Abstract

Aqueous zinc (Zn) batteries have long been considered a potentially more sustainable alternative to lithium-ion batteries because of their better environmental compatibility, enhanced safety and cost advantage. However, in the presence of an aqueous electrolyte, the Zn anode is poised to undergo dendrite failure, corrosion and hydrogen evolution, all of which resonate with each other leading to fast performance degradation. Here, in a break from the current aqueous battery path, we report a low-cost hydrous organic electrolyte involving a hydrated Zn(BF4)2 salt and an ethylene glycol solvent, which not only promotes the in situ formation of a favourable ZnF2 passivation layer to protect Zn from dendrite growth and side reactions but also embraces excellent non-flammability. Remarkably, the present Zn anode sustains a long-term cycling over 4,000 h at a current density of 0.5 mA cm−2 with a high Coulombic efficiency of 99.4% and shows an areal capacity as high as 5 mAh cm−2. Equally intriguingly, the electrolyte can run across a wide temperature range from −30 °C to 40 °C without seriously compromising performance. The Zn//V2O5 full cells with our electrolyte also perform much better in terms of capacity retention than a device with an aqueous ZnSO4 electrolyte. Our findings suggest a promising direction for developing electrolyte solutions for practical Zn batteries which combine safety, performance and sustainability.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings detailed in this study are available in the article and its Supplementary Information or from the corresponding authors on reasonable request. Source data are provided with this paper.

References

Turcheniuk, K., Bondarev, D., Singhal, V. & Yushin, G. Ten years left to redesign lithium-ion batteries. Nature 559, 467–470 (2018).

Li, M., Lu, J., Chen, Z. W. & Amine, K. 30 years of lithium-ion batteries. Adv. Mater. 30, 1800561 (2018).

Deng, J., Bae, C., Denlinger, A. & Miller, T. Electric vehicles batteries: requirements and challenges. Joule 4, 511–515 (2020).

Xu, C., Li, B., Du, H. & Kang, F. Energetic zinc ion chemistry: the rechargeable zinc ion battery. Angew. Chem. Int. Ed. 51, 933–935 (2012).

Pan, H. et al. Reversible aqueous zinc/manganese oxide energy storage from conversion reactions. Nat. Energy 1, 16039 (2016).

Kundu, D., Adams, B. D., Duffort, V., Vajargah, S. H. & Nazar, L. F. A high-capacity and long-life aqueous rechargeable zinc battery using a metal oxide intercalation cathode. Nat. Energy 1, 16119 (2016).

Ma, L. et al. Realizing high zinc reversibility in rechargeable batteries. Nat. Energy 5, 743–749 (2020).

Chao, D. et al. Roadmap for advanced aqueous batteries: from design of materials to applications. Sci. Adv. 6, eaba4098 (2020).

Jia, X., Liu, C., Neale, Z. G., Yang, J. & Cao, G. Active materials for aqueous zinc ion batteries: synthesis, crystal structure, morphology, and electrochemistry. Chem. Rev. 120, 7795–7866 (2020).

Deng, Y.-P. et al. The current state of aqueous Zn-based rechargeable batteries. ACS Energy Lett. 5, 1665–1675 (2020).

Zheng, J. et al. Reversible epitaxial electrodeposition of metals in battery anodes. Science 366, 645–648 (2019).

Parker, J. F. et al. Rechargeable nickel-3D zinc batteries: an energy-dense, safer alternative to lithium-ion. Science 356, 415–418 (2017).

Wang, F. et al. Highly reversible zinc metal anode for aqueous batteries. Nat. Mater. 17, 543–549 (2018).

Cao, L. et al. Solvation structure design for aqueous Zn metal batteries. J. Am. Chem. Soc. 142, 21404–21409 (2020).

Guan, Q. et al. Dendrite‐free flexible fiber‐shaped Zn battery with long cycle life in water and air. Adv. Energy Mater. 9, 1901434 (2019).

Blanc, L. E., Kundu, D. & Nazar, L. F. Scientific challenges for the implementation of Zn-ion batteries. Joule 4, 771–799 (2020).

Li, Q. et al. Calendar life of Zn batteries based on Zn anode with Zn powder/current collector structure. Adv. Energy Mater. 11, 2003931 (2021).

Yang, Y. et al. Synergistic manipulation of Zn2+ ion flux and desolvation effect enabled by anodic growth of a 3D ZnF2 matrix for long-lifespan and dendrite-free Zn metal anodes. Adv. Mater. 33, 2007388 (2021).

