Abstract

Octocrylene is a widely used synthetic UV absorber of sunscreens and found in several environments. Ecological consequences of the accumulation of UV filters are widely discussed. This is the first report revealing the microbial potential to transform octocrylene. A microbial community comprising four bacterial species was enriched from a landfill site using octocrylene as carbon source. From these microorganisms Mycobacterium agri and Gordonia cholesterolivorans were identified as most potent applying a new “reverse discovery” approach. This relies on the possibility that efficient strains that are already isolated and deposited can be identified through enrichment cultures. These strains formed massive biofilms on the octocrylene droplets. GC-MS analysis after cultivation for 10 days with M. agri revealed a decrease in octocrylene concentration of 19.1%. LC-MS/MS analysis was utilized in the detection and quantification of transformation products of octocrylene. M. agri thus represents an ideal candidate for bioremediation studies with octocrylene and related compounds.

Similar content being viewed by others

Introduction

Octocrylene (2-ethylhexyl 2-cyano-3,3-diphenylacrylate) is a synthetic organic filter widely used as UV-absorber (in the UVB region) in sunscreens and personal care products1. Recently, several studies focused on the extensive use and potential ecological consequences of octocrylene, since the compound was detected in various water and sediment samples in wastewater2 oceans3, lakes, and rivers4,5. Moreover, octocrylene was found in the liver tissue of Franciscana dolphins and accumulation of octocrylene in zebrafish was reported upon exposure6,7. Further, octocrylene was suggested to potentially affect transcription of genes in the zebrafish’s brain and liver8,9. So far, little is known about potential degradation and biotransformation of octocrylene by microorganisms. Hence, this is the first study, to our knowledge, which reports on microbial growth in the presence of octocrylene and its degradation and transformation to other compounds.

Results

Sediment and water samples were taken from an on-site sewage plant and soakage at a landfill site in Singhofen (Germany). Samples were subsequently used for enrichment cultures (inoculation 1% (v/v)) with 0.35% (v/v) octocrylene as carbon source. After 14 days, grown cultures were transferred into fresh medium with two subsequent streakings. Repeatedly, biomass formation on the octocrylene droplet surface could be observed and the medium became turbid compared to the controls. In order to investigate the community composition of the culture, DGGE analysis was performed10. The microbial community of the OC-colonizing enrichment culture consisted of four genera, and the distinct bands of the DGGE were obtained and assigned to the bacterial genera Gordonia (100% identity), Mycobacterium (100% identity), and Hydrogenophaga (99% identity) after excision of the respective bands and sequencing (Fig. 1).

Biofilm formation on octocrylene droplet in the enrichment culture. a Chemical structure of octocrylene. b Observation of biofilms on octocrylene droplets in the enrichment culture of landfill site samples after two transfers. The incubation temperature was 30 °C. Red arrow: biofilm on the octocrylene droplets swimming in the medium; blue arrow: biofilm on octocrylene on the medium surface. Scale represents 1 cm. c Diversity analysis of the enrichment culture using DGGE. Used primers: 314 F and 907 R. DGGE was performed at 100 V for 17 h.

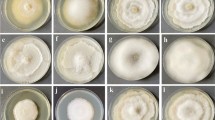

Interestingly, Mycobacterium and Gordonia species have been reported to be associated with degradation of polluting polycyclic aromatic hydrocarbons (PAHs), such as pyrene or oil, and were proposed for application in environmental bioremediation11,12,13,14. Although different techniques were performed, isolation of pure strains from the enrichment culture was not possible and resulted in mixed cultures. Therefore, the “reverse discovery” approach was integrated. This approach is based on taking use of already isolated and deposited pure strains, showing high identities to the identified 16S rRNA genes amplified from the organisms of the enrichment culture. Highly identical strains can be purchased from culture collections, in order to identify the most efficient strains capable of degrading octocrylene. Likewise, several deposited strains at the German Culture Collection (DSMZ) belonging to the genera Mycobacterium and Gordonia, whose 16S rRNA gene showed high identities to the DGGE-identified ones, were tested for their ability to grow in modified DSM media 645 and 65 at 37 °C and 30 °C in the presence of 0.35% (v/v) octocrylene. Interestingly, M. agri (DSM 44515) and Gordonia cholesterolivorans (DSM 45229) were able to colonize the octocrylene droplet rapidly forming massive biofilms on its surface (Fig. 2).

