Abstract

Planar micro-supercapacitors are recognized as one of the most competitive on-chip power sources for integrated electronics. However, most reported symmetric micro-supercapacitors suffer from low energy density. Herein, we demonstrate the facile mask-assisted fabrication of new-type all-solid-state planar hybrid micro-supercapacitors with high energy density, based on interdigital patterned films of porous vanadium nitride nanosheets as negative electrode and Co(OH)2 nanoflowers as positive electrode. The resultant planar hybrid micro-supercapacitors display high areal capacitance of 21 mF cm−2 and volumetric capacitance of 39.7 F cm−3 at 0.2 mA cm−2, and exhibit remarkable energy density of 12.4 mWh cm−3 and power density of 1750 mW cm−3, based on the whole device, outperforming most reported planar hybrid micro-supercapacitors and planar asymmetric micro-supercapacitors. Moreover, all-solid-state planar hybrid micro-supercapacitors show excellent cyclability with 84% capacitance retention after 10000 cycles, and exceptionally mechanical flexibility. Therefore, our proposed strategy for the simplified construction of planar hybrid micro-supercapacitors will offer numerous opportunities of utilizing graphene and other 2D nanosheets for high-energy microscale supercapacitors for electronics.

Similar content being viewed by others

Introduction

With speeding development of wearable and portable electronics, microscale energy storage devices with innovative characteristics of lightweight, miniaturization, flexibility, and compact energy have gained ever-increasing attentions.1 In this context, planar micro-supercapacitors (MSs) possess the intriguing merits of thinness, high power density, long-term cyclability, and fast charge-discharge capability, which are recognized as one of the most important microscale power sources for integrated electronics.2,3,4,5,6 On the other hand, hybrid supercapacitors (HSCs) deliver higher energy density than symmetric supercapacitors and larger power density than lithium ion batteries, originating from the extended voltage working windows (e.g., 1.5~2 V in aqueous electrolyte) of advanced asymmetric device geometry, efficiently combining the advantages of supercapacitive electrode with battery-like electrode into single device system.7,8 Up to now, enormous advances have been made on the development of high-peformance electrodes in sandwich-like HSCs, such as positive electrodes of capacitive counterparts (e.g., active carbon (AC),9 graphite,10 and graphene11), redox-active metal oxides/hydroxides (e.g., MnO2,12,13 Co3O4,14 Co(OH)2,15 Ni(OH)216), electrically conducting polymers17 and their hybrids,18 and negative electrode materials covering all types of nanocarbons (AC,19 porous carbon,20 CNT,21 graphene13,16), metal oxides (e.g., Mn3O4,22 MoO3,23 Fe2O324), and metal nitrides (e.g., titanium nitride,25 vanadium nitride (VN)26). However, these state-of-the-art HSCs are conventionally assembled in nonplanar dimension, and constructed with a stacked geometry of sandwiching one separator between two substrates (e.g., plastic substrate, textile) for supporting thin film electrodes, which is a huge obstacle for the miniaturized and flexible integrated circuits.

To overcome this issue, certain efforts have been recently devoted to design and fabrication of planar hybrid MSs (PHMSs) on single substrate. So far, several strategies to manufacture the planar microelectrodes for MSs based on two different electrodes have been developed by micro-electro-mechanical systems (MEMS) fabrication,27 inkjet printing,28,29,30 electrochemical deposition28,31,32 and combined with laser-irradiation assisted method.12,33 The MEMS microfabrication, combining photolithography and a wet or dry etching process, is a well-established technique for processing high-resolution micropatterns.27,34 However, this technique usually involves multiple separated steps, such as spin-coating of photoresist, masked irradiation, development, plasma etching, or magnetron sputtering,27,35 resulting in low efficiency of device assembly in a large scale. Inkjet printing is a simple, cost-effective approach for micropatterns on the targeted substrates, but highly solution-processable ink of electrode material is a prerequisite.7,30 Electrochemical deposition is efficiently scalable for fabricating PHMSs. However, the serious capacity degradation is not avoided during charge and discharge when the deposited electrodes become thicker.33 Except these techniques above, screening and integrity of different main device components, e.g., electrodes, electrolyte, current collectors, for PHMSs are still facing great challenges. In light of this, high-capacitance redox electrode materials are considered as the key for assembling high-peformance PHMSs. For instance, Co(OH)2 is one of the most attractive positive electrodes owing to high theoretical capacitance of 3460 F g−1, high redox reactivity and natural abundance.36 VN is one very promising negative electrode, delivering a high capacitance of 1340 F g−1 at 2 mV s−1, reversible and fast Faradic response, and high hydrogen evolution overpotential.37 Furthermore, the mostly reported PHMSs show huge limitations on the design and performance, e.g., the leakage of liquid electrolytes, and usage of metal current collectors (e.g., Au).31 Noteworthily, utilization of metal-free current collectors and usage of all-solid-state electrolyte represent the important future directions for efficient fabrication of PHMSs. Nevertheless, sufficient construction of PHMSs based on high-capacitance redox electrodes and metal-free current collectors in all-solid-state is still underdeveloped.

