Abstract

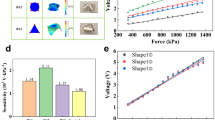

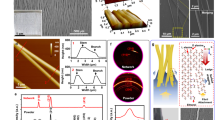

Piezoelectric microsystems are of use in areas such as mechanical sensing, energy conversion and robotics. The systems typically have a planar structure, but transforming them into complex three-dimensional (3D) frameworks could enhance and extend their various modes of operation. Here, we report a controlled, nonlinear buckling process to convert lithographically defined two-dimensional patterns of electrodes and thin films of piezoelectric polymers into sophisticated 3D piezoelectric microsystems. To illustrate the engineering versatility of the approach, we create more than twenty different 3D geometries. With these structures, we then demonstrate applications in energy harvesting with tailored mechanical properties and root-mean-square voltages ranging from 2 mV to 790 mV, in multifunctional sensors for robotic prosthetic interfaces with improved responsivity (for example, anisotropic responses and sensitivity of 60 mV N−1 for normal force), and in bio-integrated devices with in vivo operational capabilities. The 3D geometries, especially those with ultralow stiffnesses or asymmetric layouts, yield unique mechanical attributes and levels of functionality that would be difficult or impossible to achieve with conventional two-dimensional designs.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request.

References

Kim, D. H. et al. Epidermal electronics. Science 333, 838–843 (2011).

Larson, C. et al. Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 351, 1071–1074 (2016).

Tian, B. et al. Macroporous nanowire nanoelectronic scaffolds for synthetic tissues. Nat. Mater. 11, 986–994 (2012).

Hwang, G. T. et al. Self-powered cardiac pacemaker enabled by flexible single crystalline PMN-PT piezoelectric energy harvester. Adv. Mater. 26, 4880–4887 (2014).

Fan, F. R., Tian, Z. Q. & Lin Wang, Z. Flexible triboelectric generator. Nano Energy 1, 328–334 (2012).

Yin, J. et al. Generating electricity by moving a droplet of ionic liquid along graphene. Nat. Nanotech. 9, 378–383 (2014).

Jinno, H. et al. Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat. Energy 2, 780–785 (2017).

Zhao, J. et al. Air-stable and freestanding lithium alloy/graphene foil as an alternative to lithium metal anodes. Nat. Nanotech. 12, 993–999 (2017).

Li, M., Tang, H. X. & Roukes, M. L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotech. 2, 114–120 (2007).

Kan, T. et al. Enantiomeric switching of chiral metamaterial for terahertz polarization modulation employing vertically deformable MEMS spirals. Nat. Commun. 6, 8422 (2015).

Nguyen, T. D. et al. Piezoelectric nanoribbons for monitoring cellular deformations. Nat. Nanotech. 7, 587–593 (2012).

Wu, W., Wen, X. & Wang, Z. L. Taxel-addressable matrix of vertical-nanowire piezotronic transistors for active and adaptive tactile imaging. Science 340, 952–957 (2013).

Yu, X. et al. Needle-shaped ultrathin piezoelectric microsystem for guided tissue targeting via mechanical sensing. Nat. Biomed. Eng. 2, 162–172 (2018).

Yang, J. M. et al. Simultaneous functional photoacoustic and ultrasonic endoscopy of internal organs in vivo. Nat. Med. 18, 1297–1302 (2012).

Hu, H. et al. Stretchable ultrasonic transducer arrays for three-dimensional imaging on complex surfaces. Sci. Adv. 4, eaar3979 (2018).

Wang, X., Song, J., Liu, J. & Zhong, L. W. Direct-current nanogenerator driven by ultrasonic waves. Science 316, 102–105 (2007).

Dagdeviren, C. et al. Conformal piezoelectric energy harvesting and storage from motions of the heart, lung, and diaphragm. Proc. Natl Acad. Sci. USA 111, 1927–1932 (2014).

Baek, S. H. et al. Giant piezoelectricity on Si for hyperactive MEMS. Science 334, 958–961 (2011).

Ma, K. Y., Chirarattananon, P., Fuller, S. B. & Wood, R. J. Controlled flight of a biologically inspired, insect-scale robot. Science 340, 603–607 (2013).

You, Y. M. et al. An organic-inorganic perovskite ferroelectric with large piezoelectric response. Science 357, 306–309 (2017).

Curry, E. J. et al. Biodegradable piezoelectric force sensor. Proc. Natl Acad. Sci. USA 115, 909–914 (2018).

Wu, W. et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 514, 470–474 (2014).

Zhu, H. et al. Observation of piezoelectricity in free-standing monolayer MoS2. Nat. Nanotech. 10, 151–155 (2015).

Lee, B. Y. et al. Virus-based piezoelectric energy generation. Nat. Nanotech. 7, 351–356 (2012).

Chen, X., Mahadevan, L., Driks, A. & Sahin, O. Bacillus spores as building blocks for stimuli-responsive materials and nanogenerators. Nat. Nanotech. 9, 137–141 (2014).

Li, M. et al. Revisiting the δ-phase of poly(vinylidene fluoride) for solution-processed ferroelectric thin films. Nat. Mater. 12, 433–438 (2013).

Li, F. et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 17, 349–354 (2018).

Yan, Y., Zhou, J. E., Maurya, D., Wang, Y. U. & Priya, S. Giant piezoelectric voltage coefficient in grain-oriented modified PbTiO3 material. Nat. Commun. 7, 13089 (2016).

Qin, Y., Wang, X. & Wang, Z. L. Microfibre-nanowire hybrid structure for energy scavenging. Nature 451, 809–813 (2008).

