Abstract

One of the potential applications of 2D materials is to enhance multi-functionality of structures and components used in aerospace, automotive, civil and defense industries. These multi-functional attributes include sensing, energy storage, EMI shielding and property enhancement. In this article, we have explored the potential of using graphene and its variants as data generating sensory elements in Industry 4.0. We have presented a complete roadmap to cover three emerging technologies i.e. advance materials, artificial intelligence and block-chain technology. The utility of 2D materials such as graphene nanoparticles is yet to be explored as an interface for digitalization of a modern smart factory i.e. “factory-of-the-future”. In this article, we have explored how 2D material enhanced composites can act as an interface between physical and cyber spaces. An overview of employing graphene-based smart embedded sensors at various stages of composites manufacturing processes and their application in real-time structural health monitoring is presented. The technical challenges associated with interfacing graphene-based sensing networks with digital space are discussed. Additionally, an overview of the integration of associated tools such as artificial intelligence, machine learning and block-chain technology with graphene-based devices and structures is also presented.

Similar content being viewed by others

Introduction

An industrial revolution is a period of time in which significant changes occur in the way goods are produced to the extent that fundamentally transform the society, and is characterized by the introduction of disruptive technologies and novel production methods1,2,3. This typically leads to increased efficiency, reduced cost, greater production, and widespread economic and social impact3. The first industrial revolution (Industry 1.0) was characterized by the introduction of mechanical production methods using water and steam power3,4. Industry 2.0 saw the introduction of mass production using electricity and the assembly line5,6. Industry 3.0 introduced the use of information technology, computers and automation in production, leading to increased efficiency and customization6. Industry 4.0 takes this further by incorporating smart and autonomous systems, artificial intelligence, robotics, Internet of Things (IoT), cloud computing, and the integration of physical and virtual systems that leads to a further level of automation and data exchange7,8,9,10. Industry 4.0 is expected to gradually evolve into Industry 5.0 which will be characterized by further advancements in the above mentioned technologies10,11,12.

In Industry 4.0, the interconnection of the physical and virtual space is a crucial step which is necessary for realizing smart operations in the material design and manufacturing processes13,14,15,16. The physical space in a smart manufacturing setup refers to the manufacturing tools, raw materials and human resources. Whereas, the virtual space includes computational resources equipped with data storage and sharing capabilities as well as data analytics tools. The convergence of these two spaces is currently achieved through an array of embedded sensors or via imaging devices. However, these methods are inefficient and involve embedding of foreign objects within the material or structure. Replacing such devices with the material itself will revolutionize the paradigm of digital manufacturing. Such a material can be “smart” and capable of sensing and relaying the collected information or data to the virtual space in real-time.

Graphene and other 2D materials can act as the required interface and make the material directly communicate with the digital world17,18. Graphene and related 2D materials have been the focus of intensive research and development for over a decade, however products utilizing these materials have not captured the market yet. Graphene, termed as a “wonder material”, was anticipated to have wide range of applications ranging from electronics, civil/mechanical structures and water filtration to wearable technology, biosensors and medicine19. However, due to the scale and cost of production, these expectations could not be realized after more than a decade20. Currently, data generating devices (such as sensors) based on 2D materials are mostly in their initial Technology Readiness Levels (TRL). Further research is required in order to increase the technology readiness levels and have more sophisticated prototype systems manufactured for commercial deployment. In order to accelerate the path towards industrialization of 2D materials and increase their potential for future impact at commercial level, associated tools such as artificial intelligence and block-chain technology need to be developed and integrated with these devices. One of the potential applications of graphene nanoparticles is to impart multi-functionality to structures. These multi-functional attributes include sensing, energy storage, EMI shielding and property enhancement etc.21,22,23,24.

Graphene offers a number of fundamentally superior qualities that makes it a promising material for a wide range of applications, particularly in electronic devices. Graphene comes in a myriad of forms, such as nanoflakes, nanoplatelets, nanosheets, quantum dots, graphene oxide, graphite oxide, reduced graphene oxide, etc.25, with different forms provide different functionalities22,26,27. The form of graphene for a particular application may not be useful for other applications. For example, graphene used for EMI shielding cannot be used as a biosensor or as a transistor. Similarly, graphene used for energy storage is different from the one used for mechanical deformation sensing. The form of graphene focused here is the reduced Graphene Oxide (rGO) which is mainly used for sensing based on mechanical deformations. The versatility of graphene-based devices goes beyond conventional transistor circuits and includes flexible and transparent electronics, optoelectronics, piezo-resistive sensors, electromechanical systems, and energy storage devices28. Reduced Graphene Oxide based sensing has gained traction in the field of polymer composites very recently29. Graphene flakes and rGO can be embedded within a structure, such as a composite structure by either mixing it in the resin system or by coating on the fiber reinforcements29. The working principle of rGO based piezo-resistive sensors involves nanomaterials forming an electrically conductive network, and electrical tunneling between particles that is altered by external stimuli, resulting in changes in electrical resistance of the percolated network of graphene.

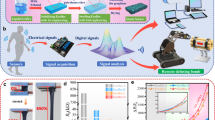

The potential role of rGO sensors as an interface between the physical and cyber worlds in a digital manufacturing of fiber reinforced polymer composites is illustrated graphically in Fig. 1. Additional sensors such as pressure transducers, digital imaging devices, etc. could also be used to augment the information obtained via rGO based sensors. On top of the sensing system, a signal processing unit with diagnostic capabilities, and a data management system are also required for smart operations30. The block-chain technology is a promising tool for data collection and management, whereas artificial intelligence tools can provide the required signal processing capabilities. Hence, rGO based sensors, AI-powered tools and block-chain technology can form a triad that could enable smart manufacturing. Moreover, the database can be diversified with the help of simulation tools and digital twins.

Flow chart illustrating the digitalization of composite structures using graphene nanoparticles as interface for creating a digital factory environment. Reduced Graphene Oxide based sensors along with traditional sensors can be incorporated in the manufacturing setup for digital manufacturing. Using the advanced tools such as block-chain technology, artificial intelligence, virtual simulations and digital twins, smart manufacturing can be achieved within Industry 4.0 framework.

In this article, we have reconnoitered the prospective utilization of graphene nanoparticles as digital materials within the context of Industry 4.0. First, we have explained how to use rGO as an embedded sensor, followed by the types of data generated by these sensors during the manufacturing process as well as during the service life of a structure. The use of block-chain technology and artificial intelligence tools for collecting and processing the data, and the role of digital twins in smart manufacturing is presented. The data generated using traditional and rGO based sensors can be collected and stored in an efficient and secure manner using block-chain technology. Machine and deep learning tools can be used for creating calibration, detection and predictive models using this database, which can analyze real-time signals captured using graphene-based sensors. In summary, we have presented a roadmap to converge three emerging technologies i.e. advanced 2D materials, artificial intelligence and block-chain in order to realize smart manufacturing in Industry 4.0.

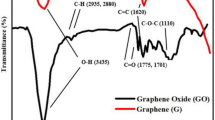

Creating reduced graphene oxide strain sensors

To make rGO based strain sensors for composites, graphene is used as a precursor, usually synthesized either by a top-down method or by a bottom-up approach31. The top-down approaches, such as mechanical exfoliation, oxidation–reduction of GO, liquid phase exfoliation and arc discharge, involve the structural breakdown of precursor such as graphite, followed by the interlayer separation to produce graphene sheets32. Chemical vapor deposition (CVD), epitaxial growth and total organic synthesis utilizing carbon source gas to synthesize graphene on a substrate, are examples of bottom-up technique31. Graphene nanoparticles and similar 2D materials can be embedded within a fiber reinforced composite structure either by dispersing them in the matrix or by coating them directly on the fiber reinforcements33,34.

Reduced graphene oxide mixed within the matrix

In this approach, the polymeric resin (matrix) is modified by dispersing graphene nanoparticles within the resin, resulting in a traditional nanocomposite35,36. Enormous amount of useful data is gathered such as, mixing ratios, mechanical stirring force, centrifugal mixing parameters, etc. The data gathered during mixing of graphene nanoparticles in the resin system is useful to predict physical state of reduced graphene oxide, such as exfoliation and quality of reduction achieved, which can directly influence properties such as electrical conductivity, EMI shielding and a number of different mechanical properties29. However, the modified resin may also cause issues such as altering resin viscosity, particle agglomeration, premature gelation, filtering effect within the fabric while infusing the resin, and uneven distribution of the filler throughout the composite laminate37,38. These issues have hindered the practical application of rGO loaded resins and their composites, especially during the manufacturing of large and thick parts e.g. wind turbine blades, where mold filling can become very challenging.

