Abstract

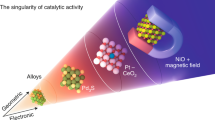

Heterogeneous catalysts control the rates of chemical reactions by changing the energy levels of bound intermediates relative to one another. However, the design flexibility in catalysis is limited by scaling relations: when a catalyst binds one adsorbate more strongly, it tends to bind similar adsorbates more strongly as well. Here we show how strain can break this constraint by employing a mechanics-based eigenstress model to rationalize the effect of strain on adsorbate–catalyst bonding. This model suggests that the sign of the binding-energy response to strain depends on the coupling of the adsorbate-induced eigenstress with the applied strain; thus, tensile strain can make binding either stronger or weaker, depending on the eigenstress characteristics of the adsorbate on the surface. We then suggest how these principles can be used in conjunction with anisotropic strain to engineer opposite responses of adjacent adsorbates to strain; such effects are expected to allow larger changes to reaction rates than predicted by scaling relations.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Stegelmann, C., Andreasen, A. & Campbell, C. T. Degree of rate control: How much the energies of intermediates and transition states control rates. J. Am. Chem. Soc. 131, 8077–8082 (2009).

Nørskov, J. K., Bligaard, T. & Kleis, J. Rate control and reaction engineering. Science 324, 1655–1656 (2009).

Avanesian, T. & Christopher, P. Scaled degree of rate control: identifying elementary steps that control differences in performance of transition-metal catalysts. ACS Catal. 6, 5268–5272 (2016).

Abild-Pedersen, F. et al. Scaling properties of adsorption energies for hydrogen-containing molecules on transition-metal surfaces. Phys. Rev. Lett. 99, 16105 (2007).

Nørskov, J. et al. Universality in heterogeneous catalysis. J. Catal. 209, 275–278 (2002).

Wang, S. et al. Universal transition state scaling relations for (de)hydrogenation over transition metals. Phys. Chem. Chem. Phys. 13, 20760–20765 (2011).

Sutton, J. E. & Vlachos, D. G. A theoretical and computational analysis of linear free energy relations for the estimation of activation energies. ACS Catal. 2, 1624–1634 (2012).

Bronsted, J. N. Acid and basic catalysis. Chem. Rev. 5, 231–338 (1928).

Bell, R. P. The theory of reactions involving proton transfers. Proc. R. Soc. A 154, 414–429 (1936).

Evans, M. G. & Polanyi, M. Inertia and driving force of chemical reactions. Trans. Faraday Soc. 34, 11–24 (1938).

Wang, P. et al. Breaking scaling relations to achieve low-temperature ammonia synthesis through LiH-mediated nitrogen transfer and hydrogenation. Nat. Chem. 9, 64–70 (2017).

Gani, T. Z. H. & Kulik, H. J. Understanding and breaking scaling relations in single-site catalysis: methane to methanol conversion by FeIV=O. ACS Catal. 8, 975–986 (2018).

Calle-Vallejo, F., Krabbe, A. & Garcia-Lastra, J. M. How covalence breaks adsorption-energy scaling relations and solvation restores them. Chem. Sci. 8, 124–130 (2017).

Xu, Y. et al. Effect of Ag on the control of Ni-catalyzed carbon formation: A density functional theory study. Catal. Today 186, 54–62 (2012).

Montemore, M. M. & Medlin, J. W. Scaling relations between adsorption energies for computational screening and design of catalysts. Catal. Sci. Technol. 4, 3748–3761 (2014).

Greeley, J. Theoretical heterogeneous catalysis: scaling relationships and computational catalyst design. Annu. Rev. Chem. Biomol. Eng. 7, 605–635 (2016).

Li, Y. & Sun, Q. Recent advances in breaking scaling relations for effective electrochemical conversion of CO2. Adv. Energy Mater. 6, 1600463 (2016).

Luo, M. & Guo, S. Strain-controlled electrocatalysis on multimetallic nanomaterials. Nat. Rev. Mater. 2, 1–13 (2017).

Weissmüller, J. Electrocapillarity of Solids and its Impact on Heterogeneous Catalysis, 163–220 (Wiley-VCH, Weinheim, 2013).