Herein, we demonstrate the facile fabrication of all-solid-state flexible PHMSs (denoted as VN//Co(OH)2-PHMSs) with exceptionally large volumetric energy density, based on interdigital patterned films of porous VN nanosheets as negative electrode and Co(OH)2 nanoflowers as positive electrode, using KOH/polyvinyl alcohol (KOH/PVA) gel as electrolyte. The asymmetric patterned microelectrodes on single substrate were directly manufactured through vacuum filtration of high-conducting electrochemically exfoliated graphene (EG) nanosheets as metal-free current collectors, and subsequent filtration of patterned films of 2D porous VN nanosheets/EG (10 wt%) and Co(OH)2 nanoflowers/EG (15 wt%) as negative and positive electrodes, respectively, with the assistance of a customized interdigital mask on nylon membrane. The resulting patterned electrodes exhibited large-area uniformity, mechanically flexibility, and high electrical conductivity, and were directly served as binder-free and additive-free flexible electrodes without need of metal-based current collectors for PHMSs. Benefiting from the synergy of VN nanosheets and Co(OH)2 nanoflowers, their strong interfacial interaction with EG nanosheets, and advanced in-plane geometry, the resultant VN//Co(OH)2-PHMSs displayed high areal capacitance of 21 mF cm−2, volumetric capacitance of 39.7 F cm−3, and remarkable energy density of 12.4 mWh cm−3, outperforming most reported PHMSs. Moreover, our PHMSs showed excellent cyclability with 84% capacitance retention after 10000 cycles, accompanied with excellent mechanical flexibility and superior integration.

Results and discussion

Fabrication of VN//Co(OH)2-PHMSs

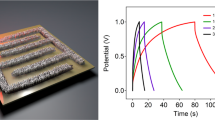

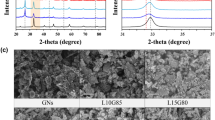

The fabrication of VN//Co(OH)2-PHMSs is schematically illustrated in Fig. 1a. Briefly, three steps were included as follows. First, high-conducting EG patterns with in-plane interdigital geometry were prepared as current collectors by vacuum filtration of EG dispersion (0.5 mL, 0.1 mg mL−1), with the help of a customized mask with four digital fingers on each side (Fig. 1a). Second, to assemble high-energy PHMSs, porous VN nanosheets and Co(OH)2 nanoflowers were chosen as negative electrode and positive electrode, respecitively. Specifically, porous VN nanosheets were synthesized by thermal treatment of (NH4)2V6O16 nanosheet precursor.38,39 As shown in Fig. 1b, X-ray diffraction (XRD) pattern unraveled that all the diffraction peaks of (111), (200), (220), (311) and (222) were assigned to the cubic VN phase (JCPDS 35-0768).39 Scanning electron microscope (SEM, Fig. 1c) and transmission electron microscope (TEM) images (Fig. 1d) disclosed the crystalline nature of mesoporous VN nanosheets, with size of several micrometers. The N2 sorption isotherm of VN nanosheets (Fig. S1a) further confirmed the mesoporosity with an average size of ~12 nm and specific surface area of 52.4 m2 g−1. On the other hand, Co(OH)2 nanoflowers were prepared by a facile precipitation method.40 XRD pattern (Fig. 1e) clearly identified the crystal and layered structure of Co(OH)2 (JCPDS 46-0605).40 SEM and TEM images (Fig. 1f, g) revealed structurally defined micro-flower-like morphology, composed of ultrathin interconnected nanosheets. Further, N2 sorption isotherm also confirmed the presence of mesoporosity (the average size of 9.6 nm) and specific surface area of 80.9 m2 g−1 (Fig. S1b). To improve the conductivity, EG was chosen as both conducting additives and current collectors. Specifically, high-quality EG nanosheets were synthesized by an electrochemical cathodic exfoliation process,41 which possessed large lateral size (10 μm), layer number of ≤5 (Fig. S2) and exceptional conductivity (339 S cm−1, Fig. S3a).

Fabrication of VN//Co(OH)2-PHMSs and characterization of VN nanosheets and Co(OH)2 nanoflowers. a Schematic illustrating the fabrication of VN//Co(OH)2-PHMSs. b XRD pattern, c low-magnification (scale bar is 1 μm) and high-magnification (inset, scale bar is 200 nm) SEM images, and d TEM image (scale bar is 250 nm) of porous VN nanosheets. e XRD pattern, f low-magnification (scale bar is 1 μm) and high-magnification (inset, scale bar is 200 nm) SEM images, and g TEM image (scale bar is 500 nm) of Co(OH)2 nanoflowers

Afterwards, the asymmetric interdigital micropatterns of VN//Co(OH)2 electrodes were directly manufactured by continuous deposition of porous VN nanosheets/EG (2.25 mL, 0.25 mg mL−1, 10 wt% EG) dispersion and Co(OH)2 nanoflowers/EG (1.0 mL, 0.25 mg mL−1, 15 wt% EG) solution on the different sides of mask as negative and positive electrodes, respectively, on nylon membrane (Fig. 1a). Top-view SEM images (Fig. S4) revealed the large-area uniform and flat morphology of VN//Co(OH)2-PHMSs electrodes. Significantly, VN/EG and Co(OH)2/EG electrodes displayed high electrical conductivity of 113 S cm−1and 97 S cm−1, respectively (Fig. S3b, c). Third, all-solid-state VN//Co(OH)2-PHMSs were obtained after drop casting and solidification of KOH/PVA electrolyte on the project area of interdigital fingers (see details in Methods).

