Abstract

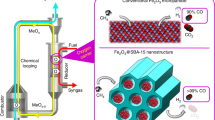

Methane-to-syngas conversion plays an important role in industrial gas-to-liquid technologies, which is commercially fulfilled by energy-intensive reforming methods. Here we present a highly selective and durable iron-based La0.6Sr0.4Fe0.8Al0.2O3-δ oxygen carrier for syngas production via a solar-driven thermochemical process. It is found that a dynamic structural transformation between the perovskite phase and a Fe0@oxides core–shell composite occurs during redox cycling. The oxide shell, acting like a micro-membrane, avoids direct contact between methane and fresh iron(0), and prevents coke deposition. This core–shell intermediate is regenerated to the original perovskite structure either in oxygen or more importantly in H2O–CO2 oxidant with simultaneous generation of another source of syngas. Doping with aluminium cations reduces the surface oxygen species, avoiding overoxidation of methane by decreasing oxygen vacancies in perovskite matrix. As a result, this material exhibits high stability with carbon monoxide selectivity above 95% and yielding an ideal syngas of H2/CO ratio of 2/1.

Similar content being viewed by others

Introduction

Taking full advantage of the abundant solar energy is a feasible approach to tackle the steeply increased global energy demand and mitigate the climate change induced by combustion of fossil fuels1. It is estimated that using only the solar energy from partial areas of the world’s desert can in principle meet the social energy requirement2. The challenge lies the in capture and storage of the relatively diffuse and labile solar energy, which could be realized through upgrading inert molecules into high-energy fuels by solar-driven thermochemical processes3. To date, significant research has been conducted into H2 and CO production by solar-driven water splitting and carbon dioxide splitting4,5. Importantly, the mixture of H2 and CO, namely, syngas, could be further converted to methanol or other value-added liquid fuels by Fischer-Tropsch process, offering advantages of being easily transported and stored than gaseous fuel6. Another attractive process gaining attention for solar harvest is conversion of methane to liquid fuel via syngas intermediate, which is motivated by the increasing production capacity of natural/shale gas in recent years7,8.

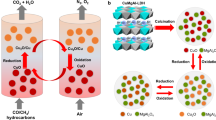

In two-step solar-driven thermochemical processes (Supplementary Fig. 1), the lattice oxygen serves as an oxygen source for selective oxidation of methane promoted by solar heat energy. Subsequently, lost oxygen can be replenished using oxidants like H2O, CO2, or air with the production of H2, CO, or process heat9. Different from the well-known continuous feeding mode of steam reforming (H2/CO = 3) and dry reforming (H2/CO = 1), direct production of syngas with H2/CO ratio of 2 becomes possible in such a two-step strategy without undesirable mixing of CH4 and O2 as in methane partial oxidation processes10.

The key to such thermochemical processes lies in the selection of suitable oxygen carriers (OCs) to give satisfactory reactivity, selectivity, and lattice oxygen capacity for syngas production. During the past decades, various kinds of OCs, including oxides of Zn, Ce, Sn, Co, Ni, and Fe etc., have been synthesized and tested11. Hereto, particular interests are focused on the inexpensive and environmental friendly Fe-based oxides12. As early as 1993, Steinfeld et al.13 have tried Fe3O4 in solar-driven thermochemical process for methane-to-syngas conversion, but pure iron oxides generally showed low reduction activity and CO selectivity. Study by Kim et al.14 showed that the production of syngas prevailed over the total oxidation to CO2 only when more than 50% of Fe3O4 was converted to FeO. Although further reduction of FeO to metallic Fe0 is favorable for higher CO/CO2 ratio and oxygen capacity, serious coke deposition would occur due to methane decomposition over Fe0, leading to increased H2/CO ratio and lower CO selectivity. Modification through structural or electronic promoters has been explored to improve the overall performance. Müller et al.15 demonstrated that Cu-modified Fe2O3/MgAl2O4 composite can result in partial coverage of reduced Fe0 with Cu, leading to better reactivity and lowered rates of carbon deposition. Li et al.16 reported that the incorporation of Fe–Ce mixed oxide can increase the CO selectivity to ca. 85%, which was attributed the strong interaction between reduced iron and cerium oxides. Neal et al.17 fabricated a Fe2O3@La0.8Sr0.2FeO3-δ composite and found that Fe2O3 could be reduced to Fe0/FeO with no coke deposition due to the good ionic-electronic conductivity of the outer perovskite layer. However, although much effort has been made, it was found that traditional modification of iron oxides generally led to relatively limited CO selectivity before coke formation.

From the above studies, we conclude that the performance of Fe-based oxides could be greatly altered by catalyst structure engineering. Perovskite (ABO3) oxides are an important class of functional materials, the structure of which can be significantly modulated by even slight substitution of A or B site cations18. For production of syngas, the single phase LaFeO3 perovskite showed significantly enhanced reactivity toward methane conversion than iron oxides19. However, Fe cations can be reduced only from Fe3+ to Fe2+ in methane atmosphere and further reduction would induce coke deposition20. Comparatively, when the A site of La in LaFeO3 was partially substituted by Sr to mitigate coke formation, the syngas selectivity was reduced due to generation of oxygen vacancies associated with more surface adsorbed oxygen21. These studies suggest a “seesaw” effect for Fe-based perovskite OCs in selective oxidation of methane, between Fe valence variation to supply more lattice oxygen, and its performance (e.g., reactivity, selectivity, and stability).

