Abstract

Recent economic and productivity gains of rechargeable batteries have cemented their dominance in energy-intensive societies. With demand soaring, enhancing battery performance through continuous monitoring is essential to limiting their environmental footprint. Although some benefits of sensing have been known for a century, the convergence of fibre optic techniques with new battery platforms is poised to change the industry as a wealth of chemical, thermal and mechanical data will transform the utilization strategies for new and used lithium-ion devices alike. This Review highlights recent advances and associated benefits with a focus on optical sensors that could improve the sustainability of batteries.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Larcher, D. & Tarascon, J. M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 7, 19–29 (2015).

Grey, C. & Tarascon, J. Sustainability and in situ monitoring in battery development. Nat. Mater. 16, 45–56 (2017).

Brudermüller, M., Sobotka, B. & Waughray, D. A Vision for a Sustainable Battery Value Chain in 2030 (World Economic Forum, 2019).

Battery pack prices cited below $100/kWh for the first time in 2020, while market average sits at $137/kWh. BloombergNEF (16 December 2020); https://about.bnef.com/blog/battery-pack-prices-cited-below-100-kwh-for-the-first-time-in-2020-while-market-average-sits-at-137-kwh/

Fichtner, M. et al. Rechargeable batteries of the future—the state of the art from a BATTERY 2030+ perspective. Adv. Energy Mater. https://doi.org/10.1002/aenm.202102904 (2022).

Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020 (European Commission, 2020).

Birkl, C. R., Roberts, M. R., McTurk, E., Bruce, P. G. & Howey, D. A. Degradation diagnostics for lithium ion cells. J. Power Sources 341, 373–386 (2017).

Blanc, F., Leskes, M. & Grey, C. P. In situ solid-state NMR spectroscopy of electrochemical cells: batteries, supercapacitors, and fuel cells. Acc. Chem. Res. 46, 1952–1963 (2013).

Ilott, A. J., Mohammadi, M., Schauerman, C. M., Ganter, M. J. & Jerschow, A. Rechargeable lithium-ion cell state of charge and defect detection by in-situ inside-out magnetic resonance imaging. Nat. Commun. 9, 1776 (2018).

Sathiya, M. et al. Electron paramagnetic resonance imaging for real-time monitoring of Li-ion batteries. Nat. Commun. 6, 6276 (2015).

Huang, J. Y. et al. In situ observation of the electrochemical lithiation of a single SnO2 nanowire electrode. Science 330, 1515–1520 (2010).

Li, W. et al. Peering into batteries: electrochemical insight through in situ and operando methods over multiple length scales. Joule 5, 77–88 (2021).

Spitthoff, L., Shearing, P. R. & Burheim, O. S. Temperature, ageing and thermal management of lithium-ion batteries. Energies 14, 1248 (2021).

Knobloch, A. et al. Fabrication of multimeasurand sensor for monitoring of a Li-ion battery. J. Electron. Packag. 140, 031002 (2018).

Amietszajew, T. et al. Hybrid thermo-electrochemical in situ instrumentation for lithium-ion energy storage. Batter. Supercaps 2, 934–940 (2019).

Martiny, N. et al. Development of an all Kapton-based thin-film thermocouple matrix for in situ temperature measurement in a lithium ion pouch cell. IEEE Sens. J. 14, 3377–3384 (2014).

Li, S. et al. Optimal cell tab design and cooling strategy for cylindrical lithium-ion batteries. J. Power Sources 492, 229594 (2021).

Bright, C. T. et al. Remarks on “On reversible lead batteries and their use for electric lighting”. J. Soc. Telegr. Eng. Electr. 16, 184–218 (1887).

Lanphier, R. C. The ampere-hour meter for electric vehicles. SAE Trans. 6, 371–393 (1911).

Mas, J. A. Battery charging system and transducer therefor. US patent 3,460,019 (1969).

Keddam, M., Stoynov, Z. & Takenouti, H. Impedance measurement on Pb/H2SO4 batteries. J. Appl. Electrochem. 7, 539–544 (1977).

Worrell, C. & Redfern, B. Acoustic emission studies of the breakdown of beta-alumina under conditions of sodium ion transport. J. Mater. Sci. 13, 1515–1520 (1978).

