Abstract

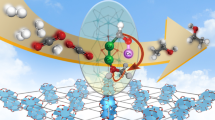

Activating high-energy multiple bonds using earth-abundant metals is one of the most significant challenges in catalysis. Here, we show that LaCoSi—a ternary intermetallic compound—is an efficient and stable catalyst for N2 activation to produce NH3. The ammonia synthesis is significantly promoted by shifting the reaction bottleneck from the sluggish N2 dissociation to NH x formation, which few catalysts have achieved. Theoretical calculations reveal that the negatively charged cobalt mediates electron transfer from lanthanum to the adsorbed N2, which further reduces the activation barrier of N2 dissociation. Most importantly, the specific LaCoSi geometric configuration stabilizes the N2 adsorption with a strong exothermic effect, which dramatically decreases the apparent energy barrier of N2 activation. Consequently, LaCoSi shows a superior activity (1,250 μmol g−1 h−1), with a 60-fold increase over the activity of supported cobalt catalysts under mild reaction conditions (400 °C, 0.1 MPa).

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Dumesic, J. A., Huber G. W. & Boudart, M. Handbook of Heterogeneous Catalysis (Wiley-VCH Verlag, Weinheim, 2008).

Huang, F., Liu, Z. Q. & Yu, Z. K. C-alkylation of ketones and related compounds by alcohols: transition-metal-catalyzed dehydrogenation. Angew. Chem. Int. Ed. 55, 862–875 (2016).

Han, F. S. Transition-metal-catalyzed Suzuki–Miyaura cross-coupling reactions: a remarkable advance from palladium to nickel catalysts. Chem. Soc. Rev. 42, 5270–5298 (2013).

Armbruster, M., Schlogl, R. & Grin, Y. Intermetallic compounds in heterogeneous catalysis—a quickly developing field. Sci. Technol. Adv. Mater. 15, 1–17 (2014).

Armbruster, M. et al. Pd–Ga intermetallic compounds as highly selective semihydrogenation catalysts. J. Am. Chem. Soc. 132, 14745–14747 (2010).

Armbrüster, M. et al. Al13Fe4 as a low-cost alternative for palladium in heterogeneous hydrogenation. Nat. Mater. 11, 690–693 (2012).

Erisman, J. W., Sutton, M. A., Galloway, J., Klimont, Z. & Winiwarter, W. How a century of ammonia synthesis changed the world. Nat. Geosci. 1, 636–639 (2008).

Gambarotta, S. & Scott, J. Multimetallic cooperative activation of N2. Angew. Chem. Int. Ed. 43, 5298–5308 (2004).

Pool, J. A., Lobkovsky, E. & Chirik, P. J. Hydrogenation and cleavage of dinitrogen to ammonia with a zirconium complex. Nature 427, 527–530 (2004).

Aika, K., Ozaki, A. & Hori, H. Activation of nitrogen by alkali metal promoted transition metal I. Ammonia synthesis over ruthenium promoted by alkali metal. J. Catal. 27, 424–431 (1972).

Ozaki, A. Development of alkali-promoted ruthenium as a novel catalyst for ammonia synthesis. Acc. Chem. Res. 14, 16–21 (1981).

Bielawa, H., Hinrichsen, O., Birkner, A. & Muhler, M. The ammonia-synthesis catalyst of the next generation: barium-promoted oxide-supported ruthenium. Angew. Chem. Int. Ed. 40, 1061–1063 (2001).

Ertl, G. Reactions at surfaces: from atoms to complexity (Nobel lecture). Angew. Chem. Int. Ed. 47, 3524–3535 (2008).

Rao, C. N. R. & Rao, G. R. Nature of nitrogen adsorbed on transition metal surfaces as revealed by electron spectroscopy and cognate techniques. Surf. Sci. Rep. 13, 221–263 (1991).

Ertl, G., Lee, S. B. & Weiss, M. Adsorption of nitrogen on potassium promoted Fe(111) and (100) surfaces. Surf. Sci. 114, 527–545 (1982).