Here, we report a perovskite oxide with formula La0.6Sr0.4Fe0.8Al0.2O3-δ for selective oxidation of methane to syngas. This perovskite with A and B sites substituted by Sr and Al cations not only reduces the surface active oxygen species for CH4 overoxidation but also facilitates in situ encapsulation of Fe0, originating from deep reduction of Fe4+ with the formation of Fe0@oxides composite. This core–shell structure switches off the pathway for Fe0 to catalyze methane pyrolysis, and also favors reformation of the original perovskite phase either in strong O2 or soft H2O–CO2 oxidant. Consequently, this material exhibits redox stability in the harsh thermochemical process and syngas selectivity of above 95% with H2/CO of 2 and no coke deposition.

Results

Structural characterization

The XRD patterns of as-prepared LaFeO3 and La0.6Sr0.4Fe1-xAlxO3-δ (denoted as LSF6410 and LSAF6428 for x = 0 and 0.2 samples, respectively) oxides indicate that all samples show pure perovskite phase and no impurities such as SrCO3, La2O3, and Al2O3 are detected (Supplementary Fig. 2). Some basic physical parameters of the fresh catalysts are listed in Supplementary Table 1. Figure 1a presents the normalized Fe K-edge XANES spectra of different catalysts at room temperature. It shows that the intensity of white line (W: 1s → 4p transition) at ca. 7130 eV notably decreases when La cations in LaFeO3 were partially substituted by Sr, which is further lowered after doping of Al (i.e., LSAF6428). Correspondingly, the absorption edge gradually shifts to higher energies accompanied with decrease of white line intensity. These results indicate that the average valence state of Fe cations increases after introduction of Sr and Al in LaFeO3 matrix to maintain charge balance22. In other words, Fe4+ cations with higher valence state (Fe3+ in LaFeO3) exist in LSF6410, the content of which is further improved after Al doping for LSAF6428. For the pre-edge feature (P) attributed to 1s → 3d transition, it is generally accepted that the intensity would increase with Fe valence state and stronger mixing between Fe 3d and O 2p states23. A more intense of P for LSF6410 than that for LaFeO3 is observed in Fig. 1, which is in agreement with the higher average valence state of Fe cations in LSF6410. However, further doping of Al results in the slightly lower intensity, which is contrary to increased Fe valence state for LSAF6428 than that for LSF6410. These results suggest that the doping of Al could weaken the admixing of O-p orbital.

The chemical state of Fe was further investigated by 57Fe Mössbauer spectroscopy (Fig. 1b) and the corresponding fitted parameters are listed in Supplementary Table 2. The Mössbauer spectra of LaFeO3 show a typical sextet with IS (isomer shift) = 0.36 mm/s, QS (quadrupole splitting) = 0.00 mm/s, and H (hyperfine field) = 51.7 T, which is characteristic of Fe3+ cations with antiferromagnetic property24. However, only a singlet with wide absorption wings is observed for LSF6410, indicating that the magnetic ordering temperature of this material is around room temperature25. The IS values for both Fe species are fitted to 0.20 mm/s, between that for Fe4+ (∼ 0.0 mm/s) and Fe3+ (∼ 0.36 mm/s), which suggests the existence of Fe3+↔4+ mixed valence state induced by rapid charge hopping at room temperature26. Combining the low temperature (77 K) Mössbauer analysis (Supplementary Fig. 3 and Supplementary Table 2), the average valence of Fe cations was calculated to be 3.36. Further introduction of Al cations leads to totally paramagnetic property of LSAF6428 material with further increase of Fe valence, in which the proportion of Fe4+ and Fe3+ is 49 and 51%, respectively, as shown in Supplementary Table 2. According to the charge balance principle, the amount of oxygen vacancies (δ) is determined to be 0.020 and 0.005 for LSF6410 and LSAF6428, respectively, indicating that partial substitution of Fe by Al can significantly suppress formation of oxygen vacancies in the perovskite matrix.

Figure 1c shows the O1s core-level photoemission spectra. Two strong features could be observed for the three as-prepared catalysts. The peak at lower binding energy (BE) of ca. 528.5 eV is assigned to the lattice oxygen (OL) while the broad shoulder lying in the region of 530.0–533.0 eV is attributed to the surface adsorbed oxygen (OA)27. By deconvoluting this broad peak, three different oxygen species are identified: the one with lowest BE (ca. 529.7 eV) is ascribed to O22−/O−, the one at BE of ca. 531.3 eV is assigned to oxygen in the form of hydroxyl (OH−) and carbonate (CO32−), and the peak with highest BE value (ca. 532.9 eV) is associated with molecular water adsorbed on the surface28,29. It is well accepted that the OA/OL ratio is proportional to the concentration of oxygen vacancies in the catalysts. According to the fitted results, this ratio increases from 1.6 for LaFeO3 to 2.7 for LSF6410, while decreases in turn to 1.7 with further doping of Al. These results further confirmed that doping of Sr would induce formation of oxygen vacancies while introduction of Al shows the opposite effect.

Catalytic performance for the production of syngas

Figure 2 displays the performance of Sr/Al-doped LaFeO3 catalysts in selective conversion of methane to syngas. The CO selectivity over LaFeO3 (Fig. 2a) is 93% with H2/CO ratio (Fig. 2b) slightly higher than 2 in the first cycle, which is similar to the previous reports30. It decreases gradually with further cycle numbers. As for LSF6410 sample, this value is initially lower of 90% and decreases to 85% after 20 cycles. In contrast, the additional dopant of Al could improve the CO selectivity, which reaches ~95% within 20 cycles with a steady H2/CO ratio of 2/1 over LSAF6428. Figure 2c shows the amount of convertible lattice oxygen, an important factor in selective oxidation of methane. LSAF6428 donates the highest amount of ~2.8 mmol O/gcat. in the first cycle, which is much higher than that for LSF6410 (~2.1 mmol O/gcat.) and LaFeO3 (~1.6 mmol O/gcat.). With increasing the cycle numbers, this value slightly changes but still follows the order of LSAF6428 > LSF6410 > LaFeO3, which is in line with conversion of CH4 (Fig. 2d). Clearly, the dopant of both Sr and Al cations plays an important role in improving the performance of this OC in terms of the excellent selectivity to CO and stability.