Nagai, Y., Tomokuni, Y. & Matsui, T. Optical-type hydrometer for lead-acid batteries and its applications. In Proc. INTELEC ‘87 – The Ninth International Telecommunications Energy Conference 640–647 (IEEE, 1987); https://doi.org/10.1109/INTLEC.1987.4794631

Garrard, W. N. C. & Charlesworth, J. M. Application of the quartz crystal microbalance to measurement of the concentration of electrolyte in lead/acid batteries. J. Power Sources 56, 19–23 (1995).

Black, N. H. & Davis, H. N. Practical Physics: Fundamental Principles and Applications to Daily Life 79 (Macmillan, 1922).

Cao-Paz, A. M., Rodríguez-Pardo, L., Fariña, J. & Marcos-Acevedo, J. Resolution in QCM sensors for the viscosity and density of liquids: application to lead acid batteries. Sensors 12, 10604–10620 (2012).

Dollé, M., Orsini, F., Gozdz, A. S. & Tarascon, J.-M. Development of reliable three-electrode impedance measurements in plastic Li-ion batteries. J. Electrochem. Soc. 148, A851–A857 (2001).

Smith, A. J., Burns, J. C., Trussler, S. & Dahn, J. R. Precision measurements of the coulombic efficiency of lithium-ion batteries and of electrode materials for lithium-ion batteries. J. Electrochem. Soc. 157, A196 (2010).

Dahn, H. M., Smith, A., Burns, J., Stevens, D. & Dahn, J. User-friendly differential voltage analysis freeware for the analysis of degradation mechanisms in Li-ion batteries. J. Electrochem. Soc. 159, A1405 (2012).

Gireaud, L., Grugeon, S., Laruelle, S., Pilard, S. & Tarascon, J. M. Identification of Li battery electrolyte degradation products through direct synthesis and characterization of alkyl carbonate salts. J. Electrochem. Soc. 152, A850 (2005).

Horsthemke, F., Winkler, V., Diehl, M., Winter, M. & Nowak, S. Concept for the analysis of the electrolyte composition within the cell manufacturing process: from sealing to sample preparation. Energy Technol. 8, 1801081 (2020).

Day, R. et al. Differential thermal analysis of Li-ion cells as an effective probe of liquid electrolyte evolution during aging. J. Electrochem. Soc. 162, A2577 (2015).

Aiken, C. et al. An apparatus for the study of in situ gas evolution in Li-ion pouch cells. J. Electrochem. Soc. 161, A1548 (2014).

Ohzuku, T., Matoba, N. & Sawai, K. Direct evidence on anomalous expansion of graphite-negative electrodes on first charge by dilatometry. J. Power Sources 97, 73–77 (2001).

Michael, H. et al. A dilatometric study of graphite electrodes during cycling with X-ray computed tomography. J. Electrochem. Soc. 168, 010507 (2021).

Al-Obeidi, A., Kramer, D., Boles, S. T., Mönig, R. & Thompson, C. V. Mechanical measurements on lithium phosphorous oxynitride coated silicon thin film electrodes for lithium-ion batteries during lithiation and delithiation. Appl. Phys. Lett. 109, 071902 (2016).

Louli, A., Ellis, L. & Dahn, J. Operando pressure measurements reveal solid electrolyte interphase growth to rank Li-ion cell performance. Joule 3, 745–761 (2019).

Ohzuku, T., Tomura, H. & Sawai, K. Monitoring of particle fracture by acoustic emission during charge and discharge of Li/MnO2 cells. J. Electrochem. Soc. 144, 3496 (1997).

Didier-Laurent, S., Idrissi, H. & Roué, L. In-situ study of the cracking of metal hydride electrodes by acoustic emission technique. J. Power Sources 179, 412–416 (2008).

Mizutani, Y. et al. Practical Acoustic Emission Testing (Springer, 2006).

Rhodes, K., Dudney, N., Lara-Curzio, E. & Daniel, C. Understanding the degradation of silicon electrodes for lithium-ion batteries using acoustic emission. J. Electrochem. Soc. 157, A1354 (2010).

Choe, C.-Y., Jung, W.-S. & Byeon, J.-W. Damage evaluation in lithium cobalt oxide/carbon electrodes of secondary battery by acoustic emission monitoring. Mater. Trans. 56, 269–273 (2015).

Schweidler, S., Bianchini, M., Hartmann, P., Brezesinski, T. & Janek, J. The sound of batteries: an operando acoustic emission study of the LiNiO2 cathode in Li-ion cells. Batter. Supercaps 3, 1021–1027 (2020).

