Abstract

With the demand for gasoline and diesel expected to decline in the near future, crude-to-chemicals technologies have the potential to become the most important processes in the petrochemical industry. This trend has triggered intense research to maximize the production of light olefins and aromatics at the expense of fuels, which calls for disruptive processes able to transform crude oil to chemicals in an efficient and environmentally friendly way. Here we propose a catalytic reactor concept consisting of a multi-zone fluidized bed that is able to perform several refining steps in a single reactor vessel. This configuration allows for in situ catalyst stripping and regeneration, while the incorporation of silicon carbide in the catalyst confers it with improved physical, mechanical and heat-transport properties. As a result, this reactor–catalyst combination has shown stable conversion of untreated Arabian Light crude into light olefins with yields per pass of over 30 wt% with a minimum production of dry gas.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data presented in this study are included in this published manuscript and its Supplementary Information or are available from the corresponding author upon reasonable request.

References

Murphree, E. V., Brown, C. L., Fischer, H. G. M., Gohr, E. J. & Sweeney, W. J. Fluid catalyst process. Catalytic cracking of petroleum. Ind. Eng. Chem. 35, 768–773 (1943).

Wilson, J. W. Fluid Catalytic Cracking Technology and Operations (PennWell Books, 1997).

World Oil Outlook 2040 (Organization of the Petroleum Exporting Countries, 2019).

Corma, A. et al. Direct crude oil cracking for producing chemicals: thermal cracking modeling. Fuel 211, 726–736 (2018).

Corma, A. et al. Crude oil to chemicals: light olefins from crude oil. Catal. Sci. Technol. 7, 12–46 (2017).

Amghizar, I., Vandewalle, L. A., Van Geem, K. M. & Marin, G. B. New trends in olefin production. Engineering 3, 171–178 (2017).

Geerts, M. et al. Crude to olefins: effect of feedstock composition on coke formation in a bench-scale steam cracking furnace. Ind. Eng. Chem. Res. 59, 2849–2859 (2020).

Alotaibi, F. M. et al. Enhancing the production of light olefins from heavy crude oils: turning challenges into opportunities. Catal. Today 317, 86–98 (2018).

Vogt, E. T. C. & Weckhuysen, B. M. Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis. Chem. Soc. Rev. 44, 7342–7370 (2015).

Knight, J. & Mehlberg, R. Maximize propylene from your FCC unit. Hydrocarb. Process. 90, 91–95 (2011).

Soni, D. S. & Castagnos, L. F. System and method for selective component cracking to maximize production of light olefins. Eur. patent EP1713884 (2005).

Pittman, R. M. & Upson, L. L. FCC process with improved yield of light olefins. US patent US6538169 (2000).

Chaohe, Y., Xiaobo, C., Jinhong, Z., Chunyi, L. & Honghong, S. Advances of two-stage riser catalytic cracking of heavy oil for maximizing propylene yield (TMP) process. Appl. Petrochem. Res. 4, 435–439 (2014).

Steinhofer, A. Make petrochemicals from crude oil. Hydrocarb. Process. Pet. Refiner 44, 134–142 (1965).

Asinger, F. Mono-Olefins: Chemistry and Technology (Elsevier Science, 2013).

朱根权, 李正, 谢朝钢, 鲁维民 (Petroleum hydrocarbon catalytic conversion method for high output of ethylene, propylene and light aromatic hydrocarbons). Chinese patent CN102443423A (2010).

Tullo, A. H. Why the future of oil is in chemicals, not fuels. Chem. Eng. News 97 (2019).

Gascon, J., Tellez, C., Herguido, J., Jakobsen, H. A. & Menéndez, M. Modeling of fluidized bed reactors with two reaction zones. AIChE J. 52, 3911–3923 (2006).

Hupp, S. S. & Swift, H. E. Oxidative coupling of toluene to stilbene. Ind. Eng. Chem. Prod. Res. Dev. 18, 117–122 (1979).

Soler, J., Nieto, J. M. L., Herguido, J., Menéndez, M. & Santamaría, J. Oxidative dehydrogenation of n-butane in a two-zone fluidized-bed reactor. Ind. Eng. Chem. Res. 38, 90–97 (1999).

Rubio, O., Herguido, J. & Menéndez, A. Two-zone fluidized bed reactor for simultaneous reaction and catalyst reoxidation: influence of reactor size. Appl. Catal. A 272, 321–327 (2004).

Gascon, J., Tellez, C., Herguido, J. & Menéndez, A. A two-zone fluidized bed reactor for catalytic propane dehydrogenation. Chem. Eng. J. 106, 91–96 (2005).

Julian, I., Herguido, J. & Menéndez, M. Particle mixing in a two-section two-zone fluidized bed reactor. Experimental technique and counter-current back-mixing model validation. Ind. Eng. Chem. Res. 52, 13587–13596 (2013).

Speight, J. G. & Özüm, B. Petroleum Refining Processes (Marcel Dekker, 2002).

Parthasarathi, R. S. & Alabduljabbar, S. S. HS-FCC high-severity fluidized catalytic cracking: a newcomer to the FCC family. Appl. Petrochem. Res. 4, 441–444 (2014).

den Hollander, M. A., Wissink, M., Makkee, M. & Moulijn, J. A. Gasoline conversion: reactivity towards cracking with equilibrated FCC and ZSM-5 catalysts. Appl. Catal. A 223, 85–102 (2002).

Zhang, J., Shan, H., Chen, X., Li, C. & Yang, C. In situ upgrading of light fluid catalytic cracking naphtha for minimum loss. Ind. Eng. Chem. Res. 52, 6366–6376 (2013).