The catalytic performances of LSAF6428 and the representative oxides reported previously are listed in Table 1. Typically, the NiO-based catalysts exhibit acceptable CO selectivity (~90%) as shown in Entries 4 and 5, but large amount of H2O is required in the feedstock to suppress carbon deposition and overoxidation of methane, leading to H2/CO ratio much higher than 231,32. LaFeO3 exhibits an initial CO selectivity of ~96% under optimized conditions as shown in Entry 8, but the quantity of CO2 increases and the deactivation is observed after only 7 cycles due to sintering of material30,33,34. The recently developed iron-titanium composite oxide (Entry 10) shows steady activity for several hours in the moving bed reactor35. However, a higher temperature of 975–1000 °C is needed to reach the 90% CO selectivity. In contrast, LSAF6428 catalyst presents almost the best CO selectivity with the desired H2/CO ratio of 2 at 900 °C (Entry 1). Even at more cycling numbers of 100, a CO selectivity of 92% still remains without changes for H2/CO ratio, indicating a good stability of this catalyst for long-term syngas production. When decreasing the reaction temperature to 800 °C, it still exhibits a good CO selectivity of 93% and ideal H2/CO ratio as shown in Entry 2. It is evident that LSAF6428 is among the best materials so far for the selective conversion of methane to syngas with an extraordinary stability36,37.

The versatility of OCs using different types of oxidants is another parameter for the potential application. Figure 3 and Entry 3 of Table 1 display the performance results with alternative soft oxidant of CO2–H2O mixture. As seen, the H2/CO ratio still remains a steady value of 2.0 with a CO selectivity of ~95% in the selective oxidation of methane. The CO2 and H2O conversion (Fig. 3b) reach as high as 61 and 64%, respectively, which is even higher than the theoretical carbon dioxide or water splitting efficiency on iron oxides (Supplementary Table 3). More importantly, during the fill of lattice oxygen with H2O and CO2, valuable syngas with H2/CO ratio of ~2 is generated. The above results indicate the good structure reversibility of LSAF6428 with strong or soft oxidant and two sources of syngas can be obtained by changing the oxidant from O2 to CO2 + H2O.

The factors for the high performance of LSAF6428

The above results show that LSAF6428 exhibit good overall performance (activity, selectivity, and stability) for the long-term redox reactions to produce syngas either with strong O2 or soft H2O/CO2 as oxidants. The structure analysis (Supplementary Fig. 4) shows that an impure phase attributed to La2O3 appears for spent LaFeO3, indicating that the single perovskite phase can not be easily regenerated after 20 cycles. In contrast, the Sr/Al-doped materials all maintain the same perovskite structure as the fresh sample, demonstrating the excellent structural stability. The typical SEM images of the spent samples are given in Supplementary Fig. 5. It is clearly noticed that the particle size of LaFeO3 and LSF6410 notably increase after 20 redox cycles. However, negligible changes of particle size and surface area are observed for LSAF6428. The above results suggest that co-doping of Sr and Al in LaFeO3 could improve the structural stability and the sintering resistance during long-term redox reactions.

The reactivity of lattice oxygen in the selective oxidation of CH4 strongly depends on the chemical state of transition metals17. Thus, CH4 pulse reaction was conducted to gain insight into the gradual evolution of the methane-to-syngas performance with extraction of lattice oxygen from LSAF6428 material. As shown in Fig. 4a, methane is mainly converted to CO2 at the very beginning of selective oxidation reaction, leading to low CO selectivity of only 35% (Fig. 4b). However, the subsequent pulse reaction results in CO selectivity up to above 95% (Fig. 4b). It is accepted that two types of oxygen species, i.e., active surface adsorbed oxygen and selective lattice oxygen, co-exist in the OCs38. The first pulse of CH4 consumed almost all of the surface oxygen on LSAF6428, which contributes to the total combustion of methane to CO2 and H2O while the following results in the production of syngas. According to the XANES (Fig. 1a) and 57Fe Mössbauer spectroscopy (Fig. 1b) analysis, doping of Al cations can facilitate the formation of Fe4+ cations and lead to declined oxygen vacancies with notably improved CO selectivity, which may be caused by the strong Al–O interaction39,40. The absolute oxygen vacancy formation energy (Evac) was calculated with the equation Evac = Edefect-surface + 1/2 EO2−Esurface based on the structure of (110) and (012) plane. Two kinds of oxygen vacancy (Supplementary Fig. 6) possibly formed on LSAF6428, i.e., oxygen vacancy neighboring to Fe site (detonated as Fe-Ovac) and oxygen vacancy neighboring to Al site (detonated as Al-Ovac). DFT calculations show that the Evac of Fe-Ovac is 1.72 eV and 0.21 eV lower than the Evac of Al-Ovac on (110) and (012), respectively, indicating that Al cations could benefit the stability of surface oxygen and suppress the formation of oxygen vacancies. Combined with the reaction results (Fig. 2), one can conclude that the reduced oxygen vacancies induced by Al introduction results in decrease of active surface adsorbed oxygen (Fig. 1c). Thus, an initial decline of CH4 conversion is observed from 70% (1st pulse) to 53% (2nd pulse). However, this conversion gradually increases to 85% (25th pulse) afterward, indicating that partial reduction of this perovskite material would contribute to enhanced reactivity. As for the H2/CO ratio, it keeps a constant value of ∼2.0 from 3rd to 25th pulse, suggesting a high lattice oxygen transferring ability from the body of LSAF6428 particle to its surface, which effectively inhibits the coke deposition by methane decomposition19. The above results give a clue that the Fe chemical state evolution induced by extraction of oxygen greatly alters the performance of LSAF6428 material.