Sood, B., Osterman, M. & Pecht, M. Health monitoring of lithium-ion batteries. In Proc. 2013 IEEE Symposium on Product Compliance Engineering (ISPCE) (IEEE, 2013); https://doi.org/10.1109/ISPCE.2013.6664165

Hsieh, A. et al. Electrochemical-acoustic time of flight: in operando correlation of physical dynamics with battery charge and health. Energy Environ. Sci. 8, 1569–1577 (2015).

Robinson, J. B. et al. Spatially resolved ultrasound diagnostics of Li-ion battery electrodes. Phys. Chem. Chem. Phys. 21, 6354–6361 (2019).

Robinson, J. B. et al. Identifying defects in Li-ion cells using ultrasound acoustic measurements. J. Electrochem. Soc. 167, 120530 (2020).

Gold, L. et al. Probing lithium-ion batteries’ state-of-charge using ultrasonic transmission – concept and laboratory testing. J. Power Sources 343, 536–544 (2017).

Davies, G. et al. State of charge and state of health estimation using electrochemical acoustic time of flight analysis. J. Electrochem. Soc. 164, A2746 (2017).

Deng, Z. et al. Ultrasonic scanning to observe wetting and “unwetting” in Li-ion pouch cells. Joule 4, 2017–2029 (2020).

Louli, A. et al. Diagnosing and correcting anode-free cell failure via electrolyte and morphological analysis. Nat. Energy 5, 693–702 (2020).

Udd, E. & Spillman Jr, W. B. (eds) Fiber Optic Sensors: An Introduction for Engineers and Scientists 2nd edn (Wiley, 2011).

Kurashima, T., Horiguchi, T. & Tateda, M. Distributed-temperature sensing using stimulated Brillouin scattering in optical silica fibers. Opt. Lett. 15, 1038–1040 (1990).

Hartog, A. & Payne, D. Remote measurement of temperature distribution using an optical fibre. In Proc. 8th European Conference on Optical Communication (ECOC-8) (ECOC, 1982).

Dakin, J., Pratt, D., Bibby, G. & Ross, J. Distributed optical fibre Raman temperature sensor using a semiconductor light source and detector. Electron. Lett. 21, 569–570 (1985).

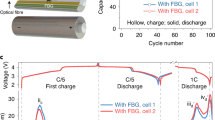

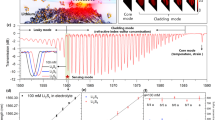

Huang, J. et al. Operando decoding of chemical and thermal events in commercial Na (Li)-ion cells via optical sensors. Nat. Energy 5, 674–683 (2020).

David, N., Wild, P., Jensen, J., Navessin, T. & Djilali, N. Simultaneous in situ measurement of temperature and relative humidity in a PEMFC using optical fiber sensors. J. Electrochem. Soc. 157, B1173 (2010).

Han, G. et al. A review on various optical fibre sensing methods for batteries. Renew. Sustain. Energy Rev. 150, 111514 (2021).

Su, Y.-D., Preger, Y., Burroughs, H., Sun, C. & Ohodnicki, P. R. Fiber optic sensing technologies for battery management systems and energy storage applications. Sensors 21, 1397 (2021).

Raghavan, A., Kiesel, P. & Saha, B. Monitoring and management for energy storage devices. US patent 9,203,122 (2015).

Leitão, C., Novo, C., Yang, G., Tang, C. & Pinto, J. Fiber Bragg grating sensors novel applications. In Proc. Latin America Optics and Photonics Conference 2012 LS2C.1 (Optical Society of America, 2012); https://opg.optica.org/abstract.cfm?URI=LAOP-2012-LS2C.1

Yang, G., Leitão, C., Li, Y., Pinto, J. & Jiang, X. Real-time temperature measurement with fiber Bragg sensors in lithium batteries for safety usage. Measurement 46, 3166–3172 (2013).

Nascimento, M., Paixão, T., Ferreira, M. S. & Pinto, J. L. Thermal mapping of a lithium polymer batteries pack with FBGs network. Batteries 4, 67 (2018).

Huang, J., Albero Blanquer, L., Gervillie, C. & Tarascon, J.-M. Distributed fiber optic sensing to assess in-live temperature imaging inside batteries: Rayleigh and FBGs. J. Electrochem. Soc. 168, 060520 (2021).