Electrochemical characterization of VN nanosheets and Co(OH)2 nanoflowers

To fabricate a stable PHMS cell, we first checked electrochemical potential and capacity to obtain an optimized working voltage window and mass match of positive electorde and negative electrode. To this end, we evaluated the electrochemical behavior of porous VN nanosheets (−0.95–0.0 V vs. Hg/HgO, Fig. S5a) or Co(OH)2 nanoflowers (−0.15–0.55 vs. Hg/HgO, Fig. S5d) as working electrode, Pt foil as counter electrode and Hg/HgO as reference electrode in a standard three-electrode system, in 1 M KOH aqueous electrolyte (Fig. 2). Remarkably, cyclic voltammogram (CV) curves of VN (Fig. 2a) collected at different scan rates exhibited a quasi-rectangular shape, which were also demonstrated by galvanostatic charge discharge (GCD, Fig. 2b) with a nearly linear triangle and unobservable IR drop. Furthermore, a linear relationship of scan rate and peak current in the CV curves is obsereved (Fig. S6a), indicating a surface-controlled, capacitive response for VN electrode. The specific capacity was calculated to be 150 C g−1 (Fig. 2c) at a current density of 0.25 A g−1. Note that the VN electrode disclosed a high-rate capability. For instance, a high capacity (128 C g−1) was still maintained at high current density of 10 A g−1, indicative of fast ion transfer behavior of porous VN. This result was well explained by Nyquist plots (Fig. S5c) ranging from 100 kHz to 0.01 Hz, featuring a low equivalent series resistance (ESR) of 1.0 Ω, as well as small charge transfer resistance. In addition, remarkable cycling performance with 97.5% capacity retention after 1000 cycles was realized (Fig. S5b). The electrochemical performances of Co(OH)2 nanoflowers were also investigated by CV and GCD curves. The Co(OH)2 nanoflowers presented one pair of strong redox peaks in the CV curves (Fig. 2d) and the pronounced potential plateau in the GCD curves (Fig. 2e), indicating a diffusion-controlled battery-type Faradaic process (Fig. S6b).42,43 The specific capacity was calculated to be 340 C g−1 (Fig. 2f) at a current density of 0.25 A g−1. Additionally, the specific capacity decreased very slowly when increasing charge-discharge current densities, for instance, high capacity of 244 C g−1 was still maintained at high current density of 10 A g−1, indicative of an excellent rate performance and fast ion transfer behavior of Co(OH)2 nanoflowers. This result was well explained by Nyquist plots (Fig. S5f), featuring a low ESR of 1.4 Ω, as well as small charge transfer resistance. Furthermore, the Co(OH)2 nanoflowers also exhibited good cycle stability with capacity retention of 91.7% after 1000 cycles as shown in Fig. S5e.

Electrochemical characterization of VN nanosheets and Co(OH)2 nanoflowers using a three-electrode system, tested in 1 M KOH electrolyte. a CV curves obtained at different scan rates of 1 ~ 100 mV s−1, b GCD profiles performed at varying current densities of 0.1 ~ 5 A g−1, and c specific capacity as a function of current density of VN nanosheets. d CV curves measured at different scan rates of 1 ~ 50 mV s−1, e GCD profiles performed at varying current densities of 0.1 ~ 2.5 A g−1, and f specific capacity as a function of current density of Co(OH)2 nanoflowers

Electrochemical characterization of VN//Co(OH)2-PHMSs

Based on the above evaluation of capacity and potential windows, we consequently constructed VN//Co(OH)2-PHMSs based on porous VN nanosheets as negative electrode and Co(OH)2 nanoflowers as positive electrode, operated at an optimized working voltage of 1.5 V (Fig. 3a, b). Cross-section SEM images (Fig. 3a) further revealed a compact layered structure of both VN negative electrode and Co(OH)2 positive electrode of PHMSs, in which high-quality EG nanosheets as both conducting additives and current collectors (Fig. S7) were well incorporated into hybrid electrode films, as confirmed by energy dispersive X-ray mapping analysis (Fig. S8). The average thickness of VN/EG and Co(OH)2/EG electrode was measured to be ~5.3 and ~4.6 μm, respectively.

Electrochemical characterization of VN//Co(OH)2-PHMSs in 1 M KOH aqueous electrolyte. a Schematic of VN//Co(OH)2-PHMSs and cross-sectional SEM images of Co(OH)2 positive electrode (left) and VN negative electrode (right), scale bar are 1 μm. b CV curves of Co(OH)2 and VN electrodes recorded at 10 mV s−1 in a three electrode cell (vs. Hg/HgO). Inset: Photograph of the as-fabricated two VN//Co(OH)2-PHMSs in a bending state. c CV curves tested at a working voltage of 1.5 V at different scan rates from 2 ~ 50 mV s−1, d GCD curves obtained at different current densities from 0.2 ~ 5 mA cm−2, e areal capacitance and volumetric capacitance as a function of current density