The evolution of Fe chemical state with CH4 pulses was tracked by Mössbauer spectroscopy. As seen from Fig. 5a, the doublets of as-prepared LSAF6428 (Fig. 1b) is transformed to overlap of sextets and doublets due to loss of lattice oxygen even after slight reduction by CH4. The fitted parameters (Supplementary Table 4) show that Fe0 species (5%) are already generated after only five CH4 pulses accompanied with the formation of LaSrFe1-xAlxO4 double perovskite oxides. However, the characteristic peaks of Fe0 phase are not identified until 10th pulse from the XRD analysis (Fig. 5b), which may be attributed to its high dispersion or low degree of crystallinity at the initial period of reaction. Combined with the reaction production analysis (Fig. 4), the generation of metallic Fe0 and double perovskite LaSrFe1-xAlxO4, induced by loss of lattice oxygen, would improve the reactivity of the catalyst. With continuous injection of CH4, 39% of Fe cations are reduced to Fe0 after 25th pulses with generation of comparative amount of LaSrFe1-xAlxO4 (39%). Combined with the gas composition analysis (Fig. 4), it was calculated that deep reduction of these Fe cations to Fe0 could supply ca. 2.7 mmol O/gcat. for methane oxidation (Supplementary Fig. 7). As for LSAF6428 reduced in fixed bed reaction (5% CH4/He for 5 min at 900 °C), the ratio of metallic Fe0 phase reaches 44% (Supplementary Fig. 8). Other Fe phases like Fe3O4 and FeO are not detected in all these samples. This result suggests that the LSAF6428 perovskite catalyst is prone to transform into Fe0 and double perovskite phase spontaneously under highly reductive atmosphere (CH4, H2, and CO).

It is well accepted that metallic Fe0 are favorable for cracking of methane to induce coke deposition41, which is another issue that lowers th CO selectivity and leads to increased H2/CO ratio much higher than 2. However, it is surprising that there is no coke deposition on LSAF6428 catalyst despite the fact that the percentage of metallic Fe0 reaches as high as 44%. XPS results in Supplementary Fig. 9 shows that only Fe3+ species are found on the surface of the reduced catalyst. These results imply that the metallic Fe0 might be encapsulated by a layer of oxides. HRTEM characterization was conducted to confirm the local structure of reduced LSAF6428 catalyst. As shown with different magnification images in Fig. 6a and Supplementary Fig. 10, all metallic Fe0 with various sizes are covered by oxide layers. This phenomenon is more clearly illustrated by detecting the environment around a particle with energy dispersive spectroscopy (EDS) mapping. As shown in Fig. 6c–h, the area enriched with Fe species has relatively low concentration of La, Sr, Al, O elements. The quantitative line scan crossing a particle and dot scan at sites in the margin and center of a particle (Supplementary Fig. 11) show that the atomic percentage of Fe (in all metal cations) in the center reaches 65%, much higher than the theoretical 40% in LSAF6428. Meanwhile, the mole ratio of oxygen/metal cations (La–Sr–Fe–Al) obviously decreases from 1.5 to 0.7 (mole ratio of O/Fe in FeO is 1), which further suggest the presence of Fe0 species in the center of a particle. In contrast, the proportion of Al in the margin increases from theoretical 10 to ~15% (Supplementary Fig. 11B). Also, the oxide in the margin exhibits lattice fringes with spacing of 2.76 and 2.81 Å (Fig. 6b), which can be ascribed to the (013), (−110), and (103) planes of LaSrFe1-xAlxO4-δ oxide. All the above results unequivocally indicate that Fe0 is dynamically formed and grows inside the particle with the cover of Al-rich perovskite oxides.

The encapsulation of metals by oxides in reducing atmosphere, known as strong metal–support interactions (SMSI), has already been identified in various systems like Pt/TiO2 and Au/ZnO42,43. As for perovskite oxides, Ramesh et al.44 also found that when La0.5Sr0.5FeO3 target was used to grow films on SrTiO3 substrate in vacuum by pulsed laser deposition method, Fe0 covered by LaSrFeO4 was obtained. The encapsulation of Fe0 by oxide layer of LaSrFe1-xAlxO4-δ may be induced by the highly reductive atmosphere, leading to SMSI state of the reduced catalyst. Under such circumstances, the channels for direct contact between metallic Fe0 and methane are switched off. This layer of LaSrFe1-xAlxO4 oxides works like a membrane45, which exhibits good lattice oxygen conductivity and can continuously devote lattice oxygen for the methane-to-syngas reaction. Thus, almost all Fe4+ cations could be deeply reduced to Fe0 while carbon deposition is avoided and a high CO selectivity is reached with favorable H2/CO ratio of 2. The CH4 pulse reaction (Fig. 4) also shows that the methane conversion is notably improved after the formation of Fe0@LaSrFe1-xAlxO4, indicating that such core–shell intermediate is capable to selectively convert CH4 to syngas more efficiently than LSAF6428. The corresponding XPS analysis (Supplementary Fig. 12A) shows that only Fe3+ cations exist while no Fe0 signals was observed even after 25th pulses. These results indicate that Fe0 species, formed initially at the surface, can be quickly covered by oxide layer containing Fe3+ cations as soon as they emerge. The surface composition analysis (Supplementary Fig. 12B) shows that the OA/OL ratio increases with CH4 pulses, which means that the concentration of oxygen vacancies at the surface rose with the reduction process. Combined the above results, it suggests that undercoordinated iron species may play the main role in methane activation. Besides, it was reported that the oxide shell with double perovskite structure exhibited higher surface oxygen exchange rate and oxygen mobility than pure perovskite oxide46, which also contributes to the increased reactivity. In a word, the in situ encapsulation of metallic Fe0 by oxide layer during methane-to-syngas process can not only improve the CO selectivity by prohibiting carbon deposition but also notably promote the syngas production efficiency.