Fleming, J. et al. Development and evaluation of in-situ instrumentation for cylindrical Li-ion cells using fibre optic sensors. HardwareX 3, 100–109 (2018).

Raghavan, A. et al. Embedded fiber-optic sensing for accurate internal monitoring of cell state in advanced battery management systems part 1: cell embedding method and performance. J. Power Sources 341, 466–473 (2017).

Ganguli, A. et al. Embedded fiber-optic sensing for accurate internal monitoring of cell state in advanced battery management systems part 2: internal cell signals and utility for state estimation. J. Power Sources 341, 474–482 (2017).

Nascimento, M. et al. Internal strain and temperature discrimination with optical fiber hybrid sensors in Li-ion batteries. J. Power Sources 410, 1–9 (2019).

Bae, C. J., Manandhar, A., Kiesel, P. & Raghavan, A. Monitoring the strain evolution of lithium‐ion battery electrodes using an optical fiber Bragg grating sensor. Energy Technol. 4, 851–855 (2016).

Albero Blanquer, L. et al. Optical sensors for operando stress monitoring in lithium-based batteries containing solid-state or liquid electrolytes. Nat. Commun. 13, 1153 (2022).

Downie, L. & Dahn, J. Determination of the voltage dependence of parasitic heat flow in lithium ion cells using isothermal microcalorimetry. J. Electrochem. Soc. 161, A1782–A1787 (2014).

Desai, P. et al. Deciphering interfacial reactions via optical sensing to tune the interphase chemistry for optimized Na‐ion electrolyte formulation. Adv. Energy Mater. 11, 2101490 (2021).

Wahl, M. S. et al. The importance of optical fibres for internal temperature sensing in lithium-ion batteries during operation. Energies 14, 3617 (2021).

Ghannoum, A. et al. Optical characterization of commercial lithiated graphite battery electrodes and in situ fiber optic evanescent wave spectroscopy. ACS Appl. Mater. Interfaces 8, 18763–18769 (2016).

Nedjalkov, A. et al. Refractive index measurement of lithium ion battery electrolyte with etched surface cladding waveguide Bragg gratings and cell electrode state monitoring by optical strain sensors. Batteries 5, 30 (2019).

James, S. W. & Tatam, R. P. Optical fibre long-period grating sensors: characteristics and application. Meas. Sci. Technol. 14, R49 (2003).

Albert, J., Shao, L. Y. & Caucheteur, C. Tilted fiber Bragg grating sensors. Laser Photonics Rev. 7, 83–108 (2013).

Marrec, L. et al. In-situ optical fibre sensors for temperature and salinity monitoring. In Proc. Europe Oceans 2005 Vol. 2, 1276–1278 (IEEE, 2005); https://doi.org/10.1109/OCEANSE.2005.1513243

Guo, T., Liu, F., Guan, B.-O. & Albert, J. Tilted fiber grating mechanical and biochemical sensors. Opt. Laser Technol. 78, 19–33 (2016).

Lao, J. et al. In situ plasmonic optical fiber detection of the state of charge of supercapacitors for renewable energy storage. Light Sci. Appl. 7, 34 (2018).

Huang, J. et al. Monitoring battery electrolyte chemistry via in-operando tilted fiber Bragg grating sensors. Energy Environ. Sci. 14, 6464–6475 (2021).

Sharma, A. K., Jha, R. & Gupta, B. D. Fiber-optic sensors based on surface plasmon resonance: a comprehensive review. IEEE Sens. J. 7, 1118–1129 (2007).

Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings 1st edn, Vol. 111 (Springer, 1988).

Anker, J. N. et al. Biosensing with plasmonic nanosensors. Nat. Mater. 7, 442–453 (2008).

Willets, K. A. & Duyne, R. P. V. Localized surface plasmon resonance spectroscopy and sensing. Annu. Rev. Phys. Chem. 58, 267–297 (2007).

Larsson, E. M., Langhammer, C., Zorić, I. & Kasemo, B. Nanoplasmonic probes of catalytic reactions. Science 326, 1091–1094 (2009).

Nugroho, F. A. A. et al. Metal–polymer hybrid nanomaterials for plasmonic ultrafast hydrogen detection. Nat. Mater. 18, 489–495 (2019).

Newman, J. & Chapman, T. W. Restricted diffusion in binary solutions. AIChE J. 19, 343–348 (1973).

