Abstract

Nanoporous patterning of two-dimensional materials using block copolymer lithography has drawn much attention. Lateral edge exposures made by the nanoporous patterning provide electrical and optical characteristics that are different from the original materials. However, nanopatterning processes inevitably generate edge exposure and surface defects that may result in poor reliability and reproducibility of the devices. In this study, we propose a reliable method to passivate nanoporous molybdenum disulfide (MoS2) thin-film transistors (TFTs) using polymer thin films, synthesized by initiated chemical vapor deposition (iCVD) to improve the electrical stability of nanoporous MoS2 TFTs. To this end, functional polymer films of electron-donating poly(1-vinylimidzole) (pVI) and inert poly(1H,1H,2H,2H-perfluorodecyl methacrylate) (pPFDMA) were utilized as passivation layers on nanoporous MoS2 TFTs. An n-type doping effect was observed in the pVI-deposited nanoporous MoS2 film due to the electron-donating imidazole ring, whereas the inert pPFDMA efficiently stabilized the electrical characteristics of the nanoporous MoS2 TFTs. Moreover, the hydrophobic fluoroalkyl chain of the pPFDMA film efficiently prevented oxygen and moisture adsorption on the nanoporous MoS2. The superior passivation effect of the pPFDMA layer was confirmed using gate-bias stress tests and long-term storage tests under ambient conditions.

Similar content being viewed by others

Introduction

Owing to their high carrier mobility, sharp subthreshold slope, and exceptional endurance to mechanical stress, two-dimensional (2D) materials are considered as potential candidates for applications in functional electronics, such as flexible thin-film transistors (TFTs) for active display matrices and integrated circuits1,2,3. Owing to their large surface-to-volume ratio, various 2D material-based sensing devices have been successfully demonstrated in the past decade, including phototransistors4,5,6, gas sensors7,8, and biosensors9,10.

The unique electrical and optical properties of 2D materials can be systematically tuned using structural engineering, making 2D materials ideal for electronic devices. Modifying the dimensions or morphology of 2D materials changes their structural properties, which imparts various exotic properties to overcome existing material limitations11. As a well-known example, the zero bandgap of pristine 2D graphene does not exhibit good capability for electronic applications. However, it has been modified to form nanodot12, nanoribbon13, and nanomesh14, achieving a finite bandgap. The nanoribbon and nanomesh graphene TFTs also exhibited superior electrical switching properties. Moreover, Kim et al.15 demonstrated the potential to overcome the low photoluminescence of molybdenum disulfide (MoS2) with an indirect bandgap by patterning the 2D materials to nanopore sheets.

Block copolymer (BCP) lithography is considered a facile but highly effective scheme for constructing nanostructured 2D materials. The self-assembled nature of BCP can provide large-area uniform patterning with regular nanosized features16,17,18. The simple BCP-based lithography process can obtain high-quality nanopatterns with various shapes without using complex, high-cost processes, such as electron beam (e-beam) irradiation. While the pristine 2D materials are comprised of van der Waals surface without any lateral edge regions, the nanostructured 2D materials made by periodically removing the layer to the size of nanometers provide the lateral edge exposures that the pristine 2D materials fundamentally cannot have. The lateral edge exposures exhibit unique properties; depending on the edge exposure structure (i.e., armchair and zigzag edges), the interaction of electron and phonon can be controlled19 or oxygen reduction reaction catalysts can be obtained20. The mentioned lateral edge exposures have been expanding the development of various applications such as optoelectronics, chemical and biomedical sensing, and catalytic activity14,15,21,22. Admittedly, nanopatterning can improve device performance. However, there is a severe disadvantage related to the lack of electrical stability, which results from the edge exposure and structural defects caused by the nanopatterning process. It is well known that the surface edges and defects on 2D materials are highly sensitive to oxygen and moisture in ambient environment23. Consequently, the adsorption of oxygen and moisture on the nanopatterned surface acts as charge trap sites, limiting electron transport, which changes the electrical characteristics of the devices24 and causes hysteresis due to charge trapping or release25. Therefore, it is essential to passivate the nanopatterned surface efficiently from external contaminants using an appropriate passivation layer without damaging the 2D semiconductor.

Various inorganic and organic layers have been employed for the passivation of 2D materials using several deposition methods, including atomic layer deposition (ALD)26,27, pulsed laser deposition28, and solution-based deposition29,30. However, these methods can induce damage and degradation on the channel surface and affect the electrical performance of nanopatterned TFTs. The deterioration in performance is caused by the susceptibility of the unstable edges and defects of the nanopatterned surface to high temperatures and solvent environments.

In this study, we propose polymeric passivation of a nanopatterned MoS2 TFT via initiated chemical vapor deposition (iCVD). The vapor-phase process enables solvent-free, near-room-temperature deposition of polymer thin films without damaging or changing the electrical characteristics of the underlying 2D materials31. In contrast, conformal coverage of 2D material surfaces without perturbation is challenging in conventional ALD and solution-based deposition, primarily because such deposition processes are highly dependent on the surface chemical properties or prone to damage from solvent32,33. Moreover, ultrathin polymer films can be deposited conformally on any arbitrary 2D material surface because, during the iCVD process, the polymer film grows on the substrate surface from the input monomers adsorbed thereon34,35. We employed two different polymer films of poly(1-vinylimidzole) (pVI) and poly(1H,1H,2H,2H-perfluorodecyl methacrylate) (pPFDMA) to passivate nanoporous MoS2 TFTs. We confirmed conformally deposited polymer layers on the nanoporous MoS2 and the corresponding electrical and chemical changes in the MoS2 using Raman spectroscopy, ultraviolet photoelectron spectroscopy (UPS), scanning transmission electron microscopy (STEM), X-ray photoelectron spectroscopy (XPS), atomic force microscopy (AFM), and current measurements. Remarkably, the deposition of the inert pPFDMA layer on the nanoporous MoS2 exhibited exceptional passivation performance under repeated gate-bias stress and long-term air exposure, which enabled the long-term stable operation of the nanoporous MoS2 TFT.

