Abstract

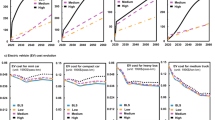

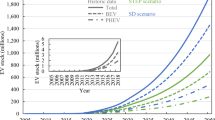

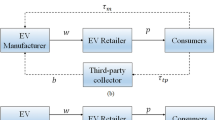

The wide adoption of lithium-ion batteries used in electric vehicles will require increased natural resources for the automotive industry. The expected rapid increase in batteries could result in new resource challenges and supply-chain risks. To strengthen the resilience and sustainability of automotive supply chains and reduce primary resource requirements, circular economy strategies are needed. Here we illustrate how these strategies can reduce the extraction of primary raw materials, that is, cobalt supplies. Material flow analysis is applied to understand current and future flows of cobalt embedded in electric vehicle batteries across the European Union. A reference scenario is presented and compared with four strategies: technology-driven substitution and technology-driven reduction of cobalt, new business models to stimulate battery reuse/recycling and policy-driven strategy to increase recycling. We find that new technologies provide the most promising strategies to reduce the reliance on cobalt substantially but could result in burden shifting such as an increase in nickel demand. To avoid the latter, technological developments should be combined with an efficient recycling system. We conclude that more-ambitious circular economy strategies, at both government and business levels, are urgently needed to address current and future resource challenges across the supply chain successfully.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All the data that were used for this study are available as supplementary tables in the Supplementary Information file. Additional questions about the data can be directed to the corresponding author.

References

Campbell, G. A. The cobalt market revisited. Miner. Econ. https://doi.org/10.1007/s13563-019-00173-8 (2019).

Shedd, K. B., McCullough, E. A. & Bleiwas, D. I. Global trends affecting the supply security of cobalt. Min. Eng. 69, 37–42 (2017).

Gulley, A. L., McCullough, E. A. & Shedd, K. B. China’s domestic and foreign influence in the global cobalt supply chain. Resour. Policy 62, 317–323 (2019).

Petavrazi, E., Gunn, G. & Kresse, C. Commodity Review: Cobalt (BGS, 2019).

Electric Vehicle Outlook 2020 (Bloomberg New Energy Finance, 2020).

Whittingham, M. S. History, evolution, and future status of energy storage. Proc. IEEE 100, 1518–1534 (2012).

Li, W., Erickson, E. M. & Manthiram, A. High-nickel layered oxide cathodes for lithium-based automotive batteries. Nat. Energy 5, 26–34 (2020).

Schmuch, R., Wagner, R., Hörpel, G., Placke, T. & Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 3, 267–278 (2018).

Final List of Critical Minerals 2018 (US Department of the Interior, 2018).

Australia’s Critical Minerals Strategy 2019 (Commonwealth of Australia, 2019).

Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the 2017 List of Critical Raw Materials for the EU (European Commision, 2017).

Lavietes, M. Tesla, Apple among firms accused of aiding child labor in Congo. Reuters (16 December 2019).

Vaalma, C., Buchholz, D., Weil, M. & Passerini, S. A cost and resource analysis of sodium-ion batteries. Nat. Rev. Mater. 3, 18013 (2018).

Cusenza, M. A., Guarino, F., Longo, S., Ferraro, M. & Cellura, M. Energy and environmental benefits of circular economy strategies: the case study of reusing used batteries from electric vehicles. J. Energy Storage https://doi.org/10.1016/j.est.2019.100845 (2019).

Yang, J., Gu, F. & Guo, J. Environmental feasibility of secondary use of electric vehicle lithium-ion batteries in communication base stations. Resour. Conserv. Recycl. https://doi.org/10.1016/j.resconrec.2020.104713 (2020).

Harper, G. et al. Recycling lithium-ion batteries from electric vehicles. Nature 575, 75–86 (2019).

Ziemann, S., Müller, D. B., Schebek, L. & Weil, M. Modeling the potential impact of lithium recycling from EV batteries on lithium demand: a dynamic MFA approach. Resour. Conserv. Recycl. 133, 76–85 (2018).

Harvey, L. D. D. Resource implications of alternative strategies for achieving zero greenhouse gas emissions from light-duty vehicles by 2060. Appl. Energy 212, 663–679 (2018).