Yamanaka, T. et al. Ultrafine fiber Raman probe with high spatial resolution and fluorescence noise reduction. J. Phys. Chem. C. 120, 2585–2591 (2016).

Fujimoto, S., Uemura, S., Imanishi, N. & Hirai, S. Oxygen concentration measurement in the porous cathode of a lithium-air battery using a fine optical fiber sensor. Mech. Eng. Lett. 5, 19-00095 (2019).

Yang, G. Structure and Physical Properties of Chalcogenide Glasses. PhD thesis, University of Rennes 1 (2012).

Tarascon, J.-M., Gervillié, C., Boussard, C., Zhang, X.-H. & Adam, J.-L. Method for operando characterization of chemical species within a battery using infrared spectroscopy. Eur. patent EP21306068.4 (2021).

Udd, E. High speed fiber grating sensors for structural monitoring. Proc. SPIE 9098, 909808 (2014).

Ogawa, K. et al. Wireless, portable fiber Bragg grating interrogation system employing optical edge filter. Sensors 19, 3222 (2019).

Mendoza, E., Kempen, C., Sun, S. & Esterkin, Y. Light weight, high-speed, and self-powered wireless fiber optic sensor (WiFOS) structural health monitor system for avionics and aerospace environments. Proc. SPIE 9202, 92020L (2014).

Sonnenfeld, C. et al. Microstructured optical fiber Bragg grating as an internal three-dimensional strain sensor for composite laminates. Smart Mater. Struct. 24, 055003 (2015).

Cubillas, A. M. et al. Photonic crystal fibres for chemical sensing and photochemistry. Chem. Soc. Rev. 42, 8629–8648 (2013).

Miele, E. et al. Operando Raman analysis of electrolyte changes in Li-ion batteries with hollow-core optical fibre sensors. Preprint at Research Square https://doi.org/10.21203/rs.3.rs-531818/v1 (2021).

Bertucci, A. et al. Detection of unamplified genomic DNA by a PNA-based microstructured optical fiber (MOF) Bragg-grating optofluidic system. Biosens. Bioelectron. 63, 248–254 (2015).

Vegge, T., Tarascon, J. M. & Edström, K. Toward better and smarter batteries by combining AI with multisensory and self‐healing approaches. Adv. Energy Mater. 11, 2100362 (2021).

Wu, B., Widanage, W. D., Yang, S. & Liu, X. Battery digital twins: perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 1, 100016 (2020).

Larkin, P. Infrared and Raman Spectroscopy: Principles and Spectral Interpretation 2nd edn (Elsevier, 2017).

Acknowledgements

We are truly thankful to L. Albero Blanquer, C. Gervillié, J. Bonefacino, J. J. Lamb, A. Grimaud and C. Delacourt for their critical reading of the manuscript, as well as to L. Quétel for sharing all of his expertise on FBG sensors. Equally, our thanks extend to H.-Y. Tam and T. Guo for in-depth discussion on various aspects of optical sensing. We are also indebted to F. Liu for providing the TFBG spectra and fruitful discussions. We acknowledge BATTERY 2030+ funded by the European Union’s Horizon 2020 research and innovation program under grant agreement no. 957213, and funding from the International Balzan Prize Foundation via the 2020 Balzan Prize to J.-M.T. Lastly, we would like to thank the Collège de France for making all of the 2020 lectures of J.-M.T. that relate to this Review available free of charge via: https://www.college-de-france.fr/site/jean-marie-tarascon/course-2020-2021.htm.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Tazdin Amietszajew and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, J., Boles, S.T. & Tarascon, JM. Sensing as the key to battery lifetime and sustainability. Nat Sustain 5, 194–204 (2022). https://doi.org/10.1038/s41893-022-00859-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-022-00859-y

This article is cited by

-

Operando monitoring of dendrite formation in lithium metal batteries via ultrasensitive tilted fiber Bragg grating sensors

Light: Science & Applications (2024)

-

Functional Optical Fiber Sensors Detecting Imperceptible Physical/Chemical Changes for Smart Batteries

Nano-Micro Letters (2024)

-

On-Chip Sub-Picometer Continuous Wavelength Fiber-Bragg-Grating Interrogator

Photonic Sensors (2024)

-

Sensing as the key to the safety and sustainability of new energy storage devices

Protection and Control of Modern Power Systems (2023)

-

Nonintrusive thermal-wave sensor for operando quantification of degradation in commercial batteries

Nature Communications (2023)