Cai, Z. et al. A replacement reaction enabled interdigitated metal/solid electrolyte architecture for battery cycling at 20 mA cm–2 and 20 mAh cm–2. J. Am. Chem. Soc. 143, 3143–3152 (2021).

Zhang, C. et al. A ZnCl2 water-in-salt electrolyte for a reversible Zn metal anode. Chem. Commun. 54, 14097–14099 (2018).

Hao, J. et al. Boosting zinc electrode reversibility in aqueous electrolyte using low‐cost antisolvents. Angew. Chem. Int. Ed. 60, 7366–7375 (2021).

Chang, N. et al. An aqueous hybrid electrolyte for low-temperature zinc-based energy storage devices. Energy Environ. Sci. 13, 3527–3535 (2020).

Qiu, H. et al. Zinc anode-compatible in-situ solid electrolyte interphase via cation solvation modulation. Nat. Commun. 10, 5374 (2019).

Naveed, A. et al. A highly reversible Zn anode with intrinsically safe organic electrolyte for long-cycle-life batteries. Adv. Mater. 31, 1900668 (2019).

Wang, J. et al. Strategies towards the challenges of zinc metal anode in rechargeable aqueous zinc ion batteries. Energy Storage Mater. 35, 19–46 (2020).

Zhang, T. et al. Fundamentals and perspectives in developing zinc-ion battery electrolytes: a comprehensive review. Energy Environ. Sci. 13, 4625–4665 (2020).

Zhao, Z. M. et al. Long-life and deeply rechargeable aqueous Zn anodes enabled by a multifunctional brightener-inspired interphase. Energy Environ. Sci. 12, 1938–1949 (2019).

Li, D., Cao, L., Deng, T., Liu, S. & Wang, C. Solid electrolyte interphase design for aqueous Zn batteries. Angew. Chem. Int. Ed. 60, 13035–13041 (2021).

Guo, X. et al. Alleviation of dendrite formation on zinc anodes via electrolyte additives. ACS Energy Lett. 6, 395–403 (2021).

Edmondson, G. K. & Benisek, L. Solvent-applied flame-resist treatments for wool, cotton, and wool-cotton blends. J. Text. Inst. 68, 230–239 (1977).

Ma, L. et al. Hydrogen-free and dendrite-free all-solid-state Zn-ion batteries. Adv. Mater. 32, 1908121 (2020).

Zhang, Y. et al. Solvent molecule cooperation enhancing lithium metal battery performance at both electrodes. Angew. Chem. Int. Ed. 59, 7797–7802 (2020).

Moilanen, D. E., Wong, D., Rosenfeld, D. E., Fenn, E. E. & Fayer, M. Ion-water hydrogen-bond switching observed with 2D IR vibrational echo chemical exchange spectroscopy. Proc. Natl Acad. Sci. USA 106, 375–380 (2009).

Sun, T., Du, H., Zheng, S., Shi, J. & Tao, Z. High power and energy density aqueous proton battery operated at –90 °C. Adv. Funct. Mater. 31, 2010127 (2021).

Yang, H. et al. Constructing a super-saturated electrolyte front surface for stable rechargeable aqueous zinc batteries. Angew. Chem. Int. Ed. 59, 9377–9381 (2020).

Freire, M. G., Neves, C. M. S. S., Marrucho, I. M., Coutinho, J. A. P. & Fernandes, A. M. Hydrolysis of tetrafluoroborate and hexafluorophosphate counter ions in imidazolium-based ionic liquids. J. Phys. Chem. A 114, 3744–3749 (2010).

Han, D. et al. A corrosion-resistant and dendrite-free zinc metal anode in aqueous systems. Small 16, 2001736 (2020).

Zhang, N. et al. Rechargeable aqueous Zn-V2O5 battery with high energy density and long cycle life. ACS Energy Lett. 3, 1366–1372 (2018).

Yang, Y. et al. Transition metal ion-preintercalated V2O5 as high-performance aqueous zinc-ion battery cathode with broad temperature adaptability. Nano Energy 61, 617–625 (2019).

Zhang, W., Liang, S., Fang, G., Yang, Y. & Zhou, J. Ultra-high mass-loading cathode for aqueous zinc-ion battery based on graphene-wrapped aluminum vanadate nanobelts. Nanomicro Lett. 11, 25 (2019).

Kundu, D. et al. Aqueous vs. nonaqueous Zn-ion batteries: consequences of the desolvation penalty at the interface. Energy Environ. Sci. 11, 881–892 (2018).

