Abstract

Automated long haul trucking is being developed for commercial deployment in the United States. One possible mode of deployment for this technology is a “transfer-hub” model where the operationally less complex highway driving is automated, while human drivers drive the more complex urban segment of the route. We study the possible net impacts on tractor-trailer operator-hours from this mode of deployment. Using data from the 2017 Commodity Flow Survey, we gather information on trucking shipments and the operator-hours required to fulfill those shipments. We find that up to 94% of long haul trucking operator-hours may be impacted as the technology improves to operate in all weather conditions. If the technology is however restricted to the southern states where the majority of companies are currently testing automated trucking, we find that only 10% of operator-hours are impacted. We conduct interviews with industry stakeholders including tractor-trailer operators on the feasibility of such a system of deployment. We find that an increase in short haul operation is unlikely to compensate for the loss in long haul operator-hours, despite public claims to this effect by the developers of the technology. Policymakers should consider the impact of different scenarios of deployment on the long haul trucking workforce.

Similar content being viewed by others

Introduction

Automated driving technology is currently being tested on public roads in the United States in both the light vehicle and heavy duty segments. Given the likely reduced operational complexity involved in highway driving, several companies are currently working on developing automation for long haul trucking, which is designed to work as per a “transfer-hub” model (Hickman et al., 2018; Transport Topics, 2018). This would involve an automated truck (AT) completing the highway leg of the route and human drivers undertaking the more complex suburban-urban segments at both the starting and end points of the journey. Truck ports near highways would be used to switch out the trailer from the prime mover and enable this switch at both ends. For a schematic of the possible transfer-hub model see Fig. 1.

The promise of ATs has led to widespread concern about job losses in long haul trucking, which is a common profession in the United States, particularly for men with high-school educations (Wertheim, 2020). On the other hand, it has also been noted, often by the companies developing this technology, that long haul trucking currently faces a labor shortage and automation will create new short haul jobs, which will more than make up for the long haul jobs lost. As a result of these conflicting claims, as well as the uncertainty over the technology itself and its limitations, there is little clarity on how automated trucking will be deployed and its economic and political ramifications, such as the impact on the long haul trucking labor market.

We use data from the Commodity Flow Survey (CFS) 2017 (United States Census Bureau, 2020), which is a dataset jointly produced by the U.S. Census Bureau, U.S. Bureau of Transportation Statistics, and the U.S. Department of Commerce. CFS produces a sample of shipments in the United States including data on the type, origin and destination, value, weight, modes of transportation, and distance shipped. We estimate the operator-hours required for different routes using origin and destination information for trucking shipments from the CFS dataset, which enables us to estimate highway and (sub)urban splits for each shipment. We consider the technological constraints of automated trucking to make more refined estimates of the possible near term impacts of automation on long haul trucking operator-hours in the United States by assessing different scenarios of deployment. We find that contrary to strong claims by companies developing this technology (Gilroy, 2019), the loss in long haul operator-hours is unlikely to be compensated for by an increase in demand for short haul drivers. We find large labor impacts from the deployment of the transfer-hub model, contingent on the pace of progress of automation technology’s ability to function in different operating conditions. We compare the capabilities of automation with the tasks truck drivers are required to perform through discussions with industry stakeholders, including long haul operators. This allows us to have a realistic assessment of the tasks the technology will be required to perform over the highway legs and explore the feasibility of such deployment scenarios. In this framework, where jobs are considered as a bundle of tasks, our work builds on an extensive literature in the social sciences (Acemoglu and Autor, 2011; Acemoglu and Restrepo, 2019; Arntz et al., 2016). Through our limited sample of interviews, we discover reluctance to shift to new modes of operation such as short haul driving that will result from any application of the transfer-hub mode of deployment. The rest of the paper is structured as follows. Section “Literature review” reviews the existing literature on job impacts of AT. Section “Methods” describes our methods for both the analysis of operator-hour impacts and semi-structured interviews. Section “Results” presents the results and section “Conclusion and policy implications” concludes.

Literature review

Given the relatively recent advances in automated driving technology, there are a limited number of studies that have been conducted on the job impacts of automation on truck driver jobs. Viscelli (2018) has analyzed the impact of automation based on a similar “transfer-hub” operational model assumption shown in Fig. 1, where highway driving is automated while human drivers perform the urban segments of the route. Using revenue data from major trucking carriers and estimates of average per driver revenue, Viscelli (2018) estimates nearly 300,000 long haul jobs to be at risk. As per the analysis, these at-risk jobs are primarily concentrated in dry van and refrigerated trucking, which are characterized by high turnover and low wages (Viscelli, 2018).

Similarly, Gittleman and Monaco (2020) have undertaken a study analyzing the potential job losses from automation. They also find that contrary to several estimates in the media, the upper bound on job losses from automation are likely to be 400,000 jobs, far less than popular estimates of 1–2 million jobs at risk. Gittleman and Monaco (2020) perform this analysis using 2002 Vehicle Inventory and Use Survey (VIUS) data to gather estimates of the operational use of heavy trucks. They then apportion the number of long haul truck drivers using Occupational Employment Statistics data from the Bureau of Labor Statistics. Their study also notes that only a specific aspect of trucking—long haul highway driving—is ripe for automation and that operators who perform other tasks or are involved in customer facing roles such as in package delivery services are unlikely to face job losses (Gittleman and Monaco, 2020).

