Abstract

Maintenance-free self-healing elastomers that switch their mechanical properties on demand would be extremely useful materials for improving the functionalities, safety, energy efficiency, and lifetimes of many kinds of products and devices. However, strength and stretchability are conflicting properties for elastomers because the inherent crosslinking density of a polymeric network is unchangeable. For example, heavily crosslinked elastomers are strong, but poorly stretchable. Here we report an ionically crosslinked polyisoprene elastomer in which the ionic moieties are continually hopping between ionic aggregates at room temperature. Thus, the network is dynamic. This elastomer spontaneously self-heals without the input of external energy or healing agents. Furthermore, it behaves like a strong elastic material under rapid deformation, but acts like a highly stretchable and viscoelastic material under slow deformation. Our ionic elastomer shows a variety of notable mechanical properties, including high fracture strength (≈7 MPa), good toughness (≈70 MJ m−3), and ultrastretchability (>13,400%).

Similar content being viewed by others

Introduction

Since the invention of the vulcanization of natural rubbers by Charles Goodyear in 18441, elastomers have made tremendous contributions to the advancement of modern technology. For example, they are applied in vehicle tires, soft and waterproof coatings, and as man-made skins in medical2 and robotic3 fields. The practical advantage of elastomers is that their fracture strength, toughness, and stretchability can be easily and widely tuned by controlling the crosslinking density of the networks4. However, the strength and stretchability of elastomers exhibit a trade-off relationship because these properties are oppositely dependent on the crosslinking density. Heavily crosslinked elastomers are strong, but poorly stretchable. Indeed, elastomers that switch their properties from strong-to-soft and stretchable on demand are as yet unrealized, despite their enormous potential. Furthermore, unlike human skin, conventional elastomers do not spontaneously self-heal5,6.

The development of elastomers that switch their mechanical properties on demand and exhibit autonomic self-healing ability at ambient temperature may have a significant impact on the improvement of functionality, safety, energy efficiency, and lifetimes of products and devices. Recently, supramolecular elastomers comprising low glass transition temperature (Tg) polymer chains and weak dynamic bonds, such as hydrogen bonds7, metal–ligand coordination8,9,10, and ionic bonds11,12,13,14,15, have been designed for autonomic self-healing at room temperature. In contrast to most self-healing materials, these supramolecular elastomers do not require the input of any external energy (such as heat or light)16,17,18,19,20, healing agents (such as monomers and catalysts)21,22, plasticizers23, or solvents24,25,26,27. When supramolecular elastomers are cut into two pieces, the weak dynamic bonds acting as crosslinks are preferentially broken. However, upon contacting the cut faces, the broken crosslinks reform and flexible polymer chains self-diffuse. Thus, the two pieces reconnect, even at room temperature.

The dynamic crosslinks also have the potential to impart high fracture strength and stretchability to a single elastomer because the “effective” crosslinking density of the dynamic crosslinks can respond to conditions or external stimuli, unlike conventional chemical and physical crosslinks. For example, Leibler et al. suggested that the “effective” crosslinking density of dynamically crosslinked elastomers will depend on the deformation speed of the specimen28. At shorter time scales than the lifetime of the dynamic crosslinks, they behave as strong crosslinks and the networks are elastic. Conversely, the chains will diffuse and viscoelastic behavior will be presented under slow deformation. Nevertheless, designing dynamic crosslinks with desired strengths and lifetimes is challenging9,10.

In the present study, we demonstrate a simple methodology to tune the strength and lifetime of the dynamic crosslinks in an elastomer. In our ionically crosslinked polyisoprene (PI) elastomer, ionic moieties continuously hop between ionic aggregates at room temperature, and the hopping rate is controllable by the neutralization level. These dynamic ionic crosslinks allow our elastomer to spontaneously self-heal at room temperature. Moreover, our elastomer demonstrates a strong and elastic response to rapid stretching while ultrastretchable behavior is demonstrated under slow stretching. Unlike previous self-healing elastomers, the self-healing rate, stretchability, toughness, and strength of our elastomer may be tuned by altering the neutralization level.

Results

Material design

We present herein a supramolecular elastomer with dynamic ionic crosslinks. The elastomer switches between strong elastic and stretchable viscoelastic behavior depending on the stretching speed. Furthermore, the elastomer exhibits autonomic self-healing.