Wan, F. et al. Aqueous rechargeable zinc/sodium vanadate batteries with enhanced performance from simultaneous insertion of dual carriers. Nat. Commun. 9, 1656 (2018).

Huang, J. Q., Guo, X., Lin, X., Zhu, Y. & Zhang, B. Hybrid aqueous/organic electrolytes enable the high-performance Zn-ion batteries. Research 2019, 2635310 (2019).

Zhu, J. et al. Building 3D structures of vanadium pentoxide nanosheets and application as electrodes in supercapacitors. Nano Lett. 13, 5408–5413 (2013).

Kresse, G. & Furthmuller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Grimme, S., Ehrlich, S. & Goerigk, L. Effect of the damping function in dispersion corrected density functional theory. J. Comput. Chem. 32, 1456–1465 (2011).

Blochl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Acknowledgements

This research was supported by grants from the National Natural Science Foundation of China (51972223, 51932005 and 51972312), China Postdoctoral Science Foundation (2021M692385), Natural Science Foundation of Tianjin (20JCYBJC01550) and the Local Innovative Research Teams Project of Guangdong Pearl River Talents Programme (2017BT01N111). We thank the National Supercomputer Center in Tianjin for computation support from TianHe-1(A) and the National Supercomputer Center in Guangzhou for computation support from Tianhe-2.

Author information

Authors and Affiliations

Contributions

Q.-H.Y., F.K. and Z.Weng proposed the project; Z.Weng and D.H. conceived the idea; and Z.Weng, F.K. and Q.-H.Y. supervised the project. D.H. and C.C. synthesized the samples and performed the characterizations and electrochemical measurements. K.Z. and L.Y. performed the simulation and data analysis. Z.Wang, Y.G., J.G. and Z.Z. contributed to the structural characterizations and electrochemical measurements. S.W. contributed to the structural and performance analysis. D.H., C.C., Z.Weng and Q.-H.Y. organized and wrote the manuscript. All authors contributed to the discussion and revision of the manuscript at all stages. D.H. and C.C. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Sustainability thanks Antonio Jesús Fernández Romero and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1−26, Tables 1−3 and References.

Supplementary Video 1

Flammability tests of the dry cotton ball.

Supplementary Video 2

Flammability tests of EG and the Zn(BF4)2/EG electrolyte.

Source data

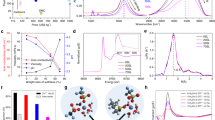

Source data for Fig. 1.

Price and volatility, flammability characterization of the Zn(BF4)2/EG electrolyte, as well as the internal interaction within the Zn(BF4)2/EG electrolyte.

Source data for Fig. 2.

SEM, XRD, Raman and XPS results of the Zn foil soaked in the 4 m Zn(BF4)2/EG electrolyte and the reference aqueous ZnSO4 electrolyte.

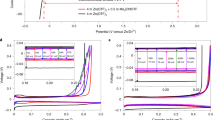

Source data for Fig. 3.

Long-term cycling, CE tests and SEM and AFM images of the Zn anodes cycled in the 4 m Zn(BF4)2/EG electrolyte and the reference aqueous ZnSO4 electrolyte.

Source data for Fig. 4.

Tolerance of the 4 m Zn(BF4)2/EG electrolyte to a wide temperature range, and the performance of Zn anodes under harsh conditions in different electrolytes.

Source data for Fig. 5.

Room- and low-temperature performance of Zn//V2O5 full cells, and images of the cycled V2O5 cathodes and the cycled separators.

Rights and permissions

About this article

Cite this article

Han, D., Cui, C., Zhang, K. et al. A non-flammable hydrous organic electrolyte for sustainable zinc batteries. Nat Sustain 5, 205–213 (2022). https://doi.org/10.1038/s41893-021-00800-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-021-00800-9

This article is cited by

-

Single [0001]-oriented zinc metal anode enables sustainable zinc batteries

Nature Communications (2024)

-

Proton-selective coating enables fast-kinetics high-mass-loading cathodes for sustainable zinc batteries

Nature Communications (2024)

-

Rapid-charging aluminium-sulfur batteries operated at 85 °C with a quaternary molten salt electrolyte

Nature Communications (2024)

-

A weakly solvating electrolyte towards practical rechargeable aqueous zinc-ion batteries

Nature Communications (2024)

-

Advances in All-Solid-State Lithium–Sulfur Batteries for Commercialization

Nano-Micro Letters (2024)