Groshen et al. (2019) consider different scenarios of adoption of automation and analyze the job impacts in different sectors of the economy using simulations and consultations with industry experts. They estimate 60–65% of heavy truck and tractor-trailer truck driving jobs to be eliminated with full implementation of automation (Groshen et al., 2019).

Waschik et al. (2021) leverage a dynamic model of the U.S. economy to simulate the macroeconomic impacts of automated trucking in the economy. They consider three different speeds of adoption: slow, medium and fast and find that employment in for-hire trucking falls by 20–25 percent and in private trucking by 4–5 percent across the scenarios considered (Waschik et al., 2021). Broader benefits in terms of productivity and employment in the economy are found to outweigh the employment impacts on long haul operators and the study assumes that long haul operators will switch to short haul jobs, minimizing the overall effect on the workforce (Waschik et al., 2021).

Finally, future of work studies around the deployment of automated vehicles have also delved into the issue of job losses in trucking from automation. For instance, Leonard et al. (2020) suggest that automation will create new roles such as remote management of trucks, dispatching, and field support while disrupting day driving jobs. However, they do not estimate the number or share of jobs at risk.

We found no examples in the literature of analyses that used trucking routes and shipment data or examined the specific capabilities of the technology (e.g., only operating in favorable weather conditions) to estimate the labor impacts of automated trucking. We also found no studies that undertook interviews with stakeholders including long haul operators to understand their perspectives on the tasks required over the highway legs.

Outside of the specific case of automated trucking, we also find a broad literature in economics on the impacts of automation on employment. Frey and Osborne (2013) model the probability of computerization for different occupations and find that workers in transportation and logistics are among those at high risk of automation, partly due to their low wages and low levels of educational qualifications. However, their methods, including considering that entire occupations rather than single tasks within jobs can be automated have faced criticism. Arntz et al. (2016) have shown that jobs are a bundle of tasks and while tasks may be easy to automate, jobs are often not. As such, forecasts of a large number of job-losses from automation, such as the study by Frey and Osborne (2013) can overestimate the impact of automation. One of the questions that therefore emerges here is the composition of tasks involved in long haul trucking. We attempt to unpack this through our semi-structured interviews with truck operators.

Borland and Coelli (2017) study the impact of automation on employment in Australia and find that total work available did not decrease following the introduction of computerization and that job turnover in the labor market has also not increased due to computer-based technologies. Mokyr et al. (2015) have analyzed the history of automation and job losses, explaining how there has always been anxiety on how technological progress will cause substitution of machines for human workers, leading to unemployment. However, such scenarios do not come to pass because the long-run effects of technology are beneficial in terms of net job-creation (Autor, 2015) and technology only impacts the type of jobs available and what they might pay. Technology can also complement labor resulting in increased productivity, earnings, and demand for labor (Autor, 2015; Bessen, 2019).

Nevertheless, perceptions of large job losses from automation are present in the social and political discourse. In terms of the perception of automation in trucking, Dodel and Mesch (2020) have shown how workers in occupations involving a greater number of manual or physical tasks, such as in the case of long haul trucking, can have more negative perceptions regarding the impact of automation on their livelihood. Orii et al. (2021) analyzed discussions related to automation among the members of the r/Truckers subreddit and found that <1% of comments had positive views on automation.

Methods

We contribute to the literature in the field by drawing on the CFS data (United States Census Bureau, 2020) to get a reliable estimate of the density of long haul trucking in different regions and the operator-hours required for different routes. Our primary analysis is centered in the use of freight data along with routing and operator-hour algorithms to estimate the share of operator-hours that may be lost to automation. We complement this quantitative analysis with a limited number of interviews with long haul trucking stakeholders to understand the feasibility of a transfer-hub mode of deployment. Overall, our mixture of quantitative and qualitative methods is based on the triangulation method (Jick, 1979), useful for analyzing socio-technical transitions and emerging technologies. We further elaborate on our methods below.

Data

The Commodity Flow Survey is a well known dataset for transportation planning and research, produced every five years by the U.S. Bureau of Transportation Statistics, U.S. Census Bureau, and the U.S. Department of Commerce. The latest iteration, CFS 2017, is a sample of 5.9 million shipments from approximately 60,000 responding establishments (United States Census Bureau, 2020). We disregard inter-modal shipments and focus on shipments delivered through for-hire trucks and private trucks. We only consider shipments routed over >150 miles as those are commonly classified as long haul (FMCSA, 2020; Viscelli, 2018). This subset contains nearly 1.5 million trucking shipments detailing origin and destination states, shipment distance, weight, and financial quarter. The data also contain a weighting factor, which can be used to estimate the total number of shipments of that type in the population.

Routing

We draw on the Google Maps API and the GGMAP package (Kahle and Wickham, 2013) in R to estimate highway and (sub)urban splits for each shipment. For the purposes of routing we categorize two types of shipments in the dataset: intrastate and inter-state. Intrastate shipments are those where the shipment does not cross state borders. Inter-state shipments are those where the state of origin is different to the state of destination.

We apply a differentiated methodology to calculate the highway and (sub)urban splits for each shipment depending on whether the shipment is within a state or across it and depending on whether the shipment has listed origin and destination Metropolitan Statistical Areas (MSAs). MSAs are listed for many but not all shipments in the dataset. If MSAs are not provided, we use the closest approximation of origin or destination location.

The different types of shipments and the methods used to calculate the highway and (sub)urban splits and highway and urban average speeds are shown in Table 1.