In this elastomer, carboxyl groups were randomly introduced to 1.7% of the repeating units of the cis-1,4 rich PI backbone (Tg ≈ −60 °C)(Supplementary Fig. 1) and 24–90% of carboxyl groups were neutralized with sodium (Fig. 1a). The carboxylic and neutralized PIs are denoted as PI–COOH and PI–xNa, respectively, where x indicates the neutralization percentage. The PI–xNa film is colorless, transparent, and stretchable (Fig. 1b). Polymers containing relatively few ions are generally called “ionomers”29. The inclusion of a small fraction of ionic groups into the hydrophobic polymer results in small ionic aggregates. The ionic aggregates comprise neutralized and unneutralized carboxyl groups30, and act as physical crosslinks (Fig. 1c). Although our designed elastomers are dimensionally stable (except for PI–24Na), the polymer chains are locally diffusing and the neutralized and unneutralized carboxyl groups can hop between neighboring ionic aggregates31,32. Therefore, rearrangement of the network crosslinks occurs continuously at room temperature. This rapid hopping of the ionic crosslinks performs several mechanical functions simultaneously: it enhances fracture resistance by the detachment of stressed chains and therefore toughens the elastomers; it enhances the fatigue resistance; and it endows the material with autonomic self-healing at room temperature without the input of energy (either heat or light) or the assistance of healing agents (e.g., catalysts, monomers, solvents, plasticizers). In addition, the ion-hopping rate of the ionomers increases with decreasing neutralization level32. Consequently, the ion-hopping feature can be used to tune over a wide range of the strength, toughness, stretchability, and self-healing rate of our elastomer.

Chemical structure of PI–xNA and a schematic of its behavior under stretching. a Chemical structure and schematic illustration of PI–xNa. b Photograph of a PI–90Na film that is transparent, colorless, and highly stretchable. c Schematic description of proposed mechanisms for elastic response under rapid stretching and viscoelastic deformation under slow stretching. Under fast stretching, ionic aggregates act as strong crosslinks. Conversely, when stretching is slow, ionic groups attached at stressed polymer chains detach from ionic aggregates and enter other aggregates to dissipate the loaded force

Characterization of ionic aggregates

PI–xNa shows a broad small-angle X-ray scattering (SAXS) peak at 1.3 nm−1 of the scattering vector (q), which is assigned to the ionic aggregates (Fig. 2a). The size of the ionic aggregates was determined by analyzing the SAXS peak using the Yarusso–Cooper model where randomly distributed sphere-shaped ionic aggregates are considered33. The radius of the ionic aggregate in PI–xNa is approximately 0.96 nm irrespective of the neutralization level (Fig. 2b). This type of consistency is generally observed for ionomers because the aggregation of neutralized and unneutralized carboxyl groups is limited by steric interactions between the polymer chains around the ionic aggregates30,34. The ionic aggregates in the ionomers have a locally higher Tg than the polymer matrix. The local Tg of the ionic aggregates was measured by our original method based on the electron spin resonance (ESR) technique35. In this method, stearic acid-based and nonadecane-based paramagnetic molecules are used as spin probes, and their selective positioning allows us to determine sub-nanoscopic maps of Tg around the ionic aggregates (Fig. 2c). The positions of the spin probes around the ionic aggregates are confirmed from one of the magnetic parameters of nitroxide, Azz, which increases with increasing polarity (Fig. 2d). Distinctly high Azz values of the 5DSA and 7DSA probes indicate that the nitroxide parts of these probes are located inside the polar ionic aggregates, as illustrated in Fig. 2c. The Tg of the ionic aggregates determined by ESR using the 5DSA probe is −46 °C (Fig. 2d and Supplementary Fig. 2). This means that the ionic aggregates are “soft.” Therefore, ion-hopping is allowed at room temperature. Conversely, the common commercial poly(ethylene-co-methacrylic acid) (EMAA) ionomer neutralized by sodium has glassy ionic aggregates (the Tg of the ionic aggregates is approximately 50 °C) while the matrix is rubbery (Tg ≈ 8 °C) at room temperature35. Therefore, ion-hopping is not observed at room temperature, and cut films of EMAA ionomers do not reconnect at room temperature31.

Size and local glass transition temperature of ionic aggregates in PI–xNA. a Experimental SAXS patterns for PI–xNa simulated using the Yarusso–Cooper model. b The size of the ionic aggregate is almost constant against the neutralization level. c Chemical structures of spin probes and suggested locations of the probes for PI–90Na based on analysis of the ESR results. nDSA (n = 5, 7, 10, and 12) are localized at polar ionic aggregates, while 10DND is dispersed in the nonpolar PI matrix. d High Azz values of 5DSA and 7DSA demonstrate localization of the nitroxide section of the probe inside the ionic aggregates. The Tg of the ionic aggregate is higher by ~10 °C than that of the PI matrix. The COOH group of the nDSA probe is assumed to localize at the center of the ionic aggregate, as illustrated in c

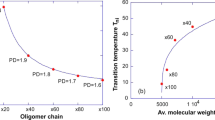

The glass transition of the ionic aggregates in the PI–xNa is detected at −49 °C as a shoulder of the glass transition of the matrix at −60 °C in the dynamic mechanical analysis (DMA) while the shoulder is not observed for PI (Fig. 3a, b). The PI–xNa shows an additional relaxation that is assigned to the ion-hopping just below room temperature; the relaxation temperature decreases with decreasing neutralization level (Fig. 3b). This means that the ion-hopping rate at room temperature increases with decreasing neutralization level.

