Abstract

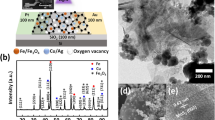

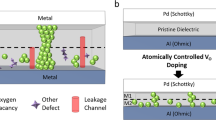

Van der Waals heterostructures are formed by stacking layers of different two-dimensional materials and offer the possibility to design new materials with atomic-level precision. By combining the valuable properties of different 2D systems, such heterostructures could potentially be used to address existing challenges in the development of electronic devices, particularly those that require vertical multi-layered structures. Here we show that robust memristors with good thermal stability, which is lacking in traditional memristors, can be created from a van der Waals heterostructure composed of graphene/MoS2–xO x /graphene. The devices exhibit excellent switching performance with an endurance of up to 107 and a high operating temperature of up to 340 °C. With the help of in situ electron microscopy, we show that the thermal stability is due to the MoS2–xO x switching layer, as well as the graphene electrodes and the atomically sharp interface between the electrodes and the switching layer. We also show that the devices have a well-defined conduction channel and a switching mechanism that is based on the migration of oxygen ions. Finally, we demonstrate that the memristor devices can be fabricated on a polyimide substrate and exhibit good endurance against over 1,000 bending cycles, illustrating their potential for flexible electronic applications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Change history

09 March 2018

In the version of this Article originally published, the author Xiaoqing Pan's two affiliations with the University of California, Irvine, were mistakenly omitted. They are: Department of Chemical Engineering and Materials Science, University of California, Irvine, CA, USA; Department of Physics and Astronomy, University of California, Irvine, CA, USA. These have now been included in the Article.

References

Chua, L. O. Memristor - Missing circuit element. IEEE Trans. Circuit Theory 18, 507–519 (1971).

Strukov, D. B., Snider, G. S., Stewart, D. R. & Williams, R. S. The missing memristor found. Nature 453, 80–83 (2008).

Yang, J. J. et al. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotech. 3, 429–433 (2008).

Waser, R. & Aono, M. Nanoionics-based resistive switching memories. Nat. Mater. 6, 833–840 (2007).

Wong, H. S. P. et al. Metal-oxide RRAM. Proc. IEEE 100, 1951–1970 (2012).

Yang, J. J., Strukov, D. B. & Stewart, D. R. Memristive devices for computing. Nat. Nanotech. 8, 13–24 (2013).

Jo, S. H. et al. Nanoscale memristor device as synapse in neuromorphic systems. Nano Lett. 10, 1297–1301 (2010).

Tuma, T., Pantazi, A., Le Gallo, M., Sebastian, A. & Eleftheriou, E. Stochastic phase-change neurons. Nat. Nanotech. 11, 693–699 (2016).

Prezioso, M. et al. Training andoperation of an integrated neuromorphic network based on metal-oxide memristors. Nature 521, 61–64 (2015).

Wang, Z. et al. Memristors with diffusive dynamics as synaptic emulators for neuromorphic computing. Nat. Mater. 16, 101–108 (2017).

Kozicki, M. N., Park, M. & Mitkova, M. Nanoscale memory elements based on solid-state electrolytes. IEEE Trans. Nanotechnol. 4, 331–338 (2005).

Szot, K., Speier, W., Bihlmayer, G. & Waser, R. Switching the electrical resistance of individual dislocations in single-crystalline SrTiO3. Nat. Mater. 5, 312–320 (2006).

Terabe, K., Hasegawa, T., Nakayama, T. & Aono, M. Quantized conductance atomic switch. Nature 433, 47–50 (2005).

Rozenberg, M. J., Inoue, I. H. & Sanchez, M. J. Nonvolatile memory with multilevel switching: A basic model. Phys. Rev. Lett. 92, 178302 (2004).

Lee, M. et al. A fast, high-endurance and scalable non-volatile memory device made from asymmetric Ta2O5-x/TaO2-x bilayer structures. Nat. Mater. 10, 625–630 (2011).

Miao, F. et al. Anatomy of a nanoscale conduction channel reveals the mechanism of a high-performance memristor. Adv. Mater. 23, 5633–5640 (2011).

Kwon, D. et al. Atomic structure of conducting nanofilaments in TiO2 resistive switching memory. Nat. Nanotech. 5, 148–153 (2010).

