Abstract

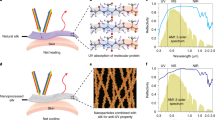

Global warming and energy crises severely limit the ability of human civilization to develop along a sustainable path. Increasing renewable energy sources and decreasing energy consumption are fundamental steps to achieve sustainability. Technological innovations that allow energy-saving behaviour can support sustainable development pathways. Energy-saving fabrics with a superior cooling effect and satisfactory wearability properties provide a novel way of saving the energy used by indoor cooling systems. Here, we report the large-scale extrusion of uniform and continuous nanoporous polyethylene (nanoPE) microfibres with cotton-like softness for industrial fabric production. The nanopores embedded in the fibre effectively scatter visible light to make it opaque without compromising the mid-infrared transparency. Moreover, using industrial machines, the nanoPE microfibres are utilized to mass produce fabrics. Compared with commercial cotton fabric of the same thickness, the nanoPE fabric exhibits a great cooling power, lowering the human skin temperature by 2.3 °C, which corresponds to a greater than 20% saving on indoor cooling energy. Besides the superior cooling effect, the nanoPE fabric also displays impressive wearability and durability. As a result, nanoPE microfibres represent basic building blocks to revolutionize fabrics for human body cooling and pave an innovative way to sustainable energy.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

King, D. A. Climate change science: adapt, mitigate, or ignore? Science 303, 176–177 (2004).

Chu, S. & Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 488, 294–303 (2012).

Roemmich, D. et al. Unabated planetary warming and its ocean structure since 2006. Nat. Clim. Change 5, 240–245 (2015).

Lee, R. The outlook for population growth. Science 333, 569–573 (2011).

Goldstein, E. A., Raman, A. P. & Fan, S. Sub-ambient non-evaporative fluid cooling with the sky. Nat. Energy 2, 17143 (2017).

Hoyt, T., Arens, E. & Zhang, H. Extending air temperature setpoints: simulated energy savings and design considerations for new and retrofit buildings. Build. Environ. 88, 89–96 (2015).

Raman, A. P., Anoma, M. A., Zhu, L., Rephaeli, E. & Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 515, 540–544 (2014).

Kou, J., Jurado, Z., Chen, Z., Fan, S. & Minnich, A. J. Daytime radiative cooling using near-black infrared emitters. ACS Photonics 4, 626–630 (2017).

Zhai, Y. et al. Scalable-manufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 355, 1062–1066 (2017).

Hsu, P.-C. et al. Personal thermal management by metallic nanowire-coated textile. Nano. Lett. 15, 365–371 (2014).

Hsu, P.-C. et al. Radiative human body cooling by nanoporous polyethylene textile. Science 353, 1019–1023 (2016).

Tong, J. K. et al. Infrared-transparent visible-opaque fabrics for wearable personal thermal management. ACS Photonics 2, 769–778 (2015).

Hardy, J. D. & Dubois, E. F. Regulation of heat loss from the human body. Proc. Natl Acad. Sci. USA 23, 624–631 (1937).

Chen, J. & Wang, Z. L. Reviving vibration energy harvesting and self-powered sensing by a triboelectric nanogenerator. Joule 1, 480–521 (2017).

Viklund, C., Svec, F. & Frechet, J. M. J. Monolithic, “molded”, porous materials with high flow characteristics for separations, catalysis, or solid-phase chemistry: control of porous properties during polymerization. Chem. Mater. 8, 744–750 (1996).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Khang, D.-Y., Jiang, H., Huang, Y. & Rogers, J. A. A stretchable form of single-crystal silicon for high-performance electronics on rubber substrates. Science 311, 208–212 (2006).

Ahn, B. Y. et al. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323, 1590–1593 (2009).

Fang, X., Wyatt, T., Hong, Y. & Yao, D. Gel spinning of UHMWPE fibres with polybutene as a new spin solvent. Polym. Eng. Sci. 56, 697–706 (2016).

Ruan, S., Gao, P. & Yu, T.-X. Ultra-strong gel-spun UHMWPE fibers reinforced using multiwalled carbon nanotubes. Polymer 47, 1604–1611 (2006).