The durability of OCs with excellent structural reversibility is of great importance for long-term redox reactions. For Fe-based perovskite OCs, the perovskite structure would collapse and transform to oxide composite (e.g., La2O3, FeOx, and LaSrFeO4) due to loss of lattice oxygen17,19. Afterward, the oxygen is replenished in oxidative atmosphere and the perovskite structure is regenerated by solid reaction. When the reduced LSAF6428 is exposed to oxygen atmosphere, it is noticed that the metallic Fe0 can never be detected after oxidation for 0.5 min and the single perovskite structure is completely regenerated after only 2 min (Supplementary Fig. 13), which indicates that regeneration of the perovskite phase in oxygen is much faster than the decomposition rate in methane reduction process (5 min). During the regeneration process, the oxide layer can deliver oxygen to inner Fe0 coupled with the oxidation of Fe0 species in oxidizing atmosphere, while the confined Fe species in the core area of particle re-enter the perovskite lattice. Various studies on the kinetics of solid reaction showed that the fabrication of core–shell structure could accelerate the formation of perovskite, since the contact area of the reactants is normally larger while the ion diffusion distance is decreased47,48. For LaFeO3, La2O3 phase appeared obviously after 20 cycles as shown in Supplementary Fig. 5, which indicates that the reduced composite without core–shell structure can not be easily transformed to original pure perovskite phase. In contrast, the in situ formation of core–shell structure for LSAF6428 in methane atmosphere is helpful for the regeneration of perovskite structure. Actually, the catalyst structure (Supplementary Fig. 14A) could be well recovered even after 100 redox cycles, accompanied by recovery of the Fe valence state (Supplementary Fig. 14B), which shows the outstanding redox stability of LSAF6428 material.

Discussion

Based on the above analysis, the structure evolution of LSAF6428 catalyst during the methane-to-syngas process can be summarized in Fig. 7. At the very beginning of the reaction cycle, methane is mainly converted to CO2 and H2O with rapid consumption of the active surface adsorbed oxygen, leading to low CO selectivity. Soon afterward, the selective lattice oxygen is used for partial oxidation of methane to produce syngas with ideal H2/CO ratio of 2 and the coordination unsaturated Fe cations can improve the conversion of methane. At the same time, the perovskite structure gradually collapsed and transformed to composite of metallic Fe0 species and LaSrFe1-xAlxO4 oxides due to loss of lattice oxygen. The SMSI between Fe0 and LaSrFe1-xAlxO4 could induce the encapsulation of Fe0 by oxide with formation of core–shell structure. Therefore, the contact tunnel for Fe0–CH4 direct contact is switched off, which greatly enhances the methane-to-syngas reactivity, supresses the coke deposition and enables deep reduction of Fe3+/4+ cations to Fe0. Such core–shell intermediate can be easily regenerated to original perovskite phase by either strong oxidant of O2 or soft ones of H2O–CO2, leading to good redox stability of this material. Importantly, when H2O–CO2 was applied for oxidant, another new source of syngas was produced.

In summary, a perovskite-type La0.6Sr0.4Fe0.8Al0.2O3-δ catalyst has been developed for the selective oxidation of CH4 to syngas using the lattice oxygen. This catalyst exhibits a good stability with CO selectivity of around 95% and syngas production with H2/CO ratio of 2/1. A reversible transformation between homogeneous perovskite and oxides-encapsulated Fe0 structures is identified during the reaction. Doping with Al greatly reduces the concentration of oxygen vacancies, which lowers the amount of active surface adsorbed oxygen. With these structure engineering processes, methane total combustion is suppressed and deep reduction of Fe cations from Fe4+ to Fe0 occurs without coke deposition, leading to better lattice oxygen donating ability, high CO selectivity, and stability of syngas production with ideal H2/CO ratio during long-term reaction process. On the other hand, this catalyst provides another source of syngas product when using CO2 + H2O alternative to O2 for recovery of the original structure. This perovskite material may be a promising catalyst system for practical application in solar-driven thermochemical process for syngas production by selective conversion of methane and H2O/CO2 or other processes to avoid the carbon deposition.

Methods

Catalyst preparation

To prepare La0.6Sr0.4Fe1-xAlxO3-δ (x = 0 and 0.2) catalysts, stoichiometric La(NO3)3∙6H2O, Sr(NO3)2, Fe(NO3)3∙9H2O, and Al(NO3)3∙9H2O were dissolved in deionized water under vigorous stirring to obtain a clear solution. Subsequently, citric acid (total metal ions/citric acid molar ratio = 1/2.5) was introduced to the solution, and the pH was adjusted to around 7 by dropwise adding of ammonia solution. The solution was concentrated to viscous gel at 80 °C. The gel was dried at 150 °C overnight, and then preheated to 450 °C for 4 h in air to remove organic species. After an intermediate grinding, the powders were further calcined at 1200 °C for 4 h in air to obtain the final La0.6Sr0.4Fe1-xAlxO3-δ catalysts. For comparison, LaFeO3 catalyst was prepared following the same procedure. The difference is that the final LaFeO3 material was obtained by calcination in air at 900 °C for 4 h to make its surface area comparable with that of LSAF6428 catalyst.