Miedema, J. H. & Moll, H. C. Lithium availability in the EU27 for battery-driven vehicles: the impact of recycling and substitution on the confrontation between supply and demand until 2050. Resour. Policy 38, 204–211 (2013).

Melin, H. E. State-of-the-Art in Reuse and Recycling of Lithium-Ion Batteries—A Research Review (Circular Energy Storage, 2019).

Nguyen, R. T., Fishman, T., Zhao, F., Imholte, D. D. & Graedel, T. E. Analyzing critical material demand: a revised approach. Sci. Total Environ. 630, 1143–1148 (2018).

Regulation (EU) 2019/631 of the European Parliament and the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/2011 (European Union, 2019).

Hill, G., Heidrich, O., Creutzig, F. & Blythe, P. The role of electric vehicles in near-term mitigation pathways and achieving the UK’s carbon budget. Appl. Energy 251, 113111 (2019).

Godoy León, M. F., Blengini, G. A. & Dewulf, J. Cobalt in end-of-life products in the EU, where does it end up? The MaTrace approach. Resour. Conserv. Recycl. https://doi.org/10.1016/j.resconrec.2020.104842 (2020).

Europe’s Clean Mobility Outlook: Scenarios for the EU Light-Duty Vehicle Fleet, Associated Energy Needs and Emissions, 2020–2050 (Ricardo, 2018).

Berg, H. & Zackrisson, M. Perspectives on environmental and cost assessment of lithium metal negative electrodes in electric vehicle traction batteries. J. Power Sources 415, 83–90 (2019).

US DRIVE—Electrochemical Energy Storage Technical Team Roadmap (DOE, 2017).

Lee, Y.-G. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat. Energy https://doi.org/10.1038/s41560-020-0575-z (2020).

Dias, A. P., Blagoeva, D. T., Pavel, C. & Arvanitidis, N. Cobalt: Demand–Supply Balances in the Transition to Electric Mobility (Publications Office of the European Union, 2018).

Lithium and Cobalt—A Tale of Two Commodities (McKinsey, 2018).

Fu, X. et al. Perspectives on cobalt supply through 2030 in the face of changing demand. Environ. Sci. Technol. 54, 2985–2993 (2020).

Neubauer, J. S., Smith, K., Wood, E. & Pesaran, A. Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries (National Renewable Energy Laboratory, 2015).

Saxena, S., Le Floch, C., MacDonald, J. & Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 282, 265–276 (2015).

Assessment of the Implementation of Directive 2000/53/EU on End-of-Life Vehicles (the ELV Directive) with Emphasis on the End of Life Vehicles of Unknown Whereabouts (European Commission, 2018).

PEFCR—Product Environmental Footprint Category Rules for High Specific Energy Rechargeable Batteries for Mobile Applications (Recharge Association, 2018).

Placke, T., Kloepsch, R., Dühnen, S. & Winter, M. Lithium ion, lithium metal, and alternative rechargeable battery technologies: the odyssey for high energy density. J. Solid State Electrochem. 21, 1939–1964 (2017).

Bianchini, M., Roca-Ayats, M., Hartmann, P., Brezesinski, T. & Janek, J. There and back again—the journey of LiNiO2 as a cathode active material. Angew. Chem. Int. Ed. Engl. 58, 10434–10458 (2019).

Boehm, M. & Thomas, O. Looking beyond the rim of one’s teacup: a multidisciplinary literature review of product–service systems in information systems, business management, and engineering & design. J. Clean. Prod. 51, 245–260 (2013).

EASE & Delta-EE European electrical storage market grows by 49% in 2017 to 589 MWh. Delta Energy & Environment (2 July 2018).

Henze, V. Energy storage investments boom as battery costs halve in the next decade. Bloomberg New Energy Finance (31 July 2019).

Hill, N., Clarke, D., Blair, L. & Menadue, H. Circular Economy Perspectives for the Management of Batteries Used in Electric Vehicles Final Project Report (Ricardo, 2019).

Circular Energy Storage Online (Circular Energy Storage, 2020).

Schmidt, T., Buchert, M. & Schebek, L. Investigation of the primary production routes of nickel and cobalt products used for Li-ion batteries. Resour. Conserv. Recycl. 112, 107–122 (2016).