Then, VN//Co(OH)2-PHMSs were examined in 1 M KOH aqueous electrolyte, taking into consideration of the optimal charge balance (See Calculation in Supplementary Information, Fig. S9) and operation voltage (Fig. S10). Figure 3c exhibited the CV curves of VN//Co(OH)2-PHMSs (VN/Co(OH)2 ratio: 2.5) measured at different scan rates of 2 ~ 50 mV s−1. It is obviously observed that VN//Co(OH)2-PHMSs showed a couple of pronounced redox peaks in CV curves even at high scan rates (e.g., 50 mV s−1), originating from fast redox reactions on both VN and Co(OH)2 electrodes. The pseudocapactive nature of VN//Co(OH)2-PHMSs was further validated by GCD measurements (Fig. 3d). Notably, VN//Co(OH)2-PHMSs delivered high areal capacitance of 33.4 mF cm−2 and volumetric capacitance of 63 F cm−3 based on the device at a current density of 0.1 mA cm−2, respectively (Fig. 3e, Table S1 and S2). The performance based on devices were much higher than the most reported MSs consisting of two different electrodes, such as 1.85 mF cm−2 and 28.5 F cm−3 for VN//NiO,44 0.667 mF cm−2 for graphene quantum dots//polyaniline,45 30 mF cm−2 and 27.5 F cm−3 for MnO2//AC,27 0.81 mF cm−2 for graphene quantum dots//MnO2,46 0.113 mF cm−2 and 1.39 F cm−3 for CNT//MnO2/CNT29 (Table S2).

Furthermore, all-solid-state VN//Co(OH)2-PHMSs were assembled using KOH/PVA gel as electrolyte (Fig. 4a), and then examined through CV curves at scan rates from 2 to 50 mV s−1 and GCD profiles at current densities from 0.5 to 5 mA cm−2 (Fig. 4b, c). Remarkably enough, all-solid-state VN//Co(OH)2-PHMSs presented similar characteristics in CV and GCD curves to those in aqueous electrolyte (Fig. 3c, d). Furthermore, all-solid-state VN//Co(OH)2-PHMSs still offered excellent areal capacitance of 21 mF cm−2 and volumetric capacitance of 39.7 F cm−3 at a current density of 0.2 mA cm−2 (Fig. 4d), these values were well comparable to the aqueous PHMSs, but much higher than those of most reported PHMSs (Table S3). Even at the high current density of 2 mA cm−2, the areal capacitance and volumetric capacitance could still keep at 9.4 mF cm−2 and 17.7 F cm−3, respectively. The good rate capability is possibly attribued to low ESR of 51.3 Ω (Fig. S11). More importantly, VN//Co(OH)2-PHMSs in gel electrolyte disclosed exceptionally durable and long-term cyclability with 84% capacitance retention after 10000 cycles (Fig. 4e), which was comparable to our aqueous device (76% after 10000 cycles, Fig. S10c) and state-of-the-art reported PHMSs and other asymmetric MSs, e.g., CNT//MnO2/CNT (74.7% after 10000 cycles),32 graphene-FeOOH//graphene-MnO2 (84% after 2000 cycles),12 graphene quantum dots//MnO2 (80% after 3000 cycles),46 graphene quantum dots//polyaniline (85% after 1500 cycles),45 and most reported sandwich ASCs, such as VN//Co(OH)2 (86% after 4000 cycles),15 Co(OH)2/graphene foam//graphene/Fe3O4@carbon (72% after 8000 cycles),47 and VN/NiOx (85% after 1000 cycles).48 In addition, our mask-assisted manufacturing strategy is highly flexible for fabricating miniaturized VN//Co(OH)2-PHMSs with tailored device size and geometries (Fig. S12).

Electrochemical characterization of all-solid-state VN//Co(OH)2-PHMSs. a Schematic of VN//Co(OH)2-PHMSs covering a thin polymer gel of KOH/PVA electrolyte. b CV curves obtained at different scan rates of 2 ~ 50 mV s−1, c GCD profiles measured at different current densities from 0.5 ~ 5 mA cm−2, d areal capacitance and volumetric capacitance as a function of current density, and e cycling stability for 10000 cycles of all-solid-state VN//Co(OH)2-PHMSs. f Ragone plot of VN//Co(OH)2-PHMSs in aqueous and gel electrolytes compared with VN//VN-PMSs, Co(OH)2//Co(OH)2-PMSs and commercially available energy-storage systems

The Ragone plot in Fig. 4f compared the volumetric energy density and power density of our VN//Co(OH)2-PHMSs with symmetric VN//VN-PMSs and Co(OH)2//Co(OH)2-PMSs (Fig. S13 and Fig. S14). Apparently, it was demonstrated that all-solid-state VN//Co(OH)2-PHMSs offered a maximum energy density of 12.4 mWh cm−3, which is comparable to aqueous VN//Co(OH)2-PHMSs (19.7 mWh cm−3), and much higher than symmetric PMSs based on VN//VN (4.4 mWh cm−3) and Co(OH)2//Co(OH)2 (0.3 mWh cm−3). Notably, the energy densities of our devices were also much larger than those of recently reported PHMSs and planar asymmetric MSs, such as graphene-FeOOH//graphene-MnO2 (2.4 mWh cm−3),12 K2Co3(P2O7)2//graphene (0.96 mWh cm−3),30 MnO2//AC (8.6 mWh cm−3),27 CNT//MnO2/CNT (0.27 mWh cm−3),32 and lithium thin-film batteries (<10 mWh cm−3). Meanwhile, VN//Co(OH)2-PHMSs presented a maximum power density of 2064 mW cm−3 at energy density of 9.3 mWh cm−3 in liquid electrolyte and 1750 mW cm−3 at energy density of 5.5 mWh cm−3 in KOH/PVA electrolyte.

