, as shown in Supplementary Fig. 2.

UV–Vis spectra for reaction monitoring. a UV–Vis spectra of the solution of precursors and the products, 1 and 2. b Increased absorbance of 1 and 2 over the precursors. c Time-dependent UV–Vis spectra. d Increased absorbance of the reaction solution for synthesizing 1 without adding Ag2CO3. e Increased absorbance of the reaction solution for synthesizing 1 with adding 4% amount of Ag2CO3, and f Increased absorbance at 330 nm (solid lines) and 370 nm (dash lines) upon time for two parallel reaction solutions with or without adding 4% amount of Ag2CO3

Combining structural analyses and kinetics investigation, we can conclude that the CO32− anion acts as a self-releasable template and accelerates the formation process of 1 in a way similar to a catalyst, which is essentially different from the conventional templates that cannot be removed or can only be removed by extra post-synthesis methods53,54,55,56. Since the formation processes of supramolecular clusters are usually referred to molecular assembly22,28,31, which mainly involve reversible coordination bonding57, we prefer to classify the as-described process in this work as a catalyzed assembly (catassembly) process58. The turn over number (TON) is calculated by measuring the amount of 1 over Ag2CO3 as 4.8. Catassembly pathway for forming 1 contains three steps as shown in Fig. 4a, and the proposed mechanism of each step is shown in Fig. 4b.

Compared to tert-butyl thiolate and salicylate, CO32− has a smaller size and higher negative charge, thus enriching a higher local concentration of Ag+ ion for the nucleation of 2. The chemical equation to form 2 can be derived as Eq. (1).

As shown in Fig. 4b, proton is generated along with the formation of 2. During the growth from 2 to 1, the local concentration of proton is further accumulated. As indicated by the single-crystal X-ray analysis, the interaction between the CO32− template and the nest structure of 2 is relatively weak. Thus, the CO32− template is removed from the nest and becomes free H2CO3 when the local proton concentration gets higher during the cluster growth. The free H2CO3 further defuses and reacts with AgStBu to generate Ag2CO3 again. The chemical equation from 2 to 1 can be derived as Eq. (2).

The side products in Eqs. (1) and (2), i.e., HStBu and MeOtBu, were confirmed by the capillary gas chromatography and mass spectrometry analyses of the reaction solution and also the gas phase in the reaction vial (Supplementary Fig. 5). Moreover, if extra Ag2CO3 (e.g., 18% molar ratio to AgStBu) was introduced into the initial reactants, it would impede the release of CO32− from 2 and stop the further growth into 1. As a result, with adding 18% amount of Ag2CO3, the main product of the reaction would become 2, corroborating the proposed mechanism in Fig. 4b.

Discussion

We have constructed a hollow silver-sulfide cluster with a catassembly strategy. Through carefully tracking and analyzing the growth process, we found a carbonate-templated nest-like intermediate, which accelerated the cluster growth in a similar way as catalyst accelerates a chemical reaction. The method to assemble hollow cluster through self-releasable template provides insights into understanding the formation mechanism of other hollow nanoclusters and may facilitate the design and construction of new hollow nanoclusters with various properties.

Methods

Chemicals and materials

Silver oxide (Ag2O), ammonia (NH3·H2O), sodium hydroxide (NaOH), trimethylamine (Et3N), methanol (MeOH), acetonitrile (MeCN), dichloromethane (DCM), chloroform (HCCl3), and diethyl ether (Et2O) were purchased from Sinopharm Chemical Reagent Co. Ltd. (Shanghai, China). 2-methylpropane-2-thiol (HStBu) was purchased from J&K Chemicals. Silver carbonate (Ag2CO3) was purchased from Adamas-Beta, Silver salicylate hydrate (AgC7H5O3·H2O) was purchased from Alfa-Aesar. AgStBu was prepared from the reaction of Ag2O, HStBu in NH3·H2O in an ice bath, and further washed in turn with H2O, MeOH, MeCN, and Et2O. Other reagents and solvents used without further purification.

