Abstract

Undoubtedly, metal corrosion is one of the most challenging problems faced by industries. Introducing corrosion inhibitors is a reasonable approach to protecting the metal surface. Due to environmental concerns and the toxicity of industrial organic corrosion inhibitors, researchers are continually exploring acceptable replacements. The current study focused on the application of Falcaria Vulgaris (FV) leaves extract to mitigate mild steel (MS) corrosion in a 1 M HCl environment. The polarization findings demonstrated that the corrosion current density decreased from 264.0 µA/cm2 (for the sample submerged in the blank solution) to 20.4 µA/cm2 when the optimal concentration of 800 ppm of FV leaves extract was added to the acid solution. Electrochemical impedance spectroscopy (EIS) analysis revealed an inhibition efficiency of 91.3% at this concentration after 6 h of immersion. It was determined by analyzing several adsorption isotherms that this corrosion inhibitor obeys the Frumkin isotherm. AFM, FE-SEM, and GIXRD surface analyses also supported the findings that adding FV leaves extract can reduce metal damage by adsorption on the metal surface.

Similar content being viewed by others

Introduction

Nowadays, metal corrosion is one of the most severe challenges confronting industries. Mild steel (MS), one of the most ubiquitous building materials, is highly susceptible to corrosive ions despite its remarkable qualities, including excellent mechanical capabilities and affordability1. Various methods are used to remove contaminants and rust from the MS surface, the most common of which is acid washing (especially using HCl)2. Consequently, it is crucial to employ strategies that minimize the rate of metal dissolution. Anti-corrosion coatings, corrosion inhibitors, anodic and cathodic protection, and other approaches have been proposed for this goal3. Among all these methods, corrosion inhibitors stand out as a promising approach. In order to select the proper corrosion inhibitor, three crucial factors must be taken into account: (1) effective adsorption, and competence in safeguarding the metal surface, (2) environmentally friendliness, and (3) affordability.

Generally, corrosion inhibitors containing heteroatoms (such as sulfur, oxygen, nitrogen, and phosphorus) can form a bond with the iron's vacant d orbital via their non-bonding electron pair, preventing metal corrosion by producing a protective layer4,5. Furthermore, compounds comprising aromatic rings and polar groups (such as C=O, –NH2, –OH, etc.) can be readily adsorbed on the metal surface via electrostatic attraction6,7. Even though some industrial organic corrosion inhibitors have the property mentioned above and exhibit potent inhibition against harsh ions, they suffer from the absence of two other qualities (they might be toxic and expensive)8,9,10,11. Hence, it is vital to discover an alternative with all the desirable features.

Recently, green organic corrosion inhibitors, including plant extracts12, expired drugs13, and ionic liquids14 with effective compounds, have been introduced as a substitution for toxic convectional corrosion inhibitors. Plant extracts, comprising leaf15, fruit 16, and seed 17 extracts, are generally biocompatible, biodegradable, and cost-effective. Also, donor electron components such as aromatic groups, heteroatoms, and compounds with π electrons in plant extract can further confirm their potential to be used as potent corrosion inhibitors18,19,20,21.

Many efforts have shown the role of different plant extracts in the protection of MS surfaces in acidic media. Mostafatabar et al. evaluated the inhibitory effect of carrot pomace extract. They clarified that the extract molecules could be adsorbed physicochemically and generate a protective layer on the MS panel, leading to 95% efficiency at 400 ppm extract concentration according to polarization assessment22. In another report, garcinia cambogia fruit rind extract derived from aqueous and alcoholic media was introduced as a green corrosion inhibitor demonstrating mix mode (cathodic and anodic) protection via Langmuir and Temkin adsorption isotherm, respectively23. Dehghani et al. investigated the inhibition action of the rosemary extract at different concentrations and temperatures. Their results showed that increasing the rosemary extract concentration to 800 ppm enhanced the corrosion inhibition efficiency to 92.0%24. Moreover, exploration of the inhibition performance of other plant extracts, including Mish Gush25, Xanthium strumarium26, Eriobotrya japonica Lindl27, Cardaria draba28, Urtica dioica29, Arbutus unedo L30, Euphorbia heterophylla L31 and Thymus vulgaris32, Onion–garlic33 obviously endorsed the potential of plant extracts as corrosion inhibitors.

Falcaria vulgaris (FV) is a species of the Apiaceae family found in West Asia, Europe, and the United States. This plant has been used for medical applications such as healing skin and gastrointestinal diseases in many regions of Iran. Furthermore, the antibacterial and antioxidant properties of FV have been approved due to the existence of carvacrol and spathulenol in its structure. In addition to the mentioned compounds, FV leaves extract contains genistin, rutin, quercetin-3-O-glucoside, and quercetin (Fig. 1)34,35.