Results and discussion

Chemical and morphological properties of nanoporous MoS2

Figure 1a shows a schematic illustration of a fabrication process of nanoporous MoS2. The multilayer MoS2 films were transferred onto a Si/SiO2 substrate by a mechanical exfoliation from bulk. A 10 nm-thick SiO2 was deposited onto the MoS2 surface to prevent surface damage of the MoS2 during the patterning process. Random copolymer (RCP) was spin-coated onto the SiO2 surface before the BCP coating to improve wetting interactions between the solid substrate and the BCP layer. The BCP layer was self-assembled under annealing at 230 °C and a periodic nanohole pattern was obtained by selective decomposition of polymer block located in the inner holes. A hexagonally packed cylindrical BCP film (Supplementary Fig. 1) was utilized as a lithographic mask to fabricate the periodic nanoholes on the multilayer MoS2. The underlying RCP, SiO2, and MoS2 were sequentially perforated by O2, SF6, and BCl3 plasma reactive ion etching (RIE), respectively. Finally, remained RCP and SiO2 layers were removed by immersing the substrate in buffered oxide etchant (BOE).

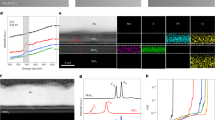

a Schematic illustration of the fabrication process of nanoporous MoS2. b Low-magnification STEM image and c cross-sectional view of nanoporous MoS2. d STEM image representing the hexagonally packed nanohole array. e Atomic configuration of the exposed edge in nanoporous MoS2. f Raman and g, h XPS spectra of nanoporous MoS2.

The morphological and chemical properties of nanoporous MoS2 were explored using STEM, Raman spectroscopy, and XPS analyses. Figure 1b illustrates a STEM image of the perforated multilayer MoS2 with periodic nanohole arrays on its surface. The average hole diameter of the MoS2 nanoholes was 24.29 ± 1.99 nm. A cross-sectional STEM image showed vertically organized nanoholes across nine MoS2 layers (Fig. 1c). Figure 1d illustrates a STEM image of the hexagonally packed nanoholes on the MoS2. The atomic configurations in the exposed edge area consist of both arm-chair and zigzag arrangements of Mo and S atoms (Fig. 1e), which may be formed by anisotropic etching under the BCl3 plasma RIE.

Raman spectroscopy and XPS analyses were conducted to investigate the electronic and chemical structure of the nanoporous MoS2. In the Raman spectra (Fig. 1f), two Raman peaks of in-plane (E12g) and out-of-plane (A1g) vibration modes were observed at 382 and 407 cm−1, respectively. The measured Raman peak intensity of A1g was 2.04 times higher than that of E12g because the vibration of A1g is preferentially promoted to the E12g vibration for the edge-exposed MoS215,21,36. Furthermore, a small peak was also observed at 226 cm−1, corresponding to a defect-induced longitudinal acoustic vibration at the M point of the Brillouin zone (LA(M))37,38. The Raman scattering mentioned above was rarely observed in the pristine MoS2, whereas it was activated considerably on the perforated MoS2 films owing to the abundant edge defects.

The XPS spectra of the nanoporous MoS2 are shown in Fig. 1g, h with respect to the core atoms of Mo and S. The spectrum of Mo 3d was deconvoluted into three components. The peaks located at 232.4 and 235.53 eV can be assigned to Mo6+ 3d5/2 and Mo6+ 3d3/2, respectively, indicating the existence of MoO339. The atomic fraction of Mo6+ 3d among the total Mo ligands was approximately 10.4%. The strong doublet at 229.19 and 232.32 eV corresponding to Mo4+ 3d5/2 and Mo4+ 3d3/2 of intrinsic MoS2 (i-MoS2) represented a stoichiometric Mo-S bonding (ratio of S/Mo = 2)40. However, nanoporous MoS2 involves many broken bonds at edge sites. The nonstoichiometric Mo-S bonding (ratio of S/Mo <2) was referred to the defective MoS2 (d-MoS2) peaks located at 228.59 eV (Mo4+ 3d5/2) and 231.72 eV (Mo4+ 3d3/2)40. The atomic fraction of d-MoS2 (16%) was higher than that of MoO3. The result indicates that many edge atoms were present with dangling bonds rather than in the oxidized form. For the S 2p spectra, two peaks were observed at 162 and 163.18 eV, corresponding to S2− 2p3/2 and S2− 2p1/2, respectively, which is attributable to Mo-S bonding39. No defective peak was observed in the S 2p spectra owing to the low energy resolution at low binding energy levels.

Polymeric passivation of nanoporous MoS2

Figure 2a shows a schematic of the polymer deposition process on the nanoporous MoS2 surface. In the iCVD process, the injected monomers are adsorbed to the cooled substrate, and initiators are decomposed to form radicals by the heated filament at a temperature of less than 200 °C. It triggers the growth of the polymeric film on the nanoporous surface41.

a Schematic illustration of the passivation of nanoporous MoS2 by iCVD process and b chemical structures of passivation layers. c, d Raman spectra and e UPS spectra of the pVI- and pPFDMA-passivated nanoporous MoS2 compared to the pristine one. f Energy band structures of the polymer-passivated nanoporous MoS2 compared to the pristine one calculated from the UPS analysis.

