Abstract

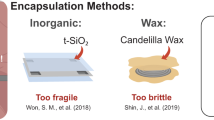

Microelectromechanical systems (MEMS) are essential components in many electronic technologies for consumer and industrial applications. Such devices are typically made using materials selected to support long operational lifetimes, but MEMS designed to physically disintegrate or to dissolve after a targeted period could provide a route to reduce electronic waste and could enable applications that require a finite operating timeframe, such as temporary medical implants. Here we report ecoresorbable and bioresorbable MEMS that are based on fully water-soluble material platforms and can either naturally resorb into the environment to eliminate solid waste or in the body to avoid a need for surgical extraction. We illustrate the biocompatibility of the approach with mechanobiology, histology and haematology studies of the implanted devices and their dissolution end products. We also demonstrate bioresorbable encapsulating materials and deployment strategies in small animal models to reduce device damage, confine mobile fragments and provide robust adhesion with adjacent tissues.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ni, X. et al. Automated, multiparametric monitoring of respiratory biomarkers and vital signs in clinical and home settings for COVID-19 patients. Proc. Natl Acad. Sci. USA 118, e2026610118 (2021).

Lee, K. et al. Mechano-acoustic sensing of physiological processes and body motions via a soft wireless device placed at the suprasternal notch. Nat. Biomed. Eng. 4, 148–158 (2020).

del Rosario, M., Redmond, S. & Lovell, N. Tracking the evolution of smartphone sensing for monitoring human movement. Sensors 15, 18901–18933 (2015).

Brigante, C. M. N., Abbate, N., Basile, A., Faulisi, A. C. & Sessa, S. Towards miniaturization of a MEMS-based wearable motion capture system. IEEE Trans. Ind. Electron. 58, 3234–3241 (2011).

Shasha Liu, P. & Tse, H.-F. Implantable sensors for heart failure monitoring. J. Arrhythmia 29, 314–319 (2013).

Mohd Ghazali, F. A. et al. MEMS actuators for biomedical applications: a review. J. Micromech. Microeng. 30, 073001 (2020).

Potekhina, A. & Wang, C. Review of electrothermal actuators and applications. Actuators 8, 69 (2019).

Zhao, C. et al. A review on coupled MEMS resonators for sensing applications utilizing mode localization. Sens. Actuators A 249, 93–111 (2016).

Totsu, K., Moriyama, M. & Esashi, M. MEMS research is better together. Nat. Electron. 2, 134–136 (2019).

Han, C.-H. et al. MEMS packaging method without any heating or external force using adhesive bonding assisted by capillary force. In 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS) 1221–1224 (IEEE, 2017).

Imboden, M. et al. Building a fab on a chip. Nanoscale 6, 5049–5062 (2014).

Guo, R., Xu, R., Wang, Z., Sui, F. & Lin, L. Accelerating MEMS design process through machine learning from pixelated binary images. In 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS) 153–156 (IEEE, 2021).

Dieseldorff, C. G. & Clark, T. MEMS & Sensors Fab Report to 2023 (2019).

O’Dea, S. Number of smartphones sold to end users worldwide from 2007 to 2021. Gartner https://www.statista.com/statistics/263437/global-smartphone-sales-to-end-users-since-2007/ (2021).

Scansen, D. How MEMS enable smartphone features. Engineering.com https://www.engineering.com/story/how-mems-enable-smartphone-features (2013).

Awasthi, A. K., Li, J., Koh, L. & Ogunseitan, O. A. Circular economy and electronic waste. Nat. Electron. 2, 86–89 (2019).

Fu, J., Zhang, H., Zhang, A. & Jiang, G. E-waste recycling in China: a challenging field. Environ. Sci. Technol. 52, 6727–6728 (2018).

Althaf, S., Babbitt, C. W. & Chen, R. Forecasting electronic waste flows for effective circular economy planning. Resour. Conserv. Recycl. 151, 104362 (2019).

Jambeck, J. R. et al. Plastic waste inputs from land into the ocean. Science 347, 768–771 (2015).