Reduced graphene oxide coating on reinforcements

Coating rGO directly onto the fibrous reinforcements instead of modifying the matrix is an alternative approach to overcome the issues highlighted above. In addition to imparting sensing abilities, the coating of reinforcements with rGO also provides the possibility of improving the mechanical and physical properties of the composite; hence, endowing multifunctional properties to the final structure39. Techniques for the depositing rGO onto fibrous reinforcements include, (i) chemical vapor deposition (CVD)40, (ii) electrophoretic deposition41, (iii) solution and spray coating42, and (iv) sizing containing rGO directly applied to the fibers during the fiber manufacturing process43. When deposited on the reinforcements, the composite part/structure becomes electrically conductive due to the formation of a network of meso-scale rGO nanoparticles30. When subjected to external stimuli, such as fluid pressure or mechanical forces, the conductive path is disrupted and the overall electrical resistance/conductivity of the part/structure is altered. This change in resistance/conductivity is measured and correlated with the external stimuli.

The overall resistance of the conductive network formed by rGO can be divided into three types: (i) intrinsic resistance of rGO, (ii) contact resistance, and (iii) tunneling/hopping resistance. This can be expressed using the following equation29

where Ri is intrinsic resistance, Rc is the contact resistance and Rt is tunneling resistance. The key requirement for these sensors is the ability to detect any small changes in the overall resistance (ΔR). The signal is normally manipulated as a relative or Fractional Change in Resistance (FCR) rather than absolute measurements. The measured value is taken relative to a reference value (R0) and normalized by the same (R0), given as;

where, R is the measured value and R0 is a reference value. The coated rGO can make the fabric material “digitally responsive” by generating signals which can be measured using any data acquisition (DAQ) system. The physical changes happening during manufacturing can easily be monitored, such as compaction response of the reinforcement, mold-clamping forces, resin pressure distribution, flow front tracking and resin cure kinetics, which were traditionally collected using external sensors and actuators that were not part of the material itself44. For process monitoring, the changes in electrical resistance can be expressed in terms of gain factor, which is a measure of the percentage change in the initial resistance of the structure. Apart from the signal, different parameters also need to be archived such as, sensor calibration, coating parameters, etc.45. There is huge amount of quantifiable parameters that can be recorded from the coating stage such as, concentration of the coating solution, sonication parameters (time, temperature and frequency), number of coating layers, rGO reduction time and temperature etc. These parameters affect the final resistance value, and hence the sensitivity of the rGO-based sensors29. The gathered data can be stored and analyzed for designing molds, selecting optimum injection gates and vents, measuring reinforcement permeability and predicting resin curing46,47,48.

Data generated by reduced graphene oxide strain sensors

While in operation, the rGO sensors generate signals that corresponds to various physical phenomenon/activities depending on the environment the smart material is exposed to. In a typical composites manufacturing process such as, Liquid Composite Molding (LCM) process, there are three main stages, i.e. compaction of the dry reinforcement, resin injection and resin curing, as shown in Fig. 2. All three stages are prone to process variabilities and need to be monitored using strain and pressure sensors. In the reported literature, rGO embedded fabric sensors have been employed for monitoring LCM processes44,45, which are some of the commonly used out-of-autoclave composite manufacturing processes. The rGO coated fabric based sensors are now being used in a variety of geometric forms (point sensors, line sensors, or area sensors) and configurations for monitoring applications45. It is also desirable that the concept of embedded sensors is applied to other composites manufacturing processes, such as filament winding and pultrusion for civil and construction industry. The embedded rGO-based sensors provide useful data at each stage throughout the manufacturing cycle, with vital information extracted related to the void content and structural health of the manufactured structure.

Data generated during the life cycle of a smart composite component, during and after manufacturing. Fabric compressibility is quantified by the applied stress required to achieve the target fiber volume fraction. The evolution of reinforcement permeability and flow characteristics are the important characteristics during the resin infusion followed by the cure kinetics of the resin. The distribution of stress within a structure is crucial for monitoring its health and for adopting prognostic measures. All aspects being monitored using in-situ coated fabrics.

Data generation during manufacturing

The first step in manufacturing of composites via Liquid Composite Molding (LCM) is the preforming step, in which the dry reinforcements are subjected to transverse compaction, so that they can conform to the mold shape and achieve the target part-thickness and fiber volume content. The compaction stage varies depending on the type of LCM technique used. The Resin Transfer Molding (RTM) is a closed-mold process where rigid mold platens apply high compaction forces on the reinforcements using a press, whereas, in Vacuum Assisted RTM (VARTM), the vacuum force is applied to compress the vacuum bag against the reinforcement laid on a single sided mold. During the compaction phase, uneven compression within a mold may result in thickness variations, particularly in the case of VARTM. In both cases, the applied compaction forces determine the fiber volume fraction of the composite, which in turn, determines the quality of the final part and mechanical properties of the composite. The rGO-based embedded sensors have been used to monitor compaction forces acting on the reinforcements in both VARTM and RTM processes. The rGO-based sensors are able to detect compaction forces of dry and resin impregnated reinforcements in the form of resistance change. During this stage, the mold clamping forces and stress relaxation data are required, which are usually proactively determined through characterization experiments49. These information are now being obtained in-situ via sensors based on 2D materials50. Recently Ali et al.50 have demonstrated that even a very complex time dependent phenomenon such as stress relaxation of the reinforcements in a closed mold can also be monitored using rGO and MXenes based embedded sensors.

During resin injection, the pressure distribution within the mold changes rapidly. This phenomenon is generally monitored using point sensors drilled within the mold51,52,53,54,55. rGO coated fabrics can act as an attractive alternative to these sensor arrays44. The resistance change data generated from the coated fabrics depends on resin conductivity and dielectric properties of the resin system used44. The conductivity/resistivity of graphene nanoparticles plays an important role when resin impregnates through the coated fibers. The gradual change in pressure inside the mold is also an indicator of resin impregnation captured via change in resistance of the embedded sensors. Moreover, race tracking and dry spot formation within the part can be detected by comparing signals from sensors placed at different spatial positions within the preform45. The interaction of resin with the sensors can provide information about the distribution of resin within the mold. It is also possible to make 2D plots of resin infusion process by spatial mapping during impregnation process56,57. This requires a virtual array of sensors, multiplexing system in combination with a Source Measure Unit (SMU) or similar resistance measuring unit.

The resistance of the embedded sensors is sensitive to gelation and crosslinking, as the resin observes shrinkage during these stages and apply compaction forces on graphene nanoparticles, thus resulting in a change in the overall electrical resistance56. Various stages of curing including, initial gelation, hardening (where resin shrinkage takes place) and post-cure are detected by monitoring relative changes in electrical resistance of the sensors such as described by Khan et al45.

Data generation during post-manufacturing

Composite structures are frequently subjected to a number of loading scenarios in multiple applications throughout their service life. Depending on the type of application, these loads can range from high-velocity to low-velocity impact producing large deflections58,59. Any structural health monitoring system consists of sensing elements, preferably embedded within the structure and connected to a signal processing unit with diagnostic algorithms, and a data management resource30. Carbon based nanomaterials coated sensors have shown great potential in recent years for sensing applications in composite structures. Compared to carbon nanotubes, rGO and graphene flake sensors standout in their sensing applications due to higher aspect ratio and cost-effectiveness60. rGO embedded composite structures can be used to sense strain and damage during their lifetime. The mechanism of piezo-resistive sensing in FRPCs depends on whether rGO is coated on fabrics or mixed within the resin. When rGO is present in the matrix, an irreversible increase of the electrical resistance61 can be detected due to the initiation of cracks in the matrix and delamination of fabric layers. Alternatively, in the cases where rGO is coated directly on reinforcements, the conductive networks are confined to fiber surface, hence, detecting matrix cracks becomes relatively difficult. Nonetheless, enormous amount of data that is generated can be used for preventive arrangements of composite structures before any catastrophic failure happens62.

A lot of work has been reported on Structural Health Monitoring (SHM) where, composites were tested in different modes including tensile, compression, bending, impact, creep and stress relaxation63. A comprehensive literature review on the subject shows that a number of studies have reported successful implication of rGO-coated fabric sensors for monitoring the flexural response of composite structures. It is quite interesting to note that apart from precise strain sensing capability under flexural loading, these smart sensors can also exhibit a distinct response for tensile and compressive loads, if placed above and below the neutral surfaces in flexural loading41,64. A number of researchers have pushed these rGO coated sensors one step further to investigate their feasibility for sensing the repetitive long-term loading in composite structures. Remarkable repeatability in the piezoresistive response has been reported in both flexural and tensile cyclic loading for as high as 3000 loading cycles65,66. It is also worth mentioning that graphene nanoparticles based fiber sensors have also been adopted in complex composite structures for successful in-situ SHM. In fact, these smart sensors were yet again capable of reporting distinctive response to compression and tension loading based on their placement above and below the neutral surface67. Interestingly, a couple of studies recently further extended the use of rGO-coated sensors in the form of smart composite face sheets in honeycomb sandwich structures for in-situ SHM. Smart aerospace sandwich structures were not only sensitive to span length and core thickness68, but also exhibited distinctive responses to multiple loading rates in beams of any arbitrary width of interest69. Considering that sandwich composites based on Nomex™ honeycomb cores are an integral part of the modern aerostructures, these recent findings show remarkable potential in terms of sensing capabilities of active rGO-coated piezoresistive sensors in the aerospace industry.