Dynamic mechanical analysis result of PI–xNa. a Temperature sweep of storage modulus (E′) and loss modulus (E″) for PI and PI–90Na measured at 1 Hz. Relaxations assigned to glass transition of ionic aggregates and ion-hopping are indicated with open and solid arrows, respectively. PI (Mn = 488000) is measured for comparison. b Temperature sweep of E′ and E″ for PI–43Na, PI–58Na, and PI–90Na measured at 1 Hz. Relaxations assigned to glass transition of ionic aggregates and ion-hopping are indicated with open and solid arrows, respectively. Room temperature (28 °C) is indicated with a vertical red broken line

Mechanical properties

Due to the hopping nature of the ionic crosslinks, the strength, toughness, and stretchability of PI–xNa depend on the stretching speed. For example, PI–58Na behaves elastically under fast stretching, whereas viscoelastic deformation is observed when the stretching is slow (Fig. 4a). The Young’s modulus, fracture stress, and toughness of PI–58Na increase with increasing stretching speed, while the stretchability decreases (Fig. 4b). In particular, the toughness is maximal (≈44 MJ m−3) under a deformation of 30 mm min−1. When the stretching is faster than 100 mm min−1, the tensile stress–strain curves for PI–58Na are similar to those of typical crosslinked elastomers, with an initial stiffening region followed by large elastic deformation4. This indicates that the ionic aggregates are acting as “strong” crosslinks and high fracture stress is induced, even though the Tg of the ionic aggregates is significantly lower than room temperature (Fig. 2d and Supplementary Fig. 3). Conversely, under stretching at 10 mm min−1, a yielding point around 2000% strain following the initial stiffening region is presented. The stress gradually decreases with increasing strain, and ultrastretchability (more than 8000%) is demonstrated (Fig. 4a). Under an external force loaded onto the specimen, the PI chains are stretched and the stress is focused on the stretching of shorter chains between the ionic aggregates. When the sample deformation is slow, the ionic groups on the stressed chains detach from the ionic aggregates to dissipate the external force. Moreover, reentry of some detached ionic groups into other ionic aggregates during stretching is indicated by time-resolved synchrotron SAXS measurements during the stretching of PI–58Na (Fig. 4c, d). In this experiment, a relatively thick PI–58Na film (1 mm) is stretched at 10 mm min−1 with a 10-mm gauge and time-resolved SAXS profiles are obtained. Even under large deformation (2900% strain), scattering from the ionic aggregates remains (Fig. 4c). By integrating Lorentz-corrected intensity (q2I) over the small-q range (1.0 < q < 4.7), the “relative invariant” (Q) is obtained. Q is related to the system’s heterogeneity, which is expressed as follows:

where ϕi is the volume fraction of the ionic aggregate and Δρ is the electron density difference between the ionic aggregate and the matrix region. Below the yielding point at ~1000% strain, Q decreases steeply with increasing strain because the ionic groups attached to the stressed chains are detached from the ionic aggregates and the concentration of isolated ionic groups in the matrix region increases (Fig. 4d). As a consequence, Δρ decreases. Conversely, Q becomes almost constant in the strain range above the yielding point. This clearly demonstrates that detachment and reentry of ionic groups between ionic aggregates are in equilibrium in this range as illustrated in Fig. 1c. This dynamic nature allows the ionic crosslinks to break and rapidly reform during stretching. Therefore, both the toughness and ultrastretchability of the material are realized.

Mechanical properties and structural analysis under stretching for PI–58Na. a Tensile stress–strain curves of PI–58Na films stretched at different speeds. The width, thickness, and gauge length were 5.0, 0.4 and 3.5 mm, respectively. b Plots of fracture strain (hollow magenta circles), Young’s modulus (hollow blue circles), fracture stress (filled magenta circles), and toughness (filled blue circles) for a PI–58Na film at different stretching speeds. c SAXS pattern measured under indicated strain. d Stress–strain curve and relative SAXS invariant Q (filled red circles) for a PI–58Na film measured at a stretching speed of 10 mm min−1. The width, thickness, and gauge length were 10.0, 1.0 and 10.0 mm, respectively

A similar mechanism during ultrastretching was previously proposed for an elastomer crosslinked by metal–ligand coordination9. The similarity between these ionic and metal–ligand coordination crosslinks are their rapid reformation ability compared to those of other dynamic crosslinks, such as hydrogen bonds, because the aggregation of the ionic groups and the formation of the metal–ligand coordination are both relatively insensitive to the direction of functional group approach, unlike for the highly directional hydrogen bonds.