In current study, we aimed to investigate the inhibitory performance of FV extract towards corrosion mitigation of MS submerged in 1 M HCl medium. Electrochemical measurements such as EIS and polarization were used to explore this compound's anti-corrosion properties. In addition, the morphology and topology of the surface were examined by exploiting energy-dispersive X-ray analysis (EDX), field-emission scanning electron microscopy (FE-SEM), and atomic force microscopy (AFM). Also, Fourier-transform infrared spectroscopy (FTIR) and grazing incidence X-ray diffraction (GIXRD) were used to assess the FV-based layer formed on the MS surface.

Materials and methods

Extraction process

FV leaves were collected from the Markazi province, Iran (with permission of the landowner) and dried and powdered after washing with distilled water. For extract preparation, 15 g of FV leaves powder was poured into 500 ml of deionized water and agitated with a heater stirrer for 12 h at 70 °C. After that, filtration was performed using filtering paper to separate dark brown liquid and solid, and in the second step, the obtained solution was centrifuged at 4000 rpm for 5 min. Finally, the prepared extract was dried at 45 °C overnight. All methods were performed in accordance with the relevant guidelines and regulations. The main chemical structure of FV leaves extracts is illustrated in Fig. 1, as already mentioned.

Sample preparation

MS plates (ST12, Foolad-E-Mobarakeh Co., Iran) were used as a working electrode. Hydrochloric acid (37%, Doctor-Mojalali Co., Iran) was diluted with distilled water to prepare 1 M HCl. Different grades of silicone carbide paper (400–1000) were used to remove the surface scales. After that, the surface was cleaned using industrial-grade of acetone. Finally, different concentrations of FV extract in 1 M HCl (0, 400, 600, 800, and 1000 ppm) were prepared for electrochemical measurement (the solubility of FV leaves extract was higher than 5 g L−1).

Electrochemical measurements

CorrTest (CS350, China) potentiostat instrument was exploited to check the corrosion inhibition effect of FV leaves extract. The electrochemical setup comprised three-electrode, including MS (contact surface = 1 cm2), Calomel and Pt rod. EIS analysis was conducted by applying 10 mV AC voltage at open circuit potential (OCP) in the frequency range of 0.01 to 10,000 Hz. Also, the polarization test was performed within the voltage range of −250 to + 250 mV versus OCP with a 0.5 mV/s sweep rate. Three experiments were performed for each concentration to guarantee the reproducibility of data.

Surface study

To study surface characteristics, MS was soaked in an acidic solution with and without 800 ppm of FV extract for 6 h. After that surface of MS was rinsed with distilled water two times and then dried at room temperature. Morphological and elemental analysis of the MS surface were assessed using FE-SEM (TE-Scan—MIRA3) and EDX (Oxford—X-MAX-80). Also, the surface topology was examined using AFM (Bruker, Icon, United States). The adsorption of FV extract molecules on the MS surface was analyzed using FTIR (Thermo, Avatar, United States), Ultraviolet–visible spectroscopy (UV–Vis, Thermo, Biomate5, United States), and GIXRD (X'Pert PRO MPD PANalytical Company).

Results and discussion

Electrochemical examinations

OCP

The OCP assessment of the MS substrate was conducted during 1500 s immersion in the HCl medium, in the presence and absence of the FV leaves extract. The data depicted in Fig. 2 reveals that the OCP reached a state of equilibrium prior to the completion of the 1500 s, as no discernible deviation from the OCP values was observed after 1000 s. The OCP trend for both conditions was congruent, commencing at a lower potential and progressively augmenting over time, a phenomenon that can be attributed to the formation of an oxide layer on the MS surface as a result of the corrosive species attack until a steady state is attained36. Notably, the initial OCP value in the FV-containing solution was higher than that of the blank solution, which may be indicative of the adsorption of inhibitors onto the MS surface36. Upon examination of the OCP values in the presence of FV, it was determined that the maximum deviation of OCP was under 85 mV, indicating that the FV extract displays properties of a mixed-type corrosion inhibitor for MS in a 1 M HCl solution37. However, a detailed analysis of the data presented in Fig. 2 highlights that FV primarily exerts its inhibition effects through inhibiting anodic reactions as OCP shows a positive shift upon addition of FV extract38.

EIS

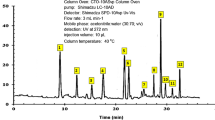

EIS analysis was used to scrutinize the corrosion-inhibiting competence of FV leaves extract. Figure 3 illustrates the Nyquist and Bode plots of MS immersed in acidic electrolytes containing various concentration of FV extract solution (400–1000 ppm) and blank solution. A depressed semicircle, representing the roughness of the tested sample's surface, can be seen in all Nyquist diagrams39. It is of note that the Nyquist graph's shape remained unchanged when various inhibitor concentrations were added, indicating that the mechanism of the corrosion reaction remained unaltered. Furthermore, only one time constant is visible on the Bode-phase angle diagram, revealing that the charge transfer mechanism predominates at the metal/electrolyte interface40.