Since the substrate temperature was <40 °C, the solvent-free vapor-phase deposition method can minimize damage to the substrate surface, which is a distinct advantage of the iCVD process, thus rendering the deposition method suitable for damage-free passivation of the nanoporous MoS2. Accordingly, pVI and pPFDMA were selected as candidate layers for the passivation layer of the nanoporous MoS2 TFTs (Fig. 2b). The pVI polymer includes an electron-donating (or electropositive) imidazole ring, which can affect the charge distribution of nanoporous MoS2. Indeed, in our previous study, threshold voltage (VTH) and Dirac voltage (VDirac) in organic and graphene field-effect transistors could be controlled systematically by exploiting the electron-donating imidazole moiety in the pVI-containing layer42,43. Meanwhile, pPFDMA contains an inert, long perfluoroalkyl chain. Ultrathin (~70 nm) pVI and pPFDMA layers were deposited directly on the nanoporous MoS2 TFT device, as shown in the high-resolution transmission electron microscopy (HRTEM) images and electrical characteristics of the polymer films (Supplementary Figs. 2 and 3 and Supplementary Table 1). Owing to the mild deposition conditions, the chemical functionalities including imidazole and fluoroalkyl moieties in each monomer were fully preserved in the resulting polymer film on the MoS2 surface, which was confirmed by Fourier transform infrared (FTIR) spectroscopy (Supplementary Fig. 4).

Raman spectroscopy and UPS analyses were performed to investigate the variation in the electrical characteristics of the nanoporous MoS2 films with each polymer passivation layer (Fig. 2c–e). The pristine nanoporous MoS2 films exhibited E12g and A1g peaks at 382 and 407 cm−1 44, respectively. The pVI-passivated nanoporous MoS2 showed a remarkable bathochromic shift in both vibration modes (Fig. 2c), whereas no apparent peak shift was observed from the pPFDMA-deposited nanoporous MoS2 film (Fig. 2d). We also performed the Raman analysis on the non-patterned MoS2 with the polymer passivation layers (Supplementary Fig. S5). The pVI layer induced a negative shift of A1g peak of the non-patterned MoS2. Since the Raman peaks of non-passivated MoS2 have a much higher intensity than the nanoporous MoS2, the shift seems to be relatively small. In addition, the shift of E12g was not observed because it is less sensitive to electron doping than the A1g vibration mode45. On the other hand, no apparent peak shift was observed in the inert pPFDMA passivation on the MoS2 regardless of the surface structures. The UPS spectra of pristine and polymer-passivated nanoporous MoS2 are shown in Fig. 2e. The work function (ϕ) can be calculated using ϕ = hν – W, where hν = 21.2 eV and W denotes the secondary electron cut-off (Ecut-off)46. The Ecut-off of the nanoporous MoS2 was shifted toward higher binding energy with the pVI passivation layer, resulting in a lower ϕ value of the pVI-passivated nanoporous MoS2 (3.24 eV) than that of the pristine nanoporous MoS2 (4.03 eV) (Fig. 2f). Meanwhile, the pPFDMA-passivated nanoporous MoS2 only exhibited a marginal increase in ϕ toward 4.10 eV, resulting from electronegative fluoroalkyl side chain47,48. These results were derived from the distinct electrical properties of the two polymers. The electron-donating group in the pVI polymer induced an n-doping effect42, while the inert fluoroalkyl chain in pPFDMA induced an insignificant p-doping effect. The similar electrical effects of two polymer layers were observed in the UPS analysis on the non-patterned MoS2 without nanoporous structure (Supplementary Fig. 6a, b), which represents highly coherent electrical properties of the polymers on the MoS2 films regardless of the surface structures.

Characterization of polymer-passivated nanoporous MoS2 film

In this study, we conducted high-angle annular dark-field (HAADF)-STEM analysis on the polymer-deposited MoS2 film to confirm the effective passivation of two different polymer layers on the nanoporous MoS2. Cross-sectional HAADF-STEM images with energy dispersive spectroscopy (EDS) mapping are shown in Fig. 3a–j. Both pVI and pPFDMA passivation layers were deposited conformally on the nanoporous MoS2 surface without any notable defects (Fig. 3a, f). The EDS mapping illustrates a uniform distribution of C and N (pVI) or C and F (pPFDMA), which are clearly distinguishable from underlying Mo and S. The surface chemical composition of the pVI- and pPFDMA-passivated nanoporous MoS2 was investigated by XPS and compared with that of pristine nanoporous MoS2 (Fig. 3k).

HAADF-STEM images and EDS elemental mapping of the a-e pVI- and f-j pPFDMA-passivated nanoporous MoS2. False color modification was attempted in EDS elemental mapping images to clearly reveal the polymeric passivation layers and nanoporous MoS2. k XPS survey scan spectra of the pristine and polymer-passivated nanoporous MoS2. The N1s and F1s peaks were detected only in the pVI- and pPFDMA-passivated nanoporous MoS2. l AFM images of the polymer-passivated nanoporous MoS2 as well as the pristine one.