Significant progress has been made thus far in terms of sensing the conventional mechanical response in composite structures. However, it is critically important to note that the inherited viscoelastic nature of the polymer resin and fiber reinforcements makes their mechanical response time-dependent, hence, the piezoresistive response of these smart sensors also becomes a function of time70. Therefore, it is very crucial to investigate the long-term creep and viscoelastic stress relaxation response using rGO-based smart sensors. Despite the importance of such response in long-term application of composite structures, this area of research has not been exploited properly yet. Irfan et al.65 conducted first of this kind of study based on rGO-based smart sensors, to investigate the effect of temperature on the mechanical performance of composites using dynamic mechanical analysis. The results were also compared with the response of MXene-coated fabric sensors under similar dynamic mechanical analysis using temperature sweep experiments. The results were quite promising as the sensors were not only capable to detect the thermomechanical response, but also detected the glass transition phenomenon and transition from glassy to rubbery region. In fact, rGO-based sensors exhibited smoother response compared to MXene-based sensors.

Therefore, rGO-based sensors have shown great potential for self-sensing applications in multiple industrial applications of composite structures. Nonetheless, self-sensing smart composite structures can be regarded as an emerging field, despite a number of limitations and challenges for researchers working in this field. Before their implication on an industrial scale, a number of areas need rigorous research. Some of these areas may include: (i) the scalability of these sensors; (ii) calibration; (iii) effect of other external stimuli, such as environmental factors; (iv) comparison with well-established conventional sensors for these applications, such as Piezoelectric Sensors (PZT) and Fiber Bragg Grating (FBG) sensors and (v) making these sensors smart enough to convey signal directly on portable devices such as mobile phones.

The meta-verse of composites manufacturing

Given the fact that rGO-based sensors have great potential to be used in an industrial environment, their integration with cyber world is still a challenge and not much work has been done. In this section, we present a roadmap of Industry 4.0 technologies and how these technologies can use data generated through these sensors (as described in above mentioned sections) to create smart factories. A smart factory is self-adapting, and highly automated manufacturing environment capable of autonomously running entire production processes and making data-driven decisions71,72. Such a manufacturing setup has the ability to self-optimize performance and improve efficiency, flexibility, and quality control by self-adapting to new conditions through learning in real- or near-real time73. It integrates digital and physical systems through an interconnected network of machines, communication mechanisms, and computing power, and uses advanced technologies such as block-chain, artificial intelligence, machine learning etc., to gather and analyze data74,75. This integration is achieved through network of sensors and actuators enabling a physical system to access the capabilities of the virtual space or the “meta-verse”75,76.

Data gathered by rGO-based sensors, can be used for conducting virtual experiments and decision making in a smart factory. The rGO-coated sensors can feed digital information from the physical space to the digital space such as rGO mixing ratios, mold clamping forces, pressure distribution in the mold etc. This digital information comes in various formats (numeric data, images, time-dependent data, etc.). The role of digital space or the “meta-verse” is to collect this data securely, interpret the data and generate actionable commands. These actionable commands could be a decision tree that can enable/disable resin feeding lines based on the information gathered from the mold using rGO-based sensors.

Creating digital material twins using data from rGO sensors

The concept of “meta-verse” is very broad and its key components are virtual/augmented reality using digital twins, artificial intelligence, block-chain, IoT etc. Digital Twin (DT) is one of the core components of Industry 4.0, which is termed as virtual replica or digital prototype of the physical process, fully integrated with the physical system and capable of performing virtual simulations in real time77,78,79. The virtual simulation is a key aspect of DT that requires continuous iterations between physical and virtual entities80,81. These simulations include physics based computational approaches (FEM/CFD)82,83,84,85,86,87 as well as data driven stochastics simulations88,89,90. The advantages of digital simulations over experimental procedures is evident in material consumption, labor hours and overall cost reduction. Apart from these advantages, these simulations can be used to generate datasets to be used in training and creating machine learning models. Although, such simulations cannot be performed in real-time, machine learning models based on the synthetic data can be useful91. The capabilities of digital twin are sometimes enhanced with the Virtual and Augmented Reality technologies92 that enable human–machine interactions93,94. For example, Perez et al.95 presented and validated a VR-enhanced DT for designing the automated process of a multi-robot manufacturing setup as well as its enhanced implementation and in-operando monitoring.

Digital twins are implemented at different yet interlinked levels13. In the context of composite structures, these levels include the design, manufacturing/assembly and in-services/operation phases80. At the design level, it is also known as “digital material twin” (DMT) which refers to the realistic computational models of the composite material that can be used for design verification and predicting the mechanical properties of the final composite, as well as estimating the process parameters such as the compaction response and resin flow properties within the reinforcing fibers96,97,98. These parameters are well captured by rGO coated fabrics (as described in previous sections) and this information can be stored and used to create “near to reality” DMTs. Moreover, rGO coated fabric sensors can also be used for the experimental validation of DT simulations.

Digital material twins for virtual manufacturing can be generated from different 3D scanning techniques, such as X-ray computed tomography (XCT)99,100,101,102,103. During production, DT is implemented at the shop-floor level for effective process monitoring, control and optimization16,104,105. Seon et al. created a DT for optimizing the de-bulking process of autoclave composites for mitigating void formation106. Zambal et al.107 generated DT for the detection of defects during carbon fiber layup using data collected from various sensors along with analytical modeling and finite element simulations. Finally, in the operational phase, DT is used for prognostics and diagnostics activities108. Milanoski et al.109,110 developed an FEM based DT for the structural health monitoring of stiffened composite panels by estimating the load acting on the structure using strain data acquired from Fiber Bragg Grating (FBG) sensors. Sisson et al.111 pursued a digital twin approach to optimize rotorcraft flight parameters by minimizing stress on critical mechanical components and through probabilistic diagnosis, prognosis, and optimization. Using the data collected from strain sensors, it is not only possible to detect the presence of the damage but also the evolution of the damage, hence remaining useful life of the part can also be predicted109. The knowledge about the health of the structures and parts helps in taking pre-emptive measures such as part replacement, repairing the damage, arresting cracks, etc.

AI assisted digital manufacturing using data from rGO sensors

Artificial Intelligence (AI) generally refers machines that are designed to perform tasks that typically require human-like intelligence, such as perception, reasoning, and decision making112,113,114. Inherently, AI systems consist of data-driven mathematical models for inference and solving problems autonomously114. AI encompasses sub-fields of machine and deep learning, computer vision, natural language processing and cognitive computing, each of which focuses on different aspects of AI technology. Artificial intelligence and 2D materials are two of the disruptive technologies that are intertwined115,116,117. On one hand, the 2D materials could be an enabler for constructing devices for AI, such as memristors, photodetectors, etc.118,119,120,121,122. On the other hand, AI tools such as machine and deep learning can not only accelerate the discovery, design and optimization of 2D materials123,124,125,126, but also can interpret the signals generated by sensors based on 2D materials. Here, since we are discussing graphene as potential sensor, we will restrict our discussions to AI tools for signal processing.

The role of AI techniques in digital manufacturing using rGO sensors can be primarily viewed as a signal processing tool. Monitoring the manufacturing process usually involves detecting anomalies and measuring physical quantities such as pressure, temperature etc., which can be easily captured using rGO sensors. The real-time processing of signals with very low computational power makes these tools very attractive127,128. The signals measured by rGO-based sensors would normally be in the form of resistance/voltage/current measurements. These signals need to be converted to physical parameters such as pressure, stress, strain, temperature etc. through different calibration and correlation models61,129,130,131,132. Such calibration models can be easily developed using machine learning tools17,50,133. Zhu et al.17 employed a machine learning tool (principle component analysis) to predict the concentration of hydrogen gas from the measured response of rGO based gas sensor. Ali et al.50 calibrated MXene coated glass fabric sensors using supervised machine learning algorithms to correlate the compressive stress with the measured signal. Hajizadegan et al.133 extracted the concentration levels of the bio-chemical dopants from the harmonic spectrum of graphene-based harmonic sensors using artificial neural networks (ANN).

