Abstract

Spin-chain–spin-ladder cuprates, such as La5Ca9Cu24O41, have notable electronic and thermal properties because of their unique electron spin arrangement. Among them, magnon thermal conductivity, which originates from the excitation of paired electron spins, is promising for the advanced thermal management applications that enable dynamic control of heat flow. This is because of its high, anisotropic thermal conductivity at room temperature and its dynamic controllability. In this study, we report nanosheet fabrications from polycrystalline La5Ca9Cu24O41 to enhance the control width. We obtained that the nanosheets with a thickness of about 3 nm are obtained via immersion of the polycrystals in a NaOH aqueous solution. We propose the exfoliation model based on the chemical reaction between the (La/Ca)2Cu2O3 subsystem and NaOH solution. The nanosheet fabrications can also lead to new research development on spin-ladder system and other strongly correlated cuprates.

Similar content being viewed by others

Introduction

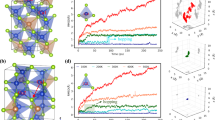

Spin-chain–spin-ladder cuprates have attracted significant attention from the viewpoint of electronic properties (e.g. superconductivity) and notable thermal conductivity due to magnons1,2,3,4,5,6. The typical spin-chain–spin-ladder cuprate La5Ca9Cu24O41 (LCCO) contains CuO2 and Cu2O3 layers interleaved by La3+ and Ca2+ (Fig. 1a); the two kinds of layers comprise spin chains and spin ladders, respectively. To be exact, La3+ and Ca2+ belong to Cu2O3 layers, i.e. the crystal consists of the negatively and positively charged subsystems, CuO2 and (La5/14Ca9/14)2Cu2O3, respectively, which are alternately stacked toward the b axis (Fig. 1b). Notably, the magnons in the Cu2O3 layers, corresponding to excitations of the singlet state of the paired electron spins to the triplet state, act as heat carriers1,4,5. Particularly, the single crystal of LCCO possesses the highest magnon thermal conductivity at ~300 K in these types of cuprates, ~90 W/(m K), only toward the c axis, i.e. the spin ladders, in contrast to the low phonon thermal conductivity, ~2 W/(m K), which is approximately isotropic4. As stated in our previous study7, the magnon thermal conductivity has the potential to be reversibly reduced by over an order of magnitude by a field-effect hole doping and subsequent decrease in the magnon mean free path, in addition to the high, anisotropic thermal conductivity8,9,10,11.

These characteristics are promising for advanced thermal management applications that enable dynamic control of heat flow12,13, e.g., smart heat dissipation for the high stability of electronic devices and improvement in heat storage and thermoelectric conversion efficiency. For this application, many studies on the dynamic control of heat flow, particularly using change in thermal conductivity by external fields, have been conducted12,13,14,15,16,17,18,19. However, in many cases, the coexistence of the high upper limit of thermal conductivity, high controllable range, and high anisotropy, which are necessary for practical uses, seems not to have been achieved. Therefore, LCCO is a promising material for applications in terms of the coexistence of the three required properties.

However, the controllable thickness of LCCO is predicted to be on the order of as thin as a few nanometers or less, which is dominated by the field-effect doping20,21; thus, giving rise to significant dead areas for the bulk crystal and decrease in controllability of thermal conductance determining effective control width of heat flow. Therefore, it is essential to use nanosheet fabrication to overcome this issue22,23,24. In this study, we aim to prepare LCCO nanosheets in which the c axis is parallel to the surface, and the thickness is comparable with the predictable controllable one. We obtained that the nanosheets with a thickness of about 3 nm are obtained by immersion of the polycrystalline LCCO in NaOH aqueous solution. We infer from the morphology observation using microscopies and micro-Raman spectroscopy that the nanosheets have been exfoliated from the crystal grains and retain the spin ladders necessary for the magnon thermal conductivity. However, details regarding structure and composition have not been perfectly revealed. We propose an exfoliation model based on the decomposition of (La5/14Ca9/14)2Cu2O3 subsystem by the solution. To the best of our knowledge, this is the first time nanosheets of spin-ladder systems are fabricated. Moreover, instead of mechanical exfoliation, a soft-chemical method is applied to nanosheet fabrications for strongly correlated cuprates, including superconductors (e.g. Bi2Sr2CaCu2Ox22,25). These fabrications can also lead to new research development on the spin-ladder cuprates ladder system and the other strongly correlated cuprates.