Qi, Y. et al. Enhanced piezoelectricity and stretchability in energy harvesting devices fabricated from buckled PZT ribbons. Nano. Lett. 11, 1331–1336 (2011).

Han, M. et al. r-shaped hybrid nanogenerator with enhanced piezoelectricity. ACS Nano 7, 8554–8560 (2013).

Saadon, S. & Sidek, O. A review of vibration-based MEMS piezoelectric energy harvesters. Energy Convers. Manag. 52, 500–504 (2011).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Cavallo, F. & Lagally, M. G. Nano-origami: Art and function. Nano Today 10, 538–541 (2015).

Sydney Gladman, A., Matsumoto, E. A., Nuzzo, R. G., Mahadevan, L. & Lewis, J. A. Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016).

Xu, S. et al. Assembly of micro/nanomaterials into complex, three-dimensional architectures by compressive buckling. Science 347, 154–159 (2015).

Yan, Z. et al. Mechanical assembly of complex, 3D mesostructures from releasable multilayers of advanced materials. Sci. Adv. 2, e1601014 (2016).

Yan, Z. et al. Deterministic assembly of 3D mesostructures in advanced materials via compressive buckling: A short review of recent progress. Extrem. Mech. Lett. 11, 96–104 (2017).

Fu, H. et al. Morphable 3D mesostructures and microelectronic devices by multistable buckling mechanics. Nat. Mater. 17, 268–276 (2018).

Lee, W. et al. Two-dimensional materials in functional three-dimensional architectures with applications in photodetection and imaging. Nat. Commun. 9, 1417 (2018).

Zhang, Y. et al. Printing, folding and assembly methods for forming 3D mesostructures in advanced materials. Nat. Rev. Mater. 2, 17019 (2017).

Wang, S. et al. Mechanics of curvilinear electronics. Soft Matter 6, 5757–5763 (2010).

Persson, B. N. J., Albohr, O., Tartaglino, U., Volokitin, A. I. & Tosatti, E. On the nature of surface roughness with application to contact mechanics, sealing, rubber friction and adhesion. J. Phys. Condens. Matter 17, 1–62 (2005).

Yin, S. et al. Measuring single cardiac myocyte contractile force via moving a magnetic bead. Biophys. J. 88, 1489–1495 (2005).

Raman, R. et al. Optogenetic skeletal muscle-powered adaptive biological machines. Proc. Natl Acad. Sci. USA 113, 3497–3502 (2016).

Ning, X. et al. 3D tunable, multiscale, and multistable vibrational micro-platforms assembled by compressive buckling. Adv. Funct. Mater. 27, 1605914 (2017).

Kulah, H. & Najafi, K. Energy scavenging from low-frequency vibrations by using frequency up-conversion for wireless sensor applications. IEEE Sens. J. 8, 261–268 (2008).

Zi, Y. et al. Harvesting low-frequency ( < 5 Hz) irregular mechanical energy: A possible killer application of triboelectric nanogenerator. ACS Nano 10, 4797–4805 (2016).

Humood, M. et al. Fabrication and deformation of 3D multilayered kirigami microstructures. Small 14, 1703852 (2018).

Ranzani, T., Gerboni, G., Cianchetti, M. & Menciassi, A. A bioinspired soft manipulator for minimally invasive surgery. Bioinspir. Biomim. 10, 035008 (2015).

Acknowledgements

J.A.R. acknowledges support from the US Department of Energy, Office of Science, Basic Energy Sciences (DE-FG02-07ER46471). Y.Z. acknowledges support from the National Natural Science Foundation of China (11722217) and the Tsinghua National Laboratory for Information Science and Technology. Y.H. acknowledges support from the NSF (CMMI1400169, CMMI1534120 and CMMI1635443). Y.X. acknowledges support from the Ryan Fellowship and the Northwestern University International Institute for Nanotechnology.

Author information

Authors and Affiliations

Contributions

M.H., H.W., Z.Y., Y.Z., Y.H. and J.A.R. conceived the idea and designed the research. M.H., Y.Y., C.L., Z.Y. and J.L. performed micro-fabrication of all structures and devices. M.H., C.L., W.B. and H.Z. performed measurements and analysed the experimental data. M.H., W.B. and I.K. evaluated the devices in animal models. X.W. and B.A. performed cell seeding and cell viability assay under the supervision of G.A.A. H.W., Y.Z. and Y.H. led the mechanical modelling and theoretical studies, with assistance from H. Li. Y.X. and H. Luan. M.H., H.W., Y.Z., Y.H. and J.A.R. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–4 and Supplementary Figures 1–46

Supplementary Video 1

Output signals from the 2D piezoelectric device with a mouse moving freely inside the enclosure.

Supplementary Video 2

Output signals from the 3D piezoelectric device with a mouse moving freely inside the enclosure.

Rights and permissions

About this article

Cite this article

Han, M., Wang, H., Yang, Y. et al. Three-dimensional piezoelectric polymer microsystems for vibrational energy harvesting, robotic interfaces and biomedical implants. Nat Electron 2, 26–35 (2019). https://doi.org/10.1038/s41928-018-0189-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-018-0189-7

This article is cited by

-

Multilayer stretchable electronics with designs enabling a compact lateral form

npj Flexible Electronics (2024)

-

Motion artefact management for soft bioelectronics

Nature Reviews Bioengineering (2024)

-

Designing transparent piezoelectric metasurfaces for adaptive optics

Nature Communications (2024)

-

Kirigami-inspired, three-dimensional piezoelectric pressure sensors assembled by compressive buckling

npj Flexible Electronics (2024)

-

An Extensive Review of Piezoelectric Energy-Harvesting Structures Utilizing Auxetic Materials

Journal of Vibration Engineering & Technologies (2024)