Accordingly, Mo 3d and S 2p peaks were detected in the XPS survey spectrum of pristine nanoporous MoS2. Moreover, Si- and O-related peaks were also detected, which resulted from the Si/SiO2 substrate. In the polymer-passivated nanoporous MoS2, the intensities of the Mo 3d and S 2p peaks were smaller than those of pristine MoS2. Evidently, the C 1s and N 1s peak intensities increased in the pVI-passivated nanoporous MoS2, and the increased intensities of C 1s and F 1s peaks were obtained in the pPFDMA-passivated nanoporous MoS2. In fact, the XPS analysis clearly revealed that the polymer passivation layer conformally covered the nanoporous MoS2 surface, which is completely consistent with the cross-sectional HAADF-STEM images.

To further investigate the surface properties of the polymer-passivated nanoporous MoS2, AFM analysis was performed (Fig. 3l). The AFM image of the pristine nanoporous MoS2 clearly exhibited porous structure and the smooth, amorphous surface morphology was confirmed with the root-mean-square roughness (Rq) <0.5 nm, which also indicates that the pVI layer conformally covered the nanoporous MoS2. On the other hand, the AFM image of the pPFDMA-passivated nanoporous MoS2 exhibited the roughened surface with the Rq value >15 nm. This rough surface morphology was originated from the highly crystalline nature of pPFDMA due to the fluoroalkyl chain49, which can also improve the hydrophobicity of the surface50,51. The water contact angle (WCA) analysis also verified that the surface property of the nanoporous MoS2 was controlled according to the deposition of the polymer films (Supplementary Fig. 7). Therefore, it follows from the comprehensive analyses that the vapor-phase-deposited polymer passivation layers conformally covered the nanoporous MoS2 surface without incurring defect or damage to the underlying MoS2, while fully retaining the chemical functionalities of each polymer film.

Electrical characteristics of nanoporous MoS2 TFTs passivated by pVI and pPFDMA polymers

To investigate the passivation effect of the pVI and pPFDMA layers on the nanoporous MoS2 TFTs, we measured the electrical characteristics of the devices before and after the passivation with each polymer layer. Figure 4a, b show a schematic illustration and an optical image of the polymer-passivated nanoporous MoS2 TFT, respectively. Figure 4c, d show the transfer curves of the pVI- and pPFDMA-passivated nanoporous MoS2 TFTs, respectively. The transfer curves are compared with those of the bare MoS2 TFT. Optical images of the MoS2 devices after the deposition of each polymer are depicted in Supplementary Fig. 8. The curves are plotted in both logarithmic and linear scales under a gate voltage (VGS) window ranging from −40 to 40 V and drain voltage (VDS) of 1 V. A hysteresis between forward and reverse VGS sweeps was suppressed when the MoS2 surfaces were passivated using both polymer layers, indicating that charge trapping on the MoS2 edge–air interface was efficiently prevented by the polymer passivation. Following the deposition of the pVI polymer on the nanoporous MoS2 TFT, a significant increase was observed in the drain current (IDS) in depletion regions and a slight increase in the accumulation region (Fig. 4c). In addition, a negative VTH shift of −8.4 V was detected. Meanwhile, the deposition of pPFDMA only exhibited a marginal shift in the transfer curve, except for a small decrease in the on-current (Fig. 4d). The variations in VTH and on–off ratio (Ion/off) were monitored for 12 and 15 MoS2 TFTs passivated with each pVI and pPFDMA layer, respectively (Supplementary Fig. 9a–d and Fig. 4e). For comparison, we defined that the current level at VGS of −40 V is off-current, even if the pVI-deposited MoS2 TFT showed metallic behavior. Generally, a strong difference was observed in VTH and Ion/off before and after the deposition of pVI; in contrast, the variation was insignificant in the case of the pPFDMA-passivated device. The n-doping behavior of the pVI-deposited nanoporous MoS2 TFT can be attributed to the electron-donating effect of the imidazole ring in pVI (Fig. 4f). On the other hand, the long fluoroalkyl chain provided a strong hydrophobicity on the polymer passivation layer51, which effectively prevented oxygen and water adsorption, which, in turn, minimized the perturbation of the electrical characteristics of the nanoporous MoS2 TFTs (Fig. 4g). In other words, the pPFDMA layer can effectively passivate the nanoporous MoS2 surface with little change in the electrical characteristics of the TFT devices. Additionally, we extracted field-effect mobilities of 12 and 15 nanoporous MoS2 TFTs before and after pVI and pPFDMA polymer passivation (Supplementary Fig. 9e, f), respectively. We calculated the mobility variation using an equation of (μafter − μbefore)/μbefore × 100 (%), where μbefore and μafter are the field-effect mobility values measured before and after the passivation, respectively. The average variations for pVI and pPFDMA are calculated as −2.1 and −1.4%, respectively. Such small variations indicate that the polymer layers rarely induce the carrier scattering at the interface between the nanoporous MoS2 and the polymer. In the output curves measured under VGS range from −20 to 40 V with an interval of 10 V, the increase in IDS was more prominent in the lower range of VGS than the higher range for pVI-deposited nanoporous MoS2 TFT, which conforms with the observation in the corresponding transfer curve. However, a practically identical shape of the output curve was observed for the pPFDMA-deposited device, except for a slight decrease in IDS in positive VGS ranges.

a Schematic and b optical images of polymer-passivated nanoporous MoS2 TFT. Transfer characteristics of the nanoporous MoS2 TFT before and after deposition of c pVI and d pPFDMA films. e Variation in VTH and Ion/off of the nanoporous MoS2 TFTs after passivation with pVI and pPFDMA layers, respectively. Schematic of electrical behavior at polymer/MoS2 interface when passivated with f pVI and g pPFDMA layers, respectively. Output curves of h pVI- and i pPFDMA-deposited nanoporous MoS2 TFTs together with the corresponding non-passivated TFTs.