Logadottir, A. & Norskov, J. K. Ammonia synthesis over a Ru(0001) surface studied by density functional calculations. J. Catal. 220, 273–279 (2003).

Kitano, M. et al. Electride support boosts nitrogen dissociation over ruthenium catalyst and shifts the bottleneck in ammonia synthesis. Nat. Commun. 6, 6731 (2015).

Wang, P. et al. Breaking scaling relations to achieve low-temperature ammonia synthesis through LiH-mediated nitrogen transfer and hydrogenation. Nat. Chem. 9, 64–70 (2017).

Inoue, Y. et al. Efficient and stable ammonia synthesis by self-organized flat Ru nanoparticles on calcium amide. ACS Catal. 6, 7577–7584 (2016).

Kitano, M. et al. Essential role of hydride ion in ruthenium-based ammonia synthesis catalysts. Chem. Sci. 7, 4036–4043 (2016).

Lu, Y. et al. Water durable electride Y5Si3: electronic structure and catalytic activity for ammonia synthesis. J. Am. Chem. Soc. 138, 3970–3973 (2016).

Kitano, M. et al. Ammonia synthesis using a stable electride as an electron donor and reversible hydrogen store. Nat. Chem. 4, 934–940 (2012).

Mizoguchi, H. et al. Hydride-based electride material, LnH2 (Ln = La, Ce, or Y). Inorg. Chem. 55, 8833–8838 (2016).

Hargreaves, J. S. J. Nitrides as ammonia synthesis catalysts and as potential nitrogen transfer reagents. Appl. Petrochem. Res. 4, 3–10 (2014).

Zeinalipour-Yazdi, C. D., Hargreaves, J. S. J. & Catlow, C. R. A. Nitrogen activation in a Mars–van Krevelen mechanism for ammonia synthesis on Co3Mo3N. J. Phys. Chem. C 119, 28368–28376 (2015).

Laassiri, S., Zeinalipour-Yazdi, C. D., Catlow, C. R. A. & Hargreaves, J. S. J. The potential of manganese nitride based materials as nitrogen transfer reagents for nitrogen chemical looping. Appl. Catal. B Environ. 223, 60–66 (2018).

Wu, J. et al. Tiered electron anions in multiple voids of LaScSi and their applications to ammonia synthesis. Adv. Mater. 29, 1700924 (2017).

Gupta, S. & Suresh, K. G. Review on magnetic and related properties of RTX compounds. J. Alloy. Compd 618, 562–606 (2015).

Welter, R., Venturini, G., Ressouche, E. & Malaman, B. Magnetic properties of RCoSi (R = La–Sm, Gd, Tb) compounds from susceptibility measurements and neutron diffraction studies. J. Alloy. Compd. 210, 279–286 (1994).

Liu, G. et al. MoS2 monolayer catalyst doped with isolated Co atoms for the hydrodeoxygenation reaction. Nat. Chem. 9, 810–816 (2017).

Zhou, J. et al. Synthesis of Co–Sn intermetallic nanocatalysts toward selective hydrogenation of citral. J. Mater. Chem. A 4, 12825–12832 (2016).

Deng, D. et al. A single iron site confined in a graphene matrix for the catalytic oxidation of benzene at room temperature. Sci. Adv. 1, e1500462 (2015).

Yano, J. & Yachandra, V. K. X-ray absorption spectroscopy. Photosynth. Res. 102, 241–254 (2009).

Tang, W., Sanville, E. & Henkelman, G. A grid-based Bader analysis algorithm without lattice bias. J. Phys. Condens. Matter 21, 084204 (2009).

Kakuta, H., Ogawa, T., Takamura, H. & Okada, M. Protium absorption properties of La–TM–Si (TM = Co, Ni) ternary intermetallic compounds. Mater. T. Jim. 39, 769–772 (1998).

Liu, H. Ammonia synthesis catalyst 100 years: practice, enlightenment and challenge. Chin. J. Catal. 35, 1619–1640 (2014).

Kojima, R. & Aika, K. Cobalt molybdenum bimetallic nitride catalysts for ammonia synthesis: Part 1. Preparation and characterization. Appl. Catal. A 215, 149–160 (2001).