The stretchability, strength, and toughness of PI–xNa are easily tunable by altering the neutralization level employed in elastomer preparation (Fig. 5a and Supplementary Figs. 4–6). When the neutralization level is high (90%), high fracture stress (~6 MPa) with relatively low stretchability (~1600%) is observed on stretching at 100 mm min−1 (Fig. 5a). The maximum fracture stress (>7 MPa) is observed for PI–90Na upon stretching at 200 mm min−1 (Fig. 5b). When PI–90Na is highly stretched, the film becomes opaque (Fig. 1b). However, the film regains its transparency upon release, and the size of the ionic aggregates in PI–90Na is essentially unchanged under stretching (Supplementary Fig. 7). In addition, PI–90Na shows good self-recovery (Fig. 5c). The internal network damage recovery is improved by prolonging the resting time before loading. At 1 h after stretching to 1000% strain at 100 mm min−1, the stress recovers to 87% of the initial state and the residual strain is less than 5%, while the stress is 74% of the initial state and the residual strain is 17% at 1 min after the initial stretching. However, when PI–90Na is left in open air to fully equilibrate with moisture, the strength drops by ≈30% (Supplementary Fig. 8).

Mechanical properties of PI–xNa. a Stress–strain curves for PI–xNa stretched at 100 mm min−1. The degree of neutralization for each sample is given. b Stress–strain curves of PI–90Na stretched at different stretching speeds. c Recovery of PI–90Na for different waiting periods performed by cyclic tensile tests at 100 min min−1. d Plots of fracture strain (hollow magenta circles), Young’s modulus (hollow blue circles), fracture stress (filled magenta circles), and toughness (filled blue circles) of PI–xNa films against the degree of neutralization

Conversely, the stretchability increases with decreasing neutralization level, and ultrastretchability (>13,400%) is observed for PI–43Na under stretching at 100 mm min−1 (Fig. 5a). Due to the limits of the drawing machine, the stretching of PI–43Na was terminated at 13,400%. A photograph of PI–43Na at 12,300% strain is presented in Supplementary Fig. 9. As shown in Fig. 5d, the Young’s modulus, fracture stress, toughness, and stretchability of PI–xNa are tunable by altering the neutralization level. In particular, excellent toughness (≈70 MJ m−3) is observed at intermediate neutralization levels. To the best of our knowledge, this presents the autonomic self-healing elastomer with the best toughness reported in the literature to date.

Self-healing properties

PI–xNa exhibits good autonomic self-healing at room temperature because of the continuous hopping nature of the ionic crosslinks. In Fig. 6a, optical microscope images of a razor scratch on the PI–55Na film stored at different healing periods are shown. Even when the film is left at room temperature (28 °C), the scratch completely disappears after 63 h. Moreover, when a PI–xNa film was cut into two pieces that were put into contact at room temperature, the pieces reconnected. In Fig. 6b, stretching of the self-healed PI–90Na film in which one of the cut films is painted black is demonstrated. As expected, rapid self-healing is observed for the elastomers with lower neutralization levels because of the faster hopping nature of their ionic crosslinks. In the case of PI–55Na, ~80% recovery is observed after 6 h at room temperature, whereas more than 40 h is required for PI–90Na.

Self-healing tests for PI–xNA at room temperature. a Optical microscopic images of a razor scratch on a PI–55Na film surface healed at 28 °C for various periods. The scale bar is 200 μm. b. Photographs of the healed PI–90Na films before and after stretching. The PI–90Na film was cut into completely separate pieces using a razor blade, and one cut film was painted black. c and d Stress–strain curves of PI–55Na (c) and PI–90Na (d) films healed at 28 °C for the indicated periods. The stretching speeds were 200 mm min−1 and 50 mm min−1 for PI–55Na (c) and PI–90Na (d), respectively

Discussion

We have developed and characterized an autonomic self-healing elastomer that demonstrates a strong and elastic response to rapid stretching while ultrastretchable behavior is demonstrated under slow stretching. In this elastomer, the ionic aggregates are soft at room temperature and, therefore, under slow stretching, ionic groups attached to the stressed chains detach from the ionic aggregates and enter other aggregates to dissipate the external force. In contrast to previous self-healing elastomers, the self-healing rate, stretchability, toughness, and strength of our elastomer are easily and widely tunable by altering the neutralization level. Finally, molecular parameters (e.g., chemical structure and Mn of the backbone polymer, content and neutralization level of the COOH groups and cation species) of our elastomer can be systematically tuned both for optimizing the polymer properties and for understanding the mechanism of this system because of its simple molecular design and well-defined synthesis.