Chen, C., Song, C., Yang, J., Zeng, F. & Pan, F. Oxygen migration induced resistive switching effect and its thermal stability in W/TaOx/Pt structure. Appl. Phys. Lett. 100, 253509 (2012).

Lee, H. Y. et al. Low power and high speed bipolar switching with a thin reactive Ti buffer layer in robust HfO2 based RRAM. 2008 IEEE Int. Electron Dev. Meeting https://doi.org/10.1109/IEDM.2008.4796677 (2008).

Rahman, A. et al. A family of CMOS analog and mixed signal circuits in SiC for high temperature electronics. 2015 IEEE Aerospace Conf. https://doi.org/10.1109/AERO.2015.7119302 (2015).

Herfurth, P. et al. GaN-on-insulator technology for high-temperature electronics beyond 400 degrees C. Semicond. Sci. Tech. 28, 0740267 (2013).

Britnell, L. et al. Field-effect tunneling transistor based on vertical graphene heterostructures. Science 335, 947–950 (2012).

Chae, S. H. et al. Transferred wrinkled Al2O3 for highly stretchable and transparent graphene-carbon nanotube transistors. Nat. Mater. 12, 403–409 (2013).

Yu, W. J. et al. Highly efficient gate-tunable photocurrent generation in vertical heterostructures of layered materials. Nat. Nanotech. 8, 952–958 (2013).

Britnell, L. et al. Strong Light-Matter Interactions in Heterostructures of Atomically Thin Films. Science 340, 1311–1314 (2013).

Long, M. et al. Broadband photovoltaic detectors based on an atomically thin heterostructure. Nano Lett. 16, 2254–2259 (2016).

Long, M. et al. Room temperature high-detectivity mid-infrared photodetectors based on black arsenic phosphorus. Sci. Adv. 3, e1700589 (2017).

Xia, F., Wang, H., Xiao, D., Dubey, M. & Ramasubramaniam, A. Two-dimensional material nanophotonics. Nat. Photon. 8, 899–907 (2014).

Liu, Y. et al. Van der Waals heterostructures and devices. Nat. Rev. Mater. 1, 16042 (2016).

Geim, A. K. & Grigorieva, I. V. Van der Waals heterostructures. Nature 499, 419–425 (2013).

Sahin, H. et al. Monolayer honeycomb structures of group-IV elements and III-V binary compounds: First-principles calculations. Phys. Rev. B 80, 155453 (2009).

Miro, P., Audiffred, M. & Heine, T. An atlas of two-dimensional materials. Chem. Soc. Rev. 43, 6537–6554 (2014).

Geim, A. K. Graphene: status and prospects. Science 324, 1530–1534 (2009).

Bertolazzi, S., Brivio, J. & Kis, A. Stretching and breaking of ultrathin MoS2. ACS Nano 5, 9703–9709 (2011).

Tan, C., Liu, Z., Huang, W. & Zhang, H. Non-volatile resistive memory devices based on solution-processed ultrathin two-dimensional nanomaterials. Chem. Soc. Rev. 44, 2615–2628 (2015).

Bessonov, A. A. et al. Layered memristive and memcapacitive switches for printable electronics. Nat. Mater. 14, 199–204 (2015).

Son, D. et al. Colloidal synthesis of uniform-sized molybdenum disulfide nanosheets for wafer-scale flexible nonvolatile memory. Adv. Mater. 28, 9326–9332 (2016).

Pan, C. et al. Coexistence of grain-boundaries-assisted bipolar and threshold resistive switching in multilayer hexagonal boron nitride. Adv. Funct. Mater. 27, 1604811 (2017).

Sangwan, V. K. et al. Gate-tunable memristive phenomena mediated by grain boundaries in single-layer MoS2. Nat. Nanotech. 10, 403–406 (2015).

Yao, J. et al. Highly transparent nonvolatile resistive memory devices from silicon oxide and graphene. Nat. Commun. 3, 1101 (2012).

Yang, Y. et al. Oxide resistive memory with functionalized graphene as built-in selector element. Adv. Mater. 26, 3693–3699 (2014).

Cheng, P., Sun, K. & Hu, Y. H. Memristive behavior and ideal memristor of 1T phase MoS2 nanosheets. Nano Lett. 16, 572–576 (2016).

Liu, S. et al. Eliminating negative-SET behavior by suppressing nanofilament overgrowth in cation-based memory. Adv. Mater. 28, 10623–10629 (2016).