Deng, Q., Smetanin, M. & Weissmüller, J. Mechanical modulation of reaction rates in electrocatalysis. J. Catal. 309, 351–361 (2014).

Yang, Y., Adit Maark, T., Peterson, A. & Kumar, S. Elastic strain effects on catalysis of a PdCuSi metallic glass thin film. Phys. Chem. Chem. Phys. 17, 1746–1754 (2015).

Yan, K. et al. The influence of elastic strain on catalytic activity in the hydrogen evolution reaction. Angew. Chem. Int. Ed. 55, 6175–6181 (2016).

Yan, K., Kim, S. K., Khorshidi, A., Guduru, P. R. & Peterson, A. A. High elastic strain directly tunes the hydrogen evolution reaction on tungsten carbide. J. Phys. Chem. C. 121, 6177–6183 (2017).

He, J. et al. The effect of surface strain on the CO-poisoned surface of Pt electrode for hydrogen adsorption. J. Catal. 350, 212–217 (2017).

Kibler, L. A., El-Aziz, A. M., Hoyer, R. & Kolb, D. M. Tuning reaction rates by lateral strain in a palladium monolayer. Angew. Chem. Int. Ed. 44, 2080–2084 (2005).

Stafford, G. R. & Bertocci, U. In situ stress and nanogravimetric measurements during underpotential deposition of Pd on (111)-textured Au. J. Phys. Chem. C. 113, 261–268 (2009).

Sethuraman, V. A. et al. Role of elastic strain on electrocatalysis of oxygen reduction reaction on Pt. J. Phys. Chem. C. 119, 19042–19052 (2015).

Strasser, P. et al. Lattice-strain control of the activity in dealloyed core-shell fuel cell catalysts. Nat. Chem. 2, 454–460 (2010).

Hammer, B. & Nørskov, J. K. Electronic factors determining the reactivity of metal surfaces. Surf. Sci. 343, 211–220 (1995).

Mavrikakis, M., Hammer, B. & Nørskov, J. K. Effect of strain on the reactivity of metal surfaces. Phys. Rev. Lett. 81, 2819–2822 (1998).

Kitchin, J. R., Nørskov, J. K., Barteau, M. A. & Chen, J. G. Role of strain and ligand effects in the modification of the electronic and chemical properties of bimetallic surfaces. Phys. Rev. Lett. 93, 156801 (2004).

Adit Maark, T. & Peterson, A. A. Understanding strain and ligand effects in hydrogen evolution over Pd(111) surfaces. J. Phys. Chem. C. 118, 4275–4281 (2014).

Shu, D. J., Liu, F. & Gong, X. G. Simple generic method for predicting the effect of strain on surface diffusion. Phys. Rev. B 64, 245410 (2001).

Sakong, S. & Groß, A. Dissociative adsorption of hydrogen on strained Cu surfaces. Surf. Sci. 525, 107–118 (2003).

Roudgar, A. & Groß, A. Local reactivity of metal overlayers: Density functional theory calculations of Pd on Au. Phys. Rev. B 67, 033409 (2003).

Pala, R. G. S. & Liu, F. Determining the adsorptive and catalytic properties of strained metal surfaces using adsorption-induced stress. J. Chem. Phys. 120, 7720–7724 (2004).

Liu, F., Wu, C., Yang, G. & Yang, S. CO oxidation over strained Pt(100) surface: A DFT study. J. Phys. Chem. C 119, 15500–15505 (2015).

Francis, M. F. & Curtin, W. A. Mechanical work makes important contributions to surface chemistry at steps. Nat. Commun. 6, 6261 (2015).

Deng, Q., Gopal, V. & Weissmüller, J. Less noble or more noble: How strain affects the binding of oxygen on gold. Angew. Chem. Int. Ed. 54, 12981–12985 (2015).

Shuttleworth, I. Strain engineering of H/transition metal systems. Surf. Sci. 661, 49–59 (2017).

Newns, D. M. Self-consistent model of hydrogen chemisorption. Phys. Rev. 178, 1123–1135 (1969).

Montemore, M. M. & Medlin, J. W. Site-specific scaling relations for hydrocarbon adsorption on hexagonal transition metal surfaces. J. Phys. Chem. C. 117, 20078–20088 (2013).

