Abstract

Research on the environmental impacts from the global value chain of plastics has typically focused on the disposal phase, considered most harmful to the environment and human health. However, the production of plastics is also responsible for substantial environmental, health and socioeconomic impacts. We show that the carbon and particulate-matter-related health footprint of plastics has doubled since 1995, due mainly to growth in plastics production in coal-based economies. Coal-based emissions have quadrupled since 1995, causing almost half of the plastics-related carbon and particulate-matter-related health footprint in 2015. Plastics-related carbon footprints of China’s transportation, Indonesia’s electronics industry and India’s construction sector have increased more than 50-fold since 1995. In 2015, plastics caused 4.5% of global greenhouse gas emissions. Moreover, 6% of global coal electricity is used for plastics production. The European Union and the United States have increasingly consumed plastics produced in coal-based economies. In 2015, 85% of the workforce required for plastics consumed by the European Union and the United States was employed abroad, but 80% of the related value added was generated domestically. As high-income regions have outsourced the energy-intensive steps of plastics production to coal-based economies, renewable energy investments throughout the plastics value chain are critical for sustainable production and consumption of plastics.

Similar content being viewed by others

Main

The global demand for plastics has quadrupled over the past four decades1 and is projected to further increase in the future, intensifying the impacts on the environment and human health2,3,4,5. Strategies for the sustainable production and consumption of plastics require information on the value chain of plastics6,7,8,9, such as fossil resource extraction and processing, resin production, manufacturing into plastics products, plastics use and end-of-life treatments. Many studies have addressed the environmental impacts of (micro)plastics pollution2,4,5,6,8,10,11,12,13,14 and plastics incineration7,15,16. Less attention has been paid to plastics production, which also has substantial environmental impacts, such as those caused by the release of greenhouse gas (GHG)17,18,19,20 emissions. Furthermore, plastics production induces health impacts, such as through the release of particulate-matter (PM) emissions, and socioeconomic impacts, such as by employing a workforce and creating value added.

Since the value chain of plastics spans the entire globe, plastics are often produced in a different country from the one in which they are ultimately consumed21. Therefore, the environmental, health and socioeconomic impacts resulting from one country’s plastics consumption can occur elsewhere around the globe. Multiregional input-output (MRIO) analysis allows these impacts to be assessed along the global value chain22,23,24,25,26,27,28. However, the accuracy of results from standard MRIO analysis has been limited when analysing the cumulative impacts of materials such as plastics due to double counting29,30,31,32. For example, when assessing cumulative GHG emissions (including upstream emissions) of primary plastics production and plastics recycling, double counting occurs because some primary plastics are ultimately recycled. In standard MRIO analysis32, the emissions of these primary plastics are counted again as upstream emissions in plastics recycling (a detailed explanation is provided in Cabernard et al.31).

In this article, we apply an enhanced method based on MRIO analysis that prevents double counting29,30,31,33 to assess the environmental impacts of global plastics production from 1995 to 2030 and extend this method to evaluate the role of coal combustion (Methods). We assess GHG emissions that occur in the global plastics value chain, called the carbon footprint of plastics. In this context, the study highlights the importance of plastics production, including resin production, manufacturing into plastics products and related upstream activities. Moreover, we analyse fossil resources used as a fuel and feedstock for plastics production, called here the fossil resource footprint of plastics. To evaluate the role of trade, the link between plastics-producing and consuming regions is mapped. Further, we analyse the future evolution of the global carbon footprint of plastics assuming that the world follows the International Energy Agency’s (IEA’s) projection for a 2 °C or 6 °C scenario34,35. Finally, this study analyses the PM health impacts, the workforce employed and value added created in the global plastics production chain to provide an overview of the health and socioeconomic impacts (Methods).

Results

Global carbon footprint of plastics and value-chain analysis

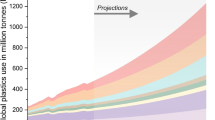

Since 1995, the carbon footprint of plastics has doubled, reaching 2 GtCO2-equivalent (CO2e) in 2015, accounting for 4.5% of global GHG emissions (Extended Data Fig. 1). The major driver of the rising carbon footprint of plastics has been the increased combustion of coal for plastics production, including resin production, manufacturing into plastics products and related upstream activities (Fig. 1a,b). As coal-based emissions for plastics production have quadrupled since 1995, plastics production accounted for the majority (96%) of the carbon footprint of plastics, while the end-of-life stages, including recycling, incineration and landfills, induced a minor fraction (6%, year 2015, Extended Data Fig. 1). Consequently, coal-based emissions caused almost half of the carbon footprint of global plastics production in 2015, due mainly to electricity and heat supply from coal for resin production and manufacturing into plastics products (Fig. 1a,b). In total, 6% of global coal electricity was used for plastics production in 2015.

a–e, The sum of each horizontal bar of the flow chart refers to the carbon footprint of global plastics production in 2015 (1.9 GtCO2e, 100%) and allocates it to the different perspectives in the global value chain: the sectors where GHG emissions are released (a); the processes that release GHG emissions, that is, combustion (88%) and non-combustion (7%) processes of fossil fuels (left side: 95% in total) and other processes (right side: 5 % in total): biogenic emissions (2.7%), hydrofluorocarbon emissions (1.7%) and cement production (0.8%) (b); the regions where GHG emissions are released (production perspective) (c); the regions where plastics are finally used (consumption perspective) (d); and the end products or sectors where plastics are finally used: plastics packaging material is allocated to the end product or sector where it is used (for example, food packaging in the food sector) (e). The flows show the linkages between the perspectives. To enhance clarity, linkages contributing to less than 0.1% of the plastics-related carbon footprint are not shown. The small graphs on the right show the temporal evolution of the carbon footprint of global plastics production for each perspective (a–e) over the past two decades (1995–2015) and in the future (2020–2030) if the world follows the IEA’s projection for a 2 °C or 6 °C scenario34,35 (but not accounting for the decrease in global GHG emissions in 2020 due to the COVID-19 pandemic, as in Liu et al.66). The colours of the graphs on the right correspond to the bars of the flow chart. The red line in each graph represents the global share. The end-of-life stages of plastics (recycling, incineration and landfills) contributed another 120 MtCO2e in 2015, not illustrated in this figure. A detailed value-chain analysis of the carbon footprint of global plastics recycling is shown in Extended Data Fig. 2.

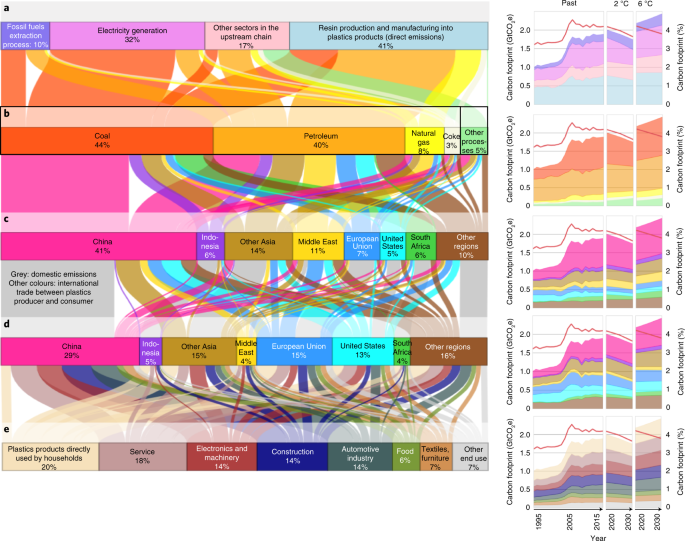

Due to the increased reliance on coal, the fossil resource footprint of plastics, including fossil resources used as fuel and feedstock for plastics production, has tripled since 1995 (Fig. 2a). Fossil fuels combusted for global plastics production released a total of 1.7 GtCO2e in 2015 (Fig. 1b, 88%). The carbon contained in fossil resources used as feedstock for plastics production accounted for another 890 MtCO2e (meaning this amount would be released if all plastics produced in 2015 were combusted without credits from energy recovery). Thus, twice as much fossil carbon is combusted as fuel for plastics production (1.7 GtCO2e) than contained as feedstock in plastics (890 MtCO2e). Our results further indicate that if all plastics produced in 2015 were incinerated, this would increase the annual carbon footprint of plastics by 19% (350 MtCO2e, subtracting credits from energy recovery36). While the GHG emissions of plastics incineration are commonly known7,8,15, our results show that even in a worst-case scenario in which all plastics were combusted, the major share of GHG emissions would still occur in the production phase.

