Abstract

The partial oxidation of methane is a promising method for the efficient production of syngas. To implement this process using common stainless steel reactors, an inexpensive catalyst that functions at 650 °C or below is necessary. However, base metal catalysts typically require much higher temperatures, and they are deactivated by re-oxidation and coke formation. Here we report that modification of a zeolite-supported 3 wt% cobalt catalyst with a trace amount of mono-atomically dispersed rhodium (0.005 wt%) dramatically improves catalytic performance and durability. Cobalt/mordenite is nearly inactive due to the oxidation of cobalt, but the catalyst modified with rhodium continuously gives 85–86% methane conversion and 90–91% CO selectivity with an H2/CO ratio of 2.0 without serious coking at 650 °C. During the reaction, mono-atomically dispersed rhodium converts cobalt oxide to Co0 active species via hydrogen spillover. Use of the zeolite support is key to the high catalytic performance.

Similar content being viewed by others

Introduction

The conversion of methane to liquid fuels and chemicals by heterogeneous catalysis has attracted increased interest since the shale gas revolution, due to the enhanced availability of methane and increasing global demands of power sources1,2,3,4. Methane-derived chemicals such as hydrocarbons and methanol are manufactured via syngas, a mixture of CO and H2. The economical synthesis of higher alcohols from syngas to produce polymers, pharmaceuticals, and energy carriers is also a hot topic5. Accordingly, the efficiency of syngas production is a critical factor to determine the economics of methane utilisation. Syngas is produced by the catalytic conversion of methane with H2O, CO2, or O2, where the reaction becomes exothermic only when O2 is involved6. The partial oxidation of methane (POM) with O2 to syngas allows the use of compact facilities in industry due to the favourable thermodynamic properties and because a water vapour supply is unnecessary. This is in contrast to the steam-reforming of methane that requires a very large-scale process to be economical7.

Catalysts for POM to syngas can be classified into two types: noble metals and base metals. Noble metal catalysts such as Rh and Pt show higher catalytic activities and work at lower temperatures, compared to base metal catalysts8,9,10,11,12, but noble metals are more costly. On the other hand, while base metals are inexpensive, they require pre-reduction, and high reaction temperatures above 800 °C (for the actual temperature of the catalyst bed) to achieve high selectivity. This high temperature exceeds the range in which common industrial stainless steel reactors can be used, specifically 650 °C or lower. Moreover, base metal catalysts are often deactivated by severe coking and re-oxidation during the reaction13,14,15. Thus, these issues with base metals often result in a high long-term cost.

A combination of base metals and noble metals is one solution to overcome these obstacles. The addition of noble metals facilitates the reduction of base metals and inhibits their re-oxidation. Rh is particularly effective for this purpose16,17,18. The amount of Rh on catalysts reported so far is typically more than 0.3 wt%. Although a catalyst of 0.005 wt% Rh–3.0 wt% NiOx/Al2O3 showed higher activity and selectivity than monometallic Rh or Ni catalysts, it still required a temperature of 800 °C to maintain its activity19. The catalyst was deactivated at lower temperatures, perhaps by re-oxidation due to the stabilisation of the oxide phase as NiAl2O420. Accordingly, it is a challenge to develop a base metal catalyst containing only a trace amount of noble metals for low-temperature POM.

In this work, we prepare highly dispersed Co particles (1.5 nm) modified with 0.005 wt% Rh on a mordenite (MOR) zeolite. The catalyst converts methane to syngas with up to 91% selectivity and 86% conversion at 650 °C with good durability. Mechanistically, mono-atomically dispersed Rh on Co particles maintains the Co0 state via hydrogen spillover during POM. The small Co0 particles (1.5 nm) not only provide high activity but also inhibit the formation of coke. The use of zeolite as a support is the key for good reducibility and high dispersion of Co. Other supports tested cannot achieve these features.