Stability tests of pPFDMA-passivated nanoporous MoS2 TFTs

The pPFDMA layer grown by iCVD provided an outstanding passivation effect on the nanoporous MoS2 by benefitting from its non-electrostatic properties and its ability to prevent the adsorption of water molecules from the air. We conducted gate-bias stress tests and long-term storage tests under ambient air conditions to examine the passivation performance of the pPFDMA layer on the nanoporous MoS2 TFTs. Positive bias stress (PBS), negative bias stress (NBS), positive bias illumination stress (PBIS), and negative bias illumination stress (NBIS) under a white light source of 1500 lux were conducted (Fig. 5a–d). VGS of 30 and −22 V were applied as positive and negative gate stress voltages (VStress), respectively. We measured the transfer curves every 10 min while giving bias stress for a total stress time of 120 min as shown in Supplementary Fig. 10. These bias stress tests were also conducted on the non-passivated nanoporous MoS2 control TFT to facilitate comparison, as shown in Supplementary Fig. 11a–d. Compared to the positive VTH shift of the non-passivated MoS2 TFT under the PBS test, no appreciable VTH change was observed in the passivated TFT (Fig. 5a), suggesting that the pPFDMA passivation layer can effectively prevent the charge trapping induced by the adsorption of oxygen or water in an ambient environment at the edge defect sites. In the case of NBS, a slight shift in VTH was observed in the passivated MoS2 TFT because the electrons pre-trapped at the edge sites in the nanoporous MoS2 were released under the negative bias stress (Fig. 5b). However, it is worth noting that the variation was considerably smaller than that of the one occurring in the non-passivated device. For the PBIS test, the VTH was positively shifted in the non-passivated nanoporous MoS2 TFT, while the passivated TFT showed a shift of VTH toward the negative direction, albeit to a minor degree (Supplementary Figs. 11c and 5c). The PBS test indicated that edge sites were efficiently stabilized and the adsorption of oxygen or water molecules can be prevented by pPFDMA passivation. However, the inherent trap states in the nanoporous MoS2 induced by the edge defects captured the photoexcited hole carriers under illumination, resulting in a positive gating effect thereby resulting in a small VTH shift toward the negative direction5,6. The negative shift was significantly activated under the NBIS test, in which the electron release and hole trapping in the trap states of the nanoporous MoS2 occur simultaneously. Figure 5e shows the shift in VTH of the nanoporous MoS2 TFT passivated and non-passivated by the pPFDMA layer at each measurement, where the variation of the passivated devices is quite small compared to that for the non-passivated TFT.

Transfer characteristics of the pPFDMA-passivated nanoporous MoS2 TFT under a PBS, b NBS, c PBIS, and d NBIS conditions with positive bias stress of 30 V and negative bias stress of −22 V. A light source of 1500 lux was used for the illumination stress. e Variation of VTH of nanoporous MoS2 TFT passivated with pPFDMA layer and non-passivated one according to the stress time. f Long-term storage test of pPFDMA-passivated and non-passivated nanoporous MoS2 TFTs under exposure in the ambient environment.

Furthermore, a long-term storage test was conducted to validate the robustness of the pPFDMA-passivated nanoporous MoS2 TFT under exposure to an ambient environment. The average VTH shift of the pPFDMA-passivated nanoporous MoS2 TFTs was monitored over 40 days with 5-day interval, compared to the non-passivated one (Fig. 5f). The raw transfer curves of each representative device are shown in Supplementary Fig. 12. The VTH of the non-passivated devices was positively shifted with time owing to the electron trapping induced by the adsorption of oxygen and water molecules on the nanoporous MoS2 surface. It is well known that the energetically unstable broken bonds located at the edges of the nanoporous MoS2 channel surface prompt the adsorption of oxygen and moisture far more than normal MoS2, which inevitably deteriorates the device performance52,53. In contrast, the nanoporous MoS2 passivated by pPFDMA does not show appreciable device degradation and has a negligible VTH shift, which verifies the excellent passivation performance of the pPFDMA polymer synthesized by the iCVD process for robust nanoporous MoS2 devices.

In summary, we demonstrated an efficient passivation method for nanoporous MoS2 using polymeric passivation layers via iCVD process. The proposed solvent-free method effectively passivated the surface edges and defects in nanoporous MoS2, without damaging or degrading its structure and electrical integrity. The pVI with an electron-donating imidazole ring and pPFDMA containing a fluoroalkyl chain were utilized as n-doping and inert polymer passivation layers, respectively. Both polymer passivation layers conformally covered the underlying nanostructured MoS2. The nanoporous MoS2-based TFT with the polymer passivation layers showed a significant negative VTH shift in the pVI-deposited nanoporous MoS2 TFT, whereas the pPFDMA-deposited nanoporous MoS2 TFT only exhibited a small reduction in the on-current. On the other hand, the long fluoroalkyl chain in the pPFDMA provided strong hydrophobicity, thus remarkably enhancing the stability of the nanoporous MoS2 TFT in ambient air. The pPFDMA-deposited nanoporous MoS2 TFT demonstrated outstanding stability in the PBS, NBS, PBIS, and NBIS tests compared to the non-passivated device, primarily because the pPFDMA can efficiently abate the water and oxygen adsorption on the nanoporous MoS2 surface. In addition, only a negligible change was observed in the long-term storage test, which confirms the robustness of the pPFDMA-deposited nanoporous MoS2 TFT. We believe that this study can provide an effective strategy for the passivation of nanostructured 2D materials. In particular, a vapor-phase deposited fluoropolymer can enhance the ambient stability of nanostructured 2D materials-based TFTs, without damaging their electrical characteristics.