Results

Scanning electron microscopy (SEM)

Figure 2a, b shows the low- and high-magnification secondary electron images of polycrystalline LCCO on the Si substrate in scanning electron microscopy (SEM), respectively (See Methods for details regarding the preparation of the polycrystals). The median diameter was evaluated to be about 3.5 μm from the analysis of grain size distribution by thresholding the low-magnification image. Figure 2b also shows the distorted, large particles with a diameter of about 30 μm, which seem to be aggregations of the small grains.

Atomic force microscopy

Figure 3 shows atomic force microscopy (AFM) images of the filter residues subjected to immersion to NaOH aqueous solution with a 5 mol/L concentration and stirring for 6 h and placed on the Si substrate (See Methods for details regarding the sample preparation). Figure 3a shows three kinds of deposits. One is the aggregations, which appear to be the bright areas, with a thickness of over several hundred nanometers. Based on the results of X-ray diffraction (XRD) in the next subsection (Fig. 4a), these aggregations can be La(OH)3, Ca(OH)2, CuO, and LCCO. Another is the strip-like thin plates, i.e. nanosheets, with about 3 nm thickness and 1 μm lateral dimension (Fig. 3b, c). Several nanosheets with a thickness of less than 2 nm have been collapsed (the inset in Fig. 3a). The other is comparatively large plates with steps and terraces (Fig. 3d, e). The lateral dimension is about 3 μm, and the step height is about 3 nm, corresponding to the median diameter of crystal grains (Fig. 2a) and the thickness of nanosheets (Fig. 3c), respectively. This coincidence strongly supports that the nanosheets have been exfoliated from the LCCO crystal grains. We measured the thickness of 283 nanosheets on the Si substrate and investigated the distribution (Fig. 3f). Almost all nanosheets have a thickness of about 2.8 nm, but parts are about 1.4 nm thick.

The sample was the filter residues of LCCO polycrystals subjected to immersion to NaOH aqueous solution with 5 mol/L concentration and stirring for 6 h. a Low-magnification image. The inset is the image of the collapsed nanosheet. High-magnification images for (b, c) the nanosheet and d, e the large plate with steps and terraces. c, e Shows the heights along the white dot lines in (b) and (d), respectively. f Thickness distribution of the nanosheets.

The sample was the filter residues of polycrystalline LCCO subjected to immersion to NaOH aqueous solution with 5 mol/L concentration and stirring for 6 h. a Spectra of areas, excluding and including the nanosheets in the Si substrate. The inset is the optical microscopy image, where the canter and 5 μm away points were inspected. Note that the nanosheets are not observed by optical microscopy. b The increase in intensity compared with the two spectra in Fig. 4a. c Raman spectra of the ca plane of the single crystal synthesized by a traveling solvent floating zone method5 (TSFZ; See Methods regarding the synthesis methods). Polarization configurations are indicated by the Porto notation42, −b(a/c, un)b, i.e. a- or c-axis linearly-polarized lights entered the ca plane toward the −b axis and the backscattered, unpolarized light was detected.