Results

Characterisation of catalysts

We prepared 3 wt% Co/MOR, 0.005 wt% Rh/MOR, and 0.005 wt% Rh–3 wt% Co/MOR, denoted Rh–Co/MOR, by simple impregnation methods. The loading amount of Rh was optimised as 0.005 wt% (Supplementary Fig. 1). MOR was chosen as a typical zeolite in this study since MOR, beta, and ZSM-5 zeolites showed similar catalytic activities in a screening test (Supplementary Fig. 2). The zeolite framework structures were confirmed by physicochemical techniques. In the X-ray diffraction (XRD) analysis, all the samples exhibited only characteristic diffraction lines of MOR (Supplementary Fig. 3). The intensity and width of the peaks were similar before and after the impregnation of metal species. Diffraction peaks for Rh or Co species were not detected due to the low content of Rh (0.005 wt%), high dispersion, or amorphous nature. N2 adsorption/desorption isotherms of pristine MOR and the catalysts (Supplementary Fig. 4) were all of the type I form, characteristic of microporous materials. The Brunauer–Emmet–Teller (BET)-specific surface area of original MOR was 520 m2 g−1, and the value decreased slightly after loading of Rh and Co (490–500 m2 g−1; Supplementary Table 1). MOR and the prepared catalysts had similar micropore volumes (0.18–0.19 cm3 g−1). These results indicate no collapse or blockage of the MOR micropores.

High-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) was employed to determine the particle size of the Co and Rh species. Bright dots were observed for Rh–Co/MOR (Fig. 1a) with a mean particle diameter of 1.5 nm (Fig. 1d). Energy dispersive X-ray (EDX) analysis at the bright dots showed strong signals of Co Kα (6.92 keV) and Lα (0.776 keV), but no signal of Rh (Supplementary Fig. 5), indicating that the particles predominantly consisted of Co. Furthermore, the dark spots gave only O, Al, and Si peaks ascribed to the MOR support (Supplementary Fig. 6). Rh species could not be detected due to their low concentration (0.005 wt%). Co/MOR had particles of Co species with an average diameter of 1.5 nm (Fig. 1b, e; EDX Supplementary Fig. 7), which was similar to that of Rh–Co/MOR. Thus, the co-impregnation of 0.005 wt% Rh did not change the dispersion of Co.

The oxidation state of the Co species on Rh–Co/MOR and Co/MOR was determined by Co 2p X-ray photoelectron spectroscopy (XPS; Fig. 2). Both samples exhibited four peaks assigned to Co 2p3/2, 2p1/2, and their satellite peaks. The presence of strong satellite peaks is evidence for high-spin Co2+ species. The position of Co 2p3/2 (782 eV) and ΔE to its satellite peak (5.3 eV) are similar to those of Co(OH)2 or CoO supported on oxides21,22,23. Further analysis by Co K-edge X-ray absorption fine structure (XAFS) confirmed the presence of Co2+ and the coordination of O to Co (Supplementary Fig. 8 and Supplementary Table 2). The particles containing the Co2+ species are hereafter referred to as Co oxide particles. Comparing the XPS spectra for Co/MOR and Rh–Co/MOR, we found no influence of Rh on the peak positions due to the low loading of Rh (0.005 wt%). Note that Rh is undetectable by XPS for the same reason.

We studied the effect of the trace amount of Rh on the reduction of Co oxide by temperature-programmed desorption (TPR; Fig. 3). Original MOR and Rh/MOR exhibited no H2 consumption peaks over the temperature range of 100–870 °C. The lack of a visible reduction peak for Rh/MOR was due to the low loading of Rh (0.005 wt%). Co/MOR showed two main peaks at around 320 and 780 °C. The former peak is assigned to the reduction of typical Co oxide24,25. The latter peak is attributed to Co oxide species directly interacting with MOR, such as Co atoms at the boundary with the support in Co oxide particles24. The temperature of the two peaks decreased by 50–100 °C by adding Rh. Hence, Rh assists in the reduction of Co oxide, which implies that Rh interacts with Co.