For inter-state shipments we proceed as follows. Where possible we use the origin and destination MSAs from the CFS dataset in Google Maps and estimate the highway and urban distance ratios (details provided in the next subsection) for those routes, which we then apply to the actual shipment distance from the dataset. To do this, we assume that the precise origin or destination is the centroid of the MSA. For shipments that specify either the origin or destination MSA (but not both), or specify neither origin nor destination metropolitan areas, we use the rest of the state centroid, which is defined as the centroid of all other areas of the state that are not listed MSAs. Note that this is an approximation that affects the estimate of the highway and sub(urban) split but does not affect the distance of the shipment, which is provided in the CFS dataset.

For intrastate journeys we apply the same method for shipments, which have specified origin and destination MSAs. For those that do not, we apply the highway and sub(urban) split derived from the Freight Analysis Framework dataset (Bureau of Transportation Statistics, 2012) by splitting the roads into those have average speeds below and above 50 mph.

Let the place of origin be designated as po,i and place of destination be designated as pd,i where i is a shipment. Then, consider a shipment from po,i to pd,i where po,i and pd,i are set as per the cases listed in Table 1. The Google Maps API where applicable then provides us with detailed route directions, which list the amount of time driven for any stretch of road before the next turn and so on. This allows us to calculate speeds for each section and then split the drive into segments, which are greater than or equal to 50 mph (classified as highway) and below 50 mph (classified as urban or suburban). Note that the route suggested by Google Maps may be different depending on the time of day that the API request is sent. We therefore ran several iterations of the routing algorithm at different times of day and found no discernible difference to our results.

Let the highway segment of this journey be hi and the urban sections ui. Let the origin-destination distance be di. The highway to total ratio ri is then defined as:

We then use these calculated ratios for each origin-destination combination and apply them to the actual shipment distance from the CFS dataset. This allows us to calculate the highway and urban leg lengths DS,H,i and DS,U,i for the shipments in the dataset.

Let the shipment distance be DS,i. Then,

and then,

Operator-hours calculation

The final step involves the calculation of urban and highway operator-hours. We assume the urban legs are equally split at the two ends of the journey with the highway leg in between. We apply a constraint of 11 h of daily driving as per hour of service (HOS) regulations (FMCSA, 2020) and then calculate the operator-hours required for the highway and urban legs of the journey. Using this information and the aforementioned weighting factor we are then able to calculate the total operator-hours as well as the share of highway and urban operator-hours.

Let day1 hours be the number of hours remaining that can be driven on day 1 of the trip after completing the initial urban leg. Let O be operator-hours described for both highway leg OH and urban leg OU. Let highway and urban driving time be TH and TU, respectively, which can be calculated from the average velocities VH and VU for the respective segments also derived from the Google Maps API where applicable. Then for shipment i:

and similarly

Then, our algorithm to estimate the operator-hours is described below. Note that ⌈(x)⌉ denotes the ceiling of x and x%y denotes the remainder of x when divided by y.

Algorithm 1

i from 1: I

\(da{y}_{1,{{{\rm{i}}}}}=11-\frac{{T}_{{{{\rm{U}}}},{{{\rm{i}}}}}}{2}\)

if day1,i ≥ TH,i then

OH,i = TH,i

else

if day1,i < TH,i then

\({O}_{{{{\rm{H}}}},{{{\rm{i}}}}}={T}_{{{{\rm{H}}}},{{{\rm{i}}}}}+\left\lceil \left(\frac{{T}_{{{{\rm{H}}}},{{{\rm{i}}}}}-da{y}_{1,{{{\rm{i}}}}}}{11}\right)\right\rceil * 10\)

end if

if \(\left(\frac{{T}_{{{{\rm{H}}}},{{{\rm{i}}}}}-da{y}_{1,{{{\rm{i}}}}}}{11}\right) \% 11+\frac{{T}_{{{{\rm{U}}}},{{{\rm{i}}}}}}{2} > 11\) then

OU,i = TU,i + 10

else

OU,i = TU,i

end if

end if

The algorithm can be explained as follows. If the highway driving time is less than the number of driving hours remaining on day 1, then the shipment is simply completed on the day and the highway operator-hours are equal to the highway driving time. However, if the highway driving time exceeds this then the driver undertakes the journey over the following days with 10 h of rest following 11 h of driving as mandated by law. The urban driving time is simply the time taken to drive the urban leg if the second and final urban segment can be completed staying within the HOS requirements, else it is completed with a day of rest.

With the calculated urban and highway operator-hours for each trip we can then estimate the total operator-hours across both highways and urban areas using the trip weighting factor provided by the CFS dataset. The weighting factor is the estimate of the true number of trips of such type in the actual population and is available for each shipment in the CFS dataset. Let the weighting factor be Π. Further let shipment weight be W. Then for the total operator-hours OTotal we have:

where TL is truckload or the total weight that can be carried on one fully loaded semi truck.

Then the urban and highway share of the total operator-hours, US and HS, is simply:

Note that the highway share (HS), across both inter-state and intrastate trucking, is the share of operator-hours at risk from automated highway trucking. US represents the share of hours that must still be driven by a human driver.

Notice that if the truckload is a constant, such as for, e.g., fully loaded class 8 semi trucks, then it cancels in both the numerator and denominator of equations (7) and (8) and is therefore irrelevant to our results. More information on methods including the limitations of our approach are provided in Supplemental Information (SI) Section 1.