Other than the calibration models, AI tools can be easily employed for detection, inspection and monitoring tasks134. These tasks may include detection of resin race-tracking in molds135, flow disturbances136, and unfilled zones formation137 during the filling stage of an LCM process as well as inspection of broken-filaments during fiber production138. Novel AI-based methods for the inspection of the Automated Fiber Placement (AFP) process have also been presented by several researchers139,140,141,142,143. As part of health monitoring of structures, machine/deep learning models have been used for defect/damage detection144,145,146,147,148,149,150, characterization of cracks/delamination151,152,153 and classification of impact levels154. Yu et al.154 demonstrated that probabilistic Bayesian and traditional artificial neural networks can successfully classify the energy levels of different impact events based on the signals obtained from a network of piezoelectric sensors. Deep learning tools are particularly capable of such tasks when the signal is in the form of 2D/3D fields and maps56,57. In such cases, these models are not only able to detect these defects, but also locate them152.

Finally, the machine/deep learning-based surrogate/predictive models can be used for process simulations155,156,157 as well as for failure predictions in diagnostic and prognostic maintenance158,159,160. Using the data provided by a set of pressure sensors, Zhu et al.161 implemented a neural network model for the prediction of flow-front patterns at any impregnation time. Similar predictive models were also presented for forecasting resin cure162 and flow front progression163. Stieber et al. presented neural network based models FlowFrontNet164 and PermeabilityNets165 for the prediction of dry spot formation and permeability maps from a sequence of flow front images respectively. Pratim et al.166 presented an ANN framework to predict the life (durability) and residual strength (damage tolerance) of fiber-reinforced polymer (FRP) composites from real-time acquired dielectric permittivity of the material. Hassan et al.167 used genetic algorithms for failure prediction in self-sensing nanocomposites based on conductivity changes observed via electrical impedance tomography.

In summary, these tools can be integrated within the digital manufacturing setup as calibration, detection and predictive models as summarized in Fig. 3. Moreover, these models can be periodically re-trained as availability of new data without losing the old weights, hence, truly updating the whole manufacturing process. Some of the models discussed here used data generated from traditional sensors or synthetic data rather than data collected by piezoresistive rGO sensors. However, the methods discussed here can easily be adapted for analyzing data obtained via rGO sensors.

Block-chain technology based on rGO sensor data

As AI tools can analyze the data collected through rGO-based sensors efficiently, the block-chain technology can collect and manage data in a secure, trustworthy and traceable manner168,169. By definition, a block-chain is an evolutionary list of immutable records, called blocks, which are linked together using cryptography and stored on a decentralized network of computers or nodes in chronological order170. Block-chain technology employs a self-executing piece-of-code, known as smart contracts, to automate the process in a much reliable and trustful way171. Currently, this technology is being exploited extensively by the financial and banking sectors, healthcare and supply chain sectors172. For example, the block-chain technology can be employed in the supply chain of fiber reinforced composite materials, in particular, in handling temperature-controlled transportation, handling and storage of prepregs on a tamper proof distributed ledger173.

While using rGO as a sensing element for the manufacturing of fiber reinforced polymer composites, the data is generated at various stages, which includes physical properties as well as process parameters. These stages form the multi-echelon supply chain that comprises raw materials, manufacturing process and the finished components/structures173,174. The nature and format of data varies depending on the processing step, and includes numeric values, time/temperature dependent curves, or even two/three dimensional fields, as well as subjective descriptions. All the data generated at each step can be collected and stored in an efficient and secured manner using block-chain. A conceptual illustration of the use of block-chain in collecting and storing the generated data is illustrated in Fig. 4. Apart from the data directly collected from rGO sensors, the data related to physical characteristics of the reinforcement and matrix, as well as data generated from physical and virtual experiments is also crucial for efficient processing. The physical characteristics of the reinforcement and matrix are usually provided by the supplier (first block in Fig. 4). These properties are then validated as well as new characteristics are determined via characterization experiments and virtual simulations using digital twins (second block in Fig. 4). The shape of the part to be produced, which will be in the form of a 3D geometry, is another important piece of data. Mold designs and other process parameters depends on the type of manufacturing method used. In case of LCM, the process parameters include the number and location of inlet/outlet ports, injection pressure, etc. For processing prepregs, the cure cycle and temperature are the main parameters. The rGO coated materials can play a vital role in in-situ data acquisition during the process. The inspection of finished parts will produce more data related to the quality of the part, such as porosity maps and void content and tolerance levels175. Finally, while in service, the smart structure based on rGO sensors will generate signals related to its structural health, which can be managed in the maintenance log-book on the block-chain ledger176. Apart from direct involvement, block-chain can also help in creating DT’s169,177 and work in conjunction with artificial intelligence to have an overall impact178. Nevertheless, block-chain technology is a secure, large-scale and reliable data collection and management tool for implementing smart operations using networks of sensory elements179, including rGO based sensors.

Concluding remarks and outlook

There are numerous challenges and opportunities for the technological applications and market penetration of graphene nanoparticles as a digital materials in various real-world applications. It is vital to consider these challenges prior to the largescale commercialization of graphene as a sensing element in fiber reinforced polymer composites, and to make them compatible with the standards of Industry 4.0. The material selection process is of paramount importance as there are several 2D materials now available, and the chosen 2D material will affect not only the processing steps but also the final sensing properties of the product. The economy of scale is also a factor when choosing a 2D material. Atomistic modeling can be a tool to narrow down the material selection for a particular application. This becomes very important when multifunctional composites are involved. The engineered 2D materials such as MXenes can be designed to obtain optimized properties. Atomistic modeling can also help in making hybrids of two or more materials. Synthesis of good quality materials is also a challenge, especially if the processes are not well defined in literature and practice. It must be decided if in-house synthesis is required or off-the-shelf options may work for an application.

Adding graphene and other 2D materials into the process chain is the next challenge. There are numerous ways in which graphene can be incorporated into composites, for example, mixing in the resin system, coating on the reinforcements, weaving a coated tow into the reinforcement fabric, or coating the final composite with the graphene solution. There is no single solution, the user needs to decide which method is optimum for the target application.

Sensor manufacturing is another closely related challenge. It is also important to decide about the size, number and spatial location of sensors in a structure. Embedding a sensor in a complex 3D shape while maintaining its sensing properties can be a difficult task. It is also important to keep in mind the manufacturing process, where it would require different approaches to embed a sensor. Whichever technique is used to embed graphene nanoparticles into the composite, it is important to quantify the sensing capability of the composite to sense any physical changes.

Sensor calibration is a major challenge in this field, especially when inter-lab sensors are involved. There is no standardization of these sensors yet, however for a commercial application, a standardization protocol is desirable. The property retention of sensors over time is also a critical factor. Environmental factors such as temperature and humidity might affect the sensing capability over time. This is also important in commercial sensors such as FBG sensors, and a routine inspection is performed to ensure the working of these sensors in real-world applications such as bridges. In the same way, graphene nanoparticles based sensors should have a provision for inspection over time. Meanwhile, in lab environments, accelerated tests can be performed to quantify the property retention.

A large-scale production system is essential for the commercialization of graphene nanoparticles as a viable digital material. As mentioned earlier, various commercial vendors are available for provision of graphene materials however, the application of graphene in different fields poses unique challenges. Graphene and other 2D materials are viable nanomaterials to be used as smart sensors in fiber reinforced composites. They can provide process and structural health monitoring at every stage of composites manufacturing and application. In addition, these materials can also enhance other base properties of the neat composite, including mechanical properties and EMI shielding.

The entities in meta-verse are far more mature than 2D materials. The digital space has seen tremendous advancements in computational capabilities that include cloud computing, big data analytics, IoT and artificial intelligence (AI). However, their integration with sensors based on 2D materials have not been achieved yet. Even, compatibility of various digital tools is also not clear. One of the key characteristic of the block-chain technology is publically available information. However, most of the information in a manufacturing environment are of propriety nature. In this regard, consortium or federated block-chains can be used where the information is restricted to a target audience only. The AI tools are data driven, and require carefully curated data sets for training. Such type of data is scarce at the moment but is expected to grow with time. Lastly, the concept of digital twin based on graphene nanoparticles sensors is also in its conceptual phase. The growth of all these technologies together can bring in the true essence of Industry 4.0. There is no doubt that there are rich opportunities for the application of graphene and other 2D materials in this area. It is a high time that academics and composites industries including aerospace and automotive sectors should work together to solve challenges in the field and aim for the wide-scale adaptation of graphene as a digital material to reap the benefits of this wondrous material.

Data availability

All data generated or analyzed during this study are included in this published article.

References

More, C. Understanding the Industrial Revolution (Routledge, 2000).

Klingenberg, C. O., Borges, M. A. V. & Antunes, J. A. D. V. Industry 4.0: What makes it a revolution? A historical framework to understand the phenomenon. Technol. Soc. 70, 102009 (2022).

Deane, P. M. The First Industrial Revolution (Cambridge University Press, 1979).