Micro-Raman spectroscopy

Figure 4a shows the Raman spectra of two different areas, excluding and including the nanosheets, A and B, in the Si substrate used in the AFM observation (Fig. 3). The two areas have a diameter of about 1 μm, corresponding to the focal spot size of the incident laser light. The spectrum of area A shows only the peaks due to Si. Meanwhile, we can see an increase in scattering intensity in the range of about 1000–4000 cm−1 in the spectrum of area B. Figure 4b shows the increase in intensity compared with the two spectra. The spectrum shows the broad peak centred at a high wavenumber of about 2800 cm−1. This broad peak, referred to as the two-magnon peak, is unique to materials having strongly antiferromagnetically coupled spins causing high thermal conductivity, as in the spin ladder of LCCO7,26,27,28,29 (Fig. 4c). Therefore, the appearance of the two-magnon peak in the nanosheets means that the spin ladders as is seen in the single crystal, providing the high, anisotropic magnon thermal conductivity, remain even in the nanosheets. By contrast, the peaks due to phonons7,30,31 observed at about 580 and 1100 cm−1 (Fig. 4c) are weakened. Such a weakening has been reported in the p-type high-Tc superconductors composed of CuO2 planes, which can be interpreted as the screening effect, i.e. the doped holes causing an increase in the total number of holes screen the layers related to the phonon modes from the incident laser light; thus, the effective scattering intensity decreases32,33. Obviously, the doped holes can affect the two-magnon peak, for which we see the broadening of the two-magnon peak to the lower wavenumber (Fig. 4b, c). This phenomenon is consistent with the previous report33. Whether this phenomenon occurs in the nanosheets is not clear; however, if it occurs, the hole doping might be induced by imperfections for the chemical reaction proposed later (Eq. (1)) or the conductive Si substrate.

a Polycrystalline LCCO. Two miller indices are indicated as hklLlC, where the subscripts, L and C, denote spin ladder and chain, respectively34. b The filter residues subjected to immersion to NaOH aqueous solution with 5 mol/L concentration at a 6 h stirring time. Dependences of the decomposition rate on c NaOH solution concentration at a 6 h stirring time and d stirring time for 5 mol/L concentration.

XRD

Figure 5a shows the XRD patterns of polycrystalline LCCO synthesised using the solid-state reaction method and filter residues subjected to immersion to NaOH aqueous solution with 5 mol/L concentration and stirring. The pattern of the polycrystal (Fig. 5a) is consistent with that of the previous reports7,34. In the 6 h stirred samples (Fig. 5b), we see the six additional peaks at 2θ~34°, 36°, 39°, 47°, 49°, and 51°. Considering the compositions of polycrystals and solution, these peaks can be assigned to Ca(OH)235 and CuO36. Focusing on the peaks from LCCO, the intensities, except for the 0400 peak at 2θ~28°, seems to be weakened via stirring. At 2θ~28°, the sharp peak disappears and, alternatively, the broad peak appears (Fig. 5b). There are two possible origins of this broad peak. One is the effect of thinning of the LCCO crystal grains. Assuming that the surface of nanosheets with a thickness of about 3 nm in Fig. 3 was normal to the b axis, the Scherrer equation gave the full width of half maximum of about 3° to the 0400 peak, which is consistent with the result of Fig. 5b. The other is the precipitation of La(OH)3 because it is likely that the La(OH)3 nanocrystal has a broad peak at about 28°37. These two possibilities may affect the broad peak. No clear peaks from crystals containing Na are found.

Figure 5c shows the dependence of the decomposition rate on NaOH solution concentration at the 6 h stirring time, where the rate was defined as the intensity ratio of CuO peak at about 39° against the strongest LCCO peak at about 33°, referred to as ICuO/I2400. The rate gradually increases as the concentration increases in the range of 0–4 mol/L and abruptly increases at 5 mol/L. Figure 5d shows the dependence of the rate on the stirring time for 5 mol/L concentration. The rate increases as stirring time increases and seems to be saturated at ~6 h and subsequently decreases. The decrease in rate may be due to a reaction between precipitated CuO and water, i.e. CuO + H2O → Cu(OH)2. Supplementary Table 1 summarises the chemical reactions with the other kinds of solutions.