The TPR study motivated us to investigate whether Rh and Co species were present in close proximity or in isolation. Because of the very low concentration of Rh (0.005 wt%) and large excess of Co (3.0 wt%), fluorescence XAFS of Rh is the most promising source to obtain such information. Thus, we analysed Rh K-edge X-ray absorption near-edge structure spectra of two samples, pristine Rh–Co/MOR and Rh–Co/MOR reduced by H2 without exposure to air, to reproduce the chemical state of the catalyst under POM (see below). The pristine Rh–Co/MOR gave an edge energy of 23,224 eV, similar to that of Rh2O3 (Fig. 4). The edge was shifted to 23,219 eV after the reduction, which was similar or slightly lower than that of Rh foil and reduced Rh/MOR (23,220 eV) (enlarged image: Supplementary Fig. 9). The negative shift is attributed to charge transfer from Co to Rh, as Rh has a higher electronegativity (χPRh = 2.28) than Co (χPCo = 1.88).

To clarify the coordination condition of the Rh atoms, we analysed extended X-ray absorption fine structure (EXAFS) spectra of pristine and reduced Rh–Co/MOR. After Fourier transformation of the EXAFS oscillations (Supplementary Fig. 10), pristine Rh–Co/MOR gave two peaks at 1.6 and 2.4 Å as non-corrected distances (Fig. 5). The former peak is assigned to the Rh–O shell, but the latter is different from the Rh–Rh shell for Rh2O3. The curve-fitting analysis was successful when a Rh–Co shell was hypothesised for the latter peak, which indicated the presence of 6.4 O atoms at 2.03 Å and 3.4 Co atoms at 2.87 Å (Table 1). Rh–Rh and Rh–Co shells could be distinguished by the clear difference in backscattering amplitude and phase shift. Accordingly, trivalent Rh atoms are located on/in cobalt oxide particles. After the reduction, Rh–Co/MOR exhibited a peak at 2.2 Å as a non-corrected distance in the Fourier transform (Fig. 5), which was also different from that of Rh foil (2.5 Å). This is not due to the presence of the MOR support because reduced Rh/MOR had a peak at 2.5 Å. Assuming a Rh–Co shell, curve-fitting analysis of the EXAFS oscillation for Rh–Co/MOR gave a coordination number of 5.6 and an interatomic distance of 2.52 Å with high consistency (R factor = 0.8%). The low coordination number of Co and absence of a Rh–Rh shell indicate that Rh atoms are mono-atomically dispersed on the surface of Co metal nanoparticles (Supplementary Fig. 11). If Rh atoms were present in the bulk phase of Co metal particles, the coordination number would theoretically be 12, which is not the case.

POM reaction

The effect of co-impregnation of Rh and Co was evaluated in POM at 600 °C, space velocity (SV) of 60,000 mL h−1 g−1, and CH4/O2 ratio of 12.5 (Table 2). Definition of conversion, yield, and selectivity is available in Supplementary Note 1. Original MOR gave only 0.6% conversion of methane and 0.01% yield of CO (entry 1), showing no contamination of active species. Rh–Co/MOR gave the highest conversion of methane (15%) among the catalysts tested (entry 2). The reaction produced CO in 14% yield with 90% selectivity and CO2 in 1.5% yield. Coke formation on the catalyst was 0.1 wt% after 18 h (Supplementary Table 3), corresponding to 0.0004% yield. Single component catalysts, Rh/MOR and Co/MOR, were significantly less active than Rh–Co/MOR under the same reaction conditions (entries 3 and 4). A physical mixture of Rh/MOR and Co/MOR containing the same amounts of Rh and Co as those in Rh–Co/MOR gave 9.7% conversion and 58% selectivity for CO (entry 5), clearly less active and less selective than Rh–Co/MOR. Accordingly, Rh and Co must be present in close proximity for high catalytic performance.