Electronic waste—our greatest threat. Recycle magazine https://www.recycling-magazine.com/2021/02/25/electronic-waste-our-greatest-threat/ (2021).

Irimia-Vladu, M. et al. Green and biodegradable electronics. Mater. Today 15, 340–346 (2012).

Williams, N. X., Bullard, G., Brooke, N., Therien, M. J. & Franklin, A. D. Printable and recyclable carbon electronics using crystalline nanocellulose dielectrics. Nat. Electron. 4, 261–268 (2021).

Hall-Stoodley, L., Costerton, J. W. & Stoodley, P. Bacterial biofilms: from the natural environment to infectious diseases. Nat. Rev. Microbiol. 2, 95–108 (2004).

Maytin, M. & Epstein, L. M. Lead extraction is preferred for lead revisions and system upgrades: when less is more. Circ. Arrhythm. Electrophysiol. 3, 413–424 (2010).

Boutry, C. M. et al. Towards biodegradable wireless implants. Philos. Trans. R. Soc. A 370, 2418–2432 (2012).

Li, C. et al. Design of biodegradable, implantable devices towards clinical translation. Nat. Rev. Mater. 5, 61–81 (2020).

Peroulis, D. et al. CMOS MEMS fabrication technologies. In Encyclopedia of Nanotechnology 441–449 (Springer, 2012).

Baltes, H., Brand, O., Hierlemann, A., Lange, D. & Hagleitner, C. CMOS MEMS—present and future. In Technical Digest. MEMS 2002 IEEE International Conference. Fifteenth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No.02CH37266) 459–466 (IEEE, 2002).

Bettinger, C. J., Bruggeman, J. P., Misra, A., Borenstein, J. T. & Langer, R. Biocompatibility of biodegradable semiconducting melanin films for nerve tissue engineering. Biomaterials 30, 3050–3057 (2009).

Boutry, C. M. et al. A stretchable and biodegradable strain and pressure sensor for orthopaedic application. Nat. Electron. 1, 314–321 (2018).

Jung, Y. H., Zhang, H., Gong, S. & Ma, Z. High-performance green semiconductor devices: materials, designs, and fabrication. Semicond. Sci. Technol. 32, 063002 (2017).

Cao, J. & Nguyen, C. T.-C. Drive amplitude dependence of micromechanical resonator series motional resistance. In 10th International Conference on Solid-State Sensors and Actuators 1826–1829 (1999).

Kaajakari, V., Koskinen, J. K. & Mattila, T. Phase noise in capacitively coupled micromechanical oscillators. IEEE Trans. Ultrason., Ferroelectr., Freq. Control 52, 2322–2331 (2005).

Lu, X. et al. Extreme strain rate and temperature dependence of the mechanical properties of nano silicon nitride thin layers in a basal plane under tension: a molecular dynamics study. Phys. Chem. Chem. Phys. 16, 15551–15557 (2014).

Heinisch, M., Voglhuber-Brunnmaier, T., Reichel, E. K., Dufour, I. & Jakoby, B. Reduced order models for resonant viscosity and mass density sensors. Sens. Actuators A 220, 76–84 (2014).

Cerimovic, S. et al. Sensing viscosity and density of glycerol–water mixtures utilizing a suspended plate MEMS resonator. Microsyst. Technol. 18, 1045–1056 (2012).

Yin, L. et al. Mechanisms for hydrolysis of silicon nanomembranes as used in bioresorbable electronics. Adv. Mater. 27, 1857–1864 (2015).

Kang, S.-K. et al. Biodegradable thin metal foils and spin-on glass materials for transient electronics. Adv. Funct. Mater. 25, 1789–1797 (2015).

Choi, Y. S. et al. Biodegradable polyanhydrides as encapsulation layers for transient electronics. Adv. Funct. Mater. 30, 2000941 (2020).

Chang, J.-K. et al. Cytotoxicity and in vitro degradation kinetics of foundry-compatible semiconductor nanomembranes and electronic microcomponents. ACS Nano 12, 9721–9732 (2018).