Methods

Materials

Isoprene (>99.0%) and N,N,N’,N’-tetramethylethylenediamine (TMEDA, >98.0%) were purchased from Tokyo Chemical Industry Co., Ltd. Molecular sieves (3 A 1/16, Nacalai Tesque, Inc.) and aluminum oxide (activated, Kanto Chemical Co., Inc.) were dried before use. sec-Butyllithium (sec-BuLi, 1.0 mol L−1, in cyclohexane (95%) and n-hexane (5%)), cyclohexane (extra-pure reagent), tetrahydrofuran (THF, extra-pure reagent), and methanol (extra-pure reagent) were obtained from Nacalai Tesque and used without further purification. 5-DOXYL-stearic acid (5DSA), 7-DOXYL-stearic acid (7DSA), 10-DOXYL-stearic acid (10DSA), and 10-DOXYL-nonadecane (10DND) were obtained from Aldrich Chemical Co., Ltd. 12-DOXYL-stearic acid (12DSA) was purchased from Santa Cruz Biotechnology.

Polymerization of PI

PI was synthesized via living anionic polymerization under N2 flow. A mixture of isoprene (230 mL) and cyclohexane (500 mL) was purified overnight using molecular sieves (3 A) and aluminum oxide (activated). A well-dried flask was charged with the mixture and a magnetic stirring bar and sealed with a three-way stopcock. Dry N2 was bubbled thorough the mixture for more than 30 min to remove oxygen from the flask. Then, sec-BuLi/cyclohexane/n-hexane solution (1.7 mL) was injected into the flask under N2 flow. The reaction was allowed to proceed at room temperature for 3 h under N2 flow and then terminated by injecting methanol. The reaction mixture was then poured into methanol and the resultant PI was purified. The PI was dried at 60 °C for more than 16 h in a vacuum. The number average molecular weight (Mn) and molecular weight distribution (Mw/Mn) determined by gel permeation chromatography (GPC) using PI standards (Scientific Polymer Products, Inc.) were 115,000 and 1.04, respectively. 13C-NMR spectroscopy confirmed that the PI contained approximately 77% cis-1,4, 18% trans-1,4, and 5% 3,4 microstructures (Supplementary Fig. 10).

Carboxylation of PI

Cyclohexane and TMEDA were purified overnight using molecular sieves (3 A) and aluminum oxide (activated). PI (38 g) was dissolved in the purified cyclohexane (700 mL). This solution was further purified using molecular sieves and aluminum oxide for more than 1 h. The carboxylation of PI is illustrated in Supplementary Fig. 11. The PI/cyclohexane solution and TMEDA (4.2 mL) were added to a well-dried flask fitted with a stirrer bar. The flask was sealed with a three-way stopcock and bubbled with dry N2 for more than 30 min. Then, sec-BuLi/cyclohexane/n-hexane solution (4.2 mL) was injected into the flask under N2 flow. The solution color changed to yellowish upon generation of anionic species (Supplementary Fig. 12). After the reaction mixture had been kept at room temperature for approximately 2 min under N2 flow, dry CO2 gas (99.9%) was flowed into the flask to terminate the reaction. Upon addition of CO2, the viscosity of the reaction mixture significantly increased (Supplementary Fig. 12). The reaction mixture was then dissolved in THF and poured into methanol, and the precipitate formed was isolated. After drying under vacuum at 60 °C for more than 15 h, the sample was dissolved in THF and aqueous HCl (35%) was added until the solution became acidic. It was then poured into excess methanol to precipitate the product. The resultant carboxylic PI (PI–COOH) was dried under vacuum at 60 °C for more than 15 h. The concentration of carboxylic acid groups in the PI–COOH was determined by Fourier-transform infrared (FT-IR) spectroscopy using mixtures of PI and lauric acid (LA) as references. The FT-IR spectra of PI–COOH and PI/LA mixtures of different concentrations are shown in Supplementary Fig. 13.