2015 Minerals Yearbook: Cobalt [Advance Release] (USGS, 2019).

Müller, M. et al. Evaluation of grid-level adaptability for stationary battery energy storage system applications in Europe. J. Energy Storage 9, 1–11 (2017).

Stahl, H. et al. Evaluation of the Directive 2006/66/EC on Batteries and Accumulators and Waste Batteries and Accumulators (Trinomics, 2018).

Tagliaferri, C. et al. Life cycle assessment of future electric and hybrid vehicles: a cradle-to-grave systems engineering approach. Chem. Eng. Res. Des. 112, 298–309 (2016).

Wang, X., Gaustad, G., Babbitt, C. W. & Richa, K. Economies of scale for future lithium-ion battery recycling infrastructure. Resour. Conserv. Recycl. 83, 53–62 (2014).

Favot, M. & Massarutto, A. Rare-earth elements in the circular economy: the case of yttrium. J. Environ. Manage. 240, 504–510 (2019).

Müller, E., Hilty, L. M., Widmer, R., Schluep, M. & Faulstich, M. Modeling metal stocks and flows: a review of dynamic material flow analysis methods. Environ. Sci. Technol. 48, 2102–2113 (2014).

Monitoring of CO2 Emissions from Passenger Cars—Data 2017 (European Environmental Agency, 2020)

Nelson, P. A., Gallagher, K. G., Bloom, I. & Dees, D. W. Modeling the Performance and Cost of Lithium-Ion Batteries for Electric-Drive Vehicles (Argonne National Laboratory, 2012).

Pillot, C. Lithium Ion Battery Raw Material Supply & Demand 2016–2025 (Avicenne Energy, 2017).

Cusenza, M. A., Bobba, S., Ardente, F., Cellura, M. & Di Persio, F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2019.01.056 (2019).

EPA’s Transportation and Air Quality Document Index System (DIS) (EPA, 2019).

Heppel, G. Cobalt shifts from metal to chemical markets. CRU (8 September 2017).

Farchy, J. & Warren, H. China has a secret weapon in the race to dominate electric cars. Bloomberg (2 December 2018).

Brunner, P. H. & Rechberger, H. Handbook of Material Flow Analysis: For Environmental, Resource, and Waste Engineers 2nd edn (CRC Press, 2016).

Wu, T., Zhao, H. & Ou, X. Vehicle ownership analysis based on GDP per capita in China: 1963–2050. Sustainability 6, 4877–4899 (2014).

Population on 1st January by Age, Sex and Type of Projection (Eurostat, 2018).

Nykvist, B., Sprei, F. & Nilsson, M. Assessing the progress toward lower priced long range battery electric vehicles. Energy Policy 124, 144–155 (2019).

European Vehicle Market Statistics: Pocketbook 2017/18 (ICCT, 2017).

Global EV Outlook 2018: Towards Cross-Modal Electrification (International Energy Agency, 2018).

Wentker, M., Greenwood, M. & Leker, J. A bottom-up approach to lithium-ion battery cost modeling with a focus on cathode active materials. Energies https://doi.org/10.3390/en12030504 (2019).

Dun, G., Pridmore, A., Gibson, G., Kollamthodi, S. & Skinner, I. Data Gathering and Analysis to Assess the Impact of Mileage on the Cost Effectiveness of the LDV CO2 Regulation (Ricardo, 2014).

Zubi, G., Dufo-López, R., Carvalho, M. & Pasaoglu, G. The lithium-ion battery: state of the art and future perspectives. Renew. Sustain. Energy Rev. 89, 292–308 (2018).

Martinez-Laserna, E. et al. Technical viability of battery second life: a study from the ageing perspective. IEEE Trans. Ind. Appl. 54, 2703–2713 (2018).

Peters, J. F., Baumann, M., Zimmermann, B., Braun, J. & Weil, M. The environmental impact of Li-ion batteries and the role of key parameters—a review. Renew. Sustain. Energy Rev. 67, 491–506 (2017).

Schmidt, T. S. et al. Additional emissions and cost from storing electricity in stationary battery systems. Environ. Sci. Technol. https://doi.org/10.1021/acs.est.8b05313 (2019).