a–d, The sum of each horizontal bar of the flow chart on the left refers to the fossil resource footprint of global plastics production in 2015 (540 Mt in 2015, 100%) and allocates it to the different perspectives in the global value chain: type of extracted fossil resource (a); region where fossil resources are extracted (b); region where fossil resources are used for plastics production (as fuel or feedstock) (c); region where plastics are consumed (d). The small graphs on the right show the temporal evolution of the fossil fuel footprint of global plastics production for each perspective (a–d) over the past two decades. The colours of the graphs on the right correspond to the bars of the flow chart. The red line in each represents the global share. EU, European Union; ME, Middle East; SA, South Africa; USA, United States; OR, other regions.

Growth in plastics production in coal-based emerging economies, such as China, Indonesia and South Africa, was the major driver of the increasing carbon footprint of plastics (Fig. 1). Since 1995, China’s plastics-related carbon footprint has more than tripled from both a production and a consumption perspective (Fig. 1b–d). In 2015, 40% of the global plastics-related carbon footprint and more than 60% of the related coal-based emissions were caused in China. In Indonesia, coal mining for plastics production has increased by a factor of 300 since 1995 (Fig. 2b). In 2015, 15% of Indonesia’s totally mined coal was used for plastics production, either domestically or abroad. More than 10% of Indonesia’s total domestic GHG emissions were attributed to plastics production in 2015. South Africa’s plastics-related carbon footprint has increased tenfold since 1995, and 95% of it was caused by domestic coal consumption in 2015. The reason for this is that South Africa uses coal not only to supply electricity and heat but also as a feedstock for plastics production37. Almost half of the plastics produced in China and South Africa were exported, such as to the European Union and to the United States (Fig. 1c,d).

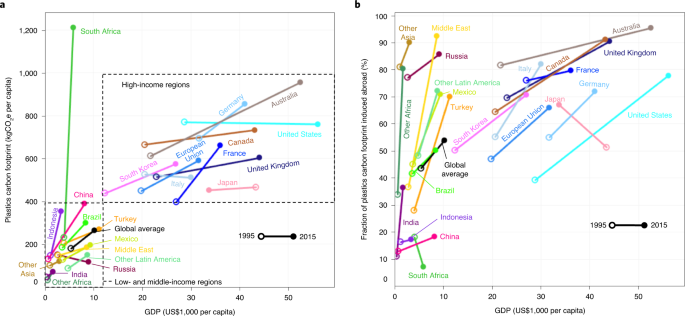

High-income regions, such as the European Union and the United States, contributed substantially to the increasing global carbon footprint of plastics by their rising demand for plastics produced in lower-income regions, particularly in coal-based economies such as China (Figs. 1 and 3 and Extended Data Fig. 3). Due to the outsourcing of plastics production to lower-income regions, the European Union’s plastics-related carbon footprint increased although their domestic plastics-related GHG emissions decreased (Extended Data Fig. 4). In 2015, two-thirds of the European Union’s plastics-related carbon footprint was emitted abroad, mainly in lower-income regions with less-stringent environmental policies. The fraction of the plastics-related carbon footprint caused abroad was even higher for Australia, Canada and the United States (>80% in 2015, Fig. 3b). Since 1995, the United States’ plastics-related carbon footprint generated abroad quadrupled, while their plastics-related domestic GHG emissions decreased (Extended Data Fig. 5). Consequently, the fraction of the United States’ plastics-related carbon footprint induced abroad increased from 39% in 1995 to 78% in 2015. One-third of the United States’ plastics-related carbon footprint in 2015 occurred in China (Fig. 1c,d; see Supplementary Results 1 for further results on the Middle East and Supplementary Results 2 and Supplementary Fig. 2 for results on the carbon intensity of plastics resin production per region).

a, Change in the per capita carbon footprints of plastics from a consumption perspective. b, Change in the fraction of the carbon footprint of plastics induced abroad due to imports plotted against the GDP and grouped by income67 from 1995 to 2015 (as single data points for these two years). The carbon footprints of plastics shown in this figure allocate the GHG emissions to the region where the plastics were finally used (consumption perspective). Net traded GHG emissions of plastics (production-based minus consumption-based GHG emissions) are shown in Extended Data Fig. 3.

In addition to increased plastics exports, emerging economies contributed to the rising global carbon footprint of plastics by their growing plastics demand, due mainly to their growing infrastructures, transportation systems and digitalization. Since 1995, the plastics-related carbon footprint of China’s transportation system, Indonesia’s electronics industry and India’s construction sector has increased more than 50-fold. In 2015, 15% of the global carbon footprint of plastics was attributed to plastics used for construction, and almost half of these emissions were attributed to China’s construction (Fig. 1d,e). In addition, plastics are responsible for 15% of the carbon footprint of the global automotive industry, and more than one-third of these GHG emissions were attributed to China’s automotive industry. While China also manufactured most of the plastics embodied in electronics (65%), a smaller portion (42%) was used by China itself, and the majority (58%) was exported to other regions.

Climate change scenarios

If the world follows the IEA’s projection for a 6 °C scenario34,35, the global carbon footprint of plastics would grow by 31% from 2015 to 2030, and thus almost at the same speed as projected plastics production (+40%, Fig. 1, see Extended Data Fig. 6 for per capita projections). The strongest increase is expected for coal-based economies, such as China, India and South Africa, while the largest international customers of plastics produced in these coal-based economies continue to be the European Union and the United States. Following the IEA’s projection for a 2 °C scenario34,35 would reduce the global carbon footprint of plastics by 10% from 2015 to 2030, while plastics production would increase by 40%. This would be attributed to investment in renewable energy production, mainly clean electricity, and improved energy efficiency in resin production. However, coal combustion would still contribute more than a third of the carbon footprint of plastics in 2030 if the world followed the IEA’s projection for a 2 °C scenario34,35. This highlights the potential of a rapid phase-out of coal to further reduce the carbon footprint of plastics in the future, as keeping global warming below 1.5 °C is critical for preventing major climate-related hazards38.

Despite the growing demand for plastics in emerging economies, the carbon footprints of plastics remain distinctly higher in high-income regions on a per capita level (Fig. 3a), and this imbalance is projected to persist into the future (Extended Data Fig. 6). Taking into account the projected reduction in plastics-related carbon footprints per region if the IEA’s measures for a 2 °C scenario34,35 were implemented, high-income regions in particular would have a high saving potential at the per capita level, which would also reduce income-related differences in the carbon footprints of plastics.