Siddiqui, M. A. B., Aitani, A. M., Saeed, M. R., Al-Yassir, N. & Al-Khattaf, S. Enhancing propylene production from catalytic cracking of Arabian Light VGO over novel zeolites as FCC catalyst additives. Fuel 90, 459–466 (2011).

Chen, S. & Manos, G. Study of coke and coke precursors during catalytic cracking of n-hexane and 1-hexene over ultrastable Y zeolite. Catal. Lett. 96, 195–200 (2004).

den Hollander, M. A., Makkee, M. & Moulijn, J. A. Coke formation in fluid catalytic cracking studied with the microriser. Catal. Today 46, 27–35 (1998).

Otterstedt, J. E., Gevert, S. B., Jäås, S. G. & Menon, P. G. Fluid catalytic cracking of heavy (residual) oil fractions: a review. Appl. Catal. 22, 159–179 (1986).

Absi-Halabi, M., Stanislaus, A. & Trimm, D. L. Coke formation on catalysts during the hydroprocessing of heavy oils. Appl. Catal. 72, 193–215 (1991).

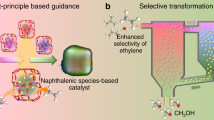

Ramirez, A. et al. Effect of zeolite topology and reactor configuration on the direct conversion of CO2 to light olefins and aromatics. ACS Catal. 9, 6320–6334 (2019).

Chowdhury, A. D. et al. Electrophilic aromatic substitution over zeolites generates Wheland-type reaction intermediates. Nat. Catal. 1, 23–31 (2018).

Qi, G. et al. Behaviors of coke deposition on SAPO-34 catalyst during methanol conversion to light olefins. Fuel Process. Technol. 88, 437–441 (2007).

Zhao, X. B. et al. Achieving a superlong lifetime in the zeolite-catalyzed MTO reaction under high pressure: synergistic effect of hydrogen and water. ACS Catal. 9, 3017–3025 (2019).

Corma, A., Marie, O. & Ortega, F. J. Interaction of water with the surface of a zeolite catalyst during catalytic cracking: a spectroscopy and kinetic study. J. Catal. 222, 338–347 (2004).

Shoinkhorova, T. et al. Shaping of ZSM-5-based catalysts via spray drying: effect on methanol-to-olefins performance. ACS Appl. Mater. Interfaces 11, 44133–44143 (2019).

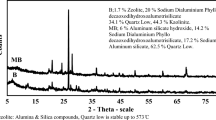

Ghrib, Y. et al. Synthesis of cocrystallized USY/ZSM-5 zeolites from kaolin and its use as fluid catalytic cracking catalysts. Catal. Sci. Technol. 8, 716–725 (2018).

Haas, A., Finger, K.-E. & Alkemade, U. Application of the energy gradient selectivity concept to fluid catalytic cracking catalysts. Appl. Catal. A 115, 103–120 (1994).

Adewuyia, Y. G., Klocke, D. J. & Buchanan, J. S. Effects of high-level additions of ZSM-5 to a fluid catalytic cracking (FCC) RE-USY catalyst. Appl. Catal. A 131, 121–133 (1995).

Rahimi, N. & Karimzadeh, R. Catalytic cracking of hydrocarbons over modified ZSM-5 zeolites to produce light olefins: a review. Appl. Catal. A 398, 1–17 (2011).

Corma, A. et al. Methylcyclohexane and methylcyclohexene cracking over zeolite Y catalysts. Appl. Catal. 67, 307–324 (1990).

Acknowledgements

We acknowledge Saudi Aramco for financial support. Y. Saih, S. Telalovic and L. E. Gevers are gratefully acknowledged for technical support and S. Ramirez Cherbuy for the artwork design.

Author information

Authors and Affiliations

Contributions

J.G. conceived, designed and supervised the project together with M.A. and A.R.-G. All catalytic assessment experiments and data interpretation were carried out by M.A. and A.R.-G. Synthesis and characterization of the ACM-101 catalyst formulation was the responsibility of T.S. and A.D. The ssNMR analysis and data interpretation was performed by A.D.C. and E.A.-H. Thermogravimetric analysis was performed by J.V., M.A., A.R.-G. and I.H. SIMDIS analysis of liquid products was performed by J.V., A.R.-G. and M.A. FT-ICR MS and GC-MS analyses were performed by I.H. and W.Z. CFD simulations were performed by S.R.K. and supervised by P.C. All kinetics simulations for AL/oxygen auto-ignition were the responsibility of S.M.S. Participation in the discussion of results and industrial applicability was contributed by A.B.S., O.S.A., I.M.-O. and W.X. The manuscript was drafted by M.A., A.R.-G. and J.G. with input from all the authors.

Corresponding author

Ethics declarations

Competing interests

Two patent applications (WO2020109885(A1) and provisional application number PCT/IB2020/057120) have been filed by the authors covering different aspects of this work.

Additional information

Peer review information Nature Catalysis thanks Guang Cao, Kevin M. Van Geem and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary methods, discussion, Figs. 1–14, Tables 1–6 and refs. 1–35.

Rights and permissions

About this article

Cite this article

Alabdullah, M., Rodriguez-Gomez, A., Shoinkhorova, T. et al. One-step conversion of crude oil to light olefins using a multi-zone reactor. Nat Catal 4, 233–241 (2021). https://doi.org/10.1038/s41929-021-00580-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-021-00580-7

This article is cited by

-

Green synthesis of propylene oxide directly from propane

Nature Communications (2022)

-

Recent Advances in Catalytic Conversion of C5/C6 Alkanes to Olefins: A Review

Catalysis Surveys from Asia (2022)