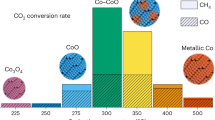

The influence of the support was studied by using SiO2–Al2O3, SiO2, and Al2O3. Their characterisation data are shown in Supplementary Figs. 12–17. The three Rh–Co catalysts achieved 8–10% conversion of methane and CO selectivity of ca. 60% (Table 2, entries 6–8), significantly lower than those by Rh–Co/MOR (15% conversion, 90% selectivity, entry 2). SiO2–Al2O3 and SiO2 produced large particles of Co3O4 (12–13 nm), which led to rapid deactivation by serious coking in POM. For example, Rh–Co/SiO2 produced 2.7 wt% of coke on the catalyst within 2 h. It is known that Co particles of 10–30 nm are active for methane decomposition to C and H226. Additionally, Co species on Rh–Co/Al2O3 were barely reducible (no reduction peak at low temperature in TPR; Supplementary Fig. 17) as reported previously20,27, thus showing low activity in POM. It is notable that Rh–Co/Al2O3 had highly dispersed Co species (TEM; Supplementary Fig. 16) and produced only a small amount of coke (0.12 wt% after 18 h), which is similar to Rh–Co/MOR. Accordingly, metallic Co is active for POM, and high dispersion is crucial to inhibit coke formation.

We carried out the pre-reduction of catalysts with H2 at 700 °C in order to elucidate the effect of the oxidation state of Co on POM (Fig. 6). Rh–Co/MOR gave almost the same catalytic performance after the pre-treatment. In contrast, the pre-reduction of Co/MOR drastically increased CO selectivity to 91%, although the conversion of methane was only 7.6%, perhaps owing to consumption of some O2 for the re-oxidation of Co metal. The CO selectivity decreased to 2.5% within 10 min, which was similar to that for the non-reduced catalyst (2.5%). Accordingly, Co0 is the active species, but it is readily re-oxidised in the absence of Rh under the reaction conditions. Similar deactivation was observed for the physical mixture of Rh/MOR and Co/MOR (Rh/MOR + Co/MOR in Fig. 6). Only Rh–Co/MOR possessed similar activity before and after the reduction. The Co 2p XPS measurement indicated Co0 as the predominant species for spent Rh–Co/MOR (Fig. 2c), which was in contrast to the spent Co/MOR bearing only Co2+ (Supplementary Fig. 18). Hence, Rh–Co/MOR readily produces and preserves metallic Co in the POM reaction.

Effect of reduction of catalysts on the partial oxidation of methane. Conditions: 600 °C, CH4/O2/He = 50/4/46, space velocity (SV) = 60,000 mL h−1 g−1. Reduction was performed under H2 flow at 700 °C. (initial) indicates the initial activity after reduction; (steady) shows the activity after reaching steady state. Star symbols show the selectivity for CO in the reaction, and lines connecting the symbols guide changes in the selectivity

It is intriguing that Co0 is formed and preserved in the metallic state by a trace amount of Rh on Rh–Co/MOR in POM. EXAFS and XPS analyses indicate that Rh3+ exists within Co oxide particles before the reaction starts. At the beginning of the reaction, zero-valent Rh is produced by the consumption of a stoichiometric amount of methane12. The reduced Rh catalyses POM to syngas in small quantities (Table 2, entry 3) and liberates atomic H species either by the dissociation of H2 formed in POM or from intermediates of POM28. The H species can be used for the reduction of Co oxide species. However, most Co oxide particles do not contain any Rh atoms. The average number of Rh atoms per Co particle is only 0.11 (Rh:Co atomic ratio = 1:1050, one particle contains ca. 120 Co atoms). To explain this, we propose that atomic H species spill over onto the MOR support and reduce neighbouring Co oxide particles to Co metal (Fig. 7). Choi and co-workers29,30 demonstrated this hydrogen spillover on an aluminosilicate zeolite, A, in the presence of Pt. The spillover was enhanced by surface Brønsted acid sites, and even a physical mixture of Pt/HA and Al-rich oxide allowed the interparticle hydrogen spillover onto Al-rich oxide to be used for hydrogenation reactions. These results indicate a high mobility of spillover H species on proton-type zeolite. In our case, many Co particles are present within a distance of 2–3 nm to each other on one proton-type MOR particle (Fig. 1a). Thus, it is plausible that the spillover H reduces Co oxide to Co0 and then maintains its zero-valent state during the reaction. This idea is supported by the TPR experiments that showed a decrease in the reduction temperature of Co when a trace amount of Rh was present (Fig. 3).