The EIS data were fitted by exploiting a one-time constant equivalent electrical circuit (chi-square < 0.005) utilizing ZView software for a more precise examination, and the related parameters are reported in Table 1. In this table, the terms Rs, CPEdl, Y0, and n connote the electrolyte resistance, constant phase element, admittance, and power of the CPE, respectively. Furthermore, Rp stands for polarization resistance, calculated by adding the charge transfer and film resistance (Rp = Rct + Rf ) 19. As demonstrated in Fig. 3, the smallest diameter of the Nyquist diagram (which indicates Rp) corresponds to the sample immersed in the inhibitor-free solution and displays a declining trend over time. The corrosion reactions instigate as soon as the working electrode is soaked in 1 M HCl medium. As a result, the attack of corrosive ions induces MS dissolution and the degradation of the porous oxide layer, culminating in poor MS resistance in the absence of corrosion inhibitors. In contrast, the diameter of the Nyquist diagram was considerably boosted by introducing diverse concentrations of FV leaves extract in the acidic solution. To gain a better insight into the corrosion-inhibiting properties of FV leaves extract, the inhibition efficiency (η) was computed using Eq. (1)41:

In this equation, Rp,0 and Rp, i denote the polarization resistance of MS in the inhibitor-free and inhibitor-containing solution, respectively. Compared to the blank solution, the sample submerged in the inhibitor-containing solution has a greater Rp, as shown in Table 1. It is worth mentioning that as the concentration of the corrosion inhibitor increased, the Rp elevated, reaching a maximum of Rp = 988.1 Ω cm2 and η % = 91.3% at 800 ppm after 6 h of immersion. This remarkable improvement is due to corrosion inhibitor adsorption on the MS surface, which establishes a protective layer and blocks the access of the corrosive electrolyte to the metal surface. Notably, the η has dropped slightly after 24 h of immersion, suggesting the extract's long-term capacity to mitigate corrosion of the MS surface.

The Bode diagram can provide more information regarding the corrosion-inhibition activity of FV leaves extract. According to the literature, rising |Z| at the lowest frequency (0.01 Hz) and decreasing the phase angle towards -90° (pure capacitor phase angle) at the highest frequency (10,000 Hz) suggests an increase in corrosion resistance36. Table 1 and the Bode graphs show that these two parameters (|Z|0.01 Hz and phase angle at 10 kHz) for the coupons dipped in the inhibitor-based solution are greater than the blank one, confirming the development of the FV-based protective film on the working electrode's surface. Further beneficial parameters in corrosion studies are capacitance (Cdl) and relaxation time (τ), which are expressed by Eqs. (2) and (3), respectively36,42, and their values are given in Table 1.

In Eq. (2), ε0 and ε symbolize the dielectric constants of air and the double layer, while A and d signify the surface area of MS and the electric double layer thickness, respectively. A close inspection of Table 1 implies that when the inhibitor is added to the acidic solution, Cdl significantly lowered in comparison to the inhibitor-free solution. These findings might be related to the replacement of inhibitor components with water molecules, leading to a drop in ε and an increase in d, resulting in a decrease in Cdl43. According to the inferences mentioned above, the decline in Cdl can be linked to a reduction in the contact area between corrosive water molecules and the MS surface. Furthermore, the increase in τ of the sample soaked in the inhibitor-based solution might be linked to the inhibitor molecule adsorption on the MS surface, which ultimately resulted in a delay in reaching equilibrium following charge distribution44.

Surface coverage (θEIS), which is given by Eq. (4)45,46, is another parameter that may be extracted from EIS data:

In this equation, Cdl,0 and Cdl,i represent the capacitance of MS in solutions without and with FV leaves extract, respectively. The orientation of corrosion inhibitor molecules on the MS surface (horizontal or vertical) can be assessed by comparing θEIS with η. When a corrosion inhibitor is adsorbed horizontally on a metal surface, it blocks the access of corrosive ions to the metal surface and leads to an increase in Rp and η. Consequently, it is demonstrated that η > θEIS when the horizontal adsorption of inhibitor molecules occurs on the MS surface43,47,48. Conversely, when corrosion inhibitor molecules are vertically oriented on the MS surface, the electric double layer thickness rises and, as a result, Cdl decreases. Meanwhile, Rp is less affected because corrosion inhibitor molecules replace just a limited number of water molecules. Thus, η < θEIS reflects the vertical adsorption of corrosion inhibitors43,47,48.