Transmission electron microscopy (TEM)

We conducted TEM, electron diffraction (ED), and energy-dispersive X-ray spectroscopy (EDX) for the same residues used in the AFM observation. The bright field/high-resolution TEM images (Fig. 6a, b) and ED pattern (Fig. 6c) were obtained because the sheets are thin enough to allow electron transmission through them. In Fig. 6c, we found that the thin sheets belong to the orthorhombic system, which corresponds to that of LCCO, and the diffraction pattern is able to be indexed using the lattice constants of LCCO (Fig. 1a). In the lattice fringes (Fig. 6b) of the TEM image, we observed the Moiré patterns throughout the area and steps along the edge, indicating that the thin sheets have layer structures with high crystal orientation that are strained and mismatched, i.e. the thin sheets are under exfoliation process, which may be consistent with the weak diffractions from the high-index planes (Fig. 6c). Moreover, these sheets are confirmed to have four elements (La, Ca, Cu, and O) composing LCCO, except for C within a resolution of 0.1 at % using EDX analysis (Fig. 6d). These results strongly support that the obtained thin sheets are LCCO. In the ED patterns and high-resolution TEM, perfect single crystals of LCCO should show diffraction patterns originating from the two kinds of subsystems and clear lattice images38. The lack of these patterns and images in the thin plate results from its structural imperfection, but which is exactly the notable feature indicating the exfoliation process.

The sample was the filter residues of polycrystalline LCCO subjected to immersion to NaOH aqueous solution with 5 mol/L concentration and 6 h stirring time. a Bright-field image of the thin sheet. b Lattice image in the edge. c Electron diffraction pattern. d EDX spectrum. The peak due to Ni is derived from the Ni mesh holder.

Discussions

We found that the nanosheets could be successfully obtained by immersing polycrystalline LCCO into NaOH aqueous solution. The nanosheets have been exfoliated from the LCCO grains and retained the spin ladders causing the magnon thermal conductivity as the AFM, Raman spectroscopy and TEM indicate. However, the nanosheets have not yet been perfectly assigned to LCCO. The XRD results showed that Ca(OH)2 and CuO are precipitated as by-products, and a notable broad peak appears. Meanwhile, for the broad peak, we could hardly distinguish the effects of La(OH)3 precipitation and thinning of the LCCO grains.

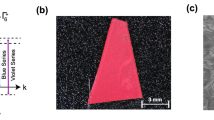

We propose an exfoliation model consistent with these results. Firstly, we must consider the origin of exfoliation. To elucidate it, we investigated the morphology of LCCO single crystals larger than the grains used for the nanosheet fabrication. Figure 7 shows the polarised optical microscopic images of the single crystals synthesised by TSFZ5 and solid-state reaction method with a higher calcination temperature (See Methods regarding the synthesis methods). After the 2 min ceria polishing for the crystal synthesised using the TSFZ method, we observed the steps and terraces in the ca plane parallel to the ab and ca plane, respectively (Fig. 7a). Interestingly, subsequent ceria polishing along the c axis easily provides the strip-like thin plates whose surface is normal to the b axis with a thickness of 80–200 nm, determined using AFM. Alternatively, the steps and terraces disappear (Fig. 7b). Moreover, the step lines parallel to the a axis (Fig. 7a) are retained in the exfoliated thin plates, clearly seen in Fig. 7b, c, i.e. the long sides of plates correspond to the a axis. We also see the steps and terraces in the as-prepared crystal synthesised using the solid-state reaction method (Fig. 7e).

The ca plane of the single crystal synthesised using the TSFZ method subjected to a 2 min and b–d 5 min ceria polishing along the c axis, followed by the rough polishing using sandpapers. b–d Show the uniformly coloured strip-like areas, suggesting that the plates are the single crystal. e An as-prepared crystal grain synthesised by the solid-state reaction method with a higher calcination temperature than that set for the nanosheet fabrication.