Mycobacteria and Gordonia species have been already described to attach to different surfaces that are composed of biomaterials and synthetic compounds initiating the synthesis of an extracellular matrix required for biofilm formation11,12. Since carbon sources can influence biofilm formation11, different concentrations of glucose and glycerol in the growth medium were tested. Remarkably, while reduction of carbon sources had no positive influence on biofilm formation of G. cholesterolivorans, M. agri showed fast and massive biofilm formation when carbon sources were significantly reduced (0.05% glucose, 0.05% glycerol). Interestingly, in absence of external carbon sources, no biofilms were formed at all, indicating the necessity of small amounts of accessible energy sources to colonize the octocrylene droplet.

Hence, in order to study transformation of octocrylene by M. agri and G. cholesterolivorans, gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-tandem mass spectrometry (LC-MS/MS) analyses were performed with the pure cultures grown with 0.35% octocrylene (v/v). Control experiments were conducted with M. agri and G. cholesterolivorans grown in the absence and presence of octocrylene. In addition, the medium containing octocrylene was incubated under the same conditions without inoculation. After 10 days of cultivation, triplicates of cultures and controls were used for GC-MS and LC-MS/MS analyses. Samples were prepared by extraction of the culture using hexane/dichloromethane (1 + 2), for LC-MS/MS measurements the GC extract was evaporated to dryness and refilled with acetonitrile, and the amount of octocrylene was determined using the GC-MS-SIM mode, with m/z 249 as the quantifying ion. The qualitative recording of products (product scan) was done by GC-MS-TIC mode. Separation was performed on an Agilent DB5MS ultra inert capillary column.

In the presence of M. agri, the concentration of octocrylene measured by GC-MS-SIM mode decreased from 3536 ± 239 mg/L (controls) to a final concentration of 2861 ± 193 mg/L at day 10, representing a decrease of 19.1% octocrylene (Fig. 3; Supplementary Table 1).

Octocrylene degradation assay with M. agri. 0.35% octocrylene was incubated in liquid medium without M. agri (controls, n = 3) and in presence with M. agri (incubation, n = 3) for 10 days. A decrease of 19.1% octocrylene was detected within the incubation time. Mean is shown in gray color, error bars are representing standard error.

In order to identify possible octocrylene metabolites produced by M. agri, analytical standards of 2-(Carboxymethyl)butyl-2-cyano-3,3-diphenylacrylate (DOCCA), 2-Cyano-3,3-diphenylacrylic-acid (CPAA), and 2-Ethyl-5-hydroxyhexyl-2-cyano-3,3-diphenylacrylate (5OH-OC) were synthesized and provided by Bury et al.9. Consequently, we were able to compare GC-MS spectra obtained in this work with the metabolite’s GC-MS spectra and LC-MS/MS which was subsequently used to quantify the metabolites in our experimental design. While the metabolites DOCCA, CPAA, and 5OH-OC were identified in the MS spectra and quantified via LC-MS/MS, one occurring peak in GC-MS run (Fig. 4, ret. time 15.32 min) could not be identified when comparing to other reported metabolites. The MS spectra of the occurring peak could also not be identified when comparing to MS spectra of published putative metabolites of octocrylene15.

GC-MS scans (a–c TIC mode, cutout, d–e: Mass spectra) of the incubation experiment with M. agri. a Control sample 0.35% octocrylene (rt 15.58 min) incubated for 10 days without M. agri. b Sample 0.35% octocrylene (rt 15.58 min) incubated for 10 days with M. agri. New metabolite was detected (rt 15.32 min). c Control sample M. agri incubated for 10 days without 0.35% octocrylene. d Mass spectrum of the peak identified as octocrylene. e Mass spectrum of the unknown metabolite peak (rt 15.32 min).

LC-MS/MS revealed the occurrence of DOCCA with 165 ± 60 µg/L, of CPAA with 11.8 ± 2.6 µg/L and of 5OH-OC with 246.0 ± 34 µg/L. This indicates that M. agri has transformed octocrylene to the respective metabolites. The concentration of the detectable metabolites, however, does not correlate with the reduction in octocrylene concentration. It is very likely that the products formed in the medium by M. agri (DOCCA, CPAA, and unknown metabolites) were further metabolized by the microorganism and utilized for growth. Non-biotic factors responsible for the reduction of octocrylene can be excluded, since controls without M. agri did not show any decrease in octocrylene concentration.