Synthesis of Ag56S12(SC4H9)20(O3H5C7)12 (1)

Mixed acetonitrile, dichloromethane and methanol (1:1:1, 75 mL) was added 3.7 mg Ag2CO3, 306.1 mg AgC7H5O3·H2O, and 892.2 mg AgStBu. Under ultrasound condition, a white suspension was formed and further refluxed under nitrogen at 80 °C with a balloon for 5 days. The reaction solution changed from colorless to yellow and finally to orange, after cooled to room temperature, orange-red solution and orange solids were obtained. The solution was further concentrated by evaporation to generate more orange solids. Orange solids were collected, and then washed with diethyl ester (50 mL, twice) and dissolved in 30 mL dichloromethane. To this dichloromethane solution, mixed acetonitrile and methanol (1:1, 15 mL) was added to give the orange powder of 1 (633.2 mg, yield 89.7% based on AgC7H5O3·H2O). Anal. Calcd. for 1: Ag56S12(SC4H9)20(O3H5C7)12: C, 19.989; H, 2.455. Found: C, 20.279; H, 2.367. IR spectrum of 1 is shown in Supplementary Fig. 6a.

Synthesis of (CO3)Ag33S3(SC4H9)16(O3H5C7)9 (2)

Mixed acetonitrile and methanol (1:1, 9 mL) was added 25.6 mg Ag2CO3, 102.8 mg AgC7H5O3·H2O, and 137.9 mg AgStBu. Under ultrasound condition, a white suspension was formed and further refluxed under nitrogen at 80 °C for 7 h. To the cooled reaction solution was added 10 mL diethyl ether, after filtered, the yellow filtrate was dried and gave yellow powder of 2 (194.2 mg, yield 91.6% based on AgStBu). Anal. Calcd. for 2: (CO3)Ag33S3(SC4H9)16(O3H5C7)9(CH3CN)3(H2O)9: C, 24.158; H, 3.268; N, 0.631. Found: C, 23.929; H, 3.064; N, 0.631. IR spectrum of 2 is shown in Supplementary Fig. 6b.

Kinetic measurements for the reaction accelerated by Ag2CO3

In a 20 mL headspace bottle, mixed acetonitrile and methanol (1:1, 5 mL) was added into 2.9 mg Ag2CO3, 40.3 mg AgC7H5O3·H2O and 109.2 mg AgStBu. Under ultrasound condition, a white suspension was formed. Then 10 mL chloroform was added, the suspension dissolved and gave a colorless transparent solution. The reaction vial was tightly sealed and stirred in an oil bath at 80 °C. At 1 h time intervals, the reaction solution (50 µL) were drawn out and injected into 5.00 mL chloroform. The diluted solutions were immediately refrigerated in a refrigerator at 4 °C for the latter UV–Vis characterizations. The spectra of refrigerated solutions did not change after being kept in liquid nitrogen for more than 24 h.

Kinetic measurements for the reaction without adding Ag2CO3

In a 20 mL headspace bottle, mixed acetonitrile and methanol (1:1, 5 mL) was added into 40.3 mg AgC7H5O3·H2O and 110.4 mg AgStBu. Following treatment was exactly the same as the above reaction accelerated by Ag2CO3.

General characterization

UV–Vis absorption spectra were collected on an Agilent Cary 5000. Fourier-transform infrared spectroscopy (FT-IR) spectra were collected from KBr pellets in the range of 4000–400 cm-1 with a Nicolet AVATAR FT-IR 380 spectrometer. Nuclear magnetic resonance (NMR) data were collected on a Bruker Avance II spectrometer (600 MHz). GC-MS analyses were performed on Shimadzu GC-2010 MS with a capillary column (Rtx-5MS). X-ray crystallography is detailed in Supplementary Note 1 and Supplementary Data 1.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request. The X-ray crystallographic coordinates for structures reported in this Article have been deposited at the Cambridge Crystallographic Data Center (CCDC), under deposition number CCDC 1825401 and 1825402. These data can be obtained free of charge from The Cambridge Crystallographic Data Center via http://www.ccdc.cam.ac.uk/data_request/cif. All other data associated with this study are available from the authors upon reasonable request.

References

Jin, R., Zeng, C., Zhou, M. & Chen, Y. Atomically precise colloidal metal nanoclusters and nanoparticles: Fundamentals and opportunities. Chem. Rev. 116, 10346–10413 (2016).

Lu, Y. & Chen, W. Sub-nanometre sized metal clusters: from synthetic challenges to the unique property discoveries. Chem. Soc. Rev. 41, 3594–3623 (2012).