A careful evaluation of Table 1 discloses that the FV leaves extract molecules (which contain diverse compounds such as carvacrol, spathulenol, genistin, etc.) are horizontally adsorbed on the MS surface during 6 h of immersion (η > θEIS). It is worth noting that some compounds in FV leaves extract may be desorbed from the metal surface after 24 h of immersion. Thus, as shown in Table 1, it is not surprising that the orientation of the remaining molecules on the MS surface has altered and become vertical (η < θEIS) after 24 h of immersion at concentrations of 400 and 600 ppm49. Higher concentrations (800 and 1000 ppm) also show a similar trend, and after 6 h, η declines and θEIS rises. Although η is still bigger than θEIS, the fact that these two values are so close to one another after 24 h compared to other times suggests that the corrosion inhibitors have the propensity to switch from horizontal to vertical orientation. This observation can be interpreted as evidence for either the durability of the protective film generated on the MS surface or the existence of more active FV molecules in the solution, which can quickly and efficiently replace the desorbed molecules.

As shown in Table 1, the maximum inhibition efficiency was observed at a concentration of 800 ppm (optimum concentration), whereas raising the concentration to 1000 ppm decreased the polarization resistance and inhibition efficiency. Based on this table, the Cdl value has increased in the solution with 800 ppm FV extract compared to 1000 ppm one, revealing a reduction in double-layer thickness and, as a result, a reduction in the thickness of adsorbed corrosion inhibitor on the surface. The reduction of the adsorbed layer thickness might be a symptom of the inhomogeneous adsorption of corrosion inhibitors on the MS surface. The following approach can be considered to analyze this behavior; Due to the concentration gradient, corrosion inhibitors tend to be adsorbed onto the metal surfaces when introduced to acid solutions. The adsorption process is optimized when the corrosion inhibitor molecules have the least interaction with each other and the most interaction with the metal surface. It is evident that elevating the concentration over the optimal concentration considerably increases the intermolecular attraction leading to the creation of clusters50. Therefore, a passageway might be created for the penetration of corrosive ions (Fig. 4). In fact, the inhibitor's intermolecular interaction at high concentrations to form clusters is more thermodynamically favored, which competes with adsorption forces between the inhibitor and the metal surface preventing them from developing a compact monolayer.

Polarization

Further investigation on the effect of FV leaves extract on cathodic and anodic reactions was investigated using polarization analysis after 24 h of submersion of MS in the electrolyte without and with various concentrations of the extract. Polarization parameters, comprising corrosion current density (icorr), corrosion potential (Ecorr) and slope of anodic and cathodic branches (βa and βc), are listed in Table 2. According to Fig. 5, it can be realized that in the presence of FV leaves extracts, the current density has decreased in both anodic and cathodic branches compared to the blank. The increase in current density in the anodic branch at -0.3 V/SCE indicates the desorption of corrosion inhibitor molecules from the MS surface at high potential51. This potential is known as the desorption potential. The FV extract seems to have a more significant impact on the anodic reaction mechanism, as observed through changes in the anodic slopes. Meanwhile, the cathodic branch diagrams remain parallel in form, indicating that the cathodic reaction mechanism remains unchanged. The corrosion inhibition efficiency (ξ) can be calculated using Eq. (5), where i0 and ii represent the MS corrosion current density in the blank and inhibitor-containing solution, respectively.

According to Table 2, the corrosion current densities' values have decreased with the addition of corrosion inhibitor, reaching 20.4 µA/cm2 at the optimum concentration (800 ppm), which is significantly lower than the blank (264.0 µA/cm2). Moreover, the inhibition efficiency at this concentration (800 ppm) is 92.2 %, highlighting this inhibitor's excellent ability to protect the MS against harsh species. Besides, since the difference in Ecorr compared to blank is less than 85 mV, it can be concluded that FV extract acts as a mixed corrosion inhibitor52.

Adsorption isotherms

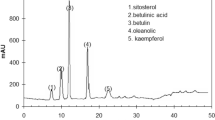

In order to explore the interaction of FV molecules and MS surface, different adsorption isotherms comprising Frumkin, Temkin, Freundlich and Langmuir were investigated. The adsorption isotherm equations are given below (Eqs. 6–9), and the corresponding diagram is shown in Fig. 6:

\({\theta }_{Pol}(=\frac{\xi \%}{100})\), α, and Kads in the above equations symbolize surface coverage based on polarization data, lateral interaction between FV leaves extract and MS surface, and adsorption/desorption equilibrium constant, respectively. According to Fig. 6, the best fit among several adsorption isotherms is the Frumkin isotherm with R2 = 0.9932. The values of Kads and α derived from the intercept and slope of the Frumkin isotherm curve are shown in Table 3.

The protective effects of natural extracts are believed to come from the presence of multiple molecules at different contents. One key factor is the synergistic interaction between these components, which increases their inhibiting effect5,7,11. The high concentration of compounds with aromatic rings containing heteroatoms (nitrogen, oxygen, and sulfur) enhances their ability to adsorb onto the metal surface and thus provides protection against corrosive ions such as H+ or Cl−. The possible adsorption mechanism of FV leaves extract molecules on the MS surface is shown in Fig. 7.

