Abstract

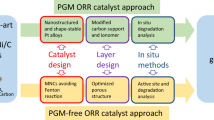

Platinum group metal (PGM)-free electrocatalysts for the oxygen reduction reaction at the polymer electrolyte fuel cell cathode have shown substantial improvements in activity—especially those derived from transition metals, nitrogen and carbon. However, their stability and durability remain insufficient. A key to enabling future improvements and performance comparisons lies in the development of test protocols that are relevant to the operating conditions of the fuel cell cathode, can be completed within a reasonable time and are ubiquitously adopted. Here we propose and validate such protocols, designed with special attention to typical catalyst degradation mechanisms of PGM-free catalysts. The results of the cross-laboratory validation study using two different catalysts attest to the strength and feasibility of the proposed approach. We hope that the information provided here can serve as a broad and effective platform for assessing the performance and durability of PGM-free catalysts for polymer electrolyte fuel cells.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Experimental data used to generate the plots and to support the findings of this study are available from the corresponding author on reasonable request.

References

James, B. Fuel Cell Systems Analysis (US Department of Energy, 2017); https://www.hydrogen.energy.gov/pdfs/review17/fc163_james_2017_o.pdf

Thompson, S. T. & Papageorgopoulos, D. Platinum group metal-free catalysts boost cost competitiveness of fuel cell vehicles. Nat. Catal. 2, 558–561 (2019).

Thompson, S. T. et al. ElectroCat: DOE’s approach to PGM-free catalyst and electrode R&D. Solid State Ion. 319, 68–76 (2018).

Chung, H. T. et al. Direct atomic-level insight into the active sites of a high-performance PGM-free ORR catalyst. Science 357, 479–484 (2017).

Proietti, E. et al. Iron-based cathode catalyst with enhanced power density in polymer electrolyte membrane fuel cells. Nat. Commun. 2, 416 (2011).

Martinez, U. et al. Progress in the development of Fe-based PGM-free electrocatalysts for the oxygen reduction reaction. Adv. Mater. 31, 1806545 (2019).

Chenitz, R. et al. A specific demetalation of Fe–N4 catalytic sites in the micropores of NC_Ar + NH3 is at the origin of the initial activity loss of the highly active Fe/N/C catalyst used for the reduction of oxygen in PEM fuel cells. Energy Environ. Sci. 11, 365–382 (2018).

Choi, C. H. et al. Stability of Fe–N–C catalysts in acidic medium studied by operando spectroscopy. Angew. Chem Int. Ed. 127, 12944–12948 (2015).

Choi, C. H. et al. The Achilles’ heel of iron-based catalysts during oxygen reduction in an acidic medium. Energy Environ. Sci. 11, 3176–3182 (2018).

Osmieri, L. et al. Status and challenges for the application of platinum group metal-free catalysts in proton-exchange membrane fuel cells. Curr. Opin. Electrochem. 25, 100627 (2021).

Multi-Year Research, Development, and Demonstration Plan—Fuel Cells Section (US Department of Energy, 2016).

Borup, R. et al. Scientific aspects of polymer electrolyte fuel cell durability and degradation. Chem. Rev. 107, 3904–3951 (2007).

Borup, R. L. et al. Recent developments in catalyst-related PEM fuel cell durability. Curr. Opin. Electrochem. 21, 192–200 (2020).

Stariha, S. et al. Recent advances in catalyst accelerated stress tests for polymer electrolyte membrane fuel cells. J. Electrochem. Soc. 165, F492 (2018).

Fuel Cell Tech Team Stress Accelerated Test and Polarization Curve Protocols for PEM Fuel Cells (US Department of Energy, 2013).

Wu, G., More, K. L., Johnston, C. M. & Zelenay, P. High-performance electrocatalysts for oxygen reduction derived from polyaniline, iron, and cobalt. Science 332, 443–447 (2011).

Wu, G. et al. Titanium dioxide-supported non-precious metal oxygen reduction electrocatalyst. Chem. Commun. 46, 7489–7491 (2010).

Zelenay, P. Non-Precious Metal Fuel Cell Cathodes: Catalyst Development and Electrode Structure Design (US Department of Energy, 2015); https://www.hydrogen.energy.gov/pdfs/review15/fc107_zelenay_2015_o.pdf

Mukerjee, S., Atanassov, P., Barton, S., Dale, N. & Halevi, B. Development of Novel Non-Pt Group Metal Electrocatalysts for PEM Fuel Cell Applications (US Department of Energy, 2016).

Kumar, K. et al. On the influence of oxygen on the degradation of Fe–N–C Catalysts. Angew. Chem. Int. Ed. 132, 3261–3269 (2020).