The flexibility and integration of all-solid-state VN//Co(OH)2-PHMSs

The excellent flexibility and integration of all-solid-state VN//Co(OH)2-PHMSs were further demonstrated, as shown in Fig. 5. It can be seen that all the CV curves measured at different bending angles from 0 to 180° almost overlapped each other (Fig. 5a, b), and 89.2% of the initial capacitance obtained at 0° was maintained even highly bended at 180°, indicative of remarkable structural stability and mechanical flexibility of our VN//Co(OH)2-PHMSs (Fig. 5c). Moreover, VN//Co(OH)2-PHMSs were readily interconnected in series or/and in parallel in order to increase desirable output voltage or/and capacitance (Fig. 5d–i). The CV curves tested at 50 mV s−1 (Fig. 5d) and GCD curves obtained at 1 mA cm−2 (Fig. 5e) exhibited unprecedented peseudocapactive response of the tandem PHMSs, connected in series from 1 to 4 cells, and presented a stepwise linear increase in the voltage from 1.5 to 6.0 V, and monotonously decrease in the capacitance (Fig. S15), suggestive of superior performance uniformity. Meanwhile, the parallel cell pack of four VN//Co(OH)2-PHMSs indeed increased the output current by a factor of 4 of the single cell, while the voltage was kept unchanged (Fig. 5f, g). Furthermore, when four VN//Co(OH)2-PHMSs were combined two in series and two in parallel, the output voltage (3.0 V) increased by a factor of 2, while capacitance was kept unchanged under the same scan rates or current densities (Fig. 5h, i). As a demonstration, such integrated PHMSs were readily capable of powering a red light-emitting diode (LED, inset in Fig. 5c).

The flexibility and integration of all-solid-state VN//Co(OH)2-PHMSs. a Photographs of VN//Co(OH)2-PHMSs tested under different bending angles, e.g, 0, 90 and 180°, respectively. b CV curves obtained at different bending angles, at 20 mV s−1. c Capacitance retention as a function of bending angle. d CV curves tested at 50 mV s−1, (inset: a red LED was lit up by four serially connected PHMSs) and e GCD profiles measured at 1 mA cm−2 of the series VN//Co(OH)2-PHMSs connected from 1 to 4 cells. f CV curves obtained at 50 mV s−1 and g GCD profiles examined at 1 mA cm−2 of the parallel VN//Co(OH)2-PHMSs connected from 1 to 4 cells. h CV curves obtained at 50 mV s−1 and i GCD profiles tested at 1 mA cm−2 of the pack of VN//Co(OH)2-PHMSs connected in a combination of two series and two parallels

The excellent performance of our VN//Co(OH)2-PHMSs was attributed to the advanced properties of two selected electrode materials, elaborated selection of high-conducting EG nanosheets as current collectors and additives, and synergistic effects of 2D nanosheet-hybrid electrodes and planar device geometry. First, both the capacitive charge storing characteristic of VN nanosheets and the battery-type charge storing characteristic of Co(OH)2 nanoflowers are with high specific capacity. The nanoflowers morphology and porous structure of Co(OH)2 and VN are favorable to enrich the electrolyte ions and shorten their diffusion paths, resulting in capacitance enhancement of PHMSs. Second, EG nanosheets serve as both high-conducting current collectors and additives in interdigital planar electrodes, which is another important factor for facilitating electron transport and thus generating high rate capability. Third, the interdigital planar geometry of PHMSs allows the flow of electrolyte ions for ultrafast uptake into (or removal from) the adjacent electrode fingers in an extremely short diffusion pathway, and eventually maximize the utilization of highly accessible surface area of 2D nanosheets electrode for efficient charge storage.

In summary, we have demonstrated the fabrication of all-solid-state, flexible, high-energy PHMSs based on porous VN nanosheets as negative electrode and Co(OH)2 nanoflowers as positive electrode on single substrate. The as-fabricated PHMSs combine the advantages of porous VN nanosheets and Co(OH)2 nanoflowers, strong interfacial interaction with EG nanosheets, simplified electrode manufacturing technique, and advanced in-plane geometry. As a consequence, VN//Co(OH)2-PHMSs offered high areal capacitance of 21 mF cm−2, volumetric capacitance of 39.7 F cm−3, and remarkable energy density of 12.4 mWh cm−3. Moreover, our all-solid-state PHMSs showed excellent cycling stability, flexibility and superior integration. Therefore, this strategy applied for the simplified construction of PHMSs will provide numerous opportunities of different graphene and 2D nanosheets for hybrid high-energy on-chip energy storage devices.

Methods

Synthesis of porous VN nanosheets

Porous VN nanosheets were fabricated through a two-step approach. First, commercial V2O5 powder (0.36 g) and ammonium persulfate (4.4 g, 20 mmol) were added to the high-purity water (36 mL). After the mixture was stirred for 48 h at 50 °C, the golden-yellow precipitate was collected by centrifugation, washed thoroughly with high-purity water, and freeze-dried. Then, (NH4)2V6O16 nanosheets were obtained.38 Second, the as-made (NH4)2V6O16 nanosheets were directly annealed in NH3 (flow rate 50 mL min−1) at 500 °C for 3 h with a heating rate of 5 °C min−1 to obtain porous VN nanosheets.39

Synthesis of Co(OH)2 nanoflowers

Co(OH)2 nanoflowers were synthesized by a facile precipitation method. Typically, 0.01 mol CoCl2·6H2O was dissolved in 10 ml high-purity water under stirring. NH4OH solution (5 wt%) was slowly added into the above CoCl2·6H2O solution until the pH = 9. The reaction mixture was stirred vigorously for 3 h at room temperature. Then, the solid was filtered and washed with a copious amount of high-purity water. The obtained product was dried at 60 °C in air for 12 h.15

Preparation of EG

EG was directly exfoliated from graphite in aqueous solution according to a reported electrochemical procedure.41 After freezing drying, the resultant EG nanosheets were dispersed in ethanol by sonication for 30 min to form 0.1 mg mL−1 stable ink.