Surface studies

FE-SEM/EDX

The surface morphology of MS was investigated after submerging an MS coupon in the acidic solution in the absence and presence of 800 ppm FV extract for 6 h. As shown in FE-SEM images, the MS surface, which was exposed to the corrosive solution without inhibitor, is severely damaged (Fig. 8a1,a2); However, adding the FV extract to the acidic solution prevented the formation of corrosion products and a relatively uniform and smooth surface can be seen (Fig. 8b1,b2). Lower damage to the metal surface in the presence of FV extract could be due to the efficient adsorption of corrosion inhibitors, which diminish the contact between the corrosive ions and the MS surface and lessens the dissolution rate53,54.

EDX analysis was also performed to demonstrate the elemental composition of the MS surface, which can be seen in Table 4. According to this table, Fe, C, and O elements were detected on the surface of MS. When the FV extract was added to the acidic solution, the percentage of the carbon was increased on the metal surface, confirming the FV-based protective film's creation. Also, the decrease in oxygen percentage on the surface can be due to the reduction of corrosion products29,55.

AFM

AFM analysis was conducted to demonstrate the effect of FV extract on the roughness and microstructure of the MS surface, which was submerged in 1 M HCl solution (Fig. 9). Based on the AFM results, the average roughness (Ra) of the MS coupons in the blank sample was 520.4 nm, while in the presence of FV extract, this value decreased to 111.2 nm suggesting a decline in metal corrosion. Besides the Ra, other parameters such as average height (Hm), peak to valley (Rp-v), and root mean square deviation (Rq) are reported in Table 5. The reduction of these parameters establishes that the FV extract molecules adsorbed on the steel surface limited corrosion attacks on the MS surface56,57.

FTIR

The FTIR spectrum was recorded to characterize the MS surface after immersing in an acidic solution containing FV extract. According to the FTIR spectrum of FV extract, which can be seen in Fig. 10, the peak at 3434 cm−1 is related to O–H stretching58. Moreover, the appearance of peaks at 2856 cm−1 and 2930 cm−1 are linked to the aliphatic CH2 stretching43,58. The peaks related to C=C stretching of the aromatic ring and C=O stretching are observed at 1605 cm−1 and 1715 cm−1, respectively58,59. The peaks between 1295 and 1490 cm−1 are correlated to C-H bending59. Besides, the peaks at 1056 cm−1 and 1260 cm−1 are linked to C–O and C–O–C stretching60. The peaks between 400 and 1000 cm−1 can be due to the aliphatic and aromatic C-H bending30. The presence of the FV extract peaks in the FTIR spectrum of the MS surface reveals that the adsorption of FV extract molecules on the metal surface occurs during immersion.

Additionally, the appearance of a new peak at 476 cm−1 is connected to the Fe–O bonds, revealing the interaction of the oxygen-containing groups of FV extract molecules and metal surfaces61. Furthermore, shifting the peaks of C=O stretching from 1715 to 1728 cm−1 and C=C stretching from 1605 to 1624 cm−1 can be due to the development of a complex between FV extract and iron ions 21. The results showed that functional groups, aromatic rings, and oxygen-containing groups in the FV extract structure could cause the interaction between FV extract compounds and the MS surface.

UV–Vis

The possibility of complex development among the FV extract compounds and iron ions was studied using the UV–Vis test. Figure 11 shows the UV–Vis spectrum before and after soaking the MS in the acidic solution containing FV extract. The UV–Vis spectrum of the solution before immersion, included three peaks centered at 206 nm, 265 nm, and 328 nm. Intensive absorption at 206 nm is related to π–π* transitions of C=C bonds in aromatic rings, and the absorption at 265 nm and 328 nm are associated with n-π* transitions of C=O and O–H bonds, respectively61,62. After immersion of the MS in the acidic solution containing the FV extract, the intensity of the absorption peaks related to π–π* and n–π* transitions dramatically decreased, and the UV–Vis spectrum shifted to a lower wavelength value (blue shift). These observations may correspond to the adsorption of FV extract molecules on the MS surface and the formation of an organic–inorganic complex via the interaction between pair electrons of FV extract molecule and vacant orbital of Fe2+/Fe3+, which causes the construction of a shielding film against corrosive species63.

GIXRD

GIXRD was recorded to investigate the crystalline composition of the MS surface after soaking in an acidic solution in the presence and absence of FV extract. As shown in Fig. 12 the peak at 2θ = 27.3° is related to γ-FeOOH, and peaks at 2θ = 35.4°, 36.3°, and 36.9° are attributed to Fe2O3/FeCl3 which are due to the presence of corrosion product on the blank specimen surface. Also, peaks at 2θ = 45.2°, and 65.6° are related to iron metal64,65. Comparing the GIXRD patterns shows that the corrosion product peaks disappeared after adding FV extract to the acidic solution. Furthermore, the intensification of the peak at 45.2° and the appearance of a peak at 65.6° (peaks related to Fe metal) can confirm the assumption of the interaction between FV extract compounds and metal surface and verify the production of less corrosion products.