Interviews

In order to obtain some assurance about the validity of the assumptions underlying the transfer-hub model, we undertook semi-structured interviews with stakeholders in the trucking industry using a purposeful sampling methodology (Robinson, 2014), which was formulated through authors’ prior work in the automated vehicle domain (Mohan et al., 2020), as well as prior informal conversations with companies and researchers in this area, which helped us identify relevant questions and stakeholders. For our conversations with drivers in particular, we used snowball sampling (Naderifar et al., 2017): we identified an initial set of drivers who have a public profile (e.g., have podcasts or YouTube Channels about trucking) and asked them to introduce us to their colleagues. We stopped when we achieved data saturation (Guest et al., 2006): that is, when conversations with new drivers did not introduce us to new concepts or phenomena (Hennink et al., 2017). We spoke with stakeholders across automated trucking startups (2), truck drivers (5), trucking logistics operators (1), and labor union representatives (1). In terms of our selection of different interviewees, we deliberately sought to elevate the voices of truck drivers in our sample, relative to other actors such as automated trucking startup CEOs or logistics operators. This is because of two reasons. Firstly, operators were best placed to provide us with the operational challenges and opportunities for the transfer-hub model of automation, given they are currently in charge of the major task that automation may replace (driving). Second, much of the narrative and coverage around automated trucking in the popular media has focused on the claims made by private operators, without much consideration of whether long haul drivers themselves believe that a switch to automation is feasible. Note that our sample size was not designed to enable generalization to all the stakeholders in long haul trucking. Our sample size and qualitative method (semi-structured interviews) were instead selected with an idiographic approach (Robinson, 2014), focused on gathering detailed insights into the tasks truck drivers performed on a journey. The interviews also highlight interesting areas for future research. Most importantly, as part of the triangulation method (Jick, 1979) we use to analyze automated trucking, the interviews complement our quantitative analysis of the CFS data and the routing and operator-hour algorithms we present by providing a feasibility check on the deployment modes assumed in this paper and which have been promoted by technology companies. The full list of interviewees is provided in Table 2.

Results

Our analysis finds that up to 94% of operator-hours for truck drivers are impacted if the technology is deployed across the continental U.S. in all conditions. However, if restricted to the states where testing is currently taking place, only 10% of operator-hours are impacted. The capabilities of the technology and decisions around where and how AT should be deployed will therefore determine the extent of impacts on the long haul operator labor market. Below we first discuss the findings from our exploration of possible scenarios of deployment, and their associated impacts on operator-hours, if realized. We analyze the extent of the possible increase in short haul jobs if AT delivers cost and time savings in freight delivery and show that this is unlikely to outweigh the hours lost to automation. Then, we present the takeaways from our semi-structured interviews with stakeholders in long haul trucking. Finally, we end with a brief discussion on the labor impacts in sectors associated with long haul trucking.

Scenarios

We consider different scenarios of deployment, which correspond to constraints the technology may face in the near-medium term. They are as follows:

-

Deployment in southern, sunny states only—To our knowledge, significant AT testing currently takes place in Florida, Texas, and Arizona. We hypothesize that initial highway deployment will be restricted to states in the southern sun-belt (see Fig. 2) to minimize risk of exposure to snow or hail, which may be outside the limits of safe operation of the technology and therefore only consider routes between or within these states.

-

Deployment across all states over the financial quarters Q2 and Q3, which encompass the spring and summer months from April 1 to September 30—The CFS dataset lists the financial quarter of shipment allowing us to assess a scenario where all journeys that would be performed in more favorable weather are automated.

-

Deployment for journeys above 500 miles only—While AT may be financially optimal at even short distances of around 100 miles (see SI Section 2), the time required for switching trailers and separating urban and highway legs could mean that journeys, which currently cannot be performed in a single day given HOS requirements will be automated first. Long haul operators can comfortably cover 500 miles without stopping so we set this as the threshold.

-

Widespread deployment—deployment of transfer-hub-based AT across the United States and automation of all highway driving. While this is likely to take several years, it can be thought of as the most extreme scenario in terms of job losses. Note that most studies in the literature (Gittleman and Monaco, 2020; Viscelli, 2018) only consider this scenario .

Operator-hours

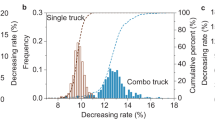

Figure 3 shows the impact on operator-hours across the different scenarios considered, with each scenario considered as additive (cumulative) to the previous scenario.

In scenario 4, with widespread deployment across the continental United States, 94% of current operator-hours may be automated. On the other hand, we find that deployment of automation only in places where companies are currently testing the technology, i.e., the southern states, limits the impact to just 10% of operator-hours (scenario 1). These estimates could represent a potential trajectory, over time, for impacts on employment, if the technology improves over time. It is likely that near term deployment, if any, will be in favorable weather conditions and in states with favorable regulation, precisely those states where testing is currently taking place. If this is then further expanded to all parts of the country but only in the favorable weather months, i.e., financial Quarter 2 and 3, then we find that over half of operator-hours could be impacted. If automation is then extended to all shipments over 500 miles, we find that a further 33% of operator-hours are impacted. Other possible deployment scenarios and their impacts are shown in Table S1.