Neutralization of PI–COOH and preparation of cast films

An appropriate amount of NaOH/methanol solution (3.9 g L−1) was slowly added to a PI–COOH/THF solution (10 wt%) under vigorous stirring. The viscosity of the solution increased owing to neutralization of the carboxyl groups. The mixture was then poured into a Teflon petri dish and dried at 35 °C to make a cast film. The cast film was further dried at 35 °C for more than 1 day in vacuum. The thickness of the cast films was approximately 0.4 mm. The FT-IR spectra of PI, PI–COOH, and PI–xNa are shown in Supplementary Fig. 14. Upon neutralization, the intensity of the COOH carbonyl stretching band at 1707 cm−1 decreases and a symmetric stretching vibration band for sodium carboxylate is generated at 1590 cm−1. The degree of neutralization is determined from the reduction of the band intensity at 1707 cm−1 normalized by the band intensities of the C = C stretching vibrations at 1665 and 1644 cm−1.

Spin probing

The spin probe regents nDSA (n = 5, 7, 10, and 12) and 10DND were dissolved in THF to make a 0.35 g L−1 solution. PI–xNa (70 mg) was dissolved in THF (approximately 1 mL), and 0.2 mL of the spin probe/THF solution was added. The mixture was dried under vacuum at 35 °C for 2 days and then under vacuum at room temperature for 2 days. The obtained sample films were cut in small pieces and encapsulated into 5 mm o.d. quartz tubes for ESR analysis. The tubes were sealed under vacuum. The concentration of the spin probes in the samples was selected to be low enough to avoid broadening of the ESR spectrum by spin–spin interactions.

Measurements

13C-NMR spectra were obtained on JEOL-ECS400 (400 MHz) spectrometer. Samples were dissolved in CDCl3 containing tetramethylsilane as an internal standard.

GPC was performed to determine the weight and number average molecular weights of the PI using an HLC-8020 apparatus manufactured by Tosoh Co., Ltd. equipped with two polystyrene gel columns (Tosoh TSK gel GMH, G4000HXL and G2000HXL) connected to a RI-4030 RI detector (JASCO). THF was used as the eluent at 40 °C. The column set was calibrated using standard PI (Scientific Polymer Products) samples with small polydispersity indices.

DSC measurements were conducted using a DSC7020 differential scanning calorimeter manufactured by SII and calibrated with indium, zinc, lead, and tin standards. A quench cooler accessory was used to cool the samples. During the measurements, the DSC cell was purged with dry nitrogen gas at a flow rate of 50 mL min−1. The samples were heated from −120 to 120 °C at a rate of 10 °C min−1. Tg determined to be the midpoint, i.e., the temperature corresponding to half of the endothermic shift, was subject to an experimental error of ± 1 °C.

FT-IR spectra were obtained with a Perkin-Elmer Spectrum400 spectrometer equipped with a DTGS detector. A thin sample film was prepared on a KBr plate from a chloroform solution. The film was dried at room temperature for more than 1 h vacuum before measurement. The sample thickness was controlled to ensure that the absorbances of the bands were within the range of the Lambert–Beer law. Measurements were performed in transmittance mode at an optical resolution with of 4 cm−1 using 16 scans.

Tensile stress–strain curves of the sample films were collected using the AND Force Tester MCT-2150 at 28 °C. The thickness and width of the test films were typically 0.4 and 5.0 mm, respectively. The initial gauge length was typically set to 3.5 mm. The stretching speed was selected from the range of 10─300 mm min−1. Each measurement was performed at least three times. The tensile stress (σ) was calculated as σ = F/wt, where F is the loading force, and w and t are the initial width and thickness of the sample film, respectively. The strain (ε) under elongation was defined as the change in length (l) relative to the initial gauge length (l0) of the specimen, ε = (l − l0)/l × 100%. The fracture toughness was characterized by the fracture energy, which was calculated by integrating the area under the stress–strain curve. For tensile cycling tests, the samples were first stretched to a maximum strain of 1000% at 100 mm min−1 and then returned at the same speed.

Dynamic mechanical properties were measured on a TA Instruments DMA Q800 under tensile mode. The tests were performed in the range of −100–150 °C at a heating rate of 2 °C min−1 and an oscillation frequency of 1 Hz.

Synchrotron SAXS measurements were performed using the BL-6A beam line at the Photon Factory of the High Energy Accelerator Research Organization (KEK) in Tsukuba, Japan. White radiation from the source was monochromatized using a Si(111) crystal double monochromator to give an intense beam of λ = 0.15 nm X-ray. A PILATUS-1M was used as the detector and located at a distance of 1.0 m from the sample position. Stearic acid and silver behenate were used as standards to calibrate the SAXS detector. The experimental data were corrected for the background scattering and sample absorption. The intensities were radially integrated, averaged, and redistributed for converting the pixel number into the corresponding scattering vector q to produce a circularly averaged pattern. A tensile stretching device (AND Force Tester MCT-2150) was installed onto the beam line and time-resolved SAXS data were recorded simultaneously during the tensile test at 25 °C. The SAXS image acquisition time for each frame was 20 s. In this measurement, the length and width of the test film were ~1.0 and 10.0 mm, respectively. The initial gauge length was 10.0 mm and it was uniaxially stretched at 10 mm min−1. The SAXS image acquisition time for each frame was 20 s for the stretching.