Comparative study

Table 6 summarizes the corrosion inhibition capabilities of several plant extracts in terms of solvent utilized, optimal inhibitor concentration, inhibition efficiency at optimal concentration, and adsorption isotherm. According to this table, the FV leaves extract with an inhibition efficacy above 90% can be designated a robust MS corrosion inhibitor. Moreover, the extraction procedure is considered environmentally friendly because water was employed as the solvent.

Conclusion

The current study sought to explore the application of FV extract as a sustainable and effective corrosion inhibitor for MS in hydrochloric acid. The results from EIS and polarization studies indicated that at an optimized concentration of FV (800 ppm), the inhibitor demonstrated a remarkable polarization resistance of 988.1 Ω cm2 and a 91.3% inhibition efficiency after 6 h of immersion. Additionally, there was a substantial reduction in corrosion current density by 92.2% compared to the blank sample. Surface coverage and inhibition efficiency data analyses revealed that the inhibitor was adsorbed horizontally on the metal surface, following the Frumkin adsorption isotherm. Furthermore, SEM and AFM analysis showed a smoother metal surface with fewer corrosion products, while EDX and FTIR verified the formation of an FV-based layer on the metal surface. In conclusion, these results demonstrate the potential of FV extract as an eco-friendly and efficient corrosion inhibitor for MS in hydrochloric acid media.

Data availability

All data generated or analysed during this study are included in this publish ed article.

References

Ghaderi, M., Saadatabadi, A. R., Mahdavian, M. & Haddadi, S. A. pH-sensitive polydopamine–La (III) complex decorated on carbon nanofiber toward on-demand release functioning of epoxy anti-corrosion coating. Langmuir 38, 11707–11723 (2022).

Sun, X., Qiang, Y., Hou, B., Zhu, H. & Tian, H. Cabbage extract as an eco-friendly corrosion inhibitor for X70 steel in hydrochloric acid medium. J. Mol. Liq. 362, 119733 (2022).

Honarvar Nazari, M. et al. Nanocomposite organic coatings for corrosion protection of metals: A review of recent advances. Prog. Org. Coatings 162, 106573 (2022).

Ouakki, M., Galai, M. & Cherkaoui, M. Imidazole derivatives as efficient and potential class of corrosion inhibitors for metals and alloys in aqueous electrolytes: A review. J. Mol. Liq. 345, 117815 (2022).

Khadom, A. A., Abd, A. N. & Ahmed, N. A. Xanthium strumarium leaves extracts as a friendly corrosion inhibitor of low carbon steel in hydrochloric acid: Kinetics and mathematical studies. S. Afr. J. Chem. Eng. 25, 13–21 (2018).

Berrissoul, A. et al. Exploitation of a new green inhibitor against mild steel corrosion in HCl: Experimental, DFT and MD simulation approach. J. Mol. Liq. 349, 118102 (2022).

Bouknana, D., Hammouti, B., Messali, M., Aouniti, A. & Sbaa, M. Phenolic and non-phenolic fractions of the olive oil mill wastewaters as corrosion inhibitor for steel in HCl medium. Port. Electrochim. Acta 32, 1–19 (2014).

Alibakhshi, E. et al. Progress in organic coatings epoxy nanocomposite coating based on calcium zinc phosphate with dual active / barrier corrosion mitigation properties. Prog. Org. Coatings 163, 106677 (2022).

Hamed, S., Yop, K., Verma, C., Quraishi, M. A. & Ebenso, E. E. Challenges and advantages of using plant extract as inhibitors in modern corrosion inhibition systems : Recent advancements. J. Mol. Liq. 321, 114666 (2021).

Arash, S. et al. Progress in organic coatings synthesis of methyltriethoxysilane-modified calcium zinc phosphate nanopigments toward epoxy nanocomposite coatings : Exploring rheological, mechanical, and anti-corrosion properties. Prog. Org. Coatings 171, 107055 (2022).

Bammou, L. et al. Thermodynamic properties of Thymus satureioides essential oils as corrosion inhibitor of tinplate in 0.5 M HCL: Chemical characterization and electrochemical study. Green Chem. Lett. Rev. 3, 173–178 (2010).

Ahanotu, C. C., Madu, K. C., Chikwe, I. S. & Chikwe, O. B. The inhibition behaviour of extracts from Plumeria rubra on the corrosion of low carbon steel in sulphuric acid solution. J. Mater. Environ. Sci. 13, 1025–1036 (2022).

Singh, A. K. & Quraishi, M. A. Effect of Cefazolin on the corrosion of mild steel in HCl solution. Corros. Sci. 52, 152–160 (2010).

Li, Y., Zhang, S., Ding, Q., Qin, B. & Hu, L. Versatile 4, 6-dimethyl-2-mercaptopyrimidine based ionic liquids as high-performance corrosion inhibitors and lubricants. J. Mol. Liq. 284, 577–585 (2019).