Goswami, N., Yao, Q., Chen, T. & Xie, J. Mechanistic exploration and controlled synthesis of precise thiolate-gold nanoclusters. Coord. Chem. Rev. 329, 1–15 (2016).

Ott, L. S. & Finke, R. G. Transition-metal nanocluster stabilization for catalysis: a critical review of ranking methods and putative stabilizers. Coord. Chem. Rev. 251, 1075–1100 (2007).

Cook, T. R. & Stang, P. J. Recent developments in the preparation and chemistry of metallacycles and metallacages via coordination. Chem. Rev. 115, 7001–7045 (2015).

Fujita, D. et al. Self-assembly of tetravalent Goldberg polyhedra from 144 small components. Nature 540, 563–566 (2016).

Zarra, S., Wood, D. M., Roberts, D. A. & Nitschke, J. R. Molecular containers in complex chemical systems. Chem. Soc. Rev. 44, 419–432 (2015).

Daniel, M.-C. & Astruc, D. Gold nanoparticles: assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem. Rev. 104, 293–346 (2004).

Levard, C., Hotze, E. M., Lowry, G. V. & Brown, G. E. Jr Environmental transformations of silver nanoparticles: impact on stability and toxicity. Environ. Sci. Technol. 46, 6900–6914 (2012).

Zhu, Y., Qian, H., Drake, B. A. & Jin, R. Atomically precise Au25(SR)18 nanoparticles as catalysts for the selective hydrogenation of a,b-unsaturated ketones and aldehydes. Angew. Chem. Int. Ed. 49, 1295–1298 (2010).

Li, G. & Jin, R. Atomically precise gold nanoclusters as new model catalysts. Acc. Chem. Res. 46, 1749–1758 (2013).

Xie, J., Zheng, Y. & Ying, J. Y. Protein-directed synthesis of highly fluorescent gold nanoclusters. J. Am. Chem. Soc. 131, 888–889 (2009).

Li, B. et al. Thermochromic Luminescent Nest-Like Silver Thiolate Cluster. Chem. Eur. J. 20, 12416–12420 (2014).

He, X., Wang, Y., Jiang, H. & Zhao, L. Structurally well-defined sigmoidal gold clusters: Probing the correlation between metal atom arrangement and chiroptical response. J. Am. Chem. Soc. 138, 5634–5643 (2016).

Huang, R. -W. et al. Hypersensitive dual-function luminescence switching of a silver-chalcogenolate cluster-based metal-organic framework. Nat. Chem. 9, 689–697 (2017).

Yao, Q., Chen, T., Yuan, X. & Xie, J. Toward total synthesis of thiolate-protected metal nanoclusters. Acc. Chem. Res. 51, 1338–1348 (2018).

Yao, Q. et al. Revealing isoelectronic size conversion dynamics of metal nanoclusters by a noncrystallization approach. Nat. Commum. 9, 1979 (2018).

Akbarzadeh, H., Yaghoubi, H., Shamkhali, A. N. & Taherkhani, F. CO adsorption on Ag nanoclusters supported on carbon nanotube: a molecular dynamics study. J. Phys. Chem. C. 118, 9187–9195 (2014).

Fenske, D. et al. Syntheses and crystal structures of [Ag123S35(StBu)50] and [Ag344S124(StBu)96]. Angew. Chem. Int. Ed. 44, 5242–5246 (2005).

Chitsaz, S., Fenske, D. & Fuhr, O. Silver chalcogenide clusters with dimethylanilinomercapto ligands: syntheses and crystal structures of [Ag65S13(SC6H4NMe2)39(dppm)5], [Ag76Se13(SC6H4NMe2)50(PPh3)6.5], and [Ag88Se12(SC6H4NMe2)63(PPh3)6]. Angew. Chem. Int. Ed. 45, 8055–8059 (2006).

Anson, C. E. et al. Synthesis and crystal structures of the ligand-stabilized silver chalcogenide clusters [Ag154Se77(dppxy)18], [Ag320(StBu)60S130(dppp)12], [Ag352S128(StC5H11)96], and [Ag490S188(StC5H11)114]. Angew. Chem. Int. Ed. 47, 1326–1331 (2008).

Liu, J. -W. et al. Anisotropic assembly of Ag52 and Ag76 nanoclusters. J. Am. Chem. Soc. 140, 1600–1603 (2018).