Interestingly, the analysis of growth experiments with G. cholesterolivorans revealed no change of octocrylene concentration during incubation, although biofilm was observed. This indicates that in this case biofilm formation does not go automatically along with transformation or degradation of octocrylene.

Discussion

Since UV filters such as octocrylene accumulate in nature, the identification of further octocrylene degrading microorganisms is desirable. It has been reported that marine environments are endangered by chemicals and UV-filters of sunscreen3 and solutions for this pollution have to be investigated. Man-made biofilms were proposed previously for bioremediation of sewage effluent contaminated with hydrocarbons16. M. agri represents a potential candidate for bioremediation, since it belongs to the rapidly growing Mycobacteria and can be found ubiquitously in soil and water systems13,17,18. Therefore, a novel eco-friendly application using M. agri or specific microbial consortia could be investigated and applied for degradation of chemical UV filter like octocrylene. This work highlights the potential of heterotrophic microorganisms to transform octocrylene in lab experiments. Due to the omnipresence of M. agri in the environment, it is conceivable that M. agri will also be able to transform the UV filter octocrylene in nature. Hence, further analysis should be conducted regarding biotransformation of octocrylene by microorganisms in natural sediments and waters. Future studies will reveal the metabolic pathway for octocrylene degradation and the key enzymes involved in this process.

Methods

Sampling and enrichment cultures

Sediment and water samples were taken from an on-site sewage plant and soakage at a landfill site in Singhofen (Germany). The samples were subsequently used for enrichment cultures (volume 20 mL) using oxic medium (0.5 g/L NaCl, 1.0 g/L KCl, 0.1 g/L MgSO4, 0.1 g/L MgCl2, 0.5 g/L NH4SO4, 0.5 g NH4NO3, 0.1 g/L CaCl2, 40 mM phosphate buffer, trace element and vitamin solution 141, and 0.005% (w/v) yeast extract). Incubation bottles were inoculated with 1% (w/v) of the soil sample and supplemented with 0.35% (v/v) octocrylene as carbon source. After 14 days of incubation, grown cultures were transferred into fresh medium with two subsequent streakings.

DGGE analysis

DGGE analysis was performed as described previously.19 Amplification of bacterial 16 S rRNA genes was performed using the forward primer 314 F:5′CGCCCGCCGCGCCCCGCGCCCGTCCCGCCGCCCCCGCCCGCCTACGGGAGGCAGCAG-3′ and 907 R: 5′-CCGTCAATTCMTTTGAGTTT-3′).10 DGGE was performed by employing a DcodeTM System (Bio-Rad Laboratories GmbH, Munich, Germany). A 6% polyacrylamide gel with a denaturing gradient of 35–70% formamide was used and electrophoresis ran for 17 h, at 55 °C and 100 V. The gel was stained in Roti-Gel Stain (Carl Roth GmbH, Karlsruhe, Germany) and afterwards analyzed with a UV transilluminator. In addition, selected bands were cut out and DNA was extracted from the gel by incubation in 10 µL sterile water over night at 4 °C, amplified by PCR and amplificated were sequenced (Eurofins Genomics).

Cultivation of Mycobacterium sp. and Gordonia sp

Several Mycobacterium sp. and Gordonia sp. showing within their 16S rRNA genes high similarities compared to the sequenced and identified fragments of the DGGE analysis were chosen and ordered from the DSMZ. Mycobacterium agri (DSM 44515), M. aichiense (DSM 44147) and M. aromaticivorans (DSM 45407) were incubated in DSMZ medium 645 (per liter: 5 mL glycerol, 0.5 g (NH4)2SO4, 1.5 g KH2PO4, 1.5 g Na2HPO4, 0.4 g Na-citrate, 0.025 g MgSO4, 0.5 mg CaCl2, 1 mg ZnSO4, 1 mg CuSO4, 0.5 g L-glutamic acid, 0.04 g ferric ammonium citrate, 1 mg pyridoxine, 0.5 mg biotin, 0.05 g oleic acid, 0.85 NaCl, 5 g BSA, 2 g glucose) supplemented with 0.35% octocrylene at a temperature of 37 °C. Gordonia caeni (DSM 45852), G. cholesterolivorans (DSM 45229), and G. defluvii (DSM 44981) were incubated in DSMZ medium 65 (per liter: 4 g glucose, 4 g yeast extract) supplemented with 0.35% octocrylene at a temperature of 30 °C.