Conceptual diagram of the proposed reduction of Co oxide by spillover H. Initially, mono-atomically dispersed Rh catalyses the partial oxidation of methane (POM) to syngas in small quantities. Rh liberates atomic H species either by the dissociation of H2 formed in POM or from intermediates of POM. The H species spill over onto the catalyst support and reduce neighbouring Co oxide particles to Co metal

The long-term stability of catalysts is crucial for the POM reaction. Therefore, a durability test of Rh–Co/MOR was performed at a temperature of 650 °C, CH4/O2 ratio of 2, and SV of 1,200,000 mL h−1 g−1. The Rh–Co/MOR catalyst steadily provided 85–86% methane conversion and 90–91% CO selectivity over 50 h (Fig. 8). The ratio of H2/CO was 2.0 in the product, which is the stoichiometric ratio for methanol production and FT synthesis. The produced amount of CO divided by the number of total Co atoms was 120,000 and that of Rh atoms reached 130,000,000, indicating very high productivity. It is noteworthy that neither a structural change of the support nor aggregation of the metal species were observed by XRD (Supplementary Fig. 19) or STEM (Fig. 1c) after the 50 h reaction.

Discussion

The main features of this work are as follows: trace Rh-decorated Co particles with an average diameter of 1.5 nm are formed on MOR zeolite (Rh–Co/MOR) by a simple impregnation method. Rh–Co/MOR is more active, selective, and durable in syngas formation than its monometallic counterparts or their physical mixture. Co oxide on Rh–Co/MOR is spontaneously reduced to form Co0 active sites in POM, whereas Co/MOR and the physical mixture of Rh/MOR and Co/MOR are not reduced and quickly re-oxidise after H2 reduction. Controlled experiments and spectroscopic studies suggest that mono-atomically dispersed Rh reduces Co oxide to Co0 and preserves the zero-valent state in POM via hydrogen spillover for Rh–Co/MOR. Regarding the effect of the catalyst support, Rh–Co bimetallic catalysts using SiO2–Al2O3, SiO2, and Al2O3 as supports have poor durability or lower activity. Large particles of Co (>10 nm) formed on SiO2–Al2O3 and SiO2 produce coke, thus showing that the highly dispersed Co species on MOR is essential to inhibit coke formation. Al2O3 produces barely reducible cobalt species, giving a lower fraction of Co0 active species. Thanks to the favourable features of Rh–Co/MOR, the catalyst gives 85–86% methane conversion and 90–91% CO selectivity with an H2/CO ratio of 2.0 at 650 °C and SV of 1,200,000 mL g−1 h−1, and maintains its activity for at least 50 h. The produced amount of CO divided by the number of total Co atoms is 120,000. Consequently, Rh–Co/MOR maintains high activity in POM despite having only a trace amount of Rh. Good reducibility and high dispersion of Co achieved by the MOR support are keys to the high catalytic performance, as other catalyst supports do not provide such attractive features. Zeolites interact with Co species but do not make mixed oxides such as CoAl2O4, which might result in their favourable features.

Methods

Catalyst preparation

A proton-type MOR with an Si/Al ratio of 45 [JRC-Z-HM90, Catalysis Society of Japan (CSJ)] was used in this study. Co(NO3)2·6H2O (0.0764 g, 262 μmol) and 3.88 mM RhCl3 aq. (62.8 μL, 0.24 μmol) were dissolved in 25 mL of water, and then 500 mg of MOR was added into the solution. The mixture was stirred at room temperature for 24 h. A solid material was recovered by evaporation of the mixture at 40 °C under vacuum. The resulting powder was dried at 110 °C overnight and then calcined at 550 °C in air for 6 h to obtain a catalyst labelled as Rh–Co/MOR. The loading amounts of Rh and Co were 0.005 wt% and 3.0 wt%, respectively. The same procedure was adopted for SiO2–Al2O3 (Si/Al = 45), SiO2 (JRC-SIO-9A, CSJ), and Al2O3 (JRC-ALO-8, CSJ) supports.