Health and socioeconomic impacts of plastics production

Since 1995, the global PM health footprint of plastics has increased by 70%, causing the loss of 2.2 million disability-adjusted life years (DALY) and representing 2.8% of global PM health impacts in 2015 (based on EXIOBASE322 and Cabernard et al.31, Extended Data Figs. 7 and 8). Similar to GHG emissions, plastics production accounted for the majority (96%) of the plastics-related PM health footprint, half of which was attributed to coal combustion (year 2015, Fig. 4a,b). Moreover, the majority (75%) of PM health impacts were caused in China, India, Indonesia and other Asia, while high-income regions increasingly consumed plastics produced in these regions (Fig. 4c,d). In 2015, the majority of the European Union’s (80%) and the United States’ (91%) plastics-related PM health footprint was caused abroad, mainly in Asia. Thus, only 8% of the global plastics-related PM health footprint effectively occurred in high-income regions (Extended Data Fig. 9c), although one-third of global plastics was consumed in high-income regions.

The format is the same as in Fig. 1. The total PM health footprint of global plastics was 2.15 million DALY31,68 in 2015, with the end-of-life stages of plastics (recycling, incineration and landfills) contributing another 910,000 DALY, not illustrated in this figure. a, Sectors where PM health impacts are caused. b, Combustion (87%) and non-combustion (1%) processes of fossil fuels (left side: 88% in total) and other non-combustion processes (right side: 12% in total): metals (7.6%), chemicals (1.8%), cement production (1.5%) and biogenic emissions (1.2%). c, Regions where PM health impacts are caused (production perspective). d, Regions where plastics are consumed (consumption perspective). e, End products or sectors where plastics are used. Plastics packaging material is allocated to the end product or sector where it is used (for example, food packaging in the food sector).

The number of employed workers for global plastics production has increased by 54% since 1995. At the same time, the value added created by global plastics production, including workforce compensation (48%), operating surplus (40%) and taxes (12%), has more than doubled. In 2015, 106 million workers (in full-time equivalents (FTE); 2.3% of the global workforce) were employed in plastics production, while the associated value added reached €1.56 trillion (2.6% of global gross domestic product (GDP)). The number of workers and the created value added are unevenly distributed around the globe: although more than 90% of the plastics-related workforce was employed in low- and middle-income regions, more than half of the plastics-related value added was generated in high-income regions (Extended Data Fig. 9d,e). China and other Asia made up the majority of the plastics-related workforce (Fig. 5a), while the European Union generated most of the plastics-related value added (Fig. 5b). In 2015, 70% of the workforce required for the European Union’s plastics consumption was employed abroad, but 80% of the related value added was generated domestically. The reliance on the low-paid foreign workforce was even higher for the United States’ plastics consumption, where 90% of the workforce was occupied abroad. This means that high-income regions, such as the European Union and the United States, outsource the low-paid steps in the plastics production value chain to lower-income regions and focus on the valuable steps of manufacturing plastics into finished products.

a,b, The sum of the vertical bars refers to the total employed workforce (106 million FTE, 100%) (a) and created value added (€1.56 trillion, 100%) (b) of global plastics production (including resin production, manufacturing into plastics products and related upstream activities) from production and consumption perspectives in 2015. The production perspective indicates the region where the plastics-related workforce is employed and the value added is created. The consumption perspective allocates the plastics-related workforce and value added to the region where plastics were finally consumed. Coloured flows refer to plastics consumed in another region than produced due to international trade. The value added of global plastics production includes workforce compensation (48%), operating surplus (40%) and taxes (12%).

Discussion

Comparison with literature

Other than previous estimates39,40,41, which indicated equal amounts of oil used as fossil fuel and feedstock for plastics production, this study showed that twice as much fossil carbon is combusted as fuel for plastics production than contained as feedstock in plastics. The reason for this difference is that our approach accounts not only for the amount of oil, but for GHG emissions released by combusting all types of fossil fuels along the plastics production chain as well, taking the increased reliance on coal into consideration. In this context, coal also contributes to the carbon footprint of plastics due to its increasing use as a feedstock for plastics production, such as in China42 and South Africa37.

The carbon footprint of plastics obtained in this study is higher (+16%) compared with Zheng and Suh17, who used bottom-up life-cycle analysis to assess the global carbon footprint of plastics in 2015 but did not account for double counting (see Extended Data Fig. 10 for a comparison of the results). In our study, double counting would have overestimated the carbon footprint of plastics by 29% but was avoided by means of the method applied31. The reason the carbon footprint of plastics obtained here is still higher compared with Zheng and Suh17 is that we considered the regionalized fuel-specific energy mix, such as the increased reliance on coal, while Zheng and Suh17 calculated with the average global energy mix.

The importance of considering the energy mix is also reflected in the results of the scenarios: in contrast to previous estimates8,15, the plastics’ share in total global GHG emissions is projected to decrease in the scenarios used here (Fig. 1). One reason for this is the assumption of increased future investment in renewable energy technologies and improved energy efficiency in the plastics production value chain, which can together exercise substantial leverage for reducing the global carbon footprint of plastics. Another reason could be that the growth in plastics production may be underestimated in the scenarios of this study. This highlights the importance of improved scenarios that take both changes in the energy mix and plastics production into consideration.

Policy implications

In addition to commonly known issues about (micro) plastics pollution2,3,4,5,6,8,10,11,12,13,14 and plastics incineration7,15,16, this study highlights the need for improved policy measures to reduce the increasing carbon footprint of plastics production, which bears the major share of the plastics-related GHG emissions (even in a worst-case scenario where all plastics would be incinerated). On the one hand, our results underscore the importance of ongoing initiatives to reduce primary plastics production by avoiding, reusing and recycling plastics as discussed in the context of circular economy8,9,39,43. However, a general ban on plastics is counterproductive as alternative materials often have higher environmental impacts44. On the other hand, this study highlights the particularly strong leverage in the plastics production chain itself to reduce the carbon footprint of plastics. Efficient measures include phasing out coal, transitioning to renewables and improving the energy efficiency in the plastics production process. As shown here for the past and future, decreasing the emissions in high-income regions as specified in the Paris Agreement is not sufficient. Such an approach even fosters a shift of plastics production to emerging regions with less-stringent environmental policies and limited economic power to implement state-of-the-art low-carbon technology. Thus, it is important that high-income regions invest in clean energy production throughout the supply chain.

Since renewable energy investments are currently hampered by the lack of economic incentives45,46,47, a key measure required is for the government to implement a carbon price, such as carbon taxes, cap-and-trade emissions schemes and renewable energy subsidies. Once a reasonable carbon price is in place on a producer and consumer level, the economic opportunities to decarbonize (plastics-related) supply-chain emissions will be particularly attractive for consumer-facing companies in high-income regions45. One reason for this is that consumer-facing companies can often reduce many more GHG emissions by decarbonizing their (plastics-related) supply chain than by focusing exclusively on their direct emissions. Another reason is that decarbonization of the (plastics-related) supply chain is less costly for consumer-facing companies in high-income regions than for plastics-producing companies in emerging markets45. This is because plastics represent only a small portion of end-use prices, and consumer-facing companies usually generate higher value per emissions produced (as shown in this study for high-income regions; Figs. 1c,d and 5).

In addition to carbon pricing, creating transparency with regard to (plastic-related) supply-chain emissions is a key measure required to incentivize consumer-facing companies to reduce their supply-chain emissions45 since it would allow companies to benefit from increased consumer demand for green products. In this study, transparency with regard to plastics-related supply-chain emissions has been improved on a global and country level using the methodology of Cabernard et al.31. Thus, future research is crucial to provide company-level data and to thereby close research information gaps.