Materials characterization

Materials characterization was conducted by XRD patterns (X’pert Pro), SEM (JSM-7800F), TEM and HRTEM (JEM-2100), nitrogen adsorption-desorption isotherm measurements (Quadrasorb SI). The thickness of EG film was examined by surface profiler (Veeco Dektak 150). And electrical conductivity of the films was measured by a standard four-point probe system (RTS-9).

Fabrication of VN//Co(OH)2 –PHMSs

VN//Co(OH)2-PHMSs were fabricated by vacuum filtration method assisted by a customize interdigital mask with four digital fingers (the finger is length of 14 mm, width of 1 mm, the interspace is width of 0.5 mm, Fig. S16) on each side. An optimized mass loading was conducted as follows: 0.5 mL ethanol dispersions of EG (0.1 mg mL−1) were firstly filtered by vacuum filtration in each side to form uniform conductive current collectors. Then, the asymmetric interdigital micropatterns of VN//Co(OH)2 electrodes were directly manufactured by continuous deposition of porous VN nanosheets/EG (2.5 mL, 0.25 mg mL−1, 10 wt% EG) dispersion and Co(OH)2 nanoflowers/EG (1.0 mL, 0.25 mg mL−1, 15 wt% EG) solution on the different sides of mask as negative and positive electrodes, respectively, on a nylon membrane. After the removal of the mask, the result micropatterned film was pressed at 15 MPa to connect with nickel conductor. Finally, a polymer gel electrolyte of KOH/PVA (or 1 M KOH aqueous electrolyte) was carefully drop-casted onto the surface of PHMS and carefully sealed.

The symmetric VN//VN PMSs and Co(OH)2//Co(OH)2 PMSs were fabricated in the same method by filtering 2.25 mL porous VN nanosheets/EG or 1.0 mL Co(OH)2 nanoflowers/EG on each side of the interdigital mask.

Polymer gel electrolyte of KOH/PVA was prepared in solution-casting method.49 First, 6 g of PVA (M = 67000) was dissolved in 30 mL of high-purity water with agitation at 85 °C in order to get a clear solution. After all the PVA was dissolved, the obtained solution was continuously stirred for 1 h at room temperature until it cooled down and presented a uniform viscous appearance. Subsequently, 2.53 g of KOH was dissolved in 15 mL of fresh high-purity water. Afterwards, the KOH solution was added to the above PVA mixture dropwise, and then stirred for 2 h.

Electrochemical characterization

The working electrode was made by mixing active materials, EG, and polytetrafluoroethylene at a weight ratio of 100:10:5 for porous VN nanosheets or 100:15:5 for Co(OH)2 nanoflowers in ethanol solution, filtering a film and transferring to a piece of nickel foam by pressing at the pressure of 10.0 MPa. The typical mass loading of electrode material was 2.0 mg. Electrochemical performances were performed using a conventional three-electrode system equipped in 1 M KOH aqueous electrolyte, using a platinum electrode and a Hg/HgO electrode as the counter and reference electrode, respectively. Before and during electrochemical measurements, we had purged out O2 from the solution by the inert gas-N2.

The electrochemical performance of electrodes and VN//Co(OH)2-PHMSs was carried out by CV test from 2 to 100 mV s−1, GCD profiles from 0.1 to 5 mA cm−2 and electrochemical impendence spectroscopy recorded in the frequency range of 100 kHz to 0.01 Hz with a 5 mV ac amplitude on a CHI 760E electrochemical workstation.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Beidaghi, M. & Gogotsi, Y. Capacitive energy storage in micro-scale devices: recent advances in design and fabrication of micro-supercapacitors. Energy Environ. Sci. 7, 867–884 (2014).

Wu, Z. S., Feng, X. L. & Cheng, H.M. Recent advances in graphene-based planar micro-supercapacitors for on-chip energy storage. Natl. Sci. Rev. 1, 277–292 (2014).

Wu, Z. S., Parvez, K., Feng, X. L. & Müllen, K. Graphene-based in-plane micro-supercapacitors with high power and energy densities. Nat. Commun. 4, 2487 (2013).

Qi, D. P., Liu, Y., Liu, Z. Y., Zhang, L. & Chen, X. D. Design of architectures and materials in in-plane micro-supercapacitors: current status and future challenges. Adv. Mater. 29, 1602802 (2017).

Wu, Z. S. et al. Stacked-layer heterostructure films of 2D thiophene nanosheets and graphene for high-rate all-solid-state pseudocapacitors with enhanced volumetric capacitance. Adv. Mater. 29, 1602960 (2017).

Wang, S. et al. Scalable fabrication of photochemically reduced graphene-based monolithic micro-supercapacitors with superior energy and power densities. ACS Nano 11, 4283–4291 (2017).

Zheng, S. et al. Graphene-based materials for high-voltage and high-energy asymmetric supercapacitors. Energy Storage Mater. 6, 70–97 (2017).

Choudhary, N. et al. Asymmetric supercapacitor electrodes and devices. Adv. Mater. 29, 1605336 (2017).