Wrigley, E. A. Reconsidering the industrial revolution: England and Wales. J. Interdiscipl. History 49(1), 9–42 (2018).

Jull, J. The second industrial revolution: The history of a concept. Rivista Internazionale Di Storia Della Storiografia 36, 81–90 (1999).

Vinitha, K., Ambrose Prabhu, R., Bhaskar, R. & Hariharan, R. Review on industrial mathematics and materials at Industry 1.0 to Industry 4.0. Mater. Today Proc. 33, 3956–3960 (2020).

Baena, F., Guarin, A., Mora, J., Sauza, J. & Retat, S. Learning Factory: The path to industry 4.0. Procedia Manuf. 9, 73–80 (2017).

Schwab, K. The Fourth Industrial Revolution (Crown Business, 2017).

Parmar, H., Khan, T., Tucci, F., Umer, R. & Carlone, P. Advanced robotics and additive manufacturing of composites: Towards a new era in industry 4.0. Mater. Manuf. Process. 37(5), 483–517 (2022).

Xu, X., Lu, Y., Vogel-Heuser, B. & Wang, L. Industry 4.0 and Industry 5.0 - Inception, conception and perception. J. Manuf. Syst. 61, 530–535 (2021).

Maddikunta, P. K. R. et al. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 26, 100257 (2022).

Nahavandi, S. Industry 5.0 - A human-centric solution. Sustainability 11(16), 4371 (2019).

Tao, F., Qi, Q., Wang, L. & Nee, A. Y. C. Digital twins and cyber-physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 5(4), 653–661 (2019).

Negri, E., Fumagalli, L. & Macchi, M. A review of the roles of digital twin in CPS-based production systems. Procedia Manuf. 11, 939–948 (2017).

Leng, J. et al. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 60, 119–137 (2021).

Tao, F. & Zhang, M. Digital twin shop-floor: a new shop-floor paradigm towards smart manufacturing. IEEE Access 5, 20418–20427 (2017).

Zhu, J. et al. Machine learning-enabled textile-based graphene gas sensing with energy harvesting-assisted IoT application. Nano Energy 86, 106035 (2021).

Levchenko, I., Bazaka, K., Belmonte, T., Keidar, M. & Xu, S. Advanced materials for next-generation spacecraft. Adv. Mater. 30(50), 1802201 (2018).

Döscher, H., Schmaltz, T., Neef, C., Thielmann, A. & Reiss, T. Graphene Roadmap Briefs (No. 2): Industrialization status and prospects 2020. 2D Mater. 8(2), 022005 (2021).

Choi, S. H. et al. Large-scale synthesis of graphene and other 2D materials towards industrialization. Nat. Commun. 13(1), 1484 (2022).

Mensah, B. et al. Graphene-reinforced elastomeric nanocomposites: A review. Polym. Testing 68, 160–184 (2018).

Ren, S., Rong, P. & Yu, Q. Preparations, properties and applications of graphene in functional devices: A concise review. Ceram. Int. 44(11), 11940–11955 (2018).

Hiew, B. Y. Z. et al. Review on synthesis of 3D graphene-based configurations and their adsorption performance for hazardous water pollutants. Process Saf. Environ. Prot. 116, 262–286 (2018).

Dasari, B. L., Nouri, J. M., Brabazon, D. & Naher, S. Graphene and derivatives - Synthesis techniques, properties and their energy applications. Energy 140, 766–778 (2017).

Bianco, A. et al. All in the graphene family - A recommended nomenclature for two-dimensional carbon materials. Carbon 65, 1–6 (2013).

Zhang, F. et al. Recent advances on graphene: Synthesis, properties and applications. Compos. A Appl. Sci. Manuf. 160, 107051 (2022).

Yu, X. et al. Graphene-based smart materials. Nat. Rev. Mater. 2(9), 17046 (2017).

Weiss, N. O. et al. Graphene: An emerging electronic material. Adv. Mater. 24(43), 5782–5825 (2012).

Irfan, M. S., Khan, T., Hussain, T., Liao, K. & Umer, R. Carbon coated piezoresistive fiber sensors: From process monitoring to structural health monitoring of composites—A review. Compos. A Appl. Sci. Manuf. 141, 106236 (2021).

Islam, M. H., Afroj, S., Uddin, M. A., Andreeva, D. V., Novoselov, K. S., Karim, N. Graphene and CNT-based smart fiber-reinforced composites: A review. Adv. Funct. Mater. (2022) 2205723.

Yan, Y. et al. Synthesis of graphene: Potential carbon precursors and approaches. Nanotechnol. Rev. 9(1), 1284–1314 (2020).

Kumar, N. et al. Top-down synthesis of graphene: A comprehensive review. FlatChem 27, 100224 (2021).

Yu, R., Zhu, C., Wan, J., Li, Y. & Hong, X. Review of graphene-based textile strain sensors, with emphasis on structure activity relationship. Polymers 13(1), 151 (2021).

Shi, J. et al. Smart textile-integrated microelectronic systems for wearable applications. Adv. Mater. 32(5), 1901958 (2020).

Zhang, H., Kuwata, M., Bilotti, E. & Peijs, T. Integrated damage sensing in fibre-reinforced composites with extremely low carbon nanotube loadings. J. Nanomater. 16(1), 243 (2015).

Lazaridou, I., Kourkoulis, S. K. & Alexopoulos, N. D. Damage monitoring of different concentration carbon nanotube/epoxy glass fiber reinforced composites under quasi-static incremental loadings. Mater. Today Proc. 12, 262–270 (2019).

Böger, L., Wichmann, M. H. G., Meyer, L. O. & Schulte, K. Load and health monitoring in glass fibre reinforced composites with an electrically conductive nanocomposite epoxy matrix. Compos. Sci. Technol. 68(7), 1886–1894 (2008).

Ma, P.-C., Mo, S.-Y., Tang, B.-Z. & Kim, J.-K. Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites. Carbon 48(6), 1824–1834 (2010).

Qian, H., Greenhalgh, E. S., Shaffer, M. S. P. & Bismarck, A. Carbon nanotube-based hierarchical composites: A review. J. Mater. Chem. 20(23), 4751–4762 (2010).

He, D. et al. Design of electrically conductive structural composites by modulating aligned CVD-grown carbon nanotube length on glass fibers. ACS Appl. Mater. Interfaces. 9(3), 2948–2958 (2017).

Mahmood, H., Vanzetti, L., Bersani, M. & Pegoretti, A. Mechanical properties and strain monitoring of glass-epoxy composites with graphene-coated fibers. Compos. A Appl. Sci. Manuf. 107, 112–123 (2018).

Tzounis, L., Kirsten, M., Simon, F., Mäder, E. & Stamm, M. The interphase microstructure and electrical properties of glass fibers covalently and non-covalently bonded with multiwall carbon nanotubes. Carbon 73, 310–324 (2014).

Wiegand, N., Haupt, M., Mäder, E. & Cherif, C. A comparative study on the textile processing of carbon and multifunctional glass fiber sensor yarns for structural health monitoring. Adv. Eng. Mater. 18(3), 385–390 (2016).

Ali, M. A. et al. Graphene coated piezo-resistive fabrics for liquid composite molding process monitoring. Compos. Sci. Technol. 148, 106–114 (2017).

Khan, T. et al. Resin infusion process monitoring using graphene coated glass fabric sensors and infusible thermoplastic and thermoset matrices. Polym. Compos. 43(5), 2924–2940 (2022).

Hsiao, K.-T. & Advani, S. G. Flow sensing and control strategies to address race-tracking disturbances in resin transfer molding. Part I: design and algorithm development. Compos. A Appl. Sci. Manuf. 35(10), 1149–1159 (2004).

Sozer, E. M., Bickerton, S. & Advani, S. G. On-line strategic control of liquid composite mould filling process. Compos. A Appl. Sci. Manuf. 31(12), 1383–1394 (2000).

Bickerton, S., Stadtfeld, H. C., Steiner, K. V. & Advani, S. G. Design and application of actively controlled injection schemes for resin-transfer molding. Compos. Sci. Technol. 61(11), 1625–1637 (2001).

Yong,A. X. H., Aktas, A., May, D., Endruweit, A., Lomov, S. V. et al., Experimental characterisation of textile compaction response: A benchmark exercise. Compos. A Appl. Sci. Manuf. 142 (2021).

Ali, M. A. et al. In-situ monitoring of reinforcement compaction response via MXene-coated glass fabric sensors. Compos. Sci. Technol. 227, 109623 (2022).

Dominauskas, A., Heider, D. & Gillespie, J. W. Electric time-domain reflectometry sensor for online flow sensing in liquid composite molding processing. Compos. A Appl. Sci. Manuf. 34(1), 67–74 (2003).