Methods

Fabrication of nanoporous MoS2 TFTs

Multilayer MoS2 nanosheets were mechanically exfoliated from bulk MoS2 and transferred onto Si/SiO2 substrates. The substrate was then placed in acetone overnight and washed with isopropyl alcohol for surface cleaning. A 10 nm-thick SiO2 layer was deposited onto the surface of MoS2 using the e-beam evaporator. Subsequently, the substrate was spin-coated with a 1 wt% toluene solution of poly (styrene-r-methyl methacrylate) (PS-r-PMMA) (Mn = 8500 Mw/Mn = 1.45, styrene content 66%, α-hydroxyl-ω-TEMPO moiety terminated) RCP, at a speed of 3000 rpm. The substrate was annealed at 250 °C for 2 hours under vacuum and washed with toluene. Next, the substrate was spin-coated with a 1 wt% toluene solution of poly (styrene-b-methyl methacrylate) (PS-b-PMMA) (PS:PMMA = 55,000:22,000, Mw/Mn = 1.09) BCP at a speed of 3000 r.p.m. and annealed at 230 °C for 2 h under vacuum conditions. The substrate was exposed to 254 nm ultraviolet irradiation for 30 min and placed in acetic acid for 15 min to decompose the PMMA section in the BCP thin film. O2 plasma RIE (10 sccm, 50 W, 4 s) was used to etch the RCP layer and control the nanohole size. Next, SF6 plasma RIE (10 sccm, 200 W, 20 s) was performed to create nanoholes on the SiO2 layer. BCl3 plasma RIE (15 sccm, 100 W) was utilized to fabricate nanoporous MoS2 by controlling the treatment time, depending on the thickness of MoS2. The final process of making nanoporous MoS2 involved immersing the substrate in BOE for 3 s to remove the SiO2 layer. The source and drain were prepatterned using photolithography to fabricate the nanoporous MoS2 TFT, and Ti and Au (20 nm/100 nm) were deposited on the nanoporous MoS2.

Synthesis of polymer films

1-Vinylimidzole (VI) (≥99%), 1H,1H,2H,2H-perfluorodecyl methacrylate (PFDMA) (97%) monomers and tert-butyl peroxide (TBPO) (98%) initiator were purchased from Sigma-Aldrich. The polymer passivation layers were deposited using a custom-built iCVD system. For the deposition of pVI, VI monomer and TBPO initiator were injected into the chamber at flow rates of 4.4 and 1.5 sccm, respectively. The chamber pressure was maintained at 450 mTorr. For the deposition of pPFDMA, PFDMA monomer and TBPO initiator were injected into the chamber at flow rates of 0.2 sccm, and the chamber pressure was maintained at 40 mTorr. For both polymer film depositions, the substrate temperature was maintained at 40 °C, and the filament was heated to 130 °C to decompose the initiator into radicals.

Characterization

Raman measurements were carried out using a micro-Raman spectrometer system (ALPHA300, WITec) with a green excitation laser. Energy band structure analysis was performed using UPS (AXIS SUPRA, Kratos. Inc.) from the Korean Basic Science Institute (KBSI). UPS was performed using a He I (hv = 21.2 eV) source from a gas discharge lamp. Plan-view and cross-sectional STEM images of the nanoporous MoS2 were obtained using a STEM measurement system (HD-2300A, Hitachi) with an accelerating voltage of 200 kV. Ion milling for the cross-sectional image was conducted using a single-beam focused ion-beam (FB-2100, Hitachi). For electrical characterization of the polymer films, 50 nm-thick Al electrode was thermally deposited under high vacuum <2 × 10−6 torr and the polymer films were deposited between top and bottom Al electrode to fabricate the metal–insulator–metal structure. The XPS spectra of the nanoporous MoS2 were obtained using K-Alpha (Thermo Fisher Scientific) with monochromated Al Kα radiation. FTIR spectra were obtained by an ALPHA FTIR (Bruker Optics) in the absorbance mode to analyze the chemical composition. The AFM images were obtained using a scanning probe microscope (XE-100, Park Systems) to analyze the surface morphology of the nanoporous MoS2 and polymer films. The WCA analysis was performed using a contact angle measurement system (Phoenix Series, S.E.O.). The device was sliced by a focused ion beam (Helios Nanolab 450, FEI) and the cross-sectional HRTEM images were obtained and analyzed by field emission TEM (Talos F200X, FEI) and EDS mapping to visualize the polymer passivation layers on top of the nanoporous MoS2. The electrical measurements of the TFTs were performed using a semiconductor characterization analyzer (4200-SCS, Keithley) equipped with a probe station for sample loading and electrode contact. We measured the same devices before and after the polymer passivation. After the measurement of the bare MoS2 devices, we deposited a polymer layer on the devices and opened the source and drain contacts by etching the local polymer layer using the BOE solution.

Data availability

The data presented in this study are available from the corresponding author upon reasonable request.

References

Li, N. et al. Large-scale flexible and transparent electronics based on monolayer molybdenum disulfide field-effect transistors. Nat. Electron. 3, 711–717 (2020).