Vetter, R. J., Williams, J. C., Hetke, J. F., Nunamaker, E. A. & Kipke, D. R. Chronic neural recording using silicon-substrate microelectrode arrays implanted in cerebral cortex. IEEE Trans. Biomed. Eng. 51, 896–904 (2004).

Shin, J. et al. Bioresorbable pressure sensors protected with thermally grown silicon dioxide for the monitoring of chronic diseases and healing processes. Nat. Biomed. Eng. 3, 37–46 (2019).

Lange, J. R. & Fabry, B. Cell and tissue mechanics in cell migration. Exp. Cell. Res. 319, 2418–2423 (2013).

Canović, E. P., Zollinger, A. J., Tam, S. N., Smith, M. L. & Stamenović, D. Tensional homeostasis in endothelial cells is a multicellular phenomenon. Am. J. Physiol. Cell Physiol. 311, C528–C535 (2016).

Bellas, E. & Chen, C. S. Forms, forces, and stem cell fate. Curr. Opin. Cell Biol. 31, 92–97 (2014).

Taylor-Weiner, H., Ravi, N. & Engler, A. J. Traction forces mediated by integrin signaling are necessary for definitive endoderm specification. J. Cell Sci. 128, 1961–1968 (2015).

Li, B. & Wang, J. H.-C. Fibroblasts and myofibroblasts in wound healing: force generation and measurement. J. Tissue Viability 20, 108–120 (2011).

Emon, B., Bauer, J., Jain, Y., Jung, B. & Saif, T. Biophysics of tumor microenvironment and cancer metastasis—a mini review. Computational Struct. Biotechnol. J. 16, 279–287 (2018).

Bauer, J. et al. Increased stiffness of the tumor microenvironment in colon cancer stimulates cancer associated fibroblast-mediated prometastatic activin A signaling. Sci. Rep. 10, 50 (2020).

Guertin, D. A. & Sabatini, D. M. Cell size control. in Encyclopedia of Life Sciences (John Wiley & Sons, 2006).

Li, J. K.-J. Dynamics of the Vascular System: Interaction with the Heart (World Scientific, 2018).

Yang, Q., Hu, Z. & Rogers, J. A. Functional hydrogel interface materials for advanced bioelectronic devices. Acc. Mater. Res. 2, 1010–1023 (2021).

Yang, Q. et al. Materials, mechanics designs, and bioresorbable multisensor platforms for pressure monitoring in the intracranial space. Adv. Funct. Mater. 30, 1910718 (2020).

Hettiaratchi, M. H. et al. A rapid method for determining protein diffusion through hydrogels for regenerative medicine applications. APL Bioeng. 2, 026110 (2018).

Leach, J. B. & Schmidt, C. E. Characterization of protein release from photocrosslinkable hyaluronic acid-polyethylene glycol hydrogel tissue engineering scaffolds. Biomaterials 26, 125–135 (2005).

Chakraborty, R. et al. Association of body length with ocular parameters in mice. Optom. Vis. Sci. 94, 387–394 (2017).

Chang, J.-K. et al. Materials and processing approaches for foundry-compatible transient electronics. Proc. Natl Acad. Sci. USA 114, E5522–E5529 (2017).

Chang, J.-K. et al. Biodegradable electronic systems in 3D, heterogeneously integrated formats. Adv. Mater. 30, 1704955 (2018).

Schneider, C. A., Rasband, W. S. & Eliceiri, K. W. NIH image to ImageJ: 25 years of image analysis. Nat. Methods 9, 671–675 (2012).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Yang, Q. et al. Photocurable bioresorbable adhesives as functional interfaces between flexible bioelectronic devices and soft biological tissues. Nat. Mater. 20, 1559–1570 (2021).

Tse, J. R. & Engler, A. J. Preparation of hydrogel substrates with tunable mechanical properties. Curr. Protoc. Cell Biol. 47, 10.16.1–10.16.16 (2010).