Li, X., Deng, S. & Fu, H. Inhibition of the corrosion of steel in HCl, H2SO4 solutions by bamboo leaf extract. Corros. Sci. 62, 163–175 (2012).

Liao, L. L., Mo, S., Luo, H. Q. & Li, N. B. Corrosion protection for mild steel by extract from the waste of lychee fruit in HCl solution: Experimental and theoretical studies. J. Colloid Interface Sci. 520, 41–49 (2018).

Hassannejad, H. & Nouri, A. Sunflower seed hull extract as a novel green corrosion inhibitor for mild steel in HCl solution. J. Mol. Liq. 254, 377–382 (2018).

Chauhan, L. R. & Gunasekaran, G. Corrosion inhibition of mild steel by plant extract in dilute HCl medium. Corros. Sci. 49, 1143–1161 (2007).

Shahmoradi, A. R. et al. Theoretical and surface/electrochemical investigations of walnut fruit green husk extract as effective inhibitor for mild-steel corrosion in 1M HCl electrolyte. J. Mol. Liq. 338, 116550 (2021).

Sin, H. L. Y. et al. Aquilaria subintergra leaves extracts as sustainable mild steel corrosion inhibitors in HCl. Meas. J. Int. Meas. Confed. 109, 334–345 (2017).

Shahini, M. H., Keramatinia, M., Ramezanzadeh, M., Ramezanzadeh, B. & Bahlakeh, G. Combined atomic-scale/DFT-theoretical simulations & electrochemical assessments of the chamomile flower extract as a green corrosion inhibitor for mild steel in HCl solution. J. Mol. Liq. 342, 117570 (2021).

Mostafatabar, A. H., Dehghani, A., Ghahremani, P., Bahlakeh, G. & Ramezanzadeh, B. Molecular-dynamic/DFT-electronic theoretical studies coupled with electrochemical investigations of the carrot pomace extract molecules inhibiting potency toward mild steel corrosion in 1 M HCl solution. J. Mol. Liq. 346, 118344 (2022).

Rani, A. T. J., Thomas, A., Arshad, M. & Joseph, A. The influence of aqueous and alcoholic extracts of Garcinia cambogia fruit rind in the management of mild steel corrosion in hydrochloric acid. Theor. Electroanal. Stud. 346, 117873 (2022).

Dehghani, A. & Ramezanzadeh, B. Rosemary extract inhibitive behavior against mild steel corrosion in tempered 1 M HCl media. Ind. Crops Prod. 193, 116183 (2023).

Shahini, M. H., Ramezanzadeh, M., Bahlakeh, G. & Ramezanzadeh, B. Superior inhibition action of the Mish Gush (MG) leaves extract toward mild steel corrosion in HCl solution: Theoretical and electrochemical studies. J. Mol. Liq. 332, 115876 (2021).

Khadom, A. A., Abd, A. N., Ahmed, N. A., Kadhim, M. M. & Fadhil, A. A. Combined influence of iodide ions and Xanthium strumarium leaves extract as eco-friendly corrosion inhibitor for low-carbon steel in hydrochloric acid. Curr. Res. Green Sustain. Chem. 5, 100278 (2022).

Nikpour, S., Ramezanzadeh, M., Bahlakeh, G., Ramezanzadeh, B. & Mahdavian, M. Eriobotrya japonica Lindl leaves extract application for effective corrosion mitigation of mild steel in HCl solution: Experimental and computational studies. Constr. Build. Mater. 220, 161–176 (2019).

Khadom, A. A., Abd, A. N. & Ahmed, N. A. Results in chemistry synergistic effect of iodide ions on the corrosion inhibition of mild steel in 1 M HCl by Cardaria draba leaf extract. Introduction 4, 1–6 (2022).

Ramezanzadeh, M., Bahlakeh, G., Sanaei, Z. & Ramezanzadeh, B. Studying the Urtica dioica leaves extract inhibition effect on the mild steel corrosion in 1 M HCl solution: Complementary experimental, ab initio quantum mechanics, Monte Carlo and molecular dynamics studies. J. Mol. Liq. 272, 120–136 (2018).

Abdelaziz, S. et al. Green corrosion inhibition of mild steel in HCl medium using leaves extract of Arbutus unedo L. plant: An experimental and computational approach. Colloids Surf. A Physicochem. Eng. Asp. 619, 126496 (2021).

Akinbulumo, O. A., Odejobi, O. J. & Odekanle, E. L. Thermodynamics and adsorption study of the corrosion inhibition of mild steel by Euphorbia heterophylla L. extract in 1.5 M HCl. Results Mater. 5, 1–6 (2020).

Lashgari, S. M., Bahlakeh, G. & Ramezanzadeh, B. Detailed theoretical DFT computation/molecular simulation and electrochemical explorations of Thymus vulgaris leave extract for effective mild-steel corrosion retardation in HCl solution. J. Mol. Liq. 335, 115897 (2021).