Characterization

The X-ray diffraction (XRD) patterns were recorded on a PANalytical X′Pert-Pro powder X-ray diffractometer (U = 40 KV, I = 40 mA) using Cu Kα radiation. The lattice parameters of the catalysts were calculated based on all diffraction peaks. Brunauer–Emmett–Teller (BET) surface area of fresh catalysts was determined by nitrogen adsorption at −196 °C using a Quadrasorb SI instrument. The BET surface area of spent catalysts at 900 °C (reduction in 5% CH4/He and reoxidation in 5% O2/He) was measured by krypton adsorption at −196 °C using a TriStar 3020 instrument. XPS experiment was conducted on an ESCALAB 250 instrument equipped with a monochromatic Al Kα source. The BE was calibrated using the adventitious carbon (C1s peak at 284.6 eV). The test of catalyst was quasi in situ conducted according to the following processes: first, it was first pretreated in CH4 atmosphere at 900 °C and then cooled to room temperature in He atmosphere; after that the catalyst was moved to glovebox and ground to dense sheet, which was then transferred to the ESCALAB 250 instrument. Scanning electron microscopy (SEM) experiments were performed with a JEOL JSM-7800F electron microscope. The element distribution (line scan) was analyzed by transmission electron microscopy (TEM, JEOL JEM-2100F) equipped with energy dispersive X-ray spectroscopy (EDS) instrument. To gain insight into the internal structure of the reduced sample, the catalyst was further diced into thin films with the thickness of 50–100 nm. Before the cutting process, the catalyst particles were protected by a layer of epoxy to prevent from altering the morphology of the thin films before it was observed by TEM. 57Fe Mössbauer spectra were collected at room temperature using 57Co γ-quantum source in the Rh matrix and the IS value was set with respect to that of α-Fe at room temperature. All spectra were computer-fitted by Lorentzian curves with a least squares fitting procedure.

The XAFS spectra at Fe K-edge of the catalysts were measured on beam line BL14W of the Shanghai Synchrotron Radiation Facility (China). A Si (111) double crystal monochromator was used and the energy was scanned from 200 eV below to 800 eV above the Fe K-edge (7112 eV). All spectra were measured in the transmission mode at room temperature.

Performance tests

The reaction of solar-driven partial oxidation of CH4 was simulated in a quartz fixed-bed micro reactor packed with 100 mg (75–180 μm) catalyst at atmospheric pressure. In a typical experiment, the temperature was gradually increased to 900 °C in the flowing 5% O2/He atmosphere. After purged by He for 5 min, the selective oxidation of methane was started by injecting 5% CH4/He for 5 min. The lattice oxygen of the reduced catalysts was replenished by oxidation in 5% O2/He for 4 min. Between the oxidation and reduction process, the reactor was flushed with He to prevent mixing of CH4 and O2. The total flow in the reactor was fixed to 30 mL/min. Twenty continuous cycles were performed for each sample, if not particularly stated. For LSAF6428 catalyst, the cycling stability was evaluated by 100 cycles. For experiment at 800 °C, the reduction time was prolonged to 7.5 min due to the relatively slow reaction rate while other conditions remain unchanged. To generate more syngas with H2/CO ratio of 2, a mixture of 2.5% CO2 and 5% H2O balanced by He was used as oxidant alternative to O2 while the oxidation time was adjusted to 3.5 min.

The reaction products were analyzed with an IPI GAM 200 quadrupole mass spectrometer system. The MS signals were calibrated before each experiment by using a calibration gas with known composition. The amount of all products (CO, CO2, and H2) and unreacted methane were calculated by integrating the MS signals of each species. The coke formation is calculated according to amount of CO and CO2 produced during regeneration of the catalyst in oxygen atmosphere. The consumed methane and generated water in the reduction period were calculated from mass balance of C and H, respectively. The CO selectivity (SCO), converted lattice oxygen per gram catalyst (OL), and methane conversion (\({{C}}_{{\mathrm{CH}}_4}\)) in each cycle were calculated as follows:

\(n_{{\mathrm{CO}}}\), \(n_{{\mathrm{CO}}_2}\), \(n_{{\mathrm{coke}}}\), \(n_{{\mathrm{H}}_2{\mathrm{O}}}\) and \(n_{{\mathrm{CH}}_4 - {\mathrm{U}}}\) represent the amount of CO, CO2, coke, H2O, and unreacted CH4, respectively.

The CH4 pulse experiment was conducted on the Micromeritics Autochem 2920 apparatus. In a typical experiment, 200 mg catalyst loaded in a U-shape quartz tube. The catalyst was pre-heated to 900 °C in flowing air (20 mL/min), then the gas was changed to pure He (30 mL/min) to purge the air. Subsequently, pulses of 90% CH4/Ar were injected to the reactor with 1 min interval between two pulses. The tail gas was analyzed using an online mass spectrometer system.

Computational details

Density functional theory calculations were performed with the Vienna Ab Initio Simulation Package. The exchange correlation was treated by the Perdew–Burke–Ernzerh generalized gradient approximation with spin-polarized functional. The projector-augmented wave method was used to describe the electron–core interaction, and the kinetic energy cutoff was set to be 450 eV. The DFT + U calculations were used to treat the on-site Coulomb and exchange interaction of the Fe d electrons with an effective U = 4.0 eV. The La0.6Sr0.4Fe0.8Al0.2O3 (012) was modeled by ten atomic layers and the bottom-three layers were fixed, with a 15 Å vacuum between the slabs.

Data availability

All data needed to evaluate the conclusions of this study are present in this article and the Supplementary Materials. Additional data related to this paper may be requested from the corresponding author.

References

Kodama, T. & Gokon, N. Thermochemical cycles for high-temperature solar hydrogen production. Chem. Rev. 107, 4048–4077 (2007).

Diver, R. B., Miller, J. E., Allendorf, M. D., Siegel, N. P. & Hogan, R. E. Solar thermochemical water-splitting ferrite-cycle heat engines. J. Sol. Energy Eng. 130, 041001–041008 (2008).

Lin, F., Rothensteiner, M., Alxneit, I., van Bokhoven, J. A. & Wokaun, A. First demonstration of direct hydrocarbon fuel production from water and carbon dioxide by solar-driven thermochemical cycles using rhodium–ceria. Energy Environ. Sci. 9, 2400–2409 (2016).