Mura, T. Micromechanics of Defects in Solids (Springer, Dordrecht, 1987).

Shodja, H. & Khorshidi, A. Tensor spherical harmonics theories on the exact nature of the elastic fields of a spherically anisotropic multi-inhomogeneous inclusion. J. Mech. Phys. Solids 61, 1124–1143 (2013).

Callister, W. D. Jr. Materials Science and Engineering: An Introduction (John Wiley & Sons, New York, 1997).

Moss, S. J. & Coady, C. J. Potential-energy surfaces and transition-state theory. J. Chem. Educ. 60, 455 (1983).

Antczak, G. & Ehrlich, G. Surface Diffusion: Metals, Metal Atoms, and Clusters (Cambridge Univ. Press, Cambridge, 2010).

Henkelman, G., Uberuaga, B. P. & Jønsson, H. A climbing image nudged elastic band method for finding saddle points and minimum energy paths. J. Chem. Phys. 113, 9901–9904 (2000).

Feibelman, P. J. & Stumpf, R. Adsorption-induced lattice relaxation and diffusion by concerted substitution. Phys. Rev. B 59, 5892–5897 (1999).

Agrawal, P. M., Rice, B. M. & Thompson, D. L. Predicting trends in rate parameters for self-diffusion on fcc metal surfaces. Surf. Sci. 515, 21–35 (2002).

Feibelman, P. J., Nelson, J. S. & Kellogg, G. L. Energetics of Pt adsorption on Pt(111). Phys. Rev. B 49, 10548–10556 (1994).

Bott, M., Hohage, M., Morgenstern, M., Michely, T. & Comsa, G. New approach for determination of diffusion parameters of adatoms. Phys. Rev. Lett. 76, 1304–1307 (1996).

Kyuno, K., Gölzhäuser, A. & Ehrlich, G. Growth and the diffusion of platinum atoms and dimers on Pt(111). Surf. Sci. 397, 191–196 (1998).

Feibelman, P. J. Interlayer self-diffusion on stepped Pt(111). Phys. Rev. Lett. 81, 168–171 (1998).

Brune, H. et al. Effect of strain on surface diffusion and nucleation. Phys. Rev. B 52, R14380–R14383 (1995).

Wang, H. et al. Direct and continuous strain control of catalysts with tunable battery electrode materials. Science 354, 1031–1036 (2016).

Acknowledgements

The authors are grateful to the Army Research Office (ARO) for funding under Award W911NF-11-1-0353. We benefited from the fruitful discussions with W. A. Curtin at École Polytechnique Fédérale de Lausanne, P. R. Guduru at Brown University, B. Hammer at Aarhus University and H. Ashouri-Choshali at Worcester Polytechnic Institute. High-performance computational work was carried out at Brown’s Center for Computation & Visualization (CCV).

Author information

Authors and Affiliations

Contributions

A.K. and A.A.P. collaboratively designed the research. A.K. and J.V. performed the calculations of self-diffusion on a Pt(100) surface. A.K. performed all other calculations of the paper. A.K. and A.A.P. collaboratively analysed the data, developed the eigenstress model, wrote the paper and prepared revisions. J.H. gave the idea of projecting the d-band along different directions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–5; Supplementary Figures 1–15; Supplementary Tables 1 and 2; Supplementary References

Rights and permissions

About this article

Cite this article

Khorshidi, A., Violet, J., Hashemi, J. et al. How strain can break the scaling relations of catalysis. Nat Catal 1, 263–268 (2018). https://doi.org/10.1038/s41929-018-0054-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-018-0054-0

This article is cited by

-

Nanocurvature-induced field effects enable control over the activity of single-atom electrocatalysts

Nature Communications (2024)

-

Lattice engineered nanoscale Fe0 for selective reductions

Nature Water (2024)

-

Site-specific reactivity of stepped Pt surfaces driven by stress release

Nature (2024)

-

Unusual Sabatier principle on high entropy alloy catalysts for hydrogen evolution reactions

Nature Communications (2024)

-

Understanding mechanical modulation of electrocatalytic reaction with an electrical circuit model

Acta Mechanica Sinica (2024)