Changes in demand and price elasticity of freight

Automation is likely to dramatically reduce the need for labor, which constitutes roughly 40% of the cost of trucking (Williams and Murray, 2020). It is also likely to eliminate HOS requirements, which currently mean that-unless two drivers work in tandem-a truck remains idle for >60% of the time in order to allow the driver to rest (FMCSA, 2020). As a consequence, automation will reduce the amortized capital cost of the truck, which constitutes another 16% of the cost of trucking (Williams and Murray, 2020). Finally, the elimination of HOS requirements will make trucking faster than it is today, since the trucks will no longer have to stop for driver breaks. Cost and delivery time reductions in the delivery of freight through automated trucking may result in increased demand for trucking shipments. This may happen in two ways.

First, freight that was previously routed through air, train, or inter-modal services may now be shifted to long haul trucking. The modal choice of freight could therefore tilt in favor of trucking. There is considerable variation in modal elasticity estimates in the literature (De Jong et al., 2010). For example, Abdelwahab (1998) has estimated an elasticity of –1.44 and –0.99 for truck modal choice given an increase in trucking shipment time and cost, respectively. More recently, Christidis et al. (2009) reviewed a number of studies and found cross-elasticities of rail and road that range from 0.3 to 2. Dahl (2012) has found limited elasticity for trucking demand to fuel costs.

Second, cost and time reductions in freight delivered through trucking may increase demand for freight services in the economy overall. This increase in demand will increase the overall operator-hours required to fulfill long haul trucking shipments.

While elasticities vary widely in the literature for these factors as described above, we find that any resultant increase in demand for freight from some or all of these factors is likely to have a small impact on operator-hours. Further, this increase is unlikely to offset the overall operator-hours at risk due to automation. For example, even a 50% increase in demand for trucking services, which translates to an overall elasticity of 5, will only offset 5% of the at-risk hours due to automation, dropping the overall share from 94% to 89% of operator-hours at risk. This is simply because even though such an increase will lead to great demand for trucking services, the large majority of all operator-hours will still be needed on the highway (Fig. 3).

A large increase in demand of the magnitude of 50% or more for trucking services is in fact unlikely. Trucking already dominates the freight market with 70% of tonnage in the United States shipped through trucks (Association, 2020a). Freight that is today delivered through competing modes such as rail is often because of reasons other than cost or shipment time, for example, gross weight requirements, or because a close coupling between the location of the rail tracks and siting of various industrial facilities. Overall, we find limited evidence in support of the claim that increases in demand for trucking due to the economic and productivity gains from automation will create short haul jobs that will offset the highway operator-hours lost due to automation.

Jobs

What do these impacts on operator-hours imply for jobs? It is important to note that we do not directly characterize job losses from automation in trucking, focusing instead on the share of operator-hours that will be impacted. This is because data for the number of long haul truck drivers in the United States is not available to a high level of accuracy, owing to the large number of owner operators. Estimates have a wide range, from a few hundred thousand to millions of jobs. Studies that attempt to put a number on the total jobs lost therefore run the risk of a large error and are often not comparable due to the differing assumptions about the baseline number of jobs.

Nevertheless, translating the share of operator-hours impacted to different estimates of the number of long haul trucking operators in the United States can provide some insight. Previous analyses has estimated the number of long haul operators to be between 300,000–400,000 (Gittleman and Monaco, 2020; Viscelli, 2018). Waschik et al. (2021) estimate that there are roughly 550,000 long haul operators, in their modeling of the macroeconomic impacts of automated trucking. Our results on the share of operator-hours at risk from automation would therefore mean that anywhere from 30,000 to >500,000 jobs may be impacted, depending on the scenarios presented above.

Impacts on workers in associated sectors

Finally, automation of highway trucking will have impacts on more than just tractor-trailer operators. While outside the focus of this paper, we offer a brief discussion here. First, automation of highway trucking could obviate the need for truck stops on the highway or at least make them far less frequented than before. Employment associated with operating truck stops will therefore be impacted. These truck stops currently employ about 70,000 people (See SI Table S2). On the other hand, the creation of truck ports to facilitate the transfer-hub model of AT will likely create new jobs. These will possibly involve new tasks such as switching trailers between the human and automated prime movers, offering services to human operators that were previously offered at truck stops, and maintenance and safety checks of sensors and other equipment on board automated trucks before their deployment on a route. To a first approximation, our analysis indicates that it is possible that the labor-hours lost at truck stops and other locations on highways could be compensated by new employment opportunities at transfer-hub ports (see SI Section 4 for more details). However, it is unclear whether operators in existing jobs at truck stops will be interested in or qualified for the new jobs that may arise from deployment of AT.

Discussion with Stakeholders

Scholars note that typically, only some of the tasks that constitute a job, are amenable to automation (Arntz et al., 2016; Autor, 2015). As such, tasks are easy to automate; jobs are often not. Existing literature has noted how truck driving jobs have increasingly been reduced to solely the task of driving (Viscelli, 2016, 2018). While this supports automation, one of the major challenges we envisaged to AT deployment on highways is maintenance and repairs. However, upon speaking with actors in the trucking industry (interviews 3–9) we found that employed truck drivers do not perform any significant maintenance and repairs on their truck. Instead, drivers simply call for assistance and trucking companies send out repair teams or arrange for a repair appointment at the nearest service station. ATs will therefore need to be able to send out distress signals and get assistance when needed. While some drivers indicated that they do perform some maintenance on their trucks (interview 7,9) this was restricted to minor fixes, for, e.g., a broken headlight. Often drivers indicated that their companies did not want them to try to repair problems with the truck but instead rely on expert help. Some trucking jobs are union jobs and in those cases the drivers often have clauses in their contracts that restrict them to only driving and not having to perform work such as maintenance and unloading (interview 2).