Pandey, G., Deffor, H., Thostenson, E. T. & Heider, D. Smart tooling with integrated time domain reflectometry sensing line for non-invasive flow and cure monitoring during composites manufacturing. Compos. A Appl. Sci. Manuf. 47, 102–108 (2013).

Yu, Y., Cui, X., Liang, Z., Qing, X. & Yan, W. Monitoring of three-dimensional resin flow front using hybrid piezoelectric-fiber sensor network in a liquid composite molding process. Compos. Sci. Technol. 229, 109712 (2022).

Matsuzaki, R., Kobayashi, S., Todoroki, A. & Mizutani, Y. Control of resin flow/temperature using multifunctional interdigital electrode array film during a VaRTM process. Compos. A Appl. Sci. Manuf. 42(7), 782–793 (2011).

Danisman, M., Tuncol, G., Kaynar, A. & Sozer, E. M. Monitoring of resin flow in the resin transfer molding (RTM) process using point-voltage sensors. Compos. Sci. Technol. 67(3), 367–379 (2007).

Dai, H. & Thostenson, E. T. Scalable and multifunctional carbon nanotube-based textile as distributed sensors for flow and cure monitoring. Carbon 164, 28–41 (2020).

Rocha, H., Fernandes, C., Ferreira, N., Lafont, U. & Nunes, J. P. Damage localization on CFRP composites by electrical impedance tomography. Mater. Today Commun. 32, 104164 (2022).

Dai, H., Thostenson, E. T. & Schumacher, T. Processing and characterization of a novel distributed strain sensor using carbon nanotube-based nonwoven composites. Sensors 15(7), 17728–17747 (2015).

Dai, H., Gallo, G. J., Schumacher, T. & Thostenson, E. T. A novel methodology for spatial damage detection and imaging using a distributed carbon nanotube-based composite sensor combined with electrical impedance tomography. J. Nondestr. Eval. 35(2), 26 (2016).

Luo, S. et al. Hybrid spray-coating, laser-scribing and ink-dispensing of graphene sensors/arrays with tunable piezoresistivity for in situ monitoring of composites. Carbon 139, 437–444 (2018).

Panozzo, F., Zappalorto, M., Carraro, P. A. & Quaresimin, M. Electrical resistance change vs damage state in cracked symmetric laminates: A closed form solution. Compos. Struct. 184, 1081–1091 (2018).

Gordan, M. et al. State-of-the-art review on advancements of data mining in structural health monitoring. Measurement 193, 110939 (2022).

Hassani, S., Mousavi, M. & Gandomi, A. H. Structural health monitoring in composite structures: A comprehensive review. Sensors 22(1), 153 (2022).

Luo, S., Obitayo, W. & Liu, T. SWCNT-thin-film-enabled fiber sensors for lifelong structural health monitoring of polymeric composites - From manufacturing to utilization to failure. Carbon 76, 321–329 (2014).

Irfan, M. S. et al. MXene and graphene coated multifunctional fiber reinforced aerospace composites with sensing and EMI shielding abilities. Compos. A Appl. Sci. Manuf. 165, 107351 (2023).

Wang, G. et al. Structure dependent properties of carbon nanomaterials enabled fiber sensors for in situ monitoring of composites. Compos. Struct. 195, 36–44 (2018).

Luo, S. & Liu, T. Graphite nanoplatelet enabled embeddable fiber sensor for in situ curing monitoring and structural health monitoring of polymeric composites. ACS Appl. Mater. Interfaces. 6(12), 9314–9320 (2014).

Ud Din, I. et al. Electromechanical behavior of self-sensing composite sandwich structures for next generation more electric aerostructures. Compos. Struct. 300, 116169 (2022).

Ud Din, I. et al. Rate dependent piezoresistive characterization of smart aerospace sandwich structures embedded with reduced graphene oxide (rGO) coated fabric sensors. Compos. Commun. 36, 101382 (2022).

Can-Ortiz, A., Abot, J. L. & Avilés, F. Electrical characterization of carbon-based fibers and their application for sensing relaxation-induced piezoresistivity in polymer composites. Carbon 145, 119–130 (2019).

Chen, B. et al. Smart factory of industry 4.0: Key technologies, application case, and challenges. IEEE Access 6, 6505–6519 (2018).

Li, C., Chen, Y. & Shang, Y. A review of industrial big data for decision making in intelligent manufacturing. Eng. Sci. Technol. Int. J. 29, 101021 (2022).

Qu, Y. J., Ming, X. G., Liu, Z. W., Zhang, X. Y. & Hou, Z. T. Smart manufacturing systems: state of the art and future trends. Int. J. Adv. Manuf. Technol. 103(9), 3751–3768 (2019).

Cheng, G. J., Liu, L. T., Qiang, X. J., Liu, Y. Industry 4.0 development and application of intelligent manufacturing. In 2016 International Conference on Information System and Artificial Intelligence (ISAI) (2016), 407–410.

Abikoye, O. C. et al. Application of Internet of Thing and Cyber Physical System in Industry 4.0 Smart Manufacturing. In Emergence of Cyber Physical System and IoT in Smart Automation and Robotics (eds Singh, K. K. et al.) 203–217 (Springer International Publishing, 2021).

Xu, L. D., He, W. & Li, S. Internet of things in industries: A survey. IEEE Trans. Industr. Inf. 10(4), 2233–2243 (2014).

Tao, F., Zhang, M. & Nee, A. Y. C. Digital Twin Driven Smart Manufacturing (Academic Press, 2019).

Glaessgen, E., & Stargel, D. The digital twin paradigm for future NASA and U.S. Air Force Vehicles. In 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, Hawaii (2012).

Tuegel, E. The airframe digital twin: Some challenges to realization In 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference (2012).

Xiong, M. & Wang, H. Digital twin applications in aviation industry: A review. Int. J. Adv. Manuf. Technol. 121(9), 5677–5692 (2022).

Phanden, R. K., Sharma, P. & Dubey, A. A review on simulation in digital twin for aerospace, manufacturing and robotics. Mater. Today Proc. 38, 174–178 (2021).

Henning, F. et al. Fast processing and continuous simulation of automotive structural composite components. Compos. Sci. Technol. 171, 261–279 (2019).

Shafto, M. et al. Modeling, simulation, information technology & processing roadmap. Nat. Aeronaut. Space Admin. 32(2012), 1–38 (2012).

Levy, A. & Kratz, J. Direct numerical simulation of infusion and flow-front tracking in materials with heterogeneous permeability using a pressure mapping sensor. J. Compos. Mater. 54(13), 1647–1661 (2019).

Chai, B. X. et al. Simulation-based optimisation for injection configuration design of liquid composite moulding processes: A review. Compos. A Appl. Sci. Manuf. 149, 106540 (2021).

Wijaya, W., Bickerton, S., Kelly, P. A. Meso-scale compaction simulation of multi-layer 2D textile reinforcements: A Kirchhoff-based large-strain non-linear elastic constitutive tow model, Compos. A Appl. Sci. Manuf. 137 (2020).

Boschert, S. & Rosen, R. Digital Twin-The Simulation Aspect. In Mechatronic Futures (eds Hehenberger, P. & Bradley, D.) (Springer, Berlin, 2016).

Yerbolat, G. et al. Composite materials property determination by rule of mixture and monte carlo simulation. IEEE International Conference on Advanced Manufacturing (ICAM) 2018, 384–387 (2018).

Dodwell, T. J. et al. Multilevel Monte Carlo simulations of composite structures with uncertain manufacturing defects. Probab. Eng. Mech. 63, 103116 (2021).

Zhou, K., Enos, R., Xu, D., Zhang, D. & Tang, J. Hierarchical multi-response Gaussian processes for uncertainty analysis with multi-scale composite manufacturing simulation. Comput. Mater. Sci. 207, 111257 (2022).

Li, L., Aslam, S., Wileman, A. & Perinpanayagam, S. Digital twin in aerospace industry: A gentle introduction. IEEE Access 10, 9543–9562 (2022).

Yin, Y., Zheng, P., Li, C. & Wang, L. A state-of-the-art survey on Augmented Reality-assisted Digital Twin for futuristic human-centric industry transformation. Robot. Comput.-Integr. Manuf. 81, 102515 (2023).

Li, S. et al. Proactive human–robot collaboration: Mutual-cognitive, predictable, and self-organising perspectives. Robot. Comput.-Integr. Manuf. 81, 102510 (2023).

Malik, A. A., Masood, T. & Bilberg, A. Virtual reality in manufacturing: Immersive and collaborative artificial-reality in design of human-robot workspace. Int. J. Comput. Integr. Manuf. 33(1), 22–37 (2020).

Pérez, L., Rodríguez-Jiménez, S., Rodríguez, N., Usamentiaga, R. & García, D. F. Digital twin and virtual reality based methodology for multi-robot manufacturing cell commissioning. Appl. Sci. 10(10), 3633 (2020).