A JEOL X-band (~9 GHz) FA100 spectrometer with 100 kHz field modulation was used for ESR measurement. The modulation amplitude, magnetic field width, sweep time, time constant, and number of scans were 0.25 mT, 15 mT, 20 s, 0.01 s, and 2, respectively. The magnetic field and g tensor were calibrated with a Mn2+ standard. The local Tg around the ionic aggregates in the PI–xNa was measured by a combination of microwave power saturation (MPS) and selective spin probing35. The principle of the MPS method was described in detail in our previous paper35. This method sensitively detects the local Tg at the spin-probed site through the MPS behavior. The saturation factor, S, is proportional to the correlation time, τc, of the molecular tumbling motion of nitroxides when τc is longer than 10−7 s. The microwave powers used for measurements with and without MPS were 16 and 0.02 mW, respectively. The measurements were performed from −80 to 50 °C at intervals of 2.5 °C. The tuning parameters (phase and detector current) of the ESR spectrometer and the sample position in the cavity were kept constant and only the temperature was varied.

Self-healing tests

A sample film was cut into two completely separated pieces. The cut faces were then put together in contact. The sample film was stored at room temperature (28 °C) for different periods. The edges of the healed films were removed using a razor. The healed PI–55Na and PI–90Na films were then stretched at 200 mm min−1 and 50 mm min−1, respectively.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information files or are available from the authors upon reasonable request.

References

Goodyear, C. Improvement in india-rubber fabrics. US patent 3633 (1844).

Van der Kerckhove, E. et al. Silicones in the rehabilitation of burns: a review and overview. Burns 27, 205–214 (2001).

Kim, S., Laschi, C. & Trimmer, B. Soft robotics: a bioinspired evolution in robotics. Trends Biotechnol. 31, 287–294 (2013).

Sperling, S. H. Introduction to Physical Polymer Science. 4th ed, (Wiley, New Jersey, 2006).

Syrett, J. A., Becer, C. R. & Haddleton, D. M. Self-healing and self-mendable polymers. Polym. Chem. 1, 978–987 (2010).

Yang, Y. & Urban, M. W. Self-healing polymeric materials. Chem. Soc. Rev. 42, 7446–7467 (2013).

Chen, Y., Kushner, A. M., Williams, G. A. & Guan, Z. Multiphase design of autonomic self-healing thermoplastic elastomers. Nat. Chem. 4, 467–472 (2012).

Mozhdehi, D., Ayala, S., Cromwell, O. R. & Guan, Z. Self-healing multiphase polymers via dynamic metal-ligand interactions. J. Am. Chem. Soc. 136, 16128–16131 (2014).

Li, C. H. et al. A highly stretchable autonomous self-healing elastomer. Nat. Chem. 8, 618–624 (2016).

Mei, J. F. et al. A highly stretchable and autonomous self-healing polymer based on combination of Pt···Pt and π–π interactions. Macromol. Rapid Commun. 37, 1667–1675 (2016).

Kalista, S. J., Pflug, J. R. & Varley, R. J. Effect of ionic content on ballistic self-healing in EMAA copolymers and ionomers. Polym. Chem. 4, 4910–4926 (2013).

Das, A. et al. Ionic modification turns commercial rubber into a self-healing material. ACS Appl. Mater. Interfaces 7, 20623–20630 (2015).

Hohlbein, N., Shaaban, A., Bras, A. R., Pyckhout-Hintzen, W. & Schmidt, A. M. Self-healing dynamic bond-based rubbers: understanding the mechanisms in ionomeric elastomer model systems. Phys. Chem. Chem. Phys. 17, 21005–21017 (2015).

Bose, R. K., Hohlbein, N., Garcia, S. J., Schmidt, A. M. & van der Zwaag, S. Connecting supramolecular bond lifetime and network mobility for scratch healing in poly(butyl acrylate) ionomers containing sodium, zinc and cobalt. Phys. Chem. Chem. Phys. 17, 1697–1704 (2015).

Xu, C., Cao, L., Lin, B., Liang, X. & Chen, Y. Design of self-healing supramolecular rubbers by introducing ionic cross-links into natural rubber via a controlled vulcanization. ACS Appl. Mater. Interfaces 8, 17728–17737 (2016).

Chen, X. et al. A thermally re-mendable cross-linked polymeric material. Science 295, 1698–1702 (2002).

Ghosh, B. & Urban, M. W. Self-repairing oxetane-substituted chitosan polyurethane networks. Science 323, 1458–1460 (2009).

