Abstract

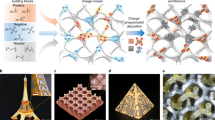

Electronic devices are typically manufactured in planar layouts, but many emerging applications, from optoelectronics to wearables, require three-dimensional curvy structures. However, the fabrication of such structures has proved challenging due, in particular, to the lack of an effective manufacturing technology. Here, we show that conformal additive stamp (CAS) printing technology can be used to reliably manufacture three-dimensional curvy electronics. CAS printing employs a pneumatically inflated elastomeric balloon as a conformal stamping medium to pick up pre-fabricated electronic devices and print them onto curvy surfaces. To illustrate the capabilities of the approach, we use it to create various devices with curvy shapes: silicon pellets, photodetector arrays, electrically small antennas, hemispherical solar cells and smart contact lenses. We also show that CAS printing can be used to print onto arbitrary three-dimensional surfaces.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request.

References

Dinyari, R., Rim, S.-B., Huang, K., Catrysse, P. B. & Peumans, P. Curving monolithic silicon for nonplanar focal plane array applications. Appl. Phys. Lett. 92, 091114 (2008).

Hung, P. J., Jeong, K., Liu, G. L. & Lee, L. P. Microfabricated suspensions for electrical connections on the tunable elastomer membrane. Appl. Phys. Lett. 85, 6051–6053 (2004).

Song, Y. M. et al. Digital cameras with designs inspired by the arthropod eye. Nature 497, 95–99 (2013).

Jeong, K.-H., Kim, J. & Lee, L. P. Biologically inspired artificial compound eyes. Science 312, 557–561 (2006).

Kim, J. et al. Wearable smart sensor systems integrated on soft contact lenses for wireless ocular diagnostics. Nat. Commun. 8, 14997 (2017).

Farandos, N. M., Yetisen, A. K., Monteiro, M. J., Lowe, C. R. & Yun, S. H. Contact lens sensors in ocular diagnostics. Adv. Healthc. Mater. 4, 792–810 (2015).

Vásquez Quintero, A., Verplancke, R., De Smet, H. & Vanfleteren, J. Stretchable electronic platform for soft and smart contact lens applications. Adv. Mater. Technol. 2, 1700073 (2017).

Adams, J. J. et al. Conformal printing of electrically small antennas on three‐dimensional surfaces. Adv. Mater. 23, 1335–1340 (2011).

Kim, O. S. Low-Q electrically small spherical magnetic dipole antennas. IEEE Trans. Antennas Propag. 58, 2210–2217 (2010).

Abadia, J., Merli, F., Zurcher, J.-F., Mosig, J. R. & Skrivervik, A. K. 3D-spiral small antenna design and realization for biomedical telemetry in the MICS band. Radioengineering 18, 359–367 (2009).

Boncheva, M. et al. Magnetic self-assembly of three-dimensional surfaces from planar sheets. Proc. Natl Acad. Sci. USA 102, 3924–3929 (2005).

Guo, X. et al. Two-and three-dimensional folding of thin film single-crystalline silicon for photovoltaic power applications. Proc. Natl Acad. Sci. USA 106, 20149–20154 (2009).

Xu, W. et al. Ultrathin thermoresponsive self-folding 3D graphene. Sci. Adv. 3, e1701084 (2017).

Liu, Y., Shaw, B., Dickey, M. D. & Genzer, J. Sequential self-folding of polymer sheets. Sci. Adv. 3, e1602417 (2017).

Mei, J., Lovell, M. R. & Mickle, M. H. Formulation and processing of novel conductive solution inks in continuous inkjet printing of 3-D electric circuits. IEEE Trans. Electron. Packag. Manuf. 28, 265–273 (2005).

Seong, B. et al. Metal-mesh based transparent electrode on a 3-D curved surface by electrohydrodynamic jet printing. J. Micromech. Microeng. 24, 097002 (2014).

An, B. W. et al. Direct printing of reduced graphene oxide on planar or highly curved surfaces with high resolutions using electrohydrodynamics. Small 11, 2263–2268 (2015).