Tang, W. et al. Aqueous supercapacitors of high energy density based on MoO3 nanoplates as anode material. Chem. Commun. 47, 10058–10060 (2011).

Wang, H., Yoshio, M., Thapa, A. K. & Nakamura, H. From symmetric AC/AC to asymmetric AC/graphite, a progress in electrochemical capacitors. J. Power Sources 169, 375–380 (2007).

Zhu, J. et al. High performance asymmetric supercapacitor based on polypyrrole/graphene composite and its derived nitrogen-doped carbon nano-sheets. J. Power Sources 346, 120–127 (2017).

Li, L. et al. High-performance pseudocapacitive microsupercapacitors from laser-induced graphene. Adv. Mater. 28, 838–845 (2016).

Wu, Z. S. et al. High-energy MnO2 nanowire/graphene and graphene asymmetric electrochemical capacitors. ACS Nano 4, 5835–5842 (2010).

Zhai, T. et al. Phosphate ion functionalized Co3O4 ultrathin nanosheets with greatly improved surface reactivity for high performance pseudocapacitors. Adv. Mater. 29, 1604167 (2017).

Wang, R., Yan, X., Lang, J., Zheng, Z. & Zhang, P. A hybrid supercapacitor based on flower-like Co(OH)2 and urchin-like VN electrode materials. J. Mater. Chem. A 2, 12724–12732 (2014).

Yan, J. et al. Advanced asymmetric supercapacitors based on Ni(OH)2/graphene and porous graphene electrodes with high energy density. Adv. Funct. Mater. 22, 2632–2641 (2012).

Yu, P. et al. A novel sustainable flour derived hierarchical nitrogen-doped porous carbon/polyaniline electrode for advanced asymmetric supercapacitors. Adv. Energy Mater. 6, 1601111 (2016).

Liu, J. et al. High-performance flexible asymmetric supercapacitors based on a new graphene foam/carbon nanotube hybrid film. Energy Environ. Sci. 7, 3709–3719 (2014).

Hong, M. S., Lee, S. H. & Kim, S. W. Use of KCl aqueous electrolyte for 2 V manganese oxide/activated carbon hybrid capacitor. Electrochem. Solid-State Lett. 5, A227–A230 (2002).

Ma, H. et al. Nickel cobalt hydroxide @reduced graphene oxide hybrid nanolayers for high performance asymmetric supercapacitors with remarkable cycling stability. ACS Appl. Mater. Interfaces 8, 1992–2000 (2016).

Xu, P. et al. Stretchable wire-shaped asymmetric supercapacitors based on pristine and MnO2 coated carbon nanotube fibers. ACS Nano 9, 6088–6096 (2015).

Feng, J. X., Ye, S. H., Lu, X. F., Tong, Y. X. & Li, G. R. Asymmetric paper supercapacitor based on amorphous porous Mn3O4 negative electrode and Ni(OH)2 positive electrode: A novel and high-performance flexible electrochemical energy storage device. ACS Appl. Mater. Interfaces 7, 11444–11451 (2015).

Peng, H., Ma, G., Mu, J., Sun, K. & Lei, Z. Low-cost and high energy density asymmetric supercapacitors based on polyaniline nanotubes and MoO3 nanobelts. J. Mater. Chem. A 2, 10384–10388 (2014).

Lu, X. et al. Oxygen-deficient hematite nanorods as high-performance and novel negative electrodes for flexible asymmetric supercapacitors. Adv. Mater. 26, 3148–3155 (2014).

Lu, X. H. et al. Improving the cycling stability of metal-nitride supercapacitor electrodes with a thin carbon shell. Adv. Energy Mater. 4, 1300994 (2014).

Lu, X. et al. High energy density asymmetric quasi-solid-state supercapacitor based on porous vanadium nitride nanowire anode. Nano Lett. 13, 2628–2633 (2013).

Shen, C. et al. A high-energy-density micro supercapacitor of asymmetric MnO2-carbon configuration by using micro-fabrication technologies. J. Power Sources 234, 302–309 (2013).

Yue, Y. et al. A flexible integrated system containing a microsupercapacitor, a photodetector, and a wireless charging coil. ACS Nano 10, 11249–11257 (2016).

Dinh, T. M., Mesnilgrente, F., Conédéra, V., Kyeremateng, N. A. & Pech, D. Realization of an asymmetric interdigitated electrochemical micro-capacitor based on carbon nanotubes and manganese oxide. J. Electrochem. Soc. 162, A2016–A2020 (2015).

Pang, H., Zhang, Y., Lai, W. Y., Hu, Z. & Huang, W. Lamellar K2Co3(P2O7)2·2H2O nanocrystal whiskers: high-performance flexible all-solid-state asymmetric micro-supercapacitors via inkjet printing. Nano Energy 15, 303–312 (2015).

Zhang, C. et al. Planar integration of flexible micro-supercapacitors with ultrafast charge and discharge based on interdigital nanoporous gold electrodes on a chip. J. Mater. Chem. A 4, 9502–9510 (2016).

Sun, L. et al. Optimization of coplanar high rate supercapacitors. J. Power Sources 315, 1–8 (2016).

El-Kady, M. F. et al. Engineering three-dimensional hybrid supercapacitors and microsupercapacitors for high-performance integrated energy storage. Proc. Natl. Acad. Sci. USA 112, 4233–4238 (2015).

Shen, C., Wang, X., Zhang, W. & Kang, F. A high-performance three-dimensional micro supercapacitor based on self-supporting composite materials. J. Power Sources 196, 10465–10471 (2011).