Yu, S. et al. Transition metal dichalcogenide-based transistor circuits for gray scale organic light-emitting displays. Adv. Funct. Mater. 27, 1603682 (2017).

Lin, Y. M. et al. Wafer-scale graphene integrated circuit. Science 332, 1294–1297 (2011).

Kim, S. G. et al. Infrared detectable MoS2 phototransistor and its application to artificial multilevel optic-neural synapse. ACS Nano 13, 10294–10300 (2019).

Park, H. et al. Exceptionally uniform and scalable multilayer MoS2 phototransistor array based on large-scale MoS2 grown by RF sputtering, electron beam irradiation, and sulfurization. ACS Appl. Mater. Interfaces 12, 20645–20652 (2020).

Kim, S. et al. Interstitial Mo-assisted photovoltaic effect in multilayer MoSe2 phototransistors. Adv. Mater. 30, 1705542 (2018).

Kim, S. et al. Active-matrix monolithic gas sensor array based on MoS2 thin-film transistors. Commun. Mater. 1, 86 (2020).

Schedin, F. et al. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 6, 652–655 (2007).

Park, H. et al. MoS2 field-effect transistor-amyloid-beta(1-42) hybrid device for signal amplified detection of MMP-9. Anal. Chem. 91, 8252–8258 (2019).

Kwong Hong Tsang, D. et al. Chemically functionalised graphene FET biosensor for the label-free sensing of exosomes. Sci. Rep. 9, 13946 (2019).

Wang, B. L. et al. Bioelectronics-related 2D materials beyond graphene: fundamentals, properties, and applications. Adv. Funct. Mater. 30, 2003732 (2020).

Camilli, L. et al. Self-assembly of ordered graphene nanodot arrays. Nat. Commun. 8, 47 (2017).

Chen, Y. C. et al. Tuning the band gap of graphene nanoribbons synthesized from molecular precursors. ACS Nano 7, 6123–6128 (2013).

Bai, J. W., Zhong, X., Jiang, S., Huang, Y. & Duan, X. F. Graphene nanomesh. Nat. Nanotechnol. 5, 190–194 (2010).

Kim, T. et al. Structural defects in a nanomesh of bulk MoS2 using an anodic aluminum oxide template for photoluminescence efficiency enhancement. Sci. Rep. 8, 1–6 (2018).

Liang, X. G. et al. Formation of bandgap and subbands in graphene nanomeshes with sub-10 nm ribbon width fabricated via nanoimprint lithography. Nano Lett. 10, 2454–2460 (2010).

Krishnamoorthy, S., Hinderling, C. & Heinzelmann, H. Nanoscale patterning with block copolymers. Mater. Today 9, 40–47 (2006).

Bang, J., Jeong, U., Ryu, D. Y., Russell, T. P. & Hawker, C. J. Block copolymer nanolithography: translation of molecular level control to nanoscale patterns. Adv. Mater. 21, 4769–4792 (2009).

Huang, T. et al. Probing the edge-related properties of atomically thin MoS2 at nanoscale. Nat. Commun. 10, 5544 (2019).

Hao, Y., Xu, L. C., Pu, J., Wang, L. & Huang, L. F. Stable zigzag edges of transition-metal dichalcogenides with high catalytic activity for oxygen reduction. Electrochim. Acta 338, 135865 (2020).

Yun, T. et al. 2D metal chalcogenide nanopatterns by block copolymer lithography. Adv. Funct. Mater. 28, 1804508 (2018).

Su, S. Q. et al. Ultrathin alumina mask-assisted nanopore patterning on monolayer MoS2 for highly catalytic efficiency in hydrogen evolution reaction. ACS Appl. Mater. Interfaces 10, 8026–8035 (2018).

Davis, S. M. & Carver, J. C. Oxygen chemisorption at defect sites in MoS2 and ReS2 basal plane surfaces. Appl. Surf. Sci. 20, 193–198 (1984).

Qiu, H. et al. Electrical characterization of back-gated bi-layer MoS2 field-effect transistors and the effect of ambient on their performances. Appl. Phys. Lett. 100, 123104 (2012).

Late, D. J., Liu, B., Matte, H., Dravid, V. P. & Rao, C. N. R. Hysteresis in single-layer MoS2 field effect transistors. ACS Nano 6, 5635–5641 (2012).

Liu, N. et al. Improving the stability of high-performance multilayer MoS2 field-effect transistors. ACS Appl. Mater. Interfaces 9, 42943–42950 (2017).

Kufer, D. & Konstantatos, G. Highly sensitive, encapsulated MoS2 photodetector with gate controllable gain and speed. Nano Lett. 15, 7307–7313 (2015).

Sirota, B., Glavin, N., Krylyuk, S., Davydov, A. V. & Voevodin, A. A. Hexagonal MoTe2 with amorphous BN passivation layer for improved oxidation resistance and endurance of 2D field effect transistors. Sci. Rep. 8, 1–8 (2018).

Doherty, J. L., Noyce, S. G., Cheng, Z. H., Abuzaid, H. & Franklin, A. D. Capping layers to improve the electrical stress stability of MoS2 transistors. ACS Appl. Mater. Interfaces 12, 35698–35706 (2020).

Roh, J. et al. Fluorinated CYTOP passivation effects on the electrical reliability of multilayer MoS2 field-effect transistors. Nanotechnology 26, 455201 (2015).

Yoo, H. et al. Highly stacked 3D organic integrated circuits with via-hole-less multilevel metal interconnects. Nat. Commun. 10, 2424 (2019).