Osmieri, L., Cullen, D. A., Chung, H. T., Ahluwalia, R. K. & Neyerlin, K. Durability evaluation of a Fe–N–C catalyst in polymer electrolyte fuel cell environment via accelerated stress tests. Nano Energy 78, 105209 (2020).

Zelenay, P., Myers, D. & Electrocatalysis Consortium. In 2019 Annual Merit Review and Peer Evaluation Meeting (US Department of Energy, 2019); https://www.hydrogen.energy.gov/pdfs/review19/fc160_myers_zelenay_2019_o.pdf

Ahluwalia, R. K. et al. Stability of atomically dispersed Fe–N–C ORR catalyst in polymer electrolyte fuel cell environment. J. Electrochem. Soc. 168, 024513 (2021).

Jia, Q. et al. Experimental observation of redox-induced Fe–N switching behavior as a determinant role for oxygen reduction activity. ACS Nano 9, 12496–12505 (2015).

Li, J., Alsudairi, A., Ma, Z.-F., Mukerjee, S. & Jia, Q. Asymmetric volcano trend in oxygen reduction activity of Pt and non-Pt catalysts: in situ identification of the site-blocking effect. J. Am. Chem. Soc. 139, 1384–1387 (2017).

Zagal, J. H. & Koper, M. T. Reactivity descriptors for the activity of molecular MN4 catalysts for the oxygen reduction reaction. Angew. Chem. Int. Ed. 55, 14510–14521 (2016).

Goellner, V., Armel, V., Zitolo, A., Fonda, E. & Jaouen, F. Degradation by hydrogen peroxide of metal–nitrogen–carbon catalysts for oxygen reduction. J. Electrochem. Soc. 162, H403 (2015).

Baker, D. R., Caulk, D. A., Neyerlin, K. C. & Murphy, M. W. Measurement of oxygen transport resistance in PEM fuel cells by limiting current methods. J. Electrochem. Soc. 156, B991 (2009).

Perry, M. L., Patterson, T. & Reiser, C. Systems strategies to mitigate carbon corrosion in fuel cells. ECS Trans. 3, 783 (2006).

Reiser, C. A. et al. A reverse-current decay mechanism for fuel cells. Electrochem. Solid-State Lett. 8, A273 (2005).

Holby, E. F., Wang, G. & Zelenay, P. Acid stability and demetalation of PGM-free ORR electrocatalyst structures from density functional theory: a model for “single-atom catalyst” dissolution. ACS Catal. 10, 14527–14539 (2020).

Osmieri, L. et al. Utilizing ink composition to tune bulk-electrode gas transport, performance, and operational robustness for a Fe–N–C catalyst in polymer electrolyte fuel cell. Nano Energy 75, 104943, (2020).

Banham, D. et al. Critical advancements in achieving high power and stable nonprecious metal catalyst–based MEAs for real-world proton exchange membrane fuel cell applications. Sci. Adv. 4, eaar7180 (2018).

Lee, J.-S. M., Briggs, M. E., Hu, C.-C. & Cooper, A. I. Controlling electric double-layer capacitance and pseudocapacitance in heteroatom-doped carbons derived from hypercrosslinked microporous polymers. Nano Energy 46, 277–289 (2018).

Frackowiak, E. & Beguin, F. Carbon materials for the electrochemical storage of energy in capacitors. Carbon 39, 937–950 (2001).

Li, G. & Pickup, P. G. Ionic conductivity of PEMFC electrodes: effect of Nafion loading. J. Electrochem. Soc. 150, C745 (2003).

Makharia, R., Mathias, M. F. & Baker, D. R. Measurement of catalyst layer electrolyte resistance in PEFCs using electrochemical impedance spectroscopy. J. Electrochem. Soc. 152, A970 (2005).

Vielstich, W., Lamm, A. & Gasteiger, H. A. Handbook of Fuel Cells: Fundamentals Technology and Applications Vol. 2 (Wiley, 2003).

Zelenay, P., Myers, D. & ElectroCatalysis Consortium. In 2017 Hydrogen and Fuel Cell Program Annual Merit Review Proceedings (US Department of Energy, 2017); https://www.hydrogen.energy.gov/pdfs/review17/fc160_zelenay_2017_o.pdf

Myers, D., Zelenay, P. & Electrocatalysis Consortium. In 2018 Hydrogen and Fuel Cell Program Annual Merit Review Proceedings (US Department of Energy, 2018); https://www.hydrogen.energy.gov/pdfs/review18/fc160_myers_2018_o.pdf

Masten, D. & Bosco, A. in Handbook of Fuel Cells (Wiley, 2010).