These results suggest that the origin of exfoliation of the strip-like nanosheets from the LCCO grains by immersion in NaOH aqueous solution can also be the intrinsic steps, which could not be clearly observed in the SEM image (Fig. 2b). In other words, we infer that the chemical reaction between the steps and solution induces the exfoliation.

Here, considering that LCCO comprises two subsystems, (La5/14Ca9/14)2Cu2O3 and CuO2, the following reaction equation can be proposed:

In the equation, (La5Ca9Cu24O41)sub is a subsystem of [7(La5/14Ca9/14)2Cu2O3]19+ sandwiched by two subsystems of [(10CuO2 + h+)/2]19/2−, where h+ is a self-doped hole and the dividing by two means half contribution of each subsystem. The subsystem of [7(La5/14Ca9/14)2Cu2O3]19+ is reacted with NaOH solution to produce La(OH)3, Ca(OH)2, and CuO, which is consistent with the XRD results (Fig. 5b). 2[(10Na1.9CuO2)/2]ex correspond to two exfoliated surfaces modified by Na+. For the thickness distribution, we have the following possible scenarios. The successive exfoliation thins down the LCCO grains into plates. Finally, the thickness of plates is close to the lattice constant b or twice of b (Fig. 3f), which may be reasonable. This is because we expect that the nanosheets with the same atomic arrangement in both exfoliated sides are energetically stable. The slight increase by ~0.2 nm from b or 2b is attributable to Na+ terminating CuO2 layers. We hardly observe the nanosheets with a thickness of about 1.4 nm because of the collapse of the nanosheets, as shown in Fig. 3f, which may arise from strains by adhesion to the substrate. However, the actual reaction could be more complicated than Eq. (1), causing higher order reaction with a nonlinear relation between the reaction rate and the solution concentration such as the rapid increase in reactivity at a concentration of 5 mol/L (Fig. 5c).

The magnon thermal conductivity and its control width in the obtained nanosheets might not be enough for the practical thermal management. This is because of the structural defects, i.e., the overdoping of holes and the strain and mismatching in layer structures by the reaction with the aqueous solution, as seen in the Raman spectrum (Fig. 4) and the TEM images (Fig. 6). However, we have two ideas to overcome it. One is annealing of the nanosheets, which is expected to revive the crystal quality29. The other is a combination with the mechanical exfoliation. We found that the mechanical process is effective for the exfoliation of LCCO but whose thickness is as thick as 80–200 nm (Fig. 7). The mechanical process with transient immersion to the NaOH solution will promote the nanosheet fabrication keeping their structural order.

In summary, we successfully fabricated the nanosheets with a thickness of about 3 nm from LCCO polycrystals with magnon thermal conductivity. We infer that the nanosheets whose surfaces are normal to the b axis and terminated by Na+ are produced by exfoliation from LCCO crystal grains from the microscopies. The Raman spectrum of the nanosheets shows the peak due to magnons, leading to the high anisotropic thermal conductivity and its controllability. By contrast, the phonon peaks disappear, which can be the hole doping, leading to the screening effect; however, the origin of the hole doping has not been clear. The nanosheets prepared in this study are likely to have a high control width of heat flow or thermal conductance as an order of magnitude; consequently, the applications for advanced thermal management will be anticipated. To the best of our knowledge, this is the first time nanosheets of the spin-ladder system are fabricated. Moreover, instead of mechanical exfoliation, a soft-chemical method is applied to nanosheet fabrications for strongly correlated cuprates, including superconductors. These fabrications can also lead to new research development on the spin-ladder system and other strongly correlated cuprates.

Methods

Sample preparation and characterisations

Polycrystalline LCCO for nanosheet fabrication was synthesised using a solid-state reaction method, according to the previous reports7,39: La2O3, CaCO3, and CuO reagents with purities over 99.9% were weighed to obtain its cation molar ratio and ground in an agate mortar. The mixed powder was placed in a Pt crucible and heated using an electric furnace with a heating rate of 10 °C/min. The calcination and grind were repeated three times. The conditions were 920, 950, and 970 °C for 24, 24, and 72 h, respectively in the order of the calcination.