Medium modification of M. agri and G. cholesterolivorans

The medium of the positive octocrylene-colonizing strains M. agri and G. cholesterolivorans was modificated in order to enhance the biofilm formation. Therefore, the carbon sources of the medium 645 of M. agri were highly decreased to 0.05% glucose and 0.05% glycerol and BSA was also reduced to 0.05%. The carbon sources of medium 65 of G. cholesterolivorans were decreased to 1 g/L glucose and 1 g/L yeast extract (no addition of malt extract). Incubation was performed in the presence of 0.35% octocrylene.

Chemicals and materials for analytical approaches

Reference standard octocrylene was purchased from Sigma Aldrich Ltd, Saint Louis, MO, USA (≥98%). Reference substances 2-(Carboxymethyl)butyl-2-cyano-3,3-diphenylacrylat (DOCCA), 2-Cyano-3,3-diphenylacrylic acid (CPAA) and 2-Ethyl-5-hydroxyhexyl-2-cyano-3,3-diphenylacrylate (5OH-OC) were provided by V.N. Belov, Max Planck Institute for Biophysical Chemistry, Göttingen, Germany. Preparation and purity (>95%) are well described in ref. 9

Hexane and dichloromethane were obtained from Merck KGaA, Darmstadt, Germany. Acetonitrile (LC-MS grade) was obtained from Merck, Darmstadt, Germany, formic acid (additive for LC-MS) was purchased from Honeywell Fluka, Muskegon, USA.

All reagents were of analytical grade. Deionized water was purified using a Milli-Q-system (Millipore,USA).

Sample preparation

The whole incubation culture of M. agri and G. cholesterolivorans (and controls) (20 mL) was transferred to a centrifuge tube and 10 mL hexane/dichloromethane (1 + 2) was added. After 30 min stirring the sample was centrifuged (6000 rpm). The lower layer was stirred with NaSO4 and centrifuged (13,000 rpm) again. For GC-MS analysis the liquid was filled in a microbial. For LC-MSMS analysis 1 mL was filled in a volumetric flask, evaporated and refilled with acetonitrile.

GC-MS analyses

Quantification of octocrylene and qualitative recording of products: The quantitative determination of octocrylene and qualitative recording of the products were carried out on an Agilent Technologies GCMS system 5977 A MSD with Gerstel KAS4 injection system. The mass selective detector (MSD) was operated in EI mode. All system operations were controlled by MassHunter B.07.001413. Separation and quantification were performed on an Agilent DB5MS ultra inert capillary column, 30 m × 0.25 mm × 0.25 µm film thickness. Sample volumes of 1 µL were injected in split mode (1:5) at 1 mL/min flow. GC system inlet and MS interface temperatures were set at 70 and 280 °C, respectively. The column temperature was programmed as follows: held at 70 °C for 2 min, then ramped up to 140 °C at 10 °C/min, held for 3 min, then to 300 °C at 100 °C/min. The total runtime was 17,6 min. The carrier gas was helium with constant flow of 1 mL/min, the MSD operating parameters were routinely set by tune file. EM potential was set at +1352 V, MS source temperature at 230 °C and the quadrupoles at 150 °C.

Quantitative determination of octocrylene was done by SIM mode, with quantifying ion with m/z 249 and qualifying fragment ions m/z 360 and 204. Recording of products was done by TIC mode (from m/z 4–450, solvent delay 5 min, dwell time 0.2 ms).

Preparation of analytical standards (GC-MS)

Stock solution was prepared with a concentration of 5300 mg/L using dichloromethane as solvent. By diluting the stock solution with hexane-dichloromethane (1 + 2) calibration standards were prepared with levels from 5,0 mg/L to 200 mg/L. While the stock solution was stored at −18 °C, the calibration standards had to be newly made for each analytical run.