Lee, S. et al. Electroless deposition-assisted 3D printing of micro circuitries for structural electronics. ACS Appl. Mater. Interfaces 11, 7123–7130 (2019).

Tan, H. W., An, J., Chua, C. K. & Tran, T. Metallic nanoparticle inks for 3D printing of electronics. Adv. Electron. Mater. 5, 1800831 (2019).

Mohammed, M. G. & Kramer, R. All‐printed flexible and stretchable electronics. Adv. Mater. 29, 1604965 (2017).

Kwon, J. et al. Three-dimensional monolithic integration in flexible printed organic transistors. Nat. Commun. 10, 54 (2019).

Ko, H. C. et al. Curvilinear electronics formed using silicon membrane circuits and elastomeric transfer elements. Small 5, 2703–2709 (2009).

Ko, H. C. et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 454, 748–753 (2008).

Huang, C. C. et al. Large field of view wide spectrum artificial reflecting superposition compound eyes. Small 10, 3050–3057 (2014).

Wu, H. et al. Conformal pad-printing electrically conductive composites onto thermoplastic hemispheres: toward sustainable fabrication of 3-cents volumetric electrically small antennas. PLoS ONE 10, e0136939 (2015).

Sim, K. et al. High fidelity tape transfer printing based on chemically induced adhesive strength modulation. Sci. Rep. 5, 16133 (2015).

Sim, K., Li, Y., Song, J. & Yu, C. Biaxially stretchable ultrathin Si enabled by serpentine structures on prestrained elastomers. Adv. Mater. Technol. 4, 1800489 (2019).

Sim, K., Rao, Z., Li, Y., Yang, D. & Yu, C. Curvy surface conformal ultra-thin transfer printed Si optoelectronic penetrating microprobe arrays. npj Flex. Electron. 2, 2 (2018).

Gao, Y. et al. Crack-insensitive wearable electronics enabled through high-strength kevlar fabrics. IEEE Trans. Compon. Packag. Manuf. Technol. 5, 1230–1236 (2015).

Xu, S. et al. Assembly of micro/nanomaterials into complex, three-dimensional architectures by compressive buckling. Science 347, 154–159 (2015).

Wang, X. et al. Freestanding 3D mesostructures, functional devices, and shape-programmable systems based on mechanically induced assembly with shape memory polymers. Adv. Mater. 31, 1805615 (2019).

Zhang, Y. et al. A mechanically driven form of kirigami as a route to 3D mesostructures in micro/nanomembranes. Proc. Natl Acad. Sci. USA 112, 11757–11764 (2015).

Humood, M. et al. Fabrication and deformation of 3D multilayered kirigami microstructures. Small 14, 1703852 (2018).

Qian, C. et al. High‐performance organic heterojunction phototransistors based on highly ordered copper phthalocyanine/para‐sexiphenyl thin films. Adv. Funct. Mater. 27, 1604933 (2017).

Noh, Y.-Y., Kim, D.-Y. & Yase, K. Highly sensitive thin-film organic phototransistors: effect of wavelength of light source on device performance. J. Appl. Phys. 98, 074505 (2005).

Adams, J., Slimmer, S. C., Lewis, J. & Bernhard, J. 3D-printed spherical dipole antenna integrated on small RF node. Electron. Lett. 51, 661–662 (2015).

Toriz-Garcia, J. et al. Fabrication of a 3D electrically small antenna using holographic photolithography. J. Micromech. Microeng. 23, 055010 (2013).

Liu, F. et al. High performance, tunable electrically small antennas through mechanically guided 3D assembly. Small 15, 1804055 (2019).

Lamoureux, A., Lee, K., Shlian, M., Forrest, S. R. & Shtein, M. Dynamic kirigami structures for integrated solar tracking. Nat. Commun. 6, 8092 (2015).

Maruyama, T. & Minami, H. Light trapping in spherical silicon solar cell module. Sol. Energy Mater. Sol. Cells 79, 113–124 (2003).