Additionally, the two kinds of crystals were used only for observing crystal planes. One is a single crystal synthesised using the TSFZ method5, whose surface was roughly polished using sandpapers and subsequently polished using ceria powder and water. The other is polycrystals by the solid-state reaction method, where only the third calcination condition was changed to 1000 °C for 72 h.

The polycrystals were immersed in eight aqueous solutions, NaOH, Ba(OH)2 ∙ 8H2O, MgO, H2O, NaCl, C6H4(COOK)(COOH), H2SO4 and HCl aq. and stirred for 0–48 h at room temperature using a magnetic stirrer with a rotational speed of 300 rpm. After stirring, the residues were separated via filter papers. For the polycrystals and separated residues, the XRD patterns were recorded with a new D8 advance apparatus (Bruker) using CuKα radiation and a θ–2θ configuration. The morphology of the polycrystals was inspected through optical microscopy and SEM (VE-9800, KEYENCE). The residues were immersed in pure water and restirred using an ultrasonic homogeniser (UH-600S, SMT Co. Ltd.). A drop of the restirred solution was placed on the Si substrate and dried in a vacuum desiccator. The deposits on the substrate were observed through AFM (Nanocute, Hitachi High-Tech Corporation) and Raman spectroscopy (NRS-4500, JASCO). For the Raman spectroscopy, the apparatus included confocal microscopy with a 100× objective lens and an excitation source of 532 nm laser light. The scattered light was detected with a backscattering configuration with no polariser, whereas the incident light was linearly polarised. The residues dispersed in ethanol and placed on a Ni mesh holder were inspected using TEM (JEM-2100F, JEOL) equipped with EDX.

Data availability

The datasets generated and/or analysed during the current study are available from the corresponding authors on reasonable request.

References

Vuletic, T. et al. The spin-ladder and spin-chain system (La, Y, Sr, Ca)14Cu24O41: Electronic phases, charge and spin dynamics. Phys. Rep. 428, 169–258 (2006).

Uehara, M. et al. Superconductivity in the ladder material Sr0.4Ca13.6Cu24O41.84. J. Phys. Soc. Jpn. 65, 2764–2767 (1996).

Kumagai, K., Tsuji, S., Kato, M. & Koike, Y. NMR study of carrier doping effects on spin gaps in the spin ladder Sr14−xAxCu24O41 (A = Ca, Y, and La). Phys. Rev. Lett. 78, 1992–1995 (1997).

Hess, C. Heat transport of cuprate-based low-dimensional quantum magnets with strong exchange coupling. Phys. Rep. 811, 1–38 (2019).

Naruse, K. et al. Thermal conductivity due to magnons in high-quality single crystals of the two-leg spin-ladder system (Ca, Sr, La)14Cu24O41. Solid State Commun. 154, 60–63 (2013).

Silva, R. A. L. & Almeida, M. Spin-ladder behaviour in molecular materials. J. Mater. Chem. C. 9, 10573–10590 (2021).

Terakado, N., Nara, Y., Machida, Y., Takahashi, Y. & Fujiwara, T. Dynamic control of heat flow using a spin-chain ladder cuprate film and an ionic liquid. Sci. Rep. 10, 14468 (2020).

Terakado, N. et al. Fabrication of glass-ceramics containing spin-chain compound SrCuO2 and its high thermal conductivity. Appl. Phys. Lett. 106, 141902 (2015).

Terakado, N., Takahashi, R., Takahashi, Y. & Fujiwara, T. Synthesis of chain-type SrCuO2 by laser irradiation on sputtered layer-type SrCuO2 film. Thin Solid Films 603, 303–306 (2016).