LC-MSMS analyses

Instrumentation and parameters: The quantitative determination of metabolites was carried out on an Agilent 1260 HPLC system (Agilent Technologies Deutschland GmbH and Co. KG, Waldbronn, Germany), equipped with binary pump, degasser, thermostat autosampler, column oven, which is coupled to the Sciex Qtrap 5500 tandem mass spectrometer (AB Sciex Germany GmbH, Darmstadt, Germany).

Separation was achieved by using a Phenomenex Synergi Fusion RP 80 A column (4 µm, 50 × 2 mm) with a Phenomenex standard C18 guard column. The mobile phase consisted of Milli-Q water with 0.1% formic acid (A) and acetonitrile with 0,1% formic acid (B), the flow rate was set to 0.7 mL/min. The gradient elution was programmed as follows: 0–3.5 min, 40% to 95% B (acetonitrile), 3.5–7.0 min 95% B, 7.1–10 min, 40% B.

The injection volume was 5 µL, the column temperature was set to 35 °C.

To detect all three available metabolites with at least two characteristic mass transitions per analyte in one run, the electrospray source of the tandem mass spectrometer operated simultaneously in positive and negative ion mode (Table 1).

Mass transitions, declustering potentials and collision energies for the compounds were obtained by direct infusion experiments with single compound standard solutions.

The following mass spectrometer settings were used: Curtain gas 40 psi, source temperature 450 °C, ion spray 4500 V, −4500 V respectively, Gas 1/Gas2: 40/60 psi.

Preparation of analytical standards

Stock solutions were prepared with a concentration of 100 mg/L using acetonitrile. By diluting a mix standard solution (concentration 10 mg/L) calibration standards were prepared with acetonitrile/water (60/40) at levels from 2,0 µg/L to 100 µg/L. While the stock solutions were stored at −18 °C, the calibration standards had to be newly made for each analytical run.

Quantification of metabolites with LC-MSMS

Due to a substantial peak separation, the identity of peaks could be confirmed using retention times and mass transitions9.

Data were acquired and processed on Analyst 1.6.3. Quantification was carried out with an external calibration. The calibration curves were calculated by linear regression with a RSD of <20% and a coefficient of determination (R2) of >0.99.

Statistics and reproducibility

All biodegradation assays were performed in biological triplicates. The dot-plot format of Fig. 3 was built using the software Interactive Dot Plot Tool20.

Reporting summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

All data are shown in the figures and tables. Raw data generated during this study are available from the corresponding author on reasonable request. All Mycobacteria and Gordonia strains tested in this study were purchased at the German collection of Microorganisms and Cell cultures GmbH (DSMZ).

References

de Groot, A. C. & Roberts, D. W. Contact and photocontact allergy to octocrylene: a review. Contact Dermat. 70, 193–204 (2014).

Balmer, M. E., Buser, H. R., Müller, M. D. & Poiger, T. Occurrence of some organic UV filters in wastewater, in surface waters, and in fish from Swiss lakes. Environ. Sci. Technol. 39, 953–962 (2005).

Tashiro, Y. & Kameda, Y. Concentration of organic sun-blocking agents in seawater of beaches and coral reefs of Okinawa Island, Japan. Mar. Pollut. Bull. 77, 333–340 (2013).

Amine, H., Gomez, E., Halwani, J., Casellas, C. & Fenet, H. UV filters, ethylhexyl methoxycinnamate, octocrylene and ethylhexyl dimethyl PABA from untreated wastewater in sediment from eastern Mediterranean river transition and coastal zones. Mar. Pollut. Bull. 64, 2435–2442 (2012).

Buser, H.-R., Balmer, M. E., Schmid, P. & Kohler, M. Occurrence of UV filters 4-methylbenzylidene camphor and octocrylene in fish from various Swiss rivers with inputs from wastewater treatment plants. Environ. Sci. Technol. 40, 1427–1431 (2006).

Gago-Ferrero, P. et al. First determination of UV filters in marine mammals. Octocrylene levels in Franciscana dolphins. Environ. Sci. Technol. 47, 5619–5625 (2013).

Zhang, Q. Y., Ma, X. Y., Wang, X. C. & Ngo, H. H. Assessment of multiple hormone activities of a UV-filter (octocrylene) in zebrafish (Danio rerio). Chemosphere 159, 433–441 (2016).