Burattini, S. et al. A healable supramolecular polymer blend based on aromatic π−π stacking and hydrogen-bonding interactions. J. Am. Chem. Soc. 132, 12051–12058 (2010).

Burnworth, M. et al. Optically healable supramolecular polymers. Nature 472, 334–337 (2011).

Amamoto, Y., Kamada, J., Otsuka, H., Takahara, A. & Matyjaszewski, K. Repeatable photoinduced self-healing of covalently cross-linked polymers through reshuffling of trithiocarbonate units. Angew. Chem. Int. Ed. 50, 1660–1663 (2011).

White, S. R. et al. Autonomic healing of polymer composites. Nature 409, 794–797 (2001).

Toohey, K. S., Sottos, N. R., Lewis, J. A., Moore, J. S. & White, S. R. Self-healing materials with microvascular networks. Nat. Mater. 6, 581–585 (2007).

Cordier, P., Tournilhac, F., Soulie-Ziakovic, C. & Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 451, 977–980 (2008).

Caruso, M. M. et al. Solvent-promoted self-healing epoxy materials. Macromolecules 40, 8830–8832 (2007).

Wang, Q. et al. High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 463, 339–343 (2010).

Nakahata, M., Takashima, Y., Yamaguchi, H. & Harada, A. Redox-responsive self-healing materials formed from host-guest polymers. Nat. Commun. 2, 511 (2011).

Sun, T. L. et al. Physical hydrogels composed of polyampholytes demonstrate high toughness and viscoelasticity. Nat. Mater. 12, 932–937 (2013).

Leibler, L., Rubinstein, M. & Colby, R. H. Dynamics of reversible networks. Macromolecules 24, 4701–4707 (1991).

Eisenberg, A. & Kim, J.-S. Introduction to Ionomers. (Wiley, New York, NY, 1998).

Kutsumizu, S., Tagawa, H., Muroga, Y. & Yano, S. Small-angle X-ray scattering investigation of noncrystalline poly(ethylene-co-methacrylic acid) ionomers. Macromolecules 33, 3818–3827 (2000).

Van Alsten, J. G. Ionic and Chain interdiffusion and interfacial strength development in ionomers of poly(ethylene-co-methacrylic acid). Macromolecules 29, 2163–2168 (1996).

Tierney, N. K. & Register, R. A. The role of excess acid groups in the dynamics of ethylene–methacrylic acid ionomer melts. Macromolecules 35, 6284–6290 (2002).

Yarusso, D. J. & Cooper, S. L. Analysis of SAXS data from ionomer systems. Polym. (Guildf.). 26, 371–378 (1985).

Eisenberg, A., Hird, B. & Moore, R. B. A new multiplet-cluster model for the morphology of random ionomers. Macromolecules 23, 4098–4107 (1990).

Miwa, Y., Kondo, T. & Kutsumizu, S. Sub-nanoscopic mapping of glass transition temperature around ionic multiplets in sodium-neutralized poly(ethylene-random-methacrylic acid) ionomer. Macromolecules 46, 5232–5237 (2013).

Acknowledgements

This research was financially supported by Japan Society for the Promotion of Science (JSPS), Grant-in-Aid for Young Scientists (B), 16K17958. Beam time at PF-KEK provided by Programs 2015G514 and 2016G627 is also acknowledged. The authors thank Prof. Tomohiro Hirano at Tokushima University for his help in synthesizing the samples.

Author information

Authors and Affiliations

Contributions

Y. M. and S. K. planned and directed the project, J. K. and Y. K. conducted the experiments, Y. M. and J. K. analyzed the data, and Y. M. and S. K. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Miwa, Y., Kurachi, J., Kohbara, Y. et al. Dynamic ionic crosslinks enable high strength and ultrastretchability in a single elastomer. Commun Chem 1, 5 (2018). https://doi.org/10.1038/s42004-017-0004-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-017-0004-9

This article is cited by

-

Effect of the Mg2+ ratio on the mechanical and self-healing properties of polyisoprene ionomers co-neutralized with Na+ and Mg2+

Polymer Journal (2024)

-

The biomimetic design provides efficient self-healing of ultrahigh-tough and damage-warning bio-based elastomer for protective clothing of metals

Nano Research (2023)

-

Highly transparent, stretchable, and self‐healing polymers crosslinked by dynamic zinc(II)-poly(amic acid) bonds

Polymer Journal (2022)

-

Preparation of dual-cross network polymers by the knitting method and evaluation of their mechanical properties

NPG Asia Materials (2022)

-

Superstretchable, yet stiff, fatigue-resistant ligament-like elastomers

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.