Knoll, S. G., Ali, M. Y. & Saif, M. T. A. A novel method for localizing reporter fluorescent beads near the cell culture surface for traction force microscopy. J. Vis. Exp. 91, e51873 (2014)

Emon, M. A. B. et al. Dose-independent threshold illumination for non-invasive time-lapse fluorescence imaging of live cells. Extrem. Mech. Lett. 46, 101249 (2021).

Acknowledgements

This work was supported by the Querrey Simpson Institute for Bioelectronics at Northwestern University. We especially thank L. Saggere at the University of Illinois Chicago for helping with the optical characterization of the devices. This work made use of the NUFAB facility of Northwestern University’s NUANCE Center, which has received support from the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-2025633); the MRSEC program (NSF DMR-1720139) at the Materials Research Center; the International Institute for Nanotechnology (IIN); the Keck Foundation; the Querrey Simpson Institute for Bioelectronics; the Keck Biophysics Facility, a shared resource of the Robert H. Lurie Comprehensive Cancer Center of Northwestern University, which has received support in part by the NCI Cancer Center Support (P30 CA060553); the Center for Advanced Molecular Imaging (RRID:SCR_021192); Northwestern University; and the State of Illinois, through the IIN. Elemental analysis was performed at the Northwestern University Quantitative Bio-element Imaging Center generously supported by NASA Ames Research Center Grant (NNA04CC36G). B.E. acknowledges support from the National Institutes of Health (T32 EB019944). M.W. acknowledges support from the National Institutes of Health (T32 AG20506). Y.K. acknowledges support from the National Institutes of Health (R01 NS107539 and R01 MH117111), Beckman Young Investigator Award, Rita Allen Foundation Scholar Award and Searle Scholar Award. M.T.A.S. acknowledges support from the National Science Foundation (ECCS 19-34991) and Illinois Cancer Center seed grant at the University of Illinois at Urbana-Champaign. Y.H. acknowledges support from the National Science Foundation (CMMI 16-35443). The diagrams in Figs. 4a and 5a are created with BioRender (https://biorender.com/).

Author information

Authors and Affiliations

Contributions

Q.Y., J.-K.C. and J.A.R. conceived the ideas and designed the research. Q.Y., T.-L.L., Y. Xue and Y.C. designed the devices. Q.Y., T.-L.L., Y. Xu, C.R., T.W., C.C., Z.H., C.W., M.H. and J.M.T. fabricated and characterized the devices. Y. Xue, H.W. and Y.H. performed the numerical simulations. B.E., M.W., I.K., C.R.H., A.B., I.S., J.H., R.A.S., L.L., Y.K. and M.T.A.S. performed the in vitro and in vivo studies. Q.Y., T.-L.L., Y. Xu, B.E., C.R., T.W. and J.H. performed the data analysis. Q.Y., J.-K.C. and J.A.R. wrote the manuscript with input from all the authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Electronics thanks Christopher Bettinger, Roozbeh Tabrizian and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–8, Tables 1–3 and Figs. 1–31.

Supplementary Video 1

Displacement vector plot of a cell in the presence of MP extracts.

Supplementary Video 2

Displacement vector plot of a cell in the presence of TP extracts.

Supplementary Video 3

Displacement vector plot of a cell in the control group.

Supplementary Video 4

Top view of stress distribution during the transfer printing process in simulation.

Supplementary Video 5

Side view of stress distribution during the transfer printing process in simulation.

Rights and permissions

About this article

Cite this article

Yang, Q., Liu, TL., Xue, Y. et al. Ecoresorbable and bioresorbable microelectromechanical systems. Nat Electron 5, 526–538 (2022). https://doi.org/10.1038/s41928-022-00791-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-022-00791-1

This article is cited by

-

Advances in 3D silicon-based lithium-ion microbatteries

Communications Materials (2024)

-

Ultra-stretchable and biodegradable elastomers for soft, transient electronics

Nature Communications (2023)

-

Neuromorphic computing based on halide perovskites

Nature Electronics (2023)

-

Low-temperature processing of screen-printed piezoelectric KNbO3 with integration onto biodegradable paper substrates

Microsystems & Nanoengineering (2023)

-

Applications of MXenes in human-like sensors and actuators

Nano Research (2023)