Catalyst characterisation

XRD patterns were measured by a diffractometer (Ultima IV, Rigaku; Cu Kα 0.154 nm) equipped with a semiconductor array detector (D/teX Ultra 2). BET surface areas of the samples were calculated from N2 adsorption isotherms at −196 °C recorded on a Belsorp-mini (Microtrac-BEL). Samples were degassed at 200 °C for 3 h under vacuum before measurement. HAADF-STEM images were taken by a JEM-ARM200F (JEOL) equipped with a JED-2300 EDX spectrometer with an acceleration voltage of 200 kV. The Cs-corrector CESCOR (CEOS) was used in the STEM mode. TEM images were obtained by using a JEM-2100F (JEOL) with an acceleration voltage of 200 kV. STEM and TEM samples were prepared by dropping an ethanol suspension of the catalyst on a holey carbon-supported copper grid. STEM and TEM images were displayed using Origin 8 and Paint Shop Pro 4. XPS were acquired on a JPC-9010MC instrument (JEOL) using the Al Kα line. Samples were exposed to air prior to the measurements. TPR was carried out on a Belcat II (Microtrac-BEL) using 5% H2/Ar mixed gas. Samples for this analysis were treated under He flow at 550 °C for 30 min in advance. Rh K-edge XAFS measurements were carried out in fluorescence mode with a 19-channel Ge solid-state detector at 298 K using synchrotron radiation through an Si (311) double-crystal monochromator at the NW10A beam line on Photon Factory Advanced Ring (PF-AR; ring energy 6.5 GeV, 60 mA) (Proposal Nos. 2016G546 and 2017G624). XAFS spectra were analysed with a REX2000 (Rigaku). EXAFS spectra were extracted with a spline smoothing method. For the curve-fitting analysis, the backscattering amplitude and the phase shift were derived from FEFF 8.40 calculations.

Partial oxidation of methane

The POM was conducted in a quartz fixed-bed flow reactor (inner diameter ⌀7). The temperature inside the catalyst bed was monitored by a thermocouple (⌀0.5). The catalyst was heated to the desired temperature under He flow (9.2 mL min−1). Afterward, the reaction gas mixture (typically, CH4 10.0 mL min−1, O2 0.8 mL min−1, He 9.2 mL min−1) was fed into the reactor. A low concentration of O2 was used to avoid the formation of hot spots31, and only a small increase in temperature in the catalyst bed occurred (5–20 °C, depending on reaction conditions). When performing the reaction at a very high SV of 1.2 × 106 mL h−1 g−1, the catalyst was diluted twice with MOR (5 mg catalyst, 5 mg MOR) to obtain reliable data. Products were analysed by an on-line gas chromatograph (Shimadzu GC-8A, thermal conductivity detector, Shincarbon ST and molecular sieve 5 A packed columns). The carbon balance calculated from the amounts of methane, CO, and CO2, determined by an internal standard method using N2, was 98.5–99.5% in the POM by Rh–Co/MOR under our reaction conditions. No other carbon-containing products were observed except for a trace amount of coke, quantified with a total organic carbon analyser (TOC-VCSN, Shimadzu). Therefore, selectivity for CO was defined as the ratio of CO/(CO + CO2) to obtain better accuracy even at low conversions of methane. Details of the calculations are available in Supplementary Note 1.

Data availability

Data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Wang, Q., Chen, X., Jha, A. N. & Rogers, H. Natural gas from shale formation—the evolution, evidences and challenges of shale gas revolution in United States. Renew. Sustain. Energy Rev. 30, 1–28 (2014).

Karakaya, C. & Kee, R. J. Progress in the direct catalytic conversion of methane to fuels and chemicals. Prog. Energy Combust. Sci. 55, 60–97 (2016).