McDaniel, A. H. et al. Sr- and Mn-doped LaAlO3-delta for solar thermochemical H2 and CO production. Energy Environ. Sci. 6, 2424–2428 (2013).

Marxer, D., Furler, P., Takacs, M. & Steinfeld, A. Solar thermochemical splitting of CO2 into separate streams of CO and O2 with high selectivity, stability, conversion, and efficiency. Energy Environ. Sci. 10, 1142–1149 (2017).

Palumbo, A. W., Sorli, J. C. & Weimer, A. W. High temperature thermochemical processing of biomass and methane for high conversion and selectivity to H2-enriched syngas. Appl. Energy 157, 13–24 (2015).

Kodama, T., Shimizu, T., Satoh, T., Nakata, M. & Shimizu, K.-I. Stepwise production of CO-rich syngas and hydrogen via solar methane reforming by using a Ni (II)–ferrite redox system. Sol. Energy 73, 363–374 (2002).

Steinfeld, A., Frei, A., Kuhn, P. & Wuillemin, D. Solar thermal production of zinc and syngas via combined ZnO-reduction and CH4-reforming processes. Int. J. Hydrog. Energy 20, 793–804 (1995).

Krenzke, P. T. & Davidson, J. H. Thermodynamic analysis of syngas production via the solar thermochemical cerium oxide redox cycle with methane-driven reduction. Energy Fuels 28, 4088–4095 (2014).

Choudhary, T. V. & Choudhary, V. R. Energy-efficient syngas production through catalytic oxy-methane reforming reactions. Angew. Chem. Int. Ed. 47, 1828–1847 (2008).

Scheffe, J. R. & Steinfeld, A. Oxygen exchange materials for solar thermochemical splitting of H2O and CO2: a review. Mater. Today 17, 341–348 (2014).

Arifin, D., Aston, V. J., Liang, X., McDaniel, A. H. & Weimer, A. W. CoFe2O4 on a porous Al2O3 nanostructure for solar thermochemical CO2 splitting. Energy Environ. Sci. 5, 9438–9443 (2012).

Steinfeld, A., Kuhn, P. & Karni, J. High-temperature solar thermochemistry: production of iron and synthesis gas by Fe3O4-reduction with methane. Energy 18, 239–249 (1993).

Go, K. S., Son, S. R., Kim, S. D., Kang, K. S. & Park, C. S. Hydrogen production from two-step steam methane reforming in a fluidized bed reactor. Int. J. Hydrog. Energy 34, 1301–1309 (2009).

Imtiaz, Q. et al. Development of MgAl2O4-stabilized, Cu-doped, Fe2O3-based oxygen carriers for thermochemical water-splitting. J. Mater. Chem. A 4, 113–123 (2016).

Li, K., Wang, H., Wei, Y. & Yan, D. Syngas production from methane and air via a redox process using Ce–Fe mixed oxides as oxygen carriers. Appl. Catal. B 97, 361–372 (2010).

Neal, L. M., Shafiefarhood, A. & Li, F. Dynamic methane partial oxidation using a Fe2O3@La0.8Sr0.2FeO3-δ core–shell redox catalyst in the absence of gaseous oxygen. ACS Catal. 4, 3560–3569 (2014).

Pena, M. A. & Fierro, J. L. G. Chemical structures and performance of perovskite oxides. Chem. Rev. 101, 1981–2017 (2001).

Mihai, O., Chen, D. & Holmen, A. Chemical looping methane partial oxidation: the effect of the crystal size and O content of LaFeO3. J. Catal. 293, 175–185 (2012).

Mihai, O., Chen, D. & Holmen, A. Catalytic consequence of oxygen of lanthanum ferrite perovskite in chemical looping reforming of methane. Ind. Eng. Chem. Res. 50, 2613–2621 (2011).

Ryden, M. et al. Novel oxygen-carrier materials for chemical-looping combustion and chemical-looping reforming; LaxSr1-xFeyCo1-yO3-δ perovskites and mixed-metal oxides of NiO, Fe2O3 and Mn3O4. Int. J. Greenh. Gas Control 2, 21–36 (2008).

Haas, O. et al. The Fe K-edge X-ray absorption characteristics of La1−xSrxFeO3−δ prepared by solid state reaction. Mater. Res. Bull. 44, 1397–1404 (2009).

Blasco, J. et al. Charge disproportionation in La1− xSrxFeO3 probed by diffraction and spectroscopic experiments. Phys. Rev. B Condens. Matter 77, 054107 (2008).

Hu, R. et al. Photocatalytic activities of LaFeO3 and La3FeTiO6 in p-chlorophenol degradation under visible light. Catal. Commun. 29, 35–39 (2012).

Yang, J. et al. Crystal structure, magnetic properties, and Mössbauer studies of La0.6Sr0.4FeO3− δ prepared by quenching in different atmospheres. Phys. Rev. B Condens. Matter 66, 184415 (2002).

Shimony, U. & Knudsen, J. M. Mössbauer studies on iron in the perovskites La1−xSrxFeO3 (0≤x≤1). Biophys. Rev. 144, 361–366 (1966).

Rida, K., Benabbas, A., Bouremmad, F., Peña, M. A. & Martínez-Arias, A. Surface properties and catalytic performance of La1−xSrxCrO3 perovskite-type oxides for CO and C3H6 combustion. Catal. Commun. 7, 963–968 (2006).

Ponce, S., Peña, M. A. & Fierro, J. L. G. Surface properties and catalytic performance in methane combustion of Sr-substituted lanthanum manganites. Appl. Catal. B 24, 193–205 (2000).

Wang, Y. et al. Nanocasted synthesis of mesoporous LaCoO3 perovskite with extremely high surface area and excellent activity in methane combustion. J. Phys. Chem. C 112, 15293–15298 (2008).