Ali, M. A., Umer, R. & Khan, K. A. A virtual permeability measurement framework for fiber reinforcements using micro CT generated digital twins. Int. J. Lightweight Mater. Manuf. 3(3), 204–216 (2020).

Huang, W., Causse, P., Hu, H. & Trochu, F. Numerical and experimental investigation of saturated transverse permeability of 2D woven glass fabrics based on material twins. Polym. Compos. 41(4), 1341–1355 (2020).

Huang, W., Xu, R., Yang, J., Huang, Q. & Hu, H. Data-driven multiscale simulation of FRP based on material twins. Compos. Struct. 256, 113013 (2021).

Ali, M. A., Umer, R. & Khan, K. A. CT Scan Generated Material Twins for Composites Manufacturing in Industry 4.0 (Springer, 2020).

Ali, M. A., Guan, Q., Umer, R., Cantwell, W. J. & Zhang, T. Efficient processing of μCT images using deep learning tools for generating digital material twins of woven fabrics. Compos. Sci. Technol. 217, 109091 (2022).

Ali, M. A., Guan, Q., Umer, R., Cantwell, W. J. & Zhang, T. Deep learning based semantic segmentation of µCT images for creating digital material twins of fibrous reinforcements. Compos. A Appl. Sci. Manuf. 139, 106131 (2020).

Huang, W., Causse, P., Brailovski, V., Hu, H. & Trochu, F. Reconstruction of mesostructural material twin models of engineering textiles based on Micro-CT Aided Geometric Modeling. Compos. A Appl. Sci. Manuf. 124, 105481 (2019).

Song, Y., Qu, Z., Liao, H. & Ai, S. Material twins generation of woven polymer composites based on ResL-U-Net convolutional neural networks. Compos. Struct. 307, 116672 (2023).

Yao, B., Xu, W., Shen, T., Ye, X. & Tian, S. Digital twin-based multi-level task rescheduling for robotic assembly line. Sci. Rep. 13(1), 1769 (2023).

Lu, Y., Liu, C., Wang, K. I. K., Huang, H., Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 61 (2020).

Seon, G., Nikishkov, Y., Makeev, A., & Ferguson, L. Towards a digital twin for mitigating void formation during debulking of autoclave composite parts. Eng. Fract. Mech. 225 (2020).

Zambal, S., Eitzinger, C., Clarke, M., Klintworth, J., & Mechin, P. A digital twin for composite parts manufacturing: Effects of defects analysis based on manufacturing data. In 2018 IEEE 16th International Conference on Industrial Informatics (INDIN) (2018), 803–808.

Lee, J., Lapira, E., Bagheri, B. & Kao, H.-A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 1(1), 38–41 (2013).

Milanoski, D., Galanopoulos, G., Zarouchas, D., Loutas, T. Multi-level damage diagnosis on stiffened composite panels based on a damage-uninformative digital twin. Struct. Health Monit. (2022) 14759217221108676.

Milanoski, D. P., Galanopoulos, G. K., & Loutas, T. H. Digital-Twins of composite aerostructures towards Structural Health Monitoring. In 2021 IEEE 8th International Workshop on Metrology for AeroSpace (MetroAeroSpace) (2021) 613–618.

Sisson, W., Karve, P. & Mahadevan, S. Digital twin approach for component health-informed rotorcraft flight parameter optimization. AIAA J. 60(3), 1923–1936 (2022).

Russell, S. J. Artificial Intelligence: A Modern Approach (Pearson Education, Inc, 2010).

Winston, P. H. Artificial Intelligence (Addison-Wesley, 1992).

Girasa, R. AI as a Disruptive Technology, Artificial Intelligence as a Disruptive Technology: Economic Transformation and Government Regulation 3–21 (Springer, 2020).

Chaudhary, V., Kaushik, A. K., Furukawa, H., Khosla, A. Towards 5th generation ai and iot driven sustainable intelligent sensors based on 2d mxenes and borophene. ECS Sensors Plus (2022).

Kaspar, C., Ravoo, B. J., van der Wiel, W. G., Wegner, S. V. & Pernice, W. H. P. The rise of intelligent matter. Nature 594(7863), 345–355 (2021).

Mennel, L. et al. Ultrafast machine vision with 2D material neural network image sensors. Nature 579(7797), 62–66 (2020).

Gao, W., Yu, C. & Chen, R. Artificial intelligence accelerators based on graphene optoelectronic devices. Adv. Photon. Res. 2(6), 2100048 (2021).

Lemme, M. C., Akinwande, D., Huyghebaert, C. & Stampfer, C. 2D materials for future heterogeneous electronics. Nat. Commun. 13(1), 1392 (2022).

Konstantatos, G. Current status and technological prospect of photodetectors based on two-dimensional materials. Nat. Commun. 9(1), 5266 (2018).

Kim, I. et al. Simulator acceleration and inverse design of fin field-effect transistors using machine learning. Sci. Rep. 12(1), 1140 (2022).

Wachter, S., Polyushkin, D. K., Bethge, O. & Mueller, T. A microprocessor based on a two-dimensional semiconductor. Nat. Commun. 8(1), 14948 (2017).

Tritsaris, G. A., Carr, S. & Schleder, G. R. Computational design of moiré assemblies aided by artificial intelligence. Appl. Phys. Rev. 8(3), 031401 (2021).

Sorkun, M. C., Astruc, S., Koelman, J. M. V. A. & Er, S. An artificial intelligence-aided virtual screening recipe for two-dimensional materials discovery. NPJ Comput. Mater. 6(1), 106 (2020).

Huang, M., Li, Z., Zhu, H. Recent advances of graphene and related materials in artificial intelligence. Adv. Intell. Syst. n/a(n/a) (2022).

Qiu, C., Han, Y., Shanmugam, L., Zhao, Y., Dong, S., Du, S., Yang, J. A deep learning-based composite design strategy for efficient selection of material and layup sequences from a given database. Compos. Sci. Technol. (2021) 109154.

Kikuchi, M., Ogasawara, T., Fujii, S. & Takeda, S.-I. Application of machine learning for improved accuracy of simultaneous temperature and strain measurements of carbon fiber-reinforced plastic laminates using an embedded tilted fiber Bragg grating sensor. Compos. A Appl. Sci. Manuf. 161, 107108 (2022).

Salehi, H. & Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 171, 170–189 (2018).

Balaji, R. & Sasikumar, M. Graphene based strain and damage prediction system for polymer composites. Compos. A Appl. Sci. Manuf. 103, 48–59 (2017).

Reghat, M. et al. Graphene as a piezo-resistive coating to enable strain monitoring in glass fiber composites. Compos. Sci. Technol. 211, 108842 (2021).

Alexopoulos, N. D., Bartholome, C., Poulin, P. & Marioli-Riga, Z. Structural health monitoring of glass fiber reinforced composites using embedded carbon nanotube (CNT) fibers. Compos. Sci. Technol. 70(2), 260–271 (2010).

Kalantari, M., Dargahi, J., Kövecses, J., Mardasi, M. G. & Nouri, S. A new approach for modeling piezoresistive force sensors based on semiconductive polymer composites. IEEE/ASME Trans. Mechatron. 17(3), 572–581 (2012).

Hajizadegan, M., Sakhdari, M., Abbasi, S. & Chen, P. Y. Machine learning assisted multi-functional graphene-based harmonic sensors. IEEE Sens. J. 21(6), 8333–8340 (2021).

Shahbazi, Z. & Byun, Y.-C. Smart manufacturing real-time analysis based on Blockchain and machine learning approaches. Appl. Sci. 11(8), 3535 (2021).

Fernández-León, J. et al. A machine learning strategy for race-tracking detection during manufacturing of composites by liquid moulding. Integr. Mater. Manuf. Innov. 11(2), 296–311 (2022).

González, C. & Fernández-León, J. A machine learning model to detect flow disturbances during manufacturing of composites by liquid moulding. J. Compos. Sci. 4(2), 71 (2020).

Mendikute, J. et al. Impregnation quality diagnosis in resin transfer moulding by machine learning. Compos. B Eng. 221, 108973 (2021).

Li, D., Hua, S., Li, Z., Gong, X. & Wang, J. Automatic vision-based online inspection system for broken-filament of carbon fiber with multiscale feature learning. IEEE Trans. Instrum. Meas. 71, 1–12 (2022).

Sacco, C., Baz Radwan, A., Anderson, A., Harik, R., Gregory, E. Machine learning in composites manufacturing: A case study of automated fiber placement inspection. Compos. Struct. 250 (2020).

Tang, Y., Wang, Q., Cheng, L., Li, J. & Ke, Y. An in-process inspection method integrating deep learning and classical algorithm for automated fiber placement. Compos. Struct. 300, 116051 (2022).