Beidaghi, M. & Wang, C. Micro-supercapacitors based on three dimensional interdigital polypyrrole/C-MEMS electrodes. Electrochim. Acta 56, 9508–9514 (2011).

Gao, S. et al. Ultrahigh energy density realized by a single-layer beta-Co(OH)2 all-solid-state asymmetric supercapacitor. Angew. Chem. Int. Ed. 53, 12789–12793 (2014).

Choi, D., Blomgren, G. E. & Kumta, P. N. Fast and reversible surface redox reaction in nanocrystalline vanadium nitride supercapacitors. Adv. Mater. 18, 1178–1182 (2006).

Wang, Z. L., Xu, D., Wang, L. M. & Zhang, X. B. Facile and low-cost synthesis of large-area pure V2O5 nanosheets for high-capacity and high-rate lithium storage over a wide temperature range. ChemPlusChem 77, 124–128 (2012).

Hou, Z. Q., Guo, K., Li, H. Q. & Zhai, T. Y. Facile synthesis and electrochemical properties of nanoflake VN for supercapacitors. Crystengcomm 18, 3040–3047 (2016).

Kong, L. B., Liu, M., Lang, J. W., Luo, Y. C. & Kang, L. Asymmetric supercapacitor based on loose-packed cobalt hydroxide nanoflake materials and activated carbon. J. Electrochem. Soc. 156, A1000–A1004 (2009).

Xiao, H. et al. One-step device fabrication of phosphorene and graphene interdigital micro-supercapacitors with high energy density. ACS Nano 11, 7284–7292 (2017).

Simon, P., Gogotsi, Y. & Dunn, B. Where do batteries end and supercapacitors begin? Science 343, 1210–1211 (2014).

Brousse, T., Belanger, D. & Long, J. W. To be or not to be pseudocapacitive? J. Electrochem. Soc. 162, A5185–A5189 (2015).

Eustache, E. et al. Asymmetric electrochemical capacitor microdevice designed with vanadium nitride and nickel oxide thin film electrodes. Electrochem. Commun. 28, 104–106 (2013).

Liu, W., Yan, X., Chen, J., Feng, Y. & Xue, Q. Novel and high-performance asymmetric micro-supercapacitors based on graphene quantum dots and polyaniline nanofibers. Nanoscale 5, 6053–6062 (2013).

Shen, B. S., Lang, J. W., Guo, R. S., Zhang, X. & Yan, X. B. Engineering the electrochemical capacitive properties of microsupercapacitors based on graphene quantum dots/MnO2 using ionic liquid gel electrolytes. ACS Appl. Mater. Interface 7, 25378–25389 (2015).

Wang, H. et al. Integrating three-dimensional graphene/Fe3O4@C composite and mesoporous Co(OH)2 nanosheets arrays/graphene foam into a superior asymmetric electrochemical capacitor. RSC Adv. 5, 88191–88201 (2015).

Gao, Z. H., Zhang, H., Cao, G. P., Han, M. F. & Yang, Y. S. Spherical porous VN and NiOx as electrode materials for asymmetric supercapacitor. Electrochim. Acta 87, 375–380 (2013).

Zhao, Y. et al. Monolayer nickel cobalt hydroxyl carbonate for high performance all-solid-state asymmetric supercapacitors. ACS Appl. Mater. Interfaces 8, 22997–23005 (2016).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant 51572259), National Key R&D Program of China (Grants 2016YFB0100100, and 2016YFA0200200), Natural Science Foundation of Liaoning Province (Grant 201602737), Recruitment Program of Global Expert (1000 Talent Plan), DICP (DICP ZZBS201708), DICP&QIBEBT (Grant DICP&QIBEBT UN201702), Dalian National Laboratory For Clean Energy (DNL), CAS, China Postdoctoral Science Foundation (Grant 2016M601348), Exploratory Research Program of Shaanxi Yanchang Petroleum (Group) CO., LTD & DICP.

Author information

Authors and Affiliations

Contributions

Z.S.W. proposed and supervised the overall project. S.W. did the fabrication of 2D materials, assembly and electrochemical measurement of PHMSs. X.Y.S., S.H.Z. and J.Q.Q. carried out the characterisation of the related materials. F.Z. and H.X. participated in the architecture design of PHMSs. S.W., Z.S.W., C.L.S. and X.H.B. analysed the data and wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, S., Wu, ZS., Zhou, F. et al. All-solid-state high-energy planar hybrid micro-supercapacitors based on 2D VN nanosheets and Co(OH)2 nanoflowers. npj 2D Mater Appl 2, 7 (2018). https://doi.org/10.1038/s41699-018-0052-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41699-018-0052-8

This article is cited by

-

Interface engineering for enhancing the performance of novel sodium-doped MoS2 nanocomposite: Synthesis and characterization functioning as a high-performance supercapacitor

Korean Journal of Chemical Engineering (2023)

-

Design and fabrication of Co3O4 anchored PANI binary composite supercapacitors with enhanced electrochemical performance and stability

Journal of Materials Science: Materials in Electronics (2022)

-

Partially reduced graphene oxide-based electrolyte: synthesis and electrochemical capacitance performance

Journal of Materials Science (2022)

-

A seamlessly integrated device of micro-supercapacitor and wireless charging with ultrahigh energy density and capacitance

Nature Communications (2021)