Corchero, C., Gonzalez-Villafranca, S. & Sanmarti, M. European electric vehicle fleet: driving and charging data analysis. In Proc. 2014 IEEE International Electric Vehicle Conference (IEVC) 1–6 (IEEE, 2014).

Canals Casals, L., Amante García, B. & Cremades, L. V. Electric vehicle battery reuse: preparing for a second life. J. Ind. Eng. Manage. https://doi.org/10.3926/jiem.2009 (2017).

Harris, S. J., Harris, D. J. & Li, C. Failure statistics for commercial lithium ion batteries: a study of 24 pouch cells. J. Power Sources 342, 589–597 (2017).

Baumhöfer, T., Brühl, M., Rothgang, S. & Sauer, D. U. Production caused variation in capacity aging trend and correlation to initial cell performance. J. Power Sources 247, 332–338 (2014).

Nissan, Sumitomo Corp. and 4R set up plant to recycle electric-car batteries. Nissan Global Newsroom (28 March 2018).

Global EV Outlook 2019 (International Energy Agency, 2019).

xStorage Home—Eaton Nissan Home Energy Storage (Nissan and Eaton, 2017).

New power from old cells: Audi and Umicore develop closed loop battery recycling. Umicore Newsroom (26 October 2018).

Bourguignon, D. Circular Economy Package: Four legislative Proposals on Waste (European Parliamentary Research Service, 2018).

Hatzi-Hull, A. The ELV Directive: What Comes Next? (European Recycling Industries’ Confederation, 2018).

Alonso, E., Gregory, J., Field, F. & Kirchain, R. Material availability and the supply chain: risks, effects, and responses. Environ. Sci. Technol. 41, 6649–6656 (2007).

Mineral Commodity Summaries 2019 (USGS, 2019).

Historical Statistics for Mineral and Material Commodities in the United States US Geological Survey Data Series 140 (USGS, 2017).

Acknowledgements

This research was kindly supported by the Chartered Institution of Wastes Management (CIWM), the UK’s Engineering and Physical Sciences Research Council (EPSRC), the Faraday Institution (EP/S003053/1) and its Recycling of Li-Ion Batteries (ReLIB) project (FIRG005), and Newcastle University. We can confirm that none of the funders had input or a role to play in the conceptualization, design, data collection, analysis, decision to publish, or preparation of the study or this manuscript. An early draft of this work was presented as a poster, winning first prize, at the International Society of Industrial Ecology Conference (Beijing, China) in July 2019.

Author information

Authors and Affiliations

Contributions

J.B. initiated the study and conducted the research under guidance of T.D., R.B. and O.H. Data were collected by J.B. and analysed by J.B., T.D., O.H. and H.E.M. The first draft was written by J.B. under guidance of O.H. Additional background information was provided by H.E.M. The manuscript was edited by T.D., O.H., H.E.M. and R.B. The writing and publication process, correspondence between authors, editors, revision and publication was led by O.H. All authors are responsible for the contributions to the manuscript from the research, data, code and materials presented in the manuscript, Supplementary Information and Methods.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary methods, Figs. 1–5, and Tables 1 and 12–20.

Supplementary Tables

Underlying data for Fig. 1 (Supplementary Tables 2–11).

Rights and permissions

About this article

Cite this article

Baars, J., Domenech, T., Bleischwitz, R. et al. Circular economy strategies for electric vehicle batteries reduce reliance on raw materials. Nat Sustain 4, 71–79 (2021). https://doi.org/10.1038/s41893-020-00607-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-020-00607-0

This article is cited by

-

Grave-to-cradle photothermal upcycling of waste polyesters over spent LiCoO2

Nature Communications (2024)

-

Regional rare-earth element supply and demand balanced with circular economy strategies

Nature Geoscience (2024)

-

Metal electrodes for next-generation rechargeable batteries

Nature Reviews Electrical Engineering (2024)

-

Electric vehicle battery chemistry affects supply chain disruption vulnerabilities

Nature Communications (2024)

-

Electric vehicle adoption and sustainability: Insights from the bibliometric analysis, cluster analysis, and morphology analysis

Operations Management Research (2024)