Meister, S., Wermes, M. Performance evaluation of CNN and R-CNN based line by line analysis algorithms for fibre placement defect classification. Prod. Eng. (2022).

Meister, S., Wermes, M., Stüve, J. & Groves, R. M. Investigations on Explainable Artificial Intelligence methods for the deep learning classification of fibre layup defect in the automated composite manufacturing. Compos. B Eng. 224, 109160 (2021).

Meister, S., Wermes, M., Stüve, J. & Groves, R. M. Cross-evaluation of a parallel operating SVM—CNN classifier for reliable internal decision-making processes in composite inspection. J. Manuf. Syst. 60, 620–639 (2021).

Li, X. et al. Deep learning-based defects detection of certain aero-engine blades and vanes with DDSC-YOLOv5s. Sci. Rep. 12(1), 13067 (2022).

Rovinelli, A., Sangid, M. D., Proudhon, H. & Ludwig, W. Using machine learning and a data-driven approach to identify the small fatigue crack driving force in polycrystalline materials. NPJ Comput. Mater. 4(1), 35 (2018).

Marani, R., Palumbo, D., Galietti, U., Stella, E., Orazio, T. D. Automatic detection of subsurface defects in composite materials using thermography and unsupervised machine learning. In 2016 IEEE 8th International Conference on Intelligent Systems (IS), 516–521 (2016).

Gong, Y., Shao, H., Luo, J. & Li, Z. A deep transfer learning model for inclusion defect detection of aeronautics composite materials. Compos. Struct. 252, 112681 (2020).

Lee, H., Lim, H. J., Skinner, T., Chattopadhyay, A. & Hall, A. Automated fatigue damage detection and classification technique for composite structures using Lamb waves and deep autoencoder. Mech. Syst. Signal Process. 163, 108148 (2022).

Dabetwar, S., Ekwaro-Osire, S., Dias, J. P. Damage detection of composite materials using data fusion with deep neural networks. ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition (2020)

Bandara, S., Herath, M., Epaarachchi, J. Sensory methods and machine learning based damage identification of fibre-reinforced composite structures: An introductory review. J. Reinforced Plast. Compos. (2022).

Guo, P., Meng, X., Meng, W. & Bao, Y. Monitoring and automatic characterization of cracks in strain-hardening cementitious composite (SHCC) through intelligent interpretation of photos. Compos. B Eng. 242, 110096 (2022).

Yoon, J., Lee, J., Kim, G., Ryu, S. & Park, J. Deep neural network-based structural health monitoring technique for real-time crack detection and localization using strain gauge sensors. Sci. Rep. 12(1), 20204 (2022).

Liu, H., Liu, S., Liu, Z., Mrad, N. & Milani, A. S. Data-driven approaches for characterization of delamination damage in composite materials. IEEE Trans. Industr. Electron. 68(3), 2532–2542 (2021).

Yu, H., Seno, A. H., Sharif Khodaei, Z. & Aliabadi, M. H. F. Structural health monitoring impact classification method based on Bayesian neural network. Polymers 14(19), 3947 (2022).

Cassola, S., Duhovic, M., Schmidt, T. & May, D. Machine learning for polymer composites process simulation—A review. Compos. B Eng. 246, 110208 (2022).

Sharma, A., Mukhopadhyay, T., Rangappa, S. M., Siengchin, S. & Kushvaha, V. Advances in computational intelligence of polymer composite materials: Machine learning assisted modeling. Analysis and Design, Archives of Computational Methods in Engineering 29(5), 3341–3385 (2022).

Tifkitsis, K. I. & Skordos, A. A. Real time uncertainty estimation in filling stage of resin transfer molding process. Polym. Compos. 41(12), 5387–5402 (2020).

Leukel, J., González, J. & Riekert, M. Adoption of machine learning technology for failure prediction in industrial maintenance: A systematic review. J. Manuf. Syst. 61, 87–96 (2021).

Elenchezhian, M. R. P., Vadlamudi, V., Raihan, R., Reifsnider, K. & Reifsnider, E. Artificial intelligence in real-time diagnostics and prognostics of composite materials and its uncertainties—a review. Smart Mater. Struct. 30(8), 083001 (2021).

Nelon, C., Myers, O. & Hall, A. The intersection of damage evaluation of fiber-reinforced composite materials with machine learning: A review. J. Compos. Mater. 56(9), 1417–1452 (2022).

Zhu, J., Droste, D., Dimassi, A. & Herrmann, A. S. A neural-network-assisted method for flow-front estimation in resin transfer molding using pressure sensors. J. Compos. Mater. 56(19), 2979–2993 (2022).

Zhang, J. & Pantelelis, N. G. Modelling and optimisation control of polymer composite moulding processes using bootstrap aggregated neural network models. International Conference on Electric Information and Control Engineering 2011, 2363–2366 (2011).

Golovatov, D. A., Tatarkanov, A. A., Shavaev, A. A., Gusev, S. A. The use of modern information technology in predicting the process of impregnating composite preforms with polymer resins. In 2019 International Conference "Quality Management, Transport and Information Security, Information Technologies" (IT&QM&IS), (2019) 486–489.

Stieber, S., Schröter, N., Schiendorfer, A., Hoffmann, A., Reif, W., FlowFrontNet: Improving carbon composite manufacturing with CNNs. In European Conference, ECML PKDD (Springer, Ghent, 2020) 411–426.

Stieber, S., Schröter, N., Fauster, E., Schiendorfer, A., & Reif, W. PermeabilityNets: Comparing neural network architectures on a sequence-to-instance task in CFRP manufacturing. In: 2021 20th IEEE International Conference on Machine Learning and Applications (ICMLA), (2021) 694–697.

Das, P. P., Elenchezhian, M., Vadlamudi, V., & Raihan, R., Artificial intelligence assisted residual strength and life prediction of fiber reinforced polymer composites. AIAA SCITECH 2023 Forum (2023).

Hassan, H. & Tallman, T. N. Failure prediction in self-sensing nanocomposites via genetic algorithm-enabled piezoresistive inversion. Struct. Health Monit. 19(3), 765–780 (2020).

Fernández-Caramés, T. M. & Fraga-Lamas, P. A review on the application of blockchain to the next generation of cybersecure industry 4.0 smart factories. IEEE Access 7, 45201–45218 (2019).

Mandolla, C., Petruzzelli, A. M., Percoco, G. & Urbinati, A. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Comput. Ind. 109, 134–152 (2019).

Teng, Y., Li, L., Song, L., Yu, F. R. & Leung, V. C. M. Profit maximizing smart manufacturing over ai-enabled configurable blockchains. IEEE Internet Things J. 9(1), 346–358 (2022).

Hasan, H., AlHadhrami, E., AlDhaheri, A., Salah, K. & Jayaraman, R. Smart contract-based approach for efficient shipment management. Comput. Ind. Eng. 136, 149–159 (2019).

Javaid, M., Haleem, A., Pratap Singh, R., Khan, S. & Suman, R. Blockchain technology applications for Industry 4.0: A literature-based review. Blockchain Res. Appl. 2(4), 100027 (2021).

Mondragon, A. E. C., Mondragon, C. E. C. & Coronado, E. S. Exploring the applicability of blockchain technology to enhance manufacturing supply chains in the composite materials industry. IEEE International Conference on Applied System Invention (ICASI) 2018, 1300–1303 (2018).

Mondragon, A. E. C., & Mondragon, C. E. C. Enhancing the supply chain with composite materials: An analysis supported by IT tools in coach/bus manufacturing. In 2017 4th International Conference on Industrial Engineering and Applications (ICIEA), 121–125 (2017).

Wang, J., Wu, P., Wang, X. & Shou, W. The outlook of blockchain technology for construction engineering management. Front. Eng. Manag. 4(1), 67–75 (2017).

Ahmad, R. W. et al. The role of blockchain technology in aviation industry. IEEE Aerosp. Electron. Syst. Mag. 36(3), 4–15 (2021).

Hasan, H. R. et al. A blockchain-based approach for the creation of digital twins. IEEE Access 8, 34113–34126 (2020).

Baalamurugan, K. M., Bacanin, P. P. N., Venkatachalam, K., Askar, S. S. & Abouhawwash, M. Blockchain-enabled K-harmonic framework for industrial IoT-based systems. Sci. Rep. 13(1), 1004 (2023).

Rovira-Sugranes, A. & Razi, A. Optimizing the age of information for blockchain technology with applications to IoT sensors. IEEE Commun. Lett. 24(1), 183–187 (2020).

Acknowledgements

This work is funded by the internal Grant CIRA-2020-007, grant number 8474000275 from Khalifa University of Science and Technology.

Author information

Authors and Affiliations

Contributions