One incentive for emerging economies to implement a carbon price to foster renewable energy investments is that such a measure can also reduce PM health impacts and thus local health costs48 (because unlike the global climate impact of GHG emissions, health impacts depend on the location where they occur). This might be of particular interest to China, which bears the burden of most plastic-related PM health impacts but has limited emission reduction potential from further flue gas treatment improvements49. By contrast, the installation of advanced flue gas treatment could substantially reduce plastic-related PM health impacts in India, Indonesia and other Asian countries49. Another incentive for emerging economies to implement a carbon price is the technical and economic opportunities that decarbonization presents in the long term, such as the future competitive advantage to be gained in view of the energy transition and the growth of new industries and services46,47,50. Consequently, decarbonization efforts might also mitigate the income-related regional imbalance between plastics-related PM health impacts, workforce and value added shown in this study.

Methods

Background

Our methodology is based on MRIO analysis. In MRIO analysis, the world economy is aggregated into a given number of regions and industrial sectors, whose transactional, environmental and socioeconomic accounts are captured for a given period22,51,52. This allows the environmental and socioeconomic impacts of these regions and sectors to be assessed along the global value chain23,24,25,26,53. Standard MRIO analysis is accurate for assessing the impacts of plastics end products such as tableware directly purchased by households25,26,27,28,54,55. However, most plastics are not directly used by households but intermediately by the industry, such as plastics for food packaging, for construction materials or in electronic products. The impacts of these intermediately used plastics could not previously be properly addressed by standard MRIO methodology25,26,27,28,54,55 due to double counting29,30,31,32,56. This methodical issue of double counting existed not only for plastics but for any materials, such as minerals, fossil resources and biomass, when assessing their cumulative impacts, including cumulative upstream and direct impacts. For example, when assessing cumulative GHG emissions of steel and coke production, double counting occurs because some coke is used for steel production. This means that the emissions related to coke production are counted again as upstream emissions in steel production. Similarly, when assessing cumulative GHG emissions of primary plastics production and plastics recycling, double counting occurs because some primary plastics are ultimately recycled. In standard MRIO analysis32, the emissions of these primary plastics are counted again as upstream emissions in plastics recycling (a detailed explanation is provided here in ref. 31).

Recently, a method was developed that prevents double counting29,30. It was extended to MRIO analysis31 to assess the cumulative impacts of any sector or regions and to track them upstream and downstream the global value chain (without double counting). It was applied to assess GHG emissions31,33, PM-related health impacts31 and other environmental and socioeconomic impacts of global material production31. An explanation of how double counting is prevented and how this affects the environmental footprint of global material production is provided by Cabernard et al.31.

Overview and scope

We used this method31 to assess fossil resource extraction, GHG emissions (carbon footprint), PM health impacts and socioeconomic impacts (value added and workforce) along the global plastics value chain. We extended this method to assess the processes of GHG and PM emissions release and the type of fossil fuels used at the different life-cycle stages in the plastics value chain. Further, we compared the amounts of fossil resources used as fuels and feedstock for plastics production. To project how the global carbon footprint of plastics will evolve until 2030, we applied our method on a forward-looking MRIO database35, covering the 2 °C and 6 °C scenarios of the IEA34. This study includes cumulative upstream and direct impacts of resin production, further manufacturing, recycling, incineration and landfills of all types of plastics and rubber, called footprint of plastics in what follows. Impacts related to plastics waste in the environment, such as microplastics pollution, were not addressed.

Database and terminology

We used the global MRIO database EXIOBASE3 (version 3.7)22, which aggregates the global economy into 163 industrial sectors for 44 countries and 5 rest-of-the-world regions (49 regions). This results in 7,987 sector–region combinations, whose economic flows are recorded in the coefficient matrix A and the final demand matrix Y for each year from 1995 to 2015 in constant prices22. The coefficient matrix A indicates the monetary input of each sector–region combination per monetary output of each sector–region combination (7,987 rows × 7,987 columns, in Euro Euro–1). The final demand matrix Y indicates the final demand of each region for each sector–region combination (7,987 rows × 49 columns, in Euro). For each sector–region combination and year, the EXIOBASE3 database provides a set of environmental and socioeconomic accounts (i), which was extended to GHG emissions and PM health impacts31, and which is called the impact coefficient matrix (D, i rows × 7,987 columns, impact/Euro). In this context, each type of GHG emission listed by the impact coefficient matrix of EXIOBASE3 (CO2, CH4, N2O, hydrofluorocarbons and perfluorinated compounds) was multiplied with the respective global warming potential to estimate the amount of emitted CO2e. To calculate PM health impacts, each type of PM emission listed by the impact coefficient matrix of EXIOBASE3 (PM2.5, NOx, SOx and NH3) was multiplied with sector-specific characterization factors (CFs) to measure the human burden of disease in DALY, as done by Cabernard et al.31. These CFs were derived from the United Nations Environment Programme (UNEP) and Society of Environmental Toxicology and Chemistry (SETAC)57, who provided CFs for PM2.5, NOx, SOx and NH3 emitted to different compartments (outdoor urban, outdoor rural, indoor urban and indoor rural) and CFs for PM2.5 emitted at different heights (ground level, low stack, high stack, very high stack). Since we cannot distinguish emission locations by population density in EXIOBASE3, we assumed rural outdoor emissions (with ground-level emissions for PM2.5) for all extracting sectors, we averaged rural and urban outdoor emissions for the manufacturing sectors and we assumed the average of urban outdoor emissions for the rest of the economy, as done by Cabernard et al.31. The indicators ‘fossil resource extraction’ (in tons of extracted fossil resources), ‘value added’ (in Euros) and ‘workforce’ (in number of people working full-time) were directly adopted from the impact coefficient matrix of EXIOBASE322.

Environmental and socioeconomic footprints of plastics

The method from Cabernard et al.31 can be applied to any industrial sector(s) and region(s) of any MRIO system. The first step is to define the sectors and regions of interest, called target sectors and target regions. Out of the 163 sectors covered by EXIOBASE3, we defined five sectors as target sectors: ‘plastics resin production’, ‘manufacturing of plastics and rubber products’, ‘plastics recycling’, ‘incineration of plastics’ and ‘landfills of plastics’. Since we analysed the global plastics value chain, we defined all 49 regions as target regions. This resulted in 245 target-sector regions (T, 5 target sectors × 49 target regions) referring to the global plastics economy, and 7,742 non-target-sector regions (O) referring to the global non-plastics economy. Both target-sector regions and non-target-sector regions represent the global economy (all, 7,987 sector regions). Following the method from Cabernard et al.31, we calculated the footprints (FP) of the entire plastics value chain for the indicators (i) fossil resource extraction, GHG emissions, PM health impacts, value added and workforce:

Equation (1) describes the cumulative upstream and direct impacts of resin production, further manufacturing, recycling, incineration and landfills of all types of plastics and rubber (called footprint of plastics in this study) but excludes the impacts related to the use phase of plastics as well as the impacts of plastics disposed to the environment. In equation (1), Di-all refers to the impact coefficients of the respective indicator (i) of the entire economy (all), indicating the impact (for example, GHG emissions) per Euro of output for each of the 7,987 sector–region combinations. Lall-T is the Leontief inverse referring to the cumulated inputs of the entire economy (all) into the plastics economy (T). The term in brackets refers to the total output of the global plastics economy. It equals the sum of the direct final demand for plastics products by the global end consumption (YT-all) and the intermediate demand for plastics by the global economy (\(A_{{\mathrm{T - O}}} \times L_{{\mathrm{O - O}}}^\prime \times Y_{{\mathrm{O - all}}}\)). The intermediate demand for plastics by the global economy is composed of the direct input of the plastics economy into the non-plastics economy (AT-o), the cumulated input of the non-plastics economy into the non-plastics economy (\(L_{{\mathrm{O - O}}}^\prime\)) and the direct final demand for the outputs of the non-plastics economy (Yo-all). This includes, for example, plastics used for electronics consumed by households. Diagonalizing the impact coefficients (diag(Di-all)) allocates the global plastics footprints to the sector and region where the fossil resources are extracted, the emissions are released, the impacts are caused, the value added is generated and the workforce is employed. A detailed explanation of equation (1) and a list of all terms is provided in Cabernard et al.31 by way of the example of global material production.