Kojima, R. & Aika, K. Cobalt molybdenum bimetallic nitride catalysts for ammonia synthesis: Part 2. Kinetic study. Appl. Catal. A 218, 121–128 (2001).

Takeshita, T., Wallace, W. E. & Craig, R. S. Rare earth intermetallics as synthetic ammonia catalysts. J. Catal. 44, 236–243 (1976).

Hagen, S. et al. Ammonia synthesis with barium-promoted iron–cobalt alloys supported on carbon. J. Catal. 214, 327–335 (2003).

Aika, K. et al. Support and promoter effect of ruthenium catalyst. III. Kinetics of ammonia synthesis over various Ru catalysts. Appl. Catal. 28, 57–68 (1986).

Kobayashi, Y., Kitano, M., Kawamura, S., Yokoyama, T. & Hosono, H. Kinetic evidence: the rate-determining step for ammonia synthesis over electride-supported Ru catalysts is no longer the nitrogen dissociation step. Catal. Sci. Technol. 7, 47–50 (2017).

Jacobsen, C. J. H. et al. Catalyst design by interpolation in the periodic table: bimetallic ammonia synthesis catalysts. J. Am. Chem. Soc. 123, 8404–8405 (2001).

Wang, J. J. et al. Adsorption of atomic and molecular oxygen on 3C-SiC(111) and (111) surfaces: a first-principles study. Phys. Rev. B 79, 125304 (2009).

Vojvodic, A. et al. Exploring the limits: a low-pressure, low-temperature Haber–Bosch process. Chem. Phys. Lett. 598, 108–112 (2014).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Zabinsky, S. I., Rehr, J. J., Ankudinov, A., Albers, R. C. & Eller, M. J. Multiple-scattering calculations of x-ray-absorption spectra. Phys. Rev. B 52, 2995–3009 (1995).

Siporin, S. E. & Davis, R. J. Use of kinetic models to explore the role of base promoters on Ru/MgO ammonia synthesis catalysts. J. Catal. 225, 359–368 (2004).

Kresse, G. & Furthmuller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Acknowledgements

This work was supported by the Accelerated Innovation Research Initiative Turning Top Science and Ideas into High-Impact Values (ACCEL) programme of the Japan Science and Technology Agency. H.H. was supported by the Japan Society for the Promotion of Science through a Grant-in-Aid for Scientific Research (S), No.17H06153. The authors thank S. Fujitsu (Tokyo Institute of Technology) for technical support with the Auger electron spectroscopy measurements.

Author information

Authors and Affiliations

Contributions

H.H. proposed the idea behind the research and supervised the project. Y.G., J.Wu, M.K., T.-N.Y., J.L., K.K. and H.Y. performed the synthesis, characterization and catalytic measurements. J.Wang carried out the model construction and density functional theory calculations. H.A. and Y.N. helped with the X-ray absorption fine-structure measurements. Y.G. and Y.K. performed the kinetic calculations. Y.G., J.Wu, J.Wang and H.H. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Methods; Supplementary Figures 1–29; Supplementary Tables 1–5; Supplementary References

Rights and permissions

About this article

Cite this article

Gong, Y., Wu, J., Kitano, M. et al. Ternary intermetallic LaCoSi as a catalyst for N2 activation. Nat Catal 1, 178–185 (2018). https://doi.org/10.1038/s41929-017-0022-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-017-0022-0

This article is cited by

-

Multiple reaction pathway on alkaline earth imide supported catalysts for efficient ammonia synthesis

Nature Communications (2023)

-

Eliminating nitrogen chemisorption barrier with single-atom supported yttrium cluster via electronic promoting effect for highly efficient ammonia synthesis

Nano Research (2023)

-

Progress and challenges in energy storage and utilization via ammonia

Surface Science and Technology (2023)

-

A spin promotion effect in catalytic ammonia synthesis

Nature Communications (2022)

-

Programmable heating and quenching for efficient thermochemical synthesis

Nature (2022)