The benefits of automation in terms of shorter trip times and lower costs could quite easily and quickly be incorporated into trucking operations and logistics, as per one of our interviews with a Senior Manager at a logistics firm (interview 4). AT startup executives acknowledged that both weather and lighter regulation motivated their decision to test in states such as Florida and Texas (interviews 1,3). This raises questions regarding the widespread application of this technology to all parts of the continental United States.

Interestingly, every operator (interviews 5–10) we spoke to said that they could not see any major barriers to ATs performing highway journeys. Several of them (interviews 5,9,10) highlighted the difficulties posed by inclement weather conditions, places where lane markings are absent, and routing if global positioning system (GPS) signal is lost, which could mean that some routes continue to be driven by human drivers. All drivers we spoke to try to use their maximum allowed driving time of 11 h in a day. They all also indicated that there are often several weeks where they do not have any direct contact with their employers and simply perform their tasks as assigned. All drivers also indicated their trucks are tracked with GPS and therefore companies and customers are continuously aware of their location. Our discussions indicate that the job of long haul trucking has indeed effectively been reduced to a single task, which-given conducive external conditions-makes it amenable to automation.

We further offer some propositions for future research to explore. Owing to the limitations of our sample size, the lack of segmentation between different types of drivers, and no consideration of potential confounders, these are not intended as conclusions.

Proposition 1

A larger volume of shorter trips may not compensate for the loss of work associated with automated long haul trips. A transfer-hub model will require drivers to shift to short haul jobs. The most common pay structure currently for “truck-load" drivers, who haul full truckloads worth of generic containerized freight for a trucking company (and not for a shipper like Walmart or Target), is payment per mile of haulage. They are often not paid for the waiting and paperwork that occurs at the beginning and end of each trip. Truckload drivers seek to maximize the time they keep the cargo moving. A shift to shorter trips would increase the ratio of stationary (unpaid) to driving (paid) time, reducing their wages per hour worked (Viscelli, 2016). In our limited sample there was near consensus among our interviewees that the shorter trips and lower pay that may come from urban driving jobs will be unattractive (interviews 5–9). Therefore, one of the interesting questions for future qualitative research based on a large sample size would be to understand operators’ views on shifting to short haul jobs and whether these might hinder or accelerate a shift to the transfer-hub model.

Proposition 2

Transfer hub deployment could create short haul jobs in locations that are different from where long haul truckers currently live. A shift to only urban driving will likely require operators to live in sub(urban) areas. At least one operator we spoke with expressed reluctance to shift to short haul trucking for this reason alone (interview 9). Around 40% of older truckers come from rural areas so it’s possible that the geographical shift will prove a barrier to transitioning current operators to short haul jobs, which speaks to the cultural significance long haul trucking jobs have carried in the U.S. (Levy, 2015). However, these new jobs may prove attractive to new truckers joining the workforce, who are increasingly from urban areas (Cheeseman Day and Hait, 2019). Again, this is an important question for future work and will require careful study. Shifting of employment from rural to urban areas for trucking will naturally have political implications, particularly given the existing rural-urban divide in the American political landscape (Thiede et al., 2017).

Proposition 3

Partial automation is viewed negatively by heavy truck operators, as previous studies have suggested (Slowik and Sharpe, 2018). Partial automation systems have also been criticized in the broader safety literature as they may lead to disengaged and distracted operators who are too quick to trust the technology and will be unable to react in a timely and safe manner should something go wrong (Endsley and Kiris, 1995). Many companies involved in self-driving technology are in fact skipping partial automation systems and focusing solely on full automation (Ayre, 2017, Naughton, 2017, Volvo, 2017). Economically, if companies still have to pay drivers for their labor and also pay for the system, it is difficult to see how this would be attractive compared to the current system of only paying drivers, unless the cost savings from increased safety were significant. All drivers (interviews 5, 7–10) in our limited sample expressed dislike for partial automation systems that they have used or experienced such as lane assist and emergency braking. How might views on such technologies differ depending on the age and experience of truck drivers? We believe that future work on the transition from human driven to automated trucks and the potential role of partial automation systems as a bridge technology must take into account the views of drivers, as they will be the primary users of such technologies.

Conclusion and policy implications

Automation of the major part of the job—in this case highway driving—will naturally put downward pressure on wages in the long haul trucking industry. It is unclear that the labor supply will easily adjust to the new level of prevailing wage and operating requirements (short haul jobs) in the market. Our limited number of interviews certainly highlight the challenges employers may face in transitioning long haul operators to different jobs such as short haul driving. It also suggests that the deployment of AT is being driven by techno-economic considerations alone with limited understanding of the social consequences, consistent with the broader narrative around automated mobility technologies (Bissell et al., 2020). Although companies have claimed that such technologies will benefit truck drivers, our evidence does not suggest that the motivations of truck drivers are part of the designed operation of this technology. Moving away from industry led visions of AT futures will require a greater understanding of the motivations and interests of long haul operators, and a participatory approach to shaping AT deployment (Mladenović, 2019).