Division by plastics sectors

To divide the environmental footprints of plastics between the plastics sectors plastics resin production, manufacturing of plastics and rubber products, plastics recycling, incineration of plastics and landfills of plastics’, we divided equation (1) into two terms referring to direct and cumulative indirect impacts, respectively:

The first term refers to the direct impacts of the plastics sectors, where Di-T equals the impact coefficients of the plastics sectors (T) and LT-T is an excerpt of the Leontief inverse, which indicates the cumulated inputs of the plastics economy into the plastics economy. The second term indicates the cumulative indirect impacts of the plastics sectors caused in the upstream chain by the non-plastics economy: Di-O equals the impact coefficients of the non-plastics economy (O) and LO-T is an excerpt of the Leontief inverse referring to the cumulated inputs of the non-plastics economy (O) into the plastics economy (T). The term \({{{{Y}}}}_{{{{\mathrm{T}}}} - {{{\mathrm{all}}}}} + {{{{A}}}}_{{{{\mathrm{T}}}} - {{{\mathrm{O}}}}} \times {{{{L}}}}_{{{{\mathrm{O}}}} - {{{\mathrm{O}}}}}^\prime \times {{{{Y}}}}_{{{{\mathrm{O}}}} - {{{\mathrm{all}}}}}\) indicates the total output of the plastics economy without double counting. In summary, equation (2) is the same as equation (1), but diagonalizing the cumulative upstream impact coefficients (\({{{\mathrm{diag}}}}\left( {{{{{D}}}}_{{{{\mathrm{i}}}} - {{{\mathrm{O}}}}} \times {{{{L}}}}_{{{{\mathrm{O}}}} - {{{\mathrm{T}}}}}} \right)\)) allocates the cumulative indirect impacts (caused in the upstream chain by the non-plastics economy) to the plastics sector (while equation (1) allocates the cumulative indirect impacts to the sector in the upstream chain). To track the footprints along the global value chain, we diagonalized the different terms of equations (1) and (2), as explained by Cabernard et al.31.

Distinguishing different processes of GHG and PM emissions

The impact coefficient matrix of EXIOBASE3 indicates the GHG and PM emissions per Euro of output for each sector–region combination and for different processes. These processes include combustion of fossil fuels, non-combustion processes of fossil resources, minerals extraction and processing, and biogenic GHG emissions due to agriculture for bio-based plastics. To allocate the carbon and PM health footprint of global plastics production to each of these processes, we applied the process-specific impact coefficients (\(D_{{\mathrm{i}_{\rm{process}}}}\)) to equations (1) and (2).

Types of fossil fuels causing combustion-related emissions

For the carbon and PM health footprint related to fossil fuel combustion, we further investigated which types of fossil fuels, such as coal, petroleum, natural gas and coke, are combusted in the global plastics value chain. Since this is not indicated by EXIOBASE3, we weighted the combustion-related carbon and PM health footprint of global plastics production with fuel-specific contribution matrices (\(C_{{\mathrm{fuel - all}}}^{{\mathrm{GHG}}}\) and \(C_{{\mathrm{fuel - all}}}^{{\mathrm{PM}}}\), 4 rows × 7,987 columns):

\(C_{{\mathrm{fuel - all}}}^{{\mathrm{GHG}}}\) and \(C_{{\mathrm{fuel - all}}}^{{\mathrm{PM}}}\) indicate the contribution (in %) to GHG emissions and PM health impacts, respectively, by the combustion of coal, petroleum, natural gas or coke (4 rows) in each sector–region combination of the EXIOBASE3 database (7,987 columns). Since each column sums up to 100%, the resulting footprints are the same as in equations (1) and (2). However, the application of the fuel-specific contribution matrices allows the types of fossil fuels combusted at the different life-cycle stages of the global plastics value chain to be distinguished, as illustrated in Figs. 1b and 4b.

We derived \(C_{{\mathrm{fuel - all}}}^{{\mathrm{GHG}}}\) and \(C_{{\mathrm{fuel - all}}}^{{\mathrm{PM}}}\) from the element-wise product of the fuel-sector outputs of the monetary transaction matrix of EXIOBASE3 (\(T_{{\mathrm{fuel - all}}}^{{\mathrm{mon}}}\), in Euros), the inverted fuel price vector (\(p_{{\mathrm{fuel}}}^{{\mathrm{phy/mon}}}\), inmetric tons (t) Euro–1) and the fuel-specific impact factor vector for GHG emissions (\(f_{{\mathrm{fuel}}}^{{\mathrm{GHG/phy}}}\), kgCO2e t–1) and PM health impacts (\(f_{{\mathrm{fuel}}}^{{\mathrm{PM/phy}}}\), DALY t–1), respectively, and by dividing each element by the column sum of the resulting matrix:

We derived the inverted fuel price vector (\(p_{{\mathrm{fuel}}}^{{\mathrm{phy/mon}}}\), kg Euro–1) from the element-wise division of the total output of each fuel sector indicated by the physical (phy) MRIO table of EXIOBASE3 for the year 2011 (\(x_{{\mathrm{fuel}}}^{{\mathrm{phy}}}\), in kg) by the respective total output indicated by the monetary MRIO table of EXIOBASE3 for the year 2011 (\(x_{{\mathrm{fuel}}}^{{\mathrm{mon}}}\), in Euros) since physical IO data are available only for the year 2011 in EXIOBASE3:

We compiled fuel-specific GHG emissions factors (\(e_{{\mathrm{fuel}}}^{{\mathrm{GHG/phy}}}\), kgCO2e t–1) for coal, petroleum, natural gas and coke58. For coal, we weighted the emission factor of anthracite, bituminous coal, sub-bituminous coal, lignite and peat with the extracted volumes indicated by the United Nations International Resource Panel Material Flows Database59. Fuel and region-specific PM health impact factors per amount of fuel (\(e_{{\mathrm{fuel}}}^{{\mathrm{PM/phy}}}\), DALY t–1) were calculated on the basis of a global coal emission inventory49 (with a few outliers and the small units below 50 MW with lower data quality being removed) in combination with a highly resolved regionalized PM health impact assessment methodology60. Emission factors for petroleum and natural gas were obtained from the European Environment Agency61. Health impact factors were approximated on the basis of Oberschelp et al.49,60 and an average electrical efficiency of 40%, assuming the same spatio-temporal emission distribution patterns as for coal power generation. The health impact factors indicate the DALY per amount of combusted coal, petroleum, natural gas and coke for each of the 49 regions covered by EXIOBASE3 for the year 2015. For coke, we assumed the same region-specific PM health impact factors as for coal.