Minemoto, T., Murozono, M., Yamaguchi, Y., Takakura, H. & Hamakawa, Y. Design strategy and development of spherical silicon solar cell with semi-concentration reflector system. Sol. Energy Mater. Sol. Cells 90, 3009–3013 (2006).

Meitl, M. A. et al. Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 5, 33–38 (2005).

Markvart, T. & Castaner, L. in Solar Cells: Materials, Manufacture and Operation 2nd edn (eds McEvoy, A. et al.) Ch. IA-1 (Academic Press, 2012).

Park, J. et al. Soft, smart contact lenses with integrations of wireless circuits, glucose sensors, and displays. Sci. Adv. 4, eaap9841 (2018).

Thomas, N., Lähdesmäki, I. & Parviz, B. A. A contact lens with an integrated lactate sensor. Sens. Actuators B 162, 128–134 (2012).

Gugleta, K., Orgül, S. & Flammer, J. Is corneal temperature correlated with blood-flow velocity in the ophthalmic artery? Curr. Eye Res. 19, 496–501 (1999).

House, J. L., Anderson, E. M. & Ward, W. K. Immobilization techniques to avoid enzyme loss from oxidase-based biosensors: a one-year study. J. Diabetes Sci. Technol. 1, 18–27 (2007).

Marzouk, S. A. et al. Amperometric monitoring of lactate accumulation in rabbit ischemic myocardium. Talanta 44, 1527–1541 (1997).

Kausaite-Minkstimiene, A., Mazeiko, V., Ramanaviciene, A. & Ramanavicius, A. Enzymatically synthesized polyaniline layer for extension of linear detection region of amperometric glucose biosensor. Biosens. Bioelectron. 26, 790–797 (2010).

Yu, J., Liu, S. & Ju, H. Glucose sensor for flow injection analysis of serum glucose based on immobilization of glucose oxidase in titania sol–gel membrane. Biosens. Bioelectron. 19, 401–409 (2003).

Puggioni, G. et al. Low-temperature storage improves the over-time stability of implantable glucose and lactate biosensors. Sensors 19, 422 (2019).

Kim, J. et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 5, 5747 (2014).

Webb, R. C. et al. Ultrathin conformal devices for precise and continuous thermal characterization of human skin. Nat. Mater. 12, 938–944 (2013).

Yu, C. et al. Adaptive optoelectronic camouflage systems with designs inspired by cephalopod skins. Proc. Natl Acad. Sci. USA 111, 12998–13003 (2014).

Acknowledgements

C.Y. thanks the funding support by National Science Foundation (ECCS-1509763 and CMMI-1554499), startup fund and the Bill D. Cook faculty scholarship from the Department of Mechanical Engineering at University of Houston.

Author information

Authors and Affiliations

Contributions

K.S., S.C. and C.Y. conceived and designed the experiment. K.S., S.C., Z.R., J.L., Y.L. and S.J. performed the experiment. Z.L. and J.X. performed numerical analysis. K.S., J.C. and C.Y. analysed experimental data. K.S., Z.L., J.X., F.E. and C.Y. wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–4, Table 1 and Figs. 1–44.

Rights and permissions

About this article

Cite this article

Sim, K., Chen, S., Li, Z. et al. Three-dimensional curvy electronics created using conformal additive stamp printing. Nat Electron 2, 471–479 (2019). https://doi.org/10.1038/s41928-019-0304-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-019-0304-4

This article is cited by

-

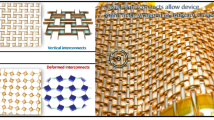

Multilayer stretchable electronics with designs enabling a compact lateral form

npj Flexible Electronics (2024)

-

Vertical serpentine interconnect-enabled stretchable and curved electronics

Microsystems & Nanoengineering (2023)

-

Low-cost fully additively manufactured passive microwave components exploiting available 3D flexibility

Scientific Reports (2023)

-

Localizing strain via micro-cage structure for stretchable pressure sensor arrays with ultralow spatial crosstalk

Nature Communications (2023)

-

Ultra-conformable liquid metal particle monolayer on air/water interface for substrate-free E-tattoo

npj Flexible Electronics (2023)