Tomkins, P., Ranocchiari, M. & van Bokhoven, J. A. Direct conversion of methane to methanol under mild conditions over Cu-zeolites and beyond. Acc. Chem. Res. 50, 418–425 (2017).

Ogo, S. & Sekine, Y. Catalytic reaction assisted by plasma or electric field. Chem. Rec. 17, 726–738 (2017).

Luk, H. T., Mondelli, C., Ferré, D. C., Stewart, J. A. & Pérez-Ramírez, J. Status and prospects in higher alcohols synthesis from syngas. Chem. Soc. Rev. 46, 1358–1426 (2017).

Tang, M., Xu, L. & Fan, M. Progress in oxygen carrier development of methane-based chemical-looping reforming: A review. Appl. Energy 151, 143–156 (2015).

Aasberg-Petersen, K. et al. Technologies for large-scale gas conversion. Appl. Catal. A Gen. 221, 379–387 (2001).

Horn, R. & Schlögl, R. Methane activation by heterogeneous catalysis. Catal. Lett. 145, 23–39 (2015).

Kraus, P. & Lindstedt, R. P. Microkinetic mechanisms for partial oxidation of methane over platinum and rhodium. J. Phys. Chem. C 121, 9442–9453 (2017).

Urasaki, K. et al. Synthesis gas production by catalytic partial oxidation of natural gas using ceramic foam catalyst. Catal. Today 299, 219–228 (2018).

Eriksson, S., Rojas, S., Boutonnet, M. & Fierro, J. L. G. Effect of Ce-doping on Rh/ZrO2 catalysts for partial oxidation of methane. Appl. Catal. A Gen. 326, 8–16 (2007).

Hou, Y., Ogasawara, S., Fukuoka, A. & Kobayashi, H. Zeolite-supported rhodium sub-nano cluster catalyst for low-temperature selective oxidation of methane to syngas. Catal. Sci. Technol. 7, 6132–6139 (2017).

Choudhary, V. R., Rajput, A. M., Prabhakar, B. & Mamman, A. S. Partial oxidation of methane to CO and H2 over nickel and/or cobalt containing ZrO2, ThO2, UO2, TiO2 and SiO2 catalysts. Fuel 77, 1803–1807 (1998).

Xia, W. et al. Partial oxidation of methane into syngas (H2+CO) over effective high-dispersed Ni/SiO2 catalysts synthesized by a sol–gel method. Int. J. Hydrogen Energy 37, 8343–8353 (2012).

Dedov, A. G. et al. Partial oxidation of methane to produce syngas over a neodymium–calcium cobaltate-based catalyst. Appl. Catal. A Gen. 489, 140–146 (2015).

Basile, F., Fornasari, G., Trifirò, F. & Vaccari, A. Rh–Ni synergy in the catalytic partial oxidation of methane: surface phenomena and catalyst stability. Catal. Today 77, 215–223 (2002).

Naito, S. et al. Promoting effect of Co addition on the catalytic partial oxidation of methane at short contact time over a Rh/MgO catalyst. J. Catal. 259, 138–146 (2008).

Cesar, D. V. et al. Stability of Ni and Rh–Ni catalysts derived from hydrotalcite-like precursors for the partial oxidation of methane. Int. J. Hydrogen Energy 38, 5616–5626 (2013).

Berger-Karin, C., Radnik, J. & Kondratenko, E. V. Mechanistic origins of the promoting effect of tiny amounts of Rh on the performance of NiOx/Al2O3 in partial oxidation of methane. J. Catal. 280, 116–124 (2011).

Roh, H.-S., Jun, K.-W., Baek, S.-C. & Park, S.-E. A highly active and stable catalyst for carbon dioxide reforming of methane: Ni/Ce–ZrO2/q-Al2O3. Catal. Lett. 81, 147–151 (2002).

Chai, J. W. et al. Thermal behaviour of ultra-thin Co overlayers on rutile TiO2(100) surface. Surf. Sci. 589, 32–41 (2005).