Wang, Z. -Y. et al. Atomically precise site-specific tailoring and directional assembly of superatomic silver nanoclusters. J. Am. Chem. Soc. 140, 1069–1076 (2018).

Qian, H., Zhu, M., Wu, Z. & Jin, R. Quantum sized gold nanoclusters with atomic precision. Acc. Chem. Res. 45, 1470–1479 (2012).

Wang, Y. et al. An intermetallic Au24Ag20 superatom nanocluster stabilized by labile ligands. J. Am. Chem. Soc. 137, 4324–4327 (2015).

Wang, Y. et al. Atomically precise alkynyl-protected metal nanoclusters as a model catalyst: Observation of promoting effect of surface ligands on catalysis by metal nanoparticles. J. Am. Chem. Soc. 138, 3278–3281 (2016).

Wan, X. -K. et al. Atomically precise bimetallic Au19Cu30 nanocluster with an icosidodecahedral Cu30 shell and an alkynyl-Cu interface. J. Am. Chem. Soc. 139, 9451–9454 (2017).

Zhan, C. et al. Time-resolved assembly of cluster-in-cluster {Ag12}-in-{W76} polyoxometalates under supramolecular control. Angew. Chem. Int. Ed. 53, 10362–10366 (2014).

Kong, X. -J. et al. A keplerate magnetic cluster featuring an icosidodecahedron of Ni(II) ions encapsulating a dodecahedron of La(III) ions. J. Am. Chem. Soc. 129, 7016–7017 (2007).

Yamazoe, S. et al. Hierarchy of bond stiffnesses within icosahedral-based gold clusters protected by thiolates. Nat. Commun. 7, 10414 (2016).

Wang, Z. et al. Assembly of silver Trigons into a buckyball-like Ag180 nanocage. Proc. Natl Acad. Sci. USA 114, 12132–12137 (2017).

Schaaff, T. G., Shafigullin, M. N., Khoury, J. T., Vezmar, I. & Whetten, R. L. Properties of a ubiquitous 29 kDa Au: SR cluster compound. J. Phys. Chem. B 105, 8785–8796 (2001).

Lopez-Acevedo, O., Akola, J., Whetten, R. L., Grönbeck, H. & Häkkinen, H. Structure and bonding in the ubiquitous icosahedral metallic gold cluster Au144(SR)60. J. Phys. Chem. C. 113, 5035–5038 (2009).

Yang, H. et al. All-thiol-stabilized Ag44 and Au12Ag32 nanoparticles with single-crystal structures. Nat. Commun. 4, 2422 (2013).

Desireddy, A. et al. Ultrastable silver nanoparticles. Nature 501, 399–402 (2013).

Jin, S. et al. Crystal structure and optical properties of the [Ag62S12(SBut)3 2]2+ nanocluster with a complete face-centered cubic kernel. J. Am. Chem. Soc. 136, 15559–15565 (2014).

Fan, H. J., Gösele, U. & Zacharias, M. Formation of nanotubes and hollow nanoparticles based on Kirkendall and diffusion processes: a review. Small 3, 1660–1671 (2007).

Chen, Y. et al. Hairy uniform permanently ligated hollow nanoparticles with precise dimension control and tunable optical properties. J. Am. Chem. Soc. 139, 12956–12967 (2017).

Chaki, N. K., Negishi, Y., Tsunoyama, H., Shichibu, Y. & Tsukuda, T. Ubiquitous 8 and 29 kDa gold: alkanethiolate cluster compounds: mass-spectrometric determination of molecular formulas and structural implications. J. Am. Chem. Soc. 130, 8608–8610 (2008).

Fields-Zinna, C. A. et al. Tandem mass spectrometry of thiolate-protected Au nanoparticles NaxAu25(SC2H4Ph)18-y(S(C2H4O)5CH3)y. J. Am. Chem. Soc. 131, 13844–13851 (2009).

García-Raya, D., Madueño, R., Blázquez, M. & Pineda, T. Electrochemistry of molecule-like Au25 nanoclusters protected by hexanethiolate. J. Phys. Chem. C. 113, 8756–8761 (2009).

Qian, H. & Jin, R. Controlling nanoparticles with atomic precision: the case of Au144(SCH2CH2Ph)60. Nano Lett. 9, 4083–4087 (2009).