Samon, J. M., Schultz, J. M. & Hsiao, B. S. Structure development in the early stages of crystallization during melt spinning. Polymer 43, 1873–1875 (2002).

Ihm, D., Noh, J. & Kim, J. Effect of polymer blending and drawing conditions on properties of polyethylene separator prepared for Li-ion secondary battery. J. Power Sources 109, 388–393 (2002).

Liu, V. & Fan, S. S4: A free electromagnetic solver for layered periodic structures. Comput. Phys. Commun. 183, 2233–2244 (2012).

Ghahramani, A., Zhang, K., Dutta, K., Yang, Z. & Gerber, B. Energy savings from temperature setpoints and deadband: Quantifying the influence of building and system properties on savings. Appl. Energy 165, 930 (2016).

Chen, Z., Zhu, L., Raman, A. & Fan, S. Radiative cooling to deep sub-freezing temperatures through a 24-h day–night cycle. Nat. Commun. 7, 13729 (2016).

Lee, H., Dellatore, S. M., Miller, W. M. & Messersmith, P. B. Mussel-inspired surface chemistry for multifunctional coatings. Science 318, 426–430 (2007).

Ryu, J., Ku, S.-H., Lee, H. & Park, C. B. Mussel‐inspired polydopamine coating as a universal route to hydroxyapatite crystallization. Adv. Funct. Mater. 20, 2132–2139 (2010).

Ryou, M.‐H., Lee, Y. M., Park, J.‐K. & Choi, J.W. Mussel‐inspired polydopamine‐treated polyethylene separators for high‐power Li‐ion batteries. Adv. Mater. 23, 3066–3070 (2011).

Kerker, M. & Matijević, E. Scattering of electromagnetic waves from concentric infinite cylinders. J. Opt. Soc. Am. 51, 506–508 (1961).

Acknowledgements

This work was sponsored by the Advanced Research Projects Agency–Energy (ARPA-E), US Department of Energy, under award DE-AR0000533. The authors thank H. Dai for lending them the thermal camera, and thank J. Lopez and V. Feig for helping with sample measurements.

Author information

Authors and Affiliations

Contributions

Y.P., J.C. and Y.C. conceived the idea, planned the study, designed the experiment, analysed the data and composed the manuscript. Y.P. and J.C. performed all of the experiments with the assistance of P.-C.H., L.C., B.L., G.Z., D.S.W. and H.R.L. Y.P. and J.C. addressed all of the reviewers’ concerns together. A.Y.S. performed the optical simulation. Y.Z. performed the energy saving calculation. P.B.C. coordinated the project. Y.C. and S.F. supervised the project. All of the authors reviewed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

Y.C., S.F., Y.P., J.C., A.Y.S., P.B.C. and P.-C.H. have a US patent application No. 62/399,974 related to this work.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–3, Supplementary Figures 1–13, Supplementary References 1–5

Supplementary Video 1

Nanoporous polyethylene thin film

Supplementary Video 2

The nanoporous polyethylene fabric

Supplementary Video 3

Continuous fibre production

Supplementary Video 4

Cotton-like soft nanoporous polyethylene microfibres

Supplementary Video 5

Washing and drying of nanoPE fabric with a commercial washing and drying machine

Rights and permissions

About this article

Cite this article

Peng, Y., Chen, J., Song, A.Y. et al. Nanoporous polyethylene microfibres for large-scale radiative cooling fabric. Nat Sustain 1, 105–112 (2018). https://doi.org/10.1038/s41893-018-0023-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41893-018-0023-2

This article is cited by

-

Preparation of thermoresponsive cotton fabric by grafting P(MEO2MA-co-OEGMA475-co-GMA) polymer for personal thermal management

Cellulose (2024)

-

Wettability Gradient-Induced Diode: MXene-Engineered Membrane for Passive-Evaporative Cooling

Nano-Micro Letters (2024)

-

Personal Thermal Management by Radiative Cooling and Heating

Nano-Micro Letters (2024)

-

Colloidal inorganic nano- and microparticles for passive daytime radiative cooling

Nano Convergence (2023)

-

Nanowire-based smart windows combining electro- and thermochromics for dynamic regulation of solar radiation

Nature Communications (2023)