Qian, M. et al. Tunable, ultralow-power switching in memristive devices enabled by a heterogeneous graphene-oxide interface. Adv. Mater. 26, 3275–3281 (2014).

Molina, J. et al. Influence of the surface roughness of the bottom electrode on the resistive-switching characteristics of Al/Al2O3/Al and Al/Al2O3/W structures fabricated on glass at 300 degrees C. Microelectron. Reliab. 54, 2747–2753 (2014).

Winer, W. O. Molybdenum disulfide as a lubricant - A review of fundamental knowledge. Wear 10, 422–450 (1967).

Martin, N., Rousselot, C., Rondot, D., Palmino, F. & Mercier, R. Microstructure modification of amorphous titanium oxide thin films during annealing treatment. Thin Solid Films 300, 113–121 (1997).

Chiu, F. C., Wang, J. J., Lee, J. Y. & Wu, S. C. Leakage currents in amorphous Ta2O5 thin films. J. Appl. Phys. 81, 6911–6915 (1997).

Pennycook, S. J. & Jesson, D. E. High-resolution Z-contrast imaging of crystals. Ultramicroscopy 37, 14–38 (1991).

Goldhirsch, I. & Ronis, D. Theory of thermophoresis. I. General considerations and mode-coupling analysis. Phys. Rev. A 27, 1616–1634 (1983).

Kempers, L. A comprehensive thermodynamic theory of the Soret effect in a multicomponent gas, liquid, or solid. J. Chem. Phys. 115, 6330–6341 (2001).

Bunch, J. S. et al. Impermeable atomic membranes from graphene sheets. Nano Lett. 8, 2458–2462 (2008).

Qiu, H. et al. Hopping transport through defect-induced localized states in molybdenum disulphide. Nat. Commun. 4, 2642 (2013).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321, 385–388 (2008).

Lee, G. et al. Flexible and transparent MoS2 field-effect transistors on hexagonal boron nitride-graphene heterostructures. ACS Nano 7, 7931–7936 (2013).

Acknowledgements

This work was supported in part by the National Key Basic Research Program of China (2015CB921600, 2015CB654901 and 2013CBA01603), National Natural Science Foundation of China (61625402, 61574076, 11474147 and 11374142), Natural Science Foundation of Jiangsu Province (BK20140017 and BK20150055), Fundamental Research Funds for the Central Universities, and Collaborative Innovation Center of Advanced Microstructures. Y.Z and J.J.Y. was supported in part by the U.S. Air Force Research Laboratory (AFRL) (Grant No. FA8750-15-2-0044) and DARPA (Contract No. D17PC00304).

Author information

Authors and Affiliations

Contributions

F.M. and M.W. conceived the project and designed the experiments. M.W., C.P., C.W., X.L. and K.X. performed the device fabrication and electrical measurements. S.C., M.W. and P.W. carried out the in situ HRTEM and cross-section STEM experiments and analyses. M.W., F.M., X.L., T.C., Z.Y. and J.J. Yang conducted the data analyses and interpretations. F.M., M.W., S.C., S.L., P.W. and J.J. Yang co-wrote the paper, and all authors contributed to the discussions and preparation of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

A correction to this article is available online at https://doi.org/10.1038/s41928-018-0044-x.

Supplementary information

Supplementary Information

Supplementary Figures 1–8 and Supplementary Notes 1–4

Rights and permissions

About this article

Cite this article

Wang, M., Cai, S., Pan, C. et al. Robust memristors based on layered two-dimensional materials. Nat Electron 1, 130–136 (2018). https://doi.org/10.1038/s41928-018-0021-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-018-0021-4

This article is cited by

-

Emerging memory electronics for non-volatile radiofrequency switching technologies

Nature Reviews Electrical Engineering (2024)

-

Atomistic description of conductive bridge formation in two-dimensional material based memristor

npj 2D Materials and Applications (2024)

-

Recent Advances in In-Memory Computing: Exploring Memristor and Memtransistor Arrays with 2D Materials

Nano-Micro Letters (2024)

-

Optoelectronic Synapses Based on MXene/Violet Phosphorus van der Waals Heterojunctions for Visual-Olfactory Crossmodal Perception

Nano-Micro Letters (2024)

-

Reconfigurable, non-volatile neuromorphic photovoltaics

Nature Nanotechnology (2023)