Terakado, N., Yokochi, Y., Watanabe, K., Takahashi, Y. & Fujiwara, T. Syntheses of spinon thermal conductivity materials in Sr–Cu–O system by glass-ceramics technique. J. Am. Ceram. Soc. 99, 1565–1572 (2016).

Terakado, N., Takahashi, R., Takahashi, Y. & Fujiwara, T. Line patterning of anisotropic spin chains by polarized laser for application in micro-thermal management. Appl. Phys. Lett. 110, 191902 (2017).

Swoboda, T., Klinar, K., Yalamarthy, A. S., Kitanovski, A. & Muñoz Rojo, M. Solid–state thermal control devices. Adv. Electron. Mater. 7, 2000625 (2021).

Wehmeyer, G., Yabuki, T., Monachon, C., Wu, J. & Dames, C. Thermal diodes, regulators, and switches: Physical mechanisms and potential applications. Appl. Phys. Rev. 4, 041304 (2017).

Cho, J. et al. Electrochemically tunable thermal conductivity of lithium cobalt oxide. Nat. Commun. 5, 4035 (2014).

Hirata, K., Matsunaga, T., Singh, S., Matsunami, M. & Takeuchi, T. Capacitor-type thin-film heat flow switching device. Jpn. J. Appl. Phys. 60, 124004 (2021).

Kang, J. S., Ke, M. & Hu, Y. Ionic intercalation in two-dimensional van der Waals materials: In situ characterization and electrochemical control of the anisotropic thermal conductivity of black phosphorus. Nano Lett. 17, 1431–1438 (2017).

Lu, Q. et al. Bi-directional tuning of thermal transport in SrCoOx with electrochemically induced phase transitions. Nat. Mater. 19, 655–662 (2020).

Nakayama, H. et al. Above-room-temperature giant thermal conductivity switching in spintronic multilayers. Appl. Phys. Lett. 118, 042409 (2021).

Sood, A. et al. An electrochemical thermal transistor. Nat. Commun. 9, 4510 (2018).

Ueno, K. et al. Electric-field-induced superconductivity in an insulator. Nat. Mater. 7, 855–858 (2008).

Bisri, S. Z., Shimizu, S., Nakano, M. & Iwasa, Y. Endeavor of iontronics: From fundamentals to applications of ion‐controlled electronics. Adv. Mater. 29, 1607054 (2017).

Novoselov, K. S. et al. Two-dimensional atomic crystals. Proc. Natl Acad. Sci. USA 102, 10451–10453 (2005).

Osada, M. & Sasaki, T. Two-dimensional dielectric nanosheets: Novel nanoelectronics from nanocrystal building blocks. Adv. Mater. 24, 210–228 (2012).

Zhang, S. et al. Full review: The progress and developing trends of nanosheet-based sensing applications. Coord. Chem. Rev. 433, 213742 (2021).

Liu, G. et al. Two-dimensional Bi2Sr2CaCu2O8+δ nanosheets for ultrafast photonics and optoelectronics. ACS Nano 15, 8919–8929 (2021).

Sugai, S. & Suzuki, M. Magnetic Raman scattering in two-leg spin ladder Sr14−xyCaxYyCu24O41. Phys. Stat. Sol. (b) 215, 653–659 (1999).

Windt, M. et al. Observation of two-magnon bound states in the two-leg ladders of (Ca, La)14Cu24O41. Phys. Rev. Lett. 87, 127002 (2001).

Devereaux, T. P. & Hackl, R. Inelastic light scattering from correlated electrons. Rev. Mod. Phys. 79, 175–233 (2007).

Chen, X. et al. Synthesis and magnon thermal transport properties of spin ladder Sr14Cu24O41 microstructures. Adv. Funct. Mater. 30, 2001637 (2020).

Popović, Z. V. et al. Optical properties of the spin-ladder compound Sr14Cu24O41. Phys. Rev. B 62, 4963–4972 (2000).