Fossil resources used as fuels and feedstock

Fossil resources are used both as fuels and feedstock for plastics production. While fossil resources used as fuels release GHG emissions during plastics production and related upstream activities, fossil resources used as feedstock release GHG emissions only if plastics are incinerated or composted. We calculated the GHG emissions of fossil resources used as fuels for plastics production (\({\mathrm{FP}}_{{\mathrm{i}},{\mathrm{comb}}}^{{\mathrm{resin + manu}}}\)) by applying equations (1) and (2) to the combustion-related GHG emissions indicated by EXIOBASE3 separately. To derive the GHG emission potential of fossil resources used as feedstock for plastics resin production (\(E_{{\mathrm{GHG}},{\mathrm{feedstock}}}^{{\mathrm{resin}}}\), in kgCO2e), we subtracted the GHG emissions directly released through plastics resin production (\(E_{{\mathrm{GHG}},\,{\mathrm{direct}}}^{{\mathrm{resin}}}\), in kgCO2e) from the GHG emission potential of the fossil resource input into plastics resin production (\(E_{{\mathrm{GHG}},{\mathrm{input}}}^{{\mathrm{resin}}}\), in kgCO2e) for the year 2015:

We derived the GHG emission potential of the fossil resource input into plastics resin production (\(E_{{\mathrm{GHG,input}}}^{{\mathrm{resin}}}\)) from the element-wise product of the monetary transaction matrix of EXIOBASE3 (\(T_{{\mathrm{fuel - resin}}}^{{\mathrm{mon}}}\), in Euros), the inverted price vector of fossil resources (\(p_{{\mathrm{fuel}}}^{{\mathrm{phy/mon}}}\), in t Euro–1) and the fuel-specific GHG emission factor vector (\(e_{fuel}^{GHG/phy}\), in kgCO2e t–1) for the year 2015:

Incineration of plastics

We estimated the annual increase in the global carbon footprint of plastics (\(I_{{\mathrm{GHG}}}^{{\mathrm{inc}}}\)) for the scenario that all plastics produced in 2015 were incinerated:

Thereby, \({\mathrm{FP}}_{{\mathrm{GHG,prod}}}^{{\mathrm{plastics}}}\) refers to the carbon footprint of global plastics production (based on equation (1)), and s refers to GHG emissions savings through heat and electricity recovery during plastics waste incineration. According to the ecoinvent 3.436 life-cycle database, the incineration of 1 kg of plastics generates on average 3.92 MJ of electricity and 7.66 MJ of useful heat, which we multiplied with the life-cycle GHG emissions of the global electricity (0.544 kgCO2e MJ–1)42,62 and heat mix (0.073 kgCO2e MJ–1)63 as well as global plastics production in 2015 to assess carbon savings through energy recovery, as done by Zheng and Suh17. This estimation assumes a scenario in which all plastics produced in 2015 end up as waste. In reality, some plastics end up in stocks (for example, infrastructure), while some plastics produced in previous years add to the waste. Further, heat and electricity savings (s) are based on average values36.

Climate change scenarios

To evaluate how the carbon footprint of plastics evolves until 2030 under different climate change scenarios, we applied the procedure described in equations (1)–(7) on a forward-looking version of EXIOBASE335, which is based on climate change scenarios of the IEA34. The forward-looking MRIO database involves different measures required to pursue the 2 °C and 6 °C scenarios until 2100 as projected by the Energy Technology Perspectives of the IEA34. The most important measures include increased investment in renewable energy technologies and improvements in material and energy efficiency on the basis of the growing world population and GDP. An overview of the measures implemented is provided in Table 1 in Wiebe et al.35. Note that the United States’ current boom in shale gas extraction may increase their domestic plastics production and related GHG emissions in the future,64,65 which was not accounted for in the scenarios used here34,35.

Reporting Summary

Further information on research design is available in the Nature Research Reporting Summary linked to this article.

Data availability

The study is based on the multiregional input-output (MRIO) database EXIOBASE322 and the impact assessment methodologies recommended by UNEP-SETAC57. A forward-looking version of EXIOBASE3 from Wiebe et al.35 was used for future scenarios, based on climate change scenarios from the International Energy Agency34. Further results of this study are presented in the Supplementary Information. All data are available upon reasonable request. Additional results on the plastics value chain and its environmental impacts, for example, for specific countries, can be calculated using the software tool from Cabernard et al.31.

Code availability

The MATLAB code to calculate the results of this study is available upon reasonable request and can be used to reproduce the results of this study.

References

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

Law, K. L. & Thompson, R. C. Microplastics in the seas. Science 345, 144–145 (2014).

Law, K. L. Plastics in the marine environment. Annu. Rev. Mar. Sci. 9, 205–229 (2017).

Rochman, C. M. et al. Classify plastic waste as hazardous. Nature 494, 169–171 (2013).

Rochman, C. M. Microplastics research—from sink to source. Science 360, 28–29 (2018).

Ryberg, M. W., Laurent, A. & Hauschild, M. Mapping of Global Plastics Value Chain and Plastics Losses to the Environment: With a Particular Focus on Marine Environment (UNEP, 2018).

Shen, M. et al. (Micro)plastic crisis: un-ignorable contribution to global greenhouse gas emissions and climate change. J. Clean. Prod. 254, 120138 (2020).

MacArthur, D. E., Waughray, D. & Stuchtey, M. in The New Plastics Economy, Rethinking the Future of Plastics (eds Neufeld, L. et al.) Ch. 1–3 (World Economic Forum, 2016).

Crippa, M. et al. A Circular Economy for Plastics: Insights from Research and Innovation to Inform Policy and Funding Decisions (European Comission, 2019).

Jambeck, J. R. et al. Plastic waste inputs from land into the ocean. Science 347, 768–771 (2015).

Horejs, C. Solutions to plastic pollution. Nat. Rev. Mater. 5, 641 (2020).

Thompson, R. C., Moore, C. J., Vom Saal, F. S. & Swan, S. H. Plastics, the environment and human health: current consensus and future trends. Philos. Trans. R. Soc. B 364, 2153–2166 (2009).

Vethaak, A. D. & Legler, J. Microplastics and human health. Science 371, 672–674 (2021).

Borrelle, S. B. et al. Predicted growth in plastic waste exceeds efforts to mitigate plastic pollution. Science 369, 1515–1518 (2020).

Hamilton, L. A. et al. Plastic & Climate: The Hidden Costs of a Plastic Planet (CIEL, 2019).

Chen, Y. et al. Life cycle assessment of end-of-life treatments of waste plastics in China. Resour. Conserv. Recycl. 146, 348–357 (2019).

Zheng, J. & Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Change 9, 374–378 (2019).

Posen, I. D., Jaramillo, P., Landis, A. E. & Griffin, W. M. Greenhouse gas mitigation for US plastics production: energy first, feedstocks later. Environ. Res. Lett. 12, 034024 (2017).

Khripko, D., Schlüter, B. A., Rommel, B., Rosano, M. & Hesselbach, J. Energy demand and efficiency measures in polymer processing: comparison between temperate and Mediterranean operating plants. Int. J. Energy Environ. Eng. 7, 225–233 (2016).

Dormer, A., Finn, D. P., Ward, P. & Cullen, J. Carbon footprint analysis in plastics manufacturing. J. Clean. Prod. 51, 133–141 (2013).

Tukker, A. et al. The Global Resource Footprint of Nations: Carbon, Water, Land and Materials Embodied in Trade and Final Consumption Calculated with EXIOBASE2 (Netherlands Organisation for Applied Scientific Research, Leiden University, Vienna University of Economics and Business, Norwegian University of Science and Technology, 2014).

Stadler, K. et al. EXIOBASE 3: developing a time series of detailed environmentally extended multi-regional input–output tables. J. Ind. Ecol. 22, 502–515 (2018).

Wiedmann, T. & Lenzen, M. Environmental and social footprints of international trade. Nat. Geosci. 11, 314–321 (2018).

Steen-Olsen, K., Weinzettel, J., Cranston, G., Ercin, A. E. & Hertwich, E. G. Carbon, land, and water footprint accounts for the European Union: consumption, production, and displacements through international trade. Environ. Sci. Technol. 46, 10883–10891 (2012).

Wood, R. et al. Growth in environmental footprints and environmental impacts embodied in trade: resource efficiency indicators from EXIOBASE3. J. Ind. Ecol. 22, 553–564 (2018).