Blüthgen, N., Meili, N., Chew, G., Odermatt, A. & Fent, K. Accumulation and effects of the UV-filter octocrylene in adult and embryonic zebrafish (Danio rerio). Sci. Total Environ. 476, 207–217 (2014).

Bury, D. et al. Determination of urinary metabolites of the emerging UV filter octocrylene by online-SPE-LC-MS/MS. Anal. Chem. 90, 944–951 (2018).

Antranikian, G. et al. Diversity of bacteria and archaea from two shallow marine hydrothermal vents from Vulcano Island. Extremophiles 21, 733–742 (2017).

Hennessee, C. T. & Li, Q. X. Effects of polycyclic aromatic hydrocarbon mixtures on degradation, gene expression, and metabolite production in four Mycobacterium species. Appl. Environ. Microbiol. 82, 3357–3369 (2016).

Hennessee, C. T., Seo, J. S., Alvarez, A. M. & Li, Q. X. Polycyclic aromatic hydrocarbon-degrading species isolated from Hawaiian soils: Mycobacterium crocinum sp. Nov., Mycobacterium pallens sp. Nov., Mycobacterium rutilum sp. Nov., Mycobacterium rufum sp. Nov. and Mycobacterium aromaticivorans sp. Nov. Int J. Syst. Evol. Microbiol. 59, 378–387 (2009).

Zeng, J., Lin, X. & Zhang, L. X. Isolation of polycyclic aromatic hydrocarbons (PAHs)-degrading Mycobacterium spp. and the degradation in soil. J. Hazard Mater. 183, 718–723 (2010).

Shen, F.-T. et al. Phylogenetic analysis of members of the metabolically diverse genus Gordonia based on proteins encoding the gyrB gene. Res. Microbiol. 157, 367–375 (2006).

Bury, D., Modick-Biermann, H., Leibold, E., Brüning, T. & Koch, H. M. Urinary metabolites of the UV filter octocrylene in humans as biomarkers of exposure. Arch. Toxicol. 93, 1227–1238 (2019).

Al-Mailem, D. M., Kansour, M. K. & Radwan, S. S. Bioremediation of hydrocarbons contaminating sewage effluent using man-made biofilms: effects of some variables. Appl. Biochem. Biotechnol. 174, 1736–1751 (2014).

Esteban, J. & García-Coca, M. Mycobacterium biofilms. Front. Microbiol. 8, 2651 (2018).

Tsukamura, M. Numerical Analysis of rapidly growing, nonphotochromogenic Mycobacteria, including Mycobacterium agri (Tsukamura 1972) Tsukamura sp. Nov., nom. rev. Int. J. Syst. Bacteriol. 31, 247–258 (2009).

Muyzer, G. DGGE/TGGE a method for identifying genes from natural ecosystems. Curr. Opin. Micro. 2, 317–322 (1999).

Weissgerber, T. L. et al. Data visualization, bar naked: a free tool for creating interactive graphics. J. Biol. Chem. 15, 20592–20598 (2017).

Acknowledgements

The authors thank Andreas Warnstedt for kindly providing environmental samples. Further, thanks are due to Vladimir N. Belov for supply of synthesized standards of octocrylene metabolites.

Author information

Authors and Affiliations

Contributions

M.S. performed all microbiological experiments; A.Si. and A.St. carried out the mass spectrometry analyses; M.S., C.S. and H.F. drafted the paper. M.S., C.S., H.F., M.K., and G.A. designed the experimental setup.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Suleiman, M., Schröder, C., Kuhn, M. et al. Microbial biofilm formation and degradation of octocrylene, a UV absorber found in sunscreen. Commun Biol 2, 430 (2019). https://doi.org/10.1038/s42003-019-0679-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42003-019-0679-9

This article is cited by

-

Microbial consortia degrade several widely used organic UV filters, but a number of hydrophobic filters remain recalcitrant to biodegradation

Environmental Science and Pollution Research (2023)

-

Advanced Treatment Technologies for the Removal of Organic Chemical Sunscreens from Wastewater: a Review

Current Pollution Reports (2022)

-

UV-filter pollution: current concerns and future prospects

Environmental Monitoring and Assessment (2021)

-

A multi-omic screening approach for the discovery of thermoactive glycoside hydrolases

Extremophiles (2021)

-

Computergestützt zu nachhaltiger Bioökonomie

BIOspektrum (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.