Holmlund, J. et al. Resonant two-phonon Raman scattering as a probe of hole crystal formation in Sr14−xCaxCu24O41. Phys. Rev. B 74, 134502 (2006).

Kakihana, M. et al. Raman-active phonons in Bi2Sr2Ca1−xYxCu2O8+d (x = 0–1): Effects of hole filling and internal pressure induced by Y doping for Ca, and implications for phonon assignments. Phys. Rev. B 53, 11796–11806 (1996).

Sugai, S., Suzuki, H., Takayanagi, Y., Hosokawa, T. & Hayamizu, N. Carrier-density-dependent momentum shift of the coherent peak and the LO phonon mode in p -type high-Tc superconductors. Phys. Rev. B 68, 184504 (2003).

Ammerahl, U. & Revcolevschi, A. Crystal growth of the spin-ladder compound (Ca, La)14Cu24O41 and observation of one-dimensional disorder. J. Cryst. Growth 197, 825–832 (1999).

Asikin-Mijan, N., Taufiq-Yap, Y. H. & Lee, H. V. Synthesis of clamshell derived Ca(OH)2 nano-particles via simple surfactant-hydration treatment. Chem. Eng. J. 262, 1043–1051 (2015).

Yao, W.-T. et al. Formation of uniform CuO nanorods by spontaneous aggregation: Selective synthesis of CuO, Cu2O, and Cu nanoparticles by a solid−liquid phase arc discharge process. J. Phys. Chem. B 109, 14011–14016 (2005).

Yousaf, A. B., Imran, M., Farooq, M. & Kasak, P. Interfacial phenomenon and nanostructural enhancements in palladium loaded lanthanum hydroxide nanorods for heterogeneous catalytic applications. Sci. Rep. 8, 4354 (2018).

Milat, O., Van Tendeloo, G., Amelinckx, S., Mehbod, M. & Deltour, R. The incommensurate structure of (Sr, Ca)14Cu24O41: A study by electron diffraction and high-resolution microscopy. Acta Crystallogr. A 48, 618–625 (1992).

Svoukis, E. et al. Structural and thermal characterization of La5Ca9Cu24O41 thin films grown by pulsed laser deposition on (1 1 0) SrTiO3 substrates. Thin Solid Films 520, 4613–4616 (2012).

Momma, K. & Izumi, F. VESTA|3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Cryst. 44, 1272–1276 (2011).

Siegrist, T. et al. A new layered cuprate structure-type, (A1−xA'x)14Cu24O41. Mat. Res. Bull. 23, 1429–1438 (1988).

Damen, T. C., Porto, S. P. S. & Tell, B. Raman effect in zinc oxide. Phys. Rev. 142, 570–574 (1966).

Acknowledgements

This work was supported by JST, PRESTO Grant Number JPMJPR18I7, Japan and JSPS KAKENHI Grant Number 17H04811. We thank Prof. Yoji Koike of Tohoku University for the advice on the cuprate characteristics. We thank Ms. Chihiro Kato of Tohoku University for her significant contributions to this work.

Author information

Authors and Affiliations

Contributions

H.K., N.T., and C.I. fabricated and characterised the samples to fabricate the nanosheet and performed the micro-Raman spectroscopy, AFM and polarised optical microscopy in the single crystal. T.M. prepared the sample for TEM and performed the observation including ED and EDX. K.N. and T.K. synthesised the single crystal by the TSFZ method and check its quality. N.T., H.K., T.F. and Y.T. designed the work. N.T., T.M., T.F. and Y.T. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing non-financial interests but the following competing financial interests: H.K., N.T., Y.T. and T.F. are co-inventors of a pending patent relating to the method described in the manuscript.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kinoshita, H., Terakado, N., Takahashi, Y. et al. Nanosheet fabrication from magnon thermal conductivity cuprates for the advanced thermal management. npj 2D Mater Appl 6, 70 (2022). https://doi.org/10.1038/s41699-022-00344-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41699-022-00344-2