Meng, B., Peters, G. P., Wang, Z. & Li, M. Tracing CO2 emissions in global value chains. Energy Econ. 73, 24–42 (2018).

Hoekstra, A. Y. & Wiedmann, T. O. Humanity’s unsustainable environmental footprint. Science 344, 1114–1117 (2014).

Peters, G. P. & Hertwich, E. G. Post-Kyoto greenhouse gas inventories: production versus consumption. Climatic Change 86, 51–66 (2008).

Dente, S. M. R., Aoki-Suzuki, C., Tanaka, D. & Hashimoto, S. Revealing the life cycle greenhouse gas emissions of materials: the Japanese case. Resour. Conserv. Recycl. 133, 395–403 (2018).

Dente, S. M. et al. Effects of a new supply chain decomposition framework on the material life cycle greenhouse gas emissions—the Japanese case. Resour. Conserv. Recycl. 143, 273–281 (2019).

Cabernard, L., Pfister, S. & Hellweg, S. A new method for analyzing sustainability performance of global supply chains and its application to material resources. Sci. Total Environ. 684, 164–177 (2019).

Hertwich, E. G. & Wood, R. The growing importance of scope 3 greenhouse gas emissions from industry. Environ. Res. Lett. 13, 104013 (2018).

Hertwich, E. G. Increased carbon footprint of materials production driven by rise in investments. Nat. Geosci. 14, 151–155 (2021).

Elzinga, D. et al. Energy Technology Perspectives 2015: Mobilising Innovation to Accelerate Climate Action (IEA, 2015).

Wiebe, K. S., Bjelle, E. L., Többen, J. & Wood, R. Implementing exogenous scenarios in a global MRIO model for the estimation of future environmental footprints. J. Econ. Struct. 7, 20 (2018).

Wernet, G. et al. The ecoinvent database version 3 (part I): overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230 (2016).

Chitaka, T. Y., Russo, V. & von Blottnitz, H. In pursuit of environmentally friendly straws: a comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 25, 1818–1832 (2020).

Hoegh-Guldberg, O. et al. The human imperative of stabilizing global climate change at 1.5 °C. Science 365, eaaw6974 (2019).

Hopewell, J., Dvorak, R. & Kosior, E. Plastics recycling: challenges and opportunities. Philos. Trans. R. Soc. B 364, 2115–2126 (2009).

World Energy Outlook 2014 (IEA, 2014).

Plastics—The Facts (PlasticsEurope, 2015).

Data and Statistics: Electricity (IEA, 2021); https://www.iea.org/statistics/electricity/

Bening, C. R., Pruess, J. T. & Blum, N. U. Towards a circular plastics economy: interacting barriers and contested solutions for flexible packaging recycling. J. Clean. Prod. 302, 126966 (2021).

Andrady, A. L. & Neal, M. A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. B 364, 1977–1984 (2009).

Net-Zero Challenge: The Supply Chain Opportunity (WEF, 2021); https://www.weforum.org/reports/net-zero-challenge-the-supply-chain-opportunity

Arndt, C., Miller, M., Tarp, F., Zinaman, O. & Arent, D. The Political Economy of Clean Energy Transitions (Oxford Univ. Press, 2017).

Luciani, G. in The Geopolitics of the Global Energy Transition (eds Hafner, M. & Tagliapietra, S.) 305–318 (Springer, 2020).

Scovronick, N. et al. The impact of human health co-benefits on evaluations of global climate policy. Nat. Commun. 10, 2095 (2019).

Oberschelp, C., Pfister, S., Raptis, C. & Hellweg, S. Global emission hotspots of coal power generation. Nat. Sustain. 2, 113–121 (2019).

Teng, F. & Jotzo, F. Reaping the economic benefits of decarbonization for China. China World Econ. 22, 37–54 (2014).

Andrew, R. M. & Peters, G. P. A multi-region input–output table based on the global trade analysis project database (GTAP-MRIO). Econ. Syst. Res. 25, 99–121 (2013).

Lenzen, M., Moran, D., Kanemoto, K. & Geschke, A. Building Eora: a global multi-region input–output database at high country and sector resolution. Econ. Syst. Res. 25, 20–49 (2013).

Weinzettel, J. & Pfister, S. International trade of global scarce water use in agriculture: modeling on watershed level with monthly resolution. Ecol. Econ. 159, 301–311 (2019).

Tukker, A., Pollitt, H. & Henkemans, M. Consumption-based carbon accounting: sense and sensibility. Clim. Policy 20, S1–S13 (2020).

Wood, R., Moran, D. D., Rodrigues, J. F. & Stadler, K. Variation in trends of consumption based carbon accounts. Sci. Data 6, 99 (2019).

Van der Voet, E., Van Oers, L., De Bruyn, S., De Jong, F. & Tukker, A. Environmental Impact of the Use of Natural Resources and Products Report 184 (CML, 2009).

Life Cycle Initiative. Global Guidance for Life Cycle Impact Assessment Indicators (UNEP-SETAC, 2016).

Combustion of Fuels—Carbon Dioxide Emission (Engineering ToolBox), accessed 8 November 2021); https://www.engineeringtoolbox.com/co2-emission-fuels-d_1085.html

Global Material Flows Database (UN IRP, 2020).

Oberschelp, C., Pfister, S. & Hellweg, S. Globally regionalized monthly life cycle impact assessment of particulate matter. Environ. Sci. Technol. 54, 16028–16038 (2020).

EMEP/EEA Air Pollutant Emission Inventory Guidebook (EEA, 2016).

Sovacool, B. K. Valuing the greenhouse gas emissions from nuclear power: a critical survey. Energy Policy 36, 2950–2963 (2008).

Posen, I. D., Jaramillo, P. & Griffin, W. M. Uncertainty in the life cycle greenhouse gas emissions from US production of three biobased polymer families. Environ. Sci. Technol. 50, 2846–2858 (2016).

Swift, T., Moore, M., Sanchez, E. & Rose-Glowacki, H. The Rising Competitive Advantage of US Plastics (ACC, 2015).

Alvarez, R. A. et al. Assessment of methane emissions from the US oil and gas supply chain. Science 361, 186–188 (2018).

Liu, Z. et al. Near-real-time monitoring of global CO2 emissions reveals the effects of the COVID-19 pandemic. Nat. Commun. 11, 5172 (2020).

Classifying Countries by Income (World Bank, 2019); https://datatopics.worldbank.org/world-development-indicators/stories/the-classification-of-countries-by-income.html

Fantke, P. et al. Characterizing aggregated exposure to primary particulate matter: recommended intake fractions for indoor and outdoor sources. Environ. Sci. Technol. 51, 9089–9100 (2017).

Acknowledgements

We thank M. Klotz and H. Wiesinger from ETH Zurich as well as M. Zhang, F. Wiss and B. Cabernard for valuable feedback on the content and comprehension of our study. We also thank A. Clarke from Eawag Zurich for language proofreading. The work of L.C. was supported by an ETH Zurich ISTP Research Incubator Grant for the Swiss Minerals Observatory Group.

Author information

Authors and Affiliations

Contributions

All authors designed the research and interpreted the results. L.C. developed the method, calculated and compiled the results and wrote the article, with inputs from all authors. C.O. compiled the fuel- and region-specific PM health impact factors.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Sustainability thanks Guangwu Chen, Jiajia Zheng and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Temporal development of the global carbon footprint (GHG emissions) of plastics from 1995 to 2015 and from 2020 to 2030 under different scenarios (2-degree and 6-degree scenario until 210034,35) divided by life-cycle stages.