Baksi, A., Chakraborty, P., Bhat, S., Natarajan, G. & Pradeep, T. [Au25(SR)18]2 2−: a noble metal cluster dimer in the gas phase. Chem. Commun. 52, 8397–8400 (2016).

Krishnadas, K. R. et al. Interparticle reactions: an emerging direction in nanomaterials chemistry. Acc. Chem. Res. 50, 1988–1996 (2017).

Yao, Q. et al. Understanding seed-mediated growth of gold nanoclusters at molecular level. Nat. Commun. 8, 927 (2017).

Jensen, K. M. O. et al. Polymorphism in magic-sized Au144(SR)60 clusters. Nat. Commun. 7, 11859 (2016).

Rais, D. et al. Anion-templated syntheses of rhombohedral silver-alkynyl cage compounds. Angew. Chem. Int. Ed. 40, 3464–3467 (2001).

Li, G., Lei, Z. & Wang, Q. -M. Luminescent molecular Ag-S nanocluster [Ag62S13(SBut)32](BF4)4. J. Am. Chem. Soc. 132, 17678–17679 (2010).

Sun, D. et al. Two birds with one stone: anion templated ball-shaped Ag56 and disc-like Ag20 clusters. Dalton. Trans. 42, 6281–6284 (2013).

Masse, P. R., Guitel, J. C. & Durif, A. Structure du carbonate d’argent. Acta Crystallogr. B. 35, 1428–1429 (1979).

Bian, S. -D., Jia, J. -H. & Wang, Q. -M. High-nuclearity silver clusters templated by carbonates generated from atmospheric carbon dioxide fixation. J. Am. Chem. Soc. 131, 3422–3423 (2009).

Yuan, S., Deng, Y. -K., Wang, X. -P. & Sun, D. A temperature-sensitive luminescent Ag20 nanocluster templated by carbonate in situ generated from atmospheric CO2 fixation. New J. Chem. 37, 2973–2977 (2013).

Wang, Q. -M., Lin, Y. -M. & Liu, K. -G. Role of anions associated with the formation and properties of silver clusters. Acc. Chem. Res. 48, 1570–1579 (2015).

Lin, Y., Massa, W. & Dehnen, S. “Zeoball” [Sn36Ge24Se132]24−: a molecular anion with zeolite-related composition and spherical shape. J. Am. Chem. Soc. 134, 4497–4500 (2012).

Zhou, K. et al. Unexpected 1D self-assembly of carbonate-templated sandwich-like macrocycle-based Ag20S10 luminescent nanoclusters. Cryst. Eng. Comm. 16, 7860–7864 (2014).

Zhang, L. L. -M. & Mak, T. C. W. Temperature-mediated template release: facile growth of copper (I) mixed ethynediide/isopropylethynide nanoclusters. Angew. Chem. Int. Ed. 56, 16228–16232 (2017).

Lehn, J. -M. From supramolecular chemistry towards constitutional dynamic chemistry and adaptive chemistry. Chem. Soc. Rev. 36, 151–160 (2007).

Wang, Y. et al. What molecular assembly can learn from catalytic chemistry. Chem. Soc. Rev. 43, 399–411 (2014).

Acknowledgements

We thank Mr. Kuang-Yu Wang at Peking University for assistance in experiments. This work was supported by National Natural Science Foundation of China (21473139, 21631007, 91227111, and 91427304).

Author information

Authors and Affiliations

Contributions

Q.W. and Z.T. supported and guided the whole experiment. Y.W. drafted the manuscript. Z.N. proposed the research direction, conducted the synthesis and characterization of the clusters. Z.C. gave some advice for the kinetics study and S.Y. picked the single crystals of the clusters.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nan, ZA., Wang, Y., Chen, ZX. et al. Catalyzed assembly of hollow silver-sulfide cluster through self-releasable anion template. Commun Chem 1, 99 (2018). https://doi.org/10.1038/s42004-018-0102-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-018-0102-3

This article is cited by

-

Homoleptic alkynyl-protected Ag32 nanocluster with atomic precision: Probing the ligand effect toward CO2 electroreduction and 4-nitrophenol reduction

Nano Research (2022)

-

Core engineering of paired core-shell silver nanoclusters

Science China Chemistry (2021)

-

Structures and properties of [Ag(Ag2S)n]+ clusters with n = 1–9: a density functional theory study

Journal of Nanoparticle Research (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.