In the currently envisioned transfer-hub model, short term adjustment costs are likely and potentially notable. As we show, a significant share of operator-hours will be affected if the technology is deployed in all conditions and locations. Further, we argue that this result is robust to increase in demand for freight delivered through trucking if as assumed, the cost of long haul trucking falls due to automation.

We do caution however that the potential loss of a significant share of operator-hours to automation need not be necessarily viewed as permanent unemployment or as a permanent welfare loss. Long haul trucking has been characterized by turnover rates of nearly 100% in recent years (Association, 2020b). The profession is increasingly unattractive to potential new entrants with most new operators lasting less than a year in the job. This has occurred in substantial part through a concerted effort to make trucking cheaper by paying drivers less; for example, by encouraging many drivers to operate as independent contractors (Viscelli, 2016). Wages may need to increase as these arms-length employment arrangements are challenged in court and as it becomes increasingly difficult to find new drivers. This dynamic may strengthen the economic case for automation.

Historically, technological change has resulted in short term employment shocks but realignment in the labor market means that these shocks have limited impact on the broader economy in the long-run, as new industries grow and workers transition to new jobs with new skill requirements (Bessen, 2019). Long haul operators may therefore move across to different sectors after a period of unemployment, some may transition to lower paying short haul jobs that will be created by the transfer-hub model, others may retire prematurely (Waschik et al., 2021).

The sharp reduction in labor cost makes the economics of ATs compelling but will disrupt livelihoods and, by potentially shifting demand from rail to trucks, likely also increase emissions of greenhouse gasses and other air pollutants (Kaack et al., 2018). The threat of jobs lost due to automation in trucking may also have profound political impacts, the existing literature has found increased support for radical right wing parties as the risk of automation increases (Im et al., 2019). Policymakers could demand that-in exchange for permission to deploy ATs on public roads-truck operators re-invest some of the monetary benefits of reduced labor costs to ameliorate the disruption to employment and in reducing the environmental footprint of the trucking industry (Viscelli, 2020). Ultimately, societal and political choices can determine the mode of deployment of AT capabilities, and accordingly, the winners and losers of any shift to automation of long haul trucking.

Data availability

The Commodity Flow Survey (2017) dataset used in this paper is publicly available from the U.S. Census Bureau.

References

Abdelwahab WM (1998) Elasticities of mode choice probabilities and market elasticities of demand: evidence from a simultaneous mode choice/shipment-size freight transport model. Transp Res Part E: Logist Transp Rev 34:257–266

Acemoglu D, Autor, D (2011) Skills, tasks and technologies: implications for employment and earnings. In Handbook of labor economics, vol. 4. Elsevier. pp. 1043–1171

Acemoglu D, Restrepo P (2019) Automation and new tasks: How technology displaces and reinstates labor. J Econ Perspect 33:3–30

Arntz M, Gregory T, Zierahn U (2016) The risk of automation for jobs in OECD countries: a comparative analysis. OECD

Association AT (2021). News & Insights. https://www.trucking.org/news-insights (2020). Accessed: 05-Apr-2021

Association AT (2020) News & Insights. https://www.trucking.org/news-insights/truckload-turnover-rises-third-quarter. Accessed: 24-Apr-2021

Autor DH (2015) Why are there still so many jobs? the history and future of workplace automation J Econ Perspect 29:3–30. https://www.aeaweb.org/articles?id=10.1257/jep.29.3.3.

Ayre J (2021) Google/Waymo stopped testing level 3 self-driving tech after testers literally fell asleep while using it, switched to full autonomy. https://tinyurl.com/yhj5cddb (2017). Accessed: 05-Apr-2021

Bessen J (2019) Automation and jobs: when technology boosts employment. Econ Policy 34:589–626

Bissell D, Birtchnell T, Elliott A, Hsu EL (2020) Autonomous automobilities: the social impacts of driverless vehicles. Curr Sociol 68:116–134

Borland J, Coelli M (2017) Are robots taking our jobs? Australian Econ Rev 50:377–397

Bureau of Transportation Statistics (2012). Freight analysis framework version 4. https://www.bts.dot.gov/faf/faf4. Accessed: 20-Nov-2020

Cheeseman Day J, Hait AW (2021) Number of truckers at all-time High. https://tinyurl.com/3uj4urr9 (2019). Accessed: 6-May-2021

Christidis P, Leduc G et al. (2009) Longer and heavier vehicles for freight transport. JRC European Commission. pp. 1–40

Dahl CA (2012) Measuring global gasoline and diesel price and income elasticities. Energy Policy 41:2–13

De Jong G, Schroten A, van Essen H, Otten M, Bucci P (2010) The price sensitivity of road freight transport: a review of elasticities. Applied transport economics, a management and policy perspective, De Boeck, Antwerp

Dodel M, Mesch GS (2020) Perceptions about the impact of automation in the workplace. Inform Commun Soc 23:665–680

Endsley MR, Kiris EO (1995) The out-of-the-loop performance problem and level of control in automation. Human factors 37:381–394

FMCSA (2020) Hours of Service (HOS). https://www.fmcsa.dot.gov/regulations/hours-of-service (2020). Accessed: 20-Nov-2020

Frey CB, Osborne M (2013) The future of employment. Oxford

Gilroy R (2020) Ike maintains automation will add truck driving jobs. https://www.ttnews.com/articles/ike-maintains-automation-will-add-truck-driving-jobs (2019). Accessed: 18-Jun-2020

Gittleman M, Monaco K (2020) Truck-driving jobs: Are they headed for rapid elimination? ILR Rev 73:3–24