Dai, X. P., Wu, Q., Li, R. J., Yu, C. C. & Hao, Z. P. Hydrogen production from a combination of the water−gas shift and redox cycle process of methane partial oxidation via lattice oxygen over LaFeO3 perovskite catalyst. J. Phys. Chem. B 110, 25856–25862 (2006).

Zafar, Q., Mattisson, T. & Gevert, B. Integrated hydrogen and power production with CO2 capture using chemical-looping reforming redox reactivity of particles of CuO, Mn2O3, NiO, and Fe2O3 using SiO2 as a support. Ind. Eng. Chem. Res. 44, 3485–3496 (2005).

Ryden, M., Johansson, M., Lyngfelt, A. & Mattisson, T. NiO supported on Mg-ZrO2 as oxygen carrier for chemical-looping combustion and chemical-looping reforming. Energy Environ. Sci. 2, 970–981 (2009).

Nakayama, O., Ikenaga, N.-o, Miyake, T., Yagasaki, E. & Suzuki, T. Partial oxidation of CH4 with air to produce pure hydrogen and syngas. Catal. Today 138, 141–146 (2008).

He, F., Trainham, J., Parsons, G., Newman, J. S. & Li, F. A hybrid solar-redox scheme for liquid fuel and hydrogen coproduction. Energy Environ. Sci. 7, 2033–2042 (2014).

Luo, S. et al. Shale gas-to-syngas chemical looping process for stable shale gas conversion to high purity syngas with a H2:CO ratio of 2:1. Energy Environ. Sci. 7, 4104–4117 (2014).

Pralhad, H. V., Feng, H., Amit, M. & Fanxing, L. Iron‐doped BaMnO3 for hybrid water splitting and syngas generation. ChemSusChem 10, 3402–3408 (2017).

Zhang, J., Haribal, V. & Li, F. Perovskite nanocomposites as effective CO2-splitting agents in a cyclic redox scheme. Sci. Adv. 3, e1701184 (2017).

He, F. et al. The use of La1−xSrxFeO3 perovskite-type oxides as oxygen carriers in chemical-looping reforming of methane. Fuel 108, 465–473 (2013).

Huang, C. et al. Sn promoted BaFeO3−δ catalysts for N2O decomposition: optimization of Fe active centers. J. Catal. 347, 9–20 (2017).

Tsvetkov, N., Lu, Q., Sun, L., Crumlin, E. J. & Yildiz, B. Improved chemical and electrochemical stability of perovskite oxides with less reducible cations at the surface. Nat. Mater. 15, 1010–1016 (2016).

Christian Enger, B., Lødeng, R. & Holmen, A. A review of catalytic partial oxidation of methane to synthesis gas with emphasis on reaction mechanisms over transition metal catalysts. Appl. Catal. A 346, 1–27 (2008).

Tauster, S., Fung, S. & Garten, R. L. Strong metal-support interactions. Group 8 noble metals supported on titanium dioxide. J. Am. Chem. Soc. 100, 170–175 (1978).

Liu, X. et al. Strong metal–support interactions between gold nanoparticles and ZnO nanorods in CO oxidation. J. Am. Chem. Soc. 134, 10251–10258 (2012).

Mohaddes-Ardabili, L. et al. Self-assembled single-crystal ferromagnetic iron nanowires formed by decomposition. Nat. Mater. 3, 533–538 (2004).

Li, W., Zhu, X., Chen, S., Yang, W. Integration of nine steps into one membrane reactor to produce synthesis gases for ammonia and liquid fuel. Angew. Chem. Int. Ed. 55, 8566–8570 (2016).

Ivanov, D. V. et al. Effect of surface decoration with LaSrFeO4 on oxygen mobility and catalytic activity of La0.4Sr0.6FeO3−δ in high-temperature N2O decomposition, methane combustion and ammonia oxidation. Appl. Catal. A 457, 42–51 (2013).

Huang, C. et al. Preparation of BaSnO3 and Ba0.96La0.04SnO3 by reactive core-shell precursor: formation process, CO sensitivity, electronic and optical properties analysis. RSC Adv. 6, 25379–25387 (2016).

Buscaglia, M. T., Buscaglia, V. & Alessio, R. Coating of BaCO3 crystals with TiO2: versatile approach to the synthesis of BaTiO3 tetragonal nanoparticles. Chem. Mater. 19, 711–718 (2007).

Acknowledgements

This work was supported by National Key Projects for Fundamental Research and Development of China (2016YFA0202801) and National Natural Science Foundation of China (21706254, 21676269, 21576251, 21406225, 91645023, 21603170). The authors thank Yang Su and Yujing Ren for fruitful discussions and support on TEM experiments. The calculations were performed by using the HPC Platform at National Supercomputing Center in Shenzhen.

Author information

Authors and Affiliations

Contributions

C.D.H. performed the catalyst preparation, characterizations, catalytic tests, and paper writing. J.L. and X.D.W. conceived the research and co-wrote this manuscript. J.W. helped the catalyst preparation and characterizations. Y.T.C. and C.R.C. conducted DFT calculations and wrote part of the paper (calculation). M.T. and A.Q.W. helped to discuss the performance results. A.I.R. and J.H.W. helped to analyze the 57Fe Mössbauer results. B.L.H. performed the thermodynamic analysis. X.L.P. conducted the STEM examinations and helped the result analysis. All authors contributed to the critical discussions of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, C., Wu, J., Chen, YT. et al. In situ encapsulation of iron(0) for solar thermochemical syngas production over iron-based perovskite material. Commun Chem 1, 55 (2018). https://doi.org/10.1038/s42004-018-0050-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-018-0050-y

This article is cited by

-

Chemical looping reforming: process fundamentals and oxygen carriers

Discover Chemical Engineering (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.