McDonnell, S. et al. HfO2 on MoS2 by atomic layer deposition: adsorption mechanisms and thickness scalability. ACS Nano 7, 10354–10361 (2013).

Wells, S. A. et al. Suppressing ambient degradation of exfoliated InSe nanosheet devices via seeded atomic layer deposition encapsulation. Nano Lett. 18, 7876–7882 (2018).

Woo, M. H. et al. Low-power nonvolatile charge storage memory based on MoS2 and an ultrathin polymer tunneling dielectric. Adv. Funct. Mater. 27, 1703545 (2017).

Yang, S. C. et al. Large-scale, low-power nonvolatile memory based on few-layer MoS2 and ultrathin polymer dielectrics. Adv. Electron. Mater. 5, 1800688 (2019).

Kong, D. S. et al. Synthesis of MoS2 and MoSe2 films with vertically aligned layers. Nano Lett. 13, 1341–1347 (2013).

Mignuzzi, S. et al. Effect of disorder on Raman scattering of single-layer MoS2. Phys. Rev. B 91, 195411 (2015).

Frey, G. L., Tenne, R., Matthews, M. J., Dresselhaus, M. S. & Dresselhaus, G. Raman and resonance Raman investigation of MoS2 nanoparticles. Phys. Rev. B 60, 2883–2892 (1999).

Brown, N. M. D., Cui, N. Y. & McKinley, A. An XPS study of the surface modification of natural MoS2 following treatment in an RF-oxygen plasma. Appl. Surf. Sci. 134, 11–21 (1998).

Kondekar, N. P., Boebinger, M. G., Woods, E. V. & McDowell, M. T. In situ XPS investigation of transformations at crystallographically oriented MoS2 interfaces. ACS Appl. Mater. Interfaces 9, 32394–32404 (2017).

Yu, S. J. et al. Initiated chemical vapor deposition: a versatile tool for various device applications. Adv. Eng. Mater. 20, 1700622 (2018).

Pak, K., Seong, H., Choi, J., Hwang, W. S. & Im, S. G. Synthesis of ultrathin, homogeneous copolymer dielectrics to control the threshold voltage of organic thin-film transistors. Adv. Funct. Mater. 26, 6574–6582 (2016).

Oh, J. G. et al. A high-performance top-gated graphene field-effect transistor with excellent flexibility enabled by an iCVD copolymer gate dielectric. Small 14, 1703035 (2018).

Li, H. et al. From bulk to monolayer MoS2: evolution of raman scattering. Adv. Funct. Mater. 22, 1385–1390 (2012).

Li, Y., Xu, C. Y., Hu, P. & Zhen, L. Carrier control of MoS2 nanoflakes by functional self-assembled monolayers. ACS Nano 7, 7795–7804 (2013).

Lee, S. Y. et al. Large work function modulation of monolayer MoS2 by ambient gases. ACS Nano 10, 6100–6107 (2016).

Zschieschang, U. et al. Mixed self-assembled monolayer gate dielectrics for continuous threshold voltage control in organic transistors and circuits. Adv. Mater. 22, 4489–4493 (2010).

Sim, D. M. et al. Controlled doping of vacancy-containing few-layer MoS2 via highly stable thiol-based molecular chemisorption. ACS Nano 9, 12115–12123 (2015).

Choi, J., Seong, H., Pak, K. & Im, S. G. Vapor-phase deposition of the fluorinated copolymer gate insulator for the p-type organic thin-film transistor. J. Inf. Disp. 17, 43–49 (2016).

Yoo, Y., You, J. B., Choi, W. & Im, S. G. A stacked polymer film for robust superhydrophobic fabrics. Polym. Chem. 4, 1664–1671 (2013).

Kim, S. Y., Kim, B. J., Kim, D. H. & Im, S. G. A monolithic integration of robust, water-/oil-repellent layer onto multilayer encapsulation films for organic electronic devices. RSC Adv. 5, 68485–68492 (2015).

Chen, X. et al. Degradation behaviors and mechanisms of MoS2 crystals relevant to bioabsorbable electronics. NPG Asia Mater. 10, 810–820 (2018).

Di Bartolomeo, A. et al. Hysteresis in the transfer characteristics of MoS2 transistors. 2D Mater. 5, 015014 (2018).

Acknowledgements

This research was supported in part by the National Research Foundation of Korea (NRF-2020R1A2C1101647, NRF-2020M3A9E4104385, NRF-2021R1A2B5B02002167, NRF-2021M3H4A1A02056037, NRF-2021R1A2B5B03001416).

Author information

Authors and Affiliations

Contributions

H.P., J.C., S.K., S.G.I., and H.Y. conceived the idea and designed the experiments. H.P. fabricated and characterized nanoporous MoS2. H.P. and J.S. measured the electrical properties of passivated and non-passivated nanoporous MoS2 TFTs. J.C. and S.M.L. fabricated the polymer thin films. J.C. analyzed the chemical and surface properties of polymer thin films. H.J.Y. performed XPS/UPS analysis. H.P., J.C., S.K., S.G.I., and H.Y. wrote the manuscript, and all authors reviewed and provided input to the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Park, H., Choi, J., Shim, J. et al. Functional polymeric passivation-led improvement of bias stress with long-term durability of edge-rich nanoporous MoS2 thin-film transistors. npj 2D Mater Appl 6, 21 (2022). https://doi.org/10.1038/s41699-022-00296-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41699-022-00296-7