Groshen EL, Helper S, MacDuffie JP, Carson C (2019) Preparing US workers and employers for an autonomous vehicle future. WE Upjohn Institute for Employment Research

Guest G, Bunce A, Johnson L (2006) How many interviews are enough? an experiment with data saturation and variability. Field Methods 18:59–82

Hennink MM, Kaiser BN, Marconi VC (2017) Code saturation versus meaning saturation: how many interviews are enough? Qual Health Res 27:591–608

Hickman J, Levy F, Burks S, Viscelli S, Lee J (2018) An NSF workshop report: effect of automated trucks on the truck driver workforce. Tech Rep, Virginia Tech Transportation Institute’s Center for Truck and Bus Safety

Im ZJ, Mayer N, Palier B, Rovny J (2019) The “losers of automation": a reservoir of votes for the radical right? Res Polit 6:2053168018822395

Jick TD (1979) Mixing qualitative and quantitative methods: Triangulation in action. Admin Sci Quart 24:602–611

Kaack LH, Vaishnav P, Morgan MG, Azevedo IL, Rai S (2018) Decarbonizing intraregional freight systems with a focus on modal shift. Environ Res Lett 13:083001

Kahle D, Wickham H (2013) ggmap: spatial visualization with ggplot2. The R J 5:144–161

Leonard JJ, Mindell DA, Stayton EL (2020) Autonomous vehicles, mobility, and employment policy: the roads ahead. Massachusetts Inst. Technol., Cambridge, MA, Rep. RB02-2020

Levy KE (2015) The contexts of control: Information, power, and truck-driving work. Inform Soc 31:160–174

Mladenović MN (2019) How should we drive self-driving vehicles? anticipation and collective imagination in planning mobility futures. In: The governance of smart transportation systems. Springer. pp. 103–122

Mohan A, Sripad S, Vaishnav P, Viswanathan V (2020) Trade-offs between automation and light vehicle electrification. Nat Energy 5:543–549

Mokyr J, Vickers C, Ziebarth NL (2015) The history of technological anxiety and the future of economic growth: Is this time different? J Econ Perspect 29:31–50

Naderifar M, Goli H, Ghaljaie F (2017) Snowball sampling: A purposeful method of sampling in qualitative research. Stride Dev Med Educ 14:e67670

Naughton K (2017) Ford’s dozing engineers side with Google in full autonomy push. https://tinyurl.com/2h98swvp. Accessed: 05-Apr-2021

Orii L, Tosca D, Kun AL, Shaer O (2021) Perceptions on the future of automation in r/truckers. In: Extended abstracts of the 2021 CHI conference on human factors in computing systems. pp. 1–6

Robinson OC (2014) Sampling in interview-based qualitative research: A theoretical and practical guide. Qual Res Psychol 11:25–41

Slowik P, Sharpe B (2018) Automation in the long haul: challenges and opportunities of autonomous heavy-duty trucking in the United States. International Council on Clean Transportation, Working Paper

Thiede B, Greiman L, Weiler S, Beda S, Conroy T (2017) Six charts that illustrate the divide between rural and urban America. The Conversation

Transport Topics (2018) How drivers and autonomous trucks could work together to move freight. https://www.ttnews.com/articles/how-drivers-and-autonomous-trucks-could-work-together-move-freight. Accessed: 18-Jun-2020

United States Census Bureau. CFS 2017. https://www.census.gov/programs-surveys/cfs.html (2020). Accessed: 20-Nov-2020

Viscelli S (2020) Will robotic trucks be" sweatshops on wheels?". Issue Sci Technol 37:79–88

Viscelli S (2016) The big rig: trucking and the decline of the American dream. Univ of California Press

Viscelli S (2018) Driverless? Autonomous trucks and the future of the American trucker. Center for Labor Research and Education, University of California, Berkeley, and Working Partnerships USA

Volvo (2017) Volvo Cars CEO urges governments and car industry to share safety-related traffic data. https://tinyurl.com/28ezuxds. Accessed: 05-Apr-2021

Waschik R, Friedman D, Taylor C, Boatner J et al. (2021) Macroeconomic impacts of automated driving systems in long-haul trucking. Tech Rep, United States. Department of Transportation. Intelligent Transportation

Wertheim J (2020) Automated trucking, a technical milestone that could disrupt hundreds of thousands of jobs, hits the road. https://tinyurl.com/przw2kj3. Accessed: 18-Jun-2020

Williams N, Murray D (2020) An analysis of the operational costs of trucking: 2020 update

Acknowledgements

The authors would like to thank Venkatasubramanian Viswanathan, Jeremy Michalek, Nicholas Muller, Jessika Trancik, and Jack Stilgoe for their helpful comments on earlier drafts of this paper. This work was supported by the CMU College of Engineering, Department of Engineering & Public Policy; and the Block Center for Technology and Society at CMU.

Author information

Authors and Affiliations

Contributions

AM and PV designed the research, conceived the paper, and developed the routing and operator-hours algorithm used in this work. AM performed the analysis and created the figures; and AM and PV wrote the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Informed consent

Informed consent was obtained from all interviewees.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohan, A., Vaishnav, P. Impact of automation on long haul trucking operator-hours in the United States. Humanit Soc Sci Commun 9, 82 (2022). https://doi.org/10.1057/s41599-022-01103-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1057/s41599-022-01103-w