Temporal development of the global carbon footprint (GHG emissions) of plastics from 1995 to 2015 and from 2020 to 2030 under different scenarios (2-degree and 6-degree scenario until 210034,35) divided by life-cycle stages. The value chain analysis of the carbon footprint of global plastics production (resin production and further manufacturing) is shown in Fig. 1 of the main article for the year 2015. The temporal development of the global carbon footprint of plastics recycling, incineration, and landfills is shown separately in Supplementary Fig. 1 of the SI.

Extended Data Fig. 2 Global value chain analysis of the carbon footprint of global plastics recycling in 2015 (50 Mt CO2-equivalents).

Global value chain analysis of the carbon footprint of global plastics recycling in 2015 (50 Mt CO2-equivalents). The format is the same as in Fig. 1 of the main article, except that Indonesia is part of ‘Other Asia’ and South Africa is part of ‘Other regions’ in this figure. It shows the cradle-to-gate GHG emissions of global plastics recycling, and excludes the GHG emissions of resin production and further manufacturing (which are shown in Fig. 1 of the main article).

Extended Data Fig. 3 Net traded GHG emissions of plastics plotted against the GDP from 1995 to 2015.

Net traded GHG emissions of plastics plotted against the GDP from 1995 to 2015. Net traded GHG emissions of plastics were calculated by the difference of the plastics-related GHG emissions from a production and a consumption perspective (which equals the difference of the plastics-related GHG emissions of exports and imports). A positive value means that a region exports more plastics (and GHG emissions related to the production of the exported plastics) than it imports. In contrast, a negative value means that a country imports more plastics (and GHG emissions related to the production of the imported plastics) than it exports. All high-income regions except South Korea are net importer of plastics-related GHG emissions, meaning their plastics-related GHG emissions are higher from a consumption than production perspective. Vice versa, most low- and middle-income regions are net exporter of plastic-related GHG emissions. The same trend can be observed for PM health impacts.

Extended Data Fig. 4 The flow chart on the left shows the global value chain analysis of the EU’s carbon footprint due to plastics production in 2015 (254 Mt CO2-equivalents, 100%) and the small graphs on the right show the temporal evolution of the EU’s carbon footprint due to plastics production from 1995 to 2030 under different scenarios (2-degree and 6-degree scenario until 210034,35).

The flow chart on the left shows the global value chain analysis of the EU’s carbon footprint due to plastics production in 2015 (254 Mt CO2-equivalents, 100%) and the small graphs on the right show the temporal evolution of the EU’s carbon footprint due to plastics production from 1995 to 2030 under different scenarios (2-degree and 6-degree scenario until 210034,35), following the format of Fig. 1 of the main article. The end-of-life stages of plastics (recycling, incineration, and landfills) contributed to another 19 Mt CO2-equivalents in 2015 (data not shown in this figure).

Extended Data Fig. 5 The flow chart on the left shows the global value chain analysis of the USA’s carbon footprint due to plastics production in 2015 (239 Mt CO2-equivalents, 100%) and the small graphs on the right show the temporal evolution of the EU’s carbon footprint due to plastics production from 1995 to 2030 under different scenarios (2-degree and 6-degree scenario until 210034,35).

The flow chart on the left shows the global value chain analysis of the USA’s carbon footprint due to plastics production in 2015 (239 Mt CO2-equivalents, 100%) and the small graphs on the right show the temporal evolution of the EU’s carbon footprint due to plastics production from 1995 to 2030 under different scenarios (2-degree and 6-degree scenario until 210034,35), following the format of Fig. 1 of the main article. The end-of-life stages of plastics (recycling, incineration, and landfills) contributed to another 20 Mt CO2-equivalents in 2015 (data not shown in this figure).

Extended Data Fig. 6 Change in per-capita carbon footprints of plastics from 2015 until 2030 if the world follows the IEA’s projections for a 2-degree or 6-degree scenario34,35 plotted against the GDP.

Change in per-capita carbon footprints of plastics from 2015 until 2030 if the world follows the IEA’s projections for a 2-degree or 6-degree scenario34,35 plotted against the GDP. The carbon footprint of plastics allocates the GHG emissions of plastics to the region where plastics are finally used (consumption perspective). Due to the expected population growth, plastics-related carbon footprints at the per-capita level are expected to increase only slightly for most regions until 2030 if the world follows a 6-degree scenario. If the world follows a 2-degree scenario instead, plastics-related carbon footprints at the per-capita level are expected to decrease for all regions except India and Other Asia. However, their plastics-related carbon footprints are still half the global average in 2030. Note that the USA’s current boom in shale gas extraction may increase the USA’s domestic plastics production and related GHG emissions in the future,64,65 which was not accounted for in the scenarios used here34,35.

Extended Data Fig. 7 Temporal development of the global PM health footprint of plastics from 1995 to 2015 divided by life-cycle stages (based on EXIOBASE322, the impact assessment recommended by UNEP-SETAC57 and the methodology of Cabernard et al31).

Temporal development of the global PM health footprint of plastics from 1995 to 2015 divided by life-cycle stages (based on EXIOBASE322, the impact assessment recommended by UNEP-SETAC57 and the methodology of Cabernard et al31). The value chain analysis of the PM health footprint of global plastics production (resin production and further manufacturing) in 2015 is shown in Fig. 4 of the research article.

Extended Data Fig. 8 Temporal development of plastics-related PM emissions and health impacts divided by type of PM emissions (based on EXIOBASE322, the impact assessment recommended by UNEP-SETAC57 and the methodology of Cabernard et al31).

Extended Data Fig. 9 Temporal evolution of the environmental and socioeconomic footprints of global plastics production over the past two decades split by plastic consumption in different income regions, and split by domestic and foreign import-related impacts.

Temporal evolution of the environmental and socioeconomic footprints of global plastics production over the past two decades split by plastic consumption in different income regions, and split by domestic and foreign import-related impacts.

Extended Data Fig. 10 Comparison of the global plastics-related carbon footprint in 2015 to the study of Zheng and Suh17, who applied bottom-up life-cycle analysis to assess the global plastics-related carbon footprint in 2015.

Comparison of the global plastics-related carbon footprint in 2015 to the study of Zheng and Suh17, who applied bottom-up life-cycle analysis to assess the global plastics-related carbon footprint in 2015. This study’s global carbon footprint of plastics production is 16% higher compared to Zheng and Suh17. The reason for this might be that the MRIO-based approach applied here accounts for the fuel-specific energy mix, such as the increased reliance on coal, while Zheng and Suh17 calculated with average global energy mixes. The study of Zheng and Suh17 further assumed that 24% of global plastics produced in 2015 were incinerated, releasing 96 Mt CO2-equivalents. This means that 400 Mt CO2-equivalents would have been released if all plastics were incinerated according to Zheng and Suh17, which is comparable to the 350 Mt CO2-equivalents calculated in this study.

Supplementary information

Supplementary Information

Supplementary Figs. 1 and 2, Methods and Results.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Cabernard, L., Pfister, S., Oberschelp, C. et al. Growing environmental footprint of plastics driven by coal combustion. Nat Sustain 5, 139–148 (2022). https://doi.org/10.1038/s41893-021-00807-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-021-00807-2

This article is cited by

-

A Unified View of Carbon Neutrality: Solar-Driven Selective Upcycling of Waste Plastics

Transactions of Tianjin University (2024)

-

Role of Microplastics in Global Warming and Climate Change: A Review

Water, Air, & Soil Pollution (2024)

-

Towards circular plastics within planetary boundaries

Nature Sustainability (2023)

-

Valorization of waste biodegradable polyester for methyl methacrylate production

Nature Sustainability (2023)

-

Plastics can be used more sustainably in agriculture

Communications Earth & Environment (2023)