Ahluwalia, R., Wang, X. & Steinbach, A. Performance of advanced automotive fuel cell systems with heat rejection constraint. J. Power Sources 309, 178–191 (2016).

Serov, A. et al. Highly stable precious metal-free cathode catalyst for fuel cell application. J. Power Sources 327, 557–564 (2016).

Du, L. et al. Low‐PGM and PGM‐free catalysts for proton exchange membrane fuel cells: stability challenges and material solutions. Adv. Mater. 33, 1908232 (2020).

Shao, Y., Dodelet, J. P., Wu, G. & Zelenay, P. PGM‐free cathode catalysts for PEM fuel cells: a mini‐review on stability challenges. Adv. Mater. 31, 1807615 (2019).

Mauger, S. A. et al. Fabrication of high-performance gas-diffusion-electrode based membrane-electrode assemblies. J. Power Sources 450, 227581 (2020).

Yin, X. et al. Effects of MEA fabrication and ionomer composition on fuel cell performance of PGM-free ORR catalyst. ECS Trans. 77, 1273 (2017).

Cetinbas, F. C. et al. Microstructural analysis and transport resistances of low-platinum-loaded PEFC electrodes. J. Electrochem. Soc. 164, F1596 (2017).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Acknowledgements

Funding was provided by US DOE Office of Energy Efficiency and Renewable Energy, Hydrogen and Fuel Cell Technologies Office, under the ElectroCat Consortium, DOE technology managers D. Peterson and D. Papageorgopolous. This work was authored in part by Los Alamos National Laboratory operated by Triad National Security, LLC under US DOE contract no. 89233218CNA000001, by Argonne National Laboratory, a US DOE Office of Science laboratory operated under contract no. DE-AC02-06CH11357, by the National Renewable Energy Laboratory, managed and operated by the Alliance for Sustainable Energy, LLC, for the US DOE under contract no. DE-AC36-08GO28308, and by Oak Ridge National Laboratory operated by UT-Battelle, LLC, under contract no. DE-AC05-00OR22725. This work used the resources of the Center for Nanophase Materials Sciences, which is a DOE Office of Science User Facility at Oak Ridge National Laboratory and the resources of the APS, a DOE Office of Science User Facility operated by Argonne National Laboratory under contract no. DE-AC36-08GO28308. ICP-OES was performed by Seema Naik of ANL’s Analytical Chemistry Laboratory. The authors wish to thank A. J. Kropf and E. Wegener for acquiring the X-ray absorption spectroscopy data, the staff of the APS’s MR-CAT and MR-CAT’s member institutions, V. D. Andrade of the APS’s 32-ID, and C. F. Cetinbas from Nuclear Science and Engineering Division at ANL for performing X-ray nano-computed tomography experiments. We also gratefully acknowledge the computing resources provided on Blues (and/or Bebop), a high-performance computing cluster operated by the Laboratory Computing Resource Center at ANL. The Talos F200X S/TEM tool was provided by US DOE, Office of Nuclear Energy, Fuel Cycle R&D Program, and the Nuclear Science User Facilities.

Author information

Authors and Affiliations

Contributions

H.Z. performed fuel cell testing at LANL and analysed test data with support from L.O. L.O. fabricated MEAs, carried out XFR measurements and fuel cell testing at NREL. J.H.P performed fuel cell testing at ANL. H.T.C. synthesized the Fe–N–C_LANL catalyst. D.A.C. carried out STEM-EDS experiments. J.H.P. and D.J.M. performed ICP analysis and EXAFS experiments. H.Z., L.O. and J.H.P. prepared the manuscript draft. D.A.C., K.C.N., D.J.M. and P.Z. completed the write-up. K.C.N., D.J.M and P.Z. conceptualized and supervised the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Catalysis thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–11, Tables 1–8, and Notes 1 and 2.

Rights and permissions

About this article

Cite this article

Zhang, H., Osmieri, L., Park, J.H. et al. Standardized protocols for evaluating platinum group metal-free oxygen reduction reaction electrocatalysts in polymer electrolyte fuel cells. Nat Catal 5, 455–462 (2022). https://doi.org/10.1038/s41929-022-00778-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-022-00778-3

This article is cited by

-

Tuning the thermal activation atmosphere breaks the activity–stability trade-off of Fe–N–C oxygen reduction fuel cell catalysts

Nature Catalysis (2023)

-

CO2-mediated organocatalytic chlorine evolution under industrial conditions

Nature (2023)

-

Modifying Fe–N interaction to boost catalytic performance

Nature Catalysis (2023)