Dominguez, M., Taboada, E., Idriss, H., Molins, E. & Llorca, J. Fast and efficient hydrogen generation catalyzed by cobalt talc nanolayers dispersed in silica aerogel. J. Mater. Chem. 20, 4875–4883 (2010).

Tan, B. J., Klabunde, K. J. & Sherwood, P. M. A. XPS studies of solvated metal atom dispersed (SMAD) catalysts. Evidence for layered cobalt-manganese particles on alumina and silica. J. Am. Chem. Soc. 113, 855–861 (1991).

Lónyi, F., Solt, H. E., Pászti, Z. & Valyon, J. Mechanism of NO-SCR by methane over Co,H-ZSM-5 and Co,H-mordenite catalysts. Appl. Catal. B 150, 151, 218–229 (2014).

Kim, D. J. et al. Enhancement in the reducibility of cobalt oxides on a mesoporous silica supported cobalt catalyst. Chem. Commun. 1462–1464 (2005).

Takenaka, S., Ishida, M., Serizawa, M., Tanabe, E. & Otsuka, K. Formation of carbon nanofibers and carbon nanotubes through methane decomposition over supported cobalt catalysts. J. Phys. Chem. B 108, 11464–11472 (2004).

Lapidus, A. et al. Hydrocarbon synthesis from carbon monoxide and hydrogen on impregnated cobalt catalysts. Part I. Physico-chemical properties of 10% cobalt/alumina and 10% cobalt/silica. Appl. Catal. 73, 65–81 (1991).

Mimeault, V. J. & Hansen, R. S. Flash desorption and isotopic mixing of hydrogen and deuterium adsorbed on tungsten, iridium, and rhodium. J. Phys. Chem. 45, 2240–2250 (1966).

Im, J., Shin, H., Jang, H., Kim, H. & Choi, M. Maximizing the catalytic function of hydrogen spillover in platinum-encapsulated aluminosilicates with controlled nanostructures. Nat. Commun. 5, 3370 (2014).

Lee, S., Lee, K., Im, J., Kim, H. & Choi, M. Revisiting hydrogen spillover in Pt/LTA: effects of physical diluents having different acid site distributions. J. Catal. 325, 26–34 (2015).

Tanaka, H., Kaino, R., Okumura, K., Kizuka, T. & Tomishige, K. Catalytic performance and characterization of Rh–CeO2/MgO catalysts for the catalytic partial oxidation of methane at short contact time. J. Catal. 268, 1–8 (2009).

Acknowledgements

We thank Ms. N. Hirai (technical division) for taking the STEM images. This work was supported by Japan Science and Technology Agency (JST) CREST Grant Number JPMJCR15P4. The Open Facility of Institute for Catalysis was utilised for the XPS and TEM measurements.

Author information

Authors and Affiliations

Contributions

Y.H. performed POM and characterisations. S.N. and K.A. measured XAFS spectra and assisted in their analysis. Y.H., H.K., and A.F. wrote the manuscript. H.K. conducted the project with the advice of A.F.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hou, Y., Nagamatsu, S., Asakura, K. et al. Trace mono-atomically dispersed rhodium on zeolite-supported cobalt catalyst for the efficient methane oxidation. Commun Chem 1, 41 (2018). https://doi.org/10.1038/s42004-018-0044-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-018-0044-9

This article is cited by

-

Direct methane activation by atomically thin platinum nanolayers on two-dimensional metal carbides

Nature Catalysis (2021)

-

Ultrasmall and Stable Pd and Pt Nanoparticles Within Zeolite HY Through Impregnated Method with Enhanced Semihydrogenation Selectivity

Catalysis Letters (2021)

-

Zeolite-supported ultra-small nickel as catalyst for selective oxidation of methane to syngas

Communications Chemistry (2020)

-

Unravelling platinum nanoclusters as active sites to lower the catalyst loading for formaldehyde oxidation

Communications Chemistry (2019)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.