Rashid, K. H., Khadom, A. A. & Abbas, S. H. Optimization, kinetics, and electrochemical investigations for green corrosion inhibition of low-carbon steel in 1 M HCl by a blend of onion-garlic leaves wastes. Bioresour. Technol. Rep. 19, 101194 (2022).

Jaberian, H., Piri, K. & Nazari, J. Phytochemical composition and in vitro antimicrobial and antioxidant activities of some medicinal plants. Food Chem. 136, 237–244 (2013).

Abdulmanea, K., Prokudina, E. A., Lanková, P. & Vaní, L. Immunochemical and HPLC identification of iso flavonoids in the Apiaceae family. Biochem. Syst. Evol. 45, 237–243 (2012).

Rahimi, A. et al. Novel sucrose derivative as a thermally stable inhibitor for mild steel corrosion in 15 % HCl medium : An experimental and computational study. Chem. Eng. J. 446, 136938 (2022).

Farhadian, A. et al. A theoretical and experimental study of castor oil-based inhibitor for corrosion inhibition of mild steel in acidic medium at elevated temperatures. Corros. Sci. 175, 108871 (2020).

El-Azabawy, O. E. et al. Studying the temperature influence on carbon steel in sour petroleum media using facilely-designed Schiff base polymers as corrosion inhibitors. J. Mol. Struct. 1275, 134518 (2022).

Singh, A., Ansari, K. R., Alanazi, A. K., Quraishi, M. A. & Banerjee, P. Biological macromolecule as an eco-friendly high temperature corrosion inhibitor for P110 steel under sweet environment in NACE brine ID196: Experimental and computational approaches. J. Mol. Liq. 345, 117866 (2022).

Shahini, M. H., Keramatinia, M., Ramezanzadeh, M., Ramezanzadeh, B. & Bahlakeh, G. Combined atomic-scale/DFT-theoretical simulations & electrochemical assessments of the chamomile flower extract as a green corrosion inhibitor for mild steel in HCl solution. J. Mol. Liq. 342, 117570 (2021).

Damej, M. et al. An environmentally friendly formulation based on Cannabis sativa L. seed oil for corrosion inhibition of E24 steel in HCl medium : Experimental and theoretical study. Colloids Surf. A Physicochem. Eng. Asp. 643, 128745 (2022).

Daoudi, W. et al. Essential oil of Dysphania ambrosioides as a green corrosion inhibitor for mild steel in HCl solution. J. Mol. Liq. 363, 119839 (2022).

Ghaderi, M. et al. Corrosion inhibition of a novel antihistamine-based compound for mild steel in hydrochloric acid solution: Experimental and computational studies. Sci. Rep. 12, 13450 (2022).

El Basiony, N. M., Badr, E. E., Baker, S. A. & El-Tabei, A. S. Experimental and theoretical (DFT&MC) studies for the adsorption of the synthesized Gemini cationic surfactant based on hydrazide moiety as X-65 steel acid corrosion inhibitor. Appl. Surf. Sci. 539, 148246 (2021).

Alibakhshi, E., Ramezanzadeh, M., Bahlakeh, G. & Ramezanzadeh, B. Glycyrrhiza glabra leaves extract as a green corrosion inhibitor for mild steel in 1 M hydrochloric acid solution : Experimental, molecular dynamics, Monte Carlo and quantum mechanics study. J. Mol. Liq. 255, 185–198 (2018).

Cao, C. On electrochemical techniques for interface inhibitor research. Corros. Sci. 38, 2073–2082 (1996).

Mahdavian, M. et al. Corrosion of mild steel in hydrochloric acid solution in the presence of two cationic Gemini surfactants with and without hydroxyl substituted spacers. Corros. Sci. 137, 62–75 (2018).

Motamedi, M., Tehrani-bagha, A. R. & Mahdavian, M. Effect of aging time on corrosion inhibition of cationic surfactant on mild steel in sulfamic acid cleaning solution. Corros. Sci. 70, 46–54 (2013).

Hammouti, B., Aouniti, A., Taleb, M., Brighli, M. & Kertit, S. L-Methionine methyl ester hydrochloride as a corrosion inhibitor of iron in acid chloride solution. Corrosion 51, 06 (1995).

Teymouri, F., Allahkaram, S. R., Shekarchi, M., Azamian, I. & Johari, M. A comprehensive study on the inhibition behaviour of four carboxylate-based corrosion inhibitors focusing on efficiency drop after the optimum concentration for carbon steel in the simulated concrete pore solution. Constr. Build. Mater. 296, 123702 (2021).

Abbout, S. et al. Ceratonia siliqua L. seeds extract as eco-friendly corrosion inhibitor for carbon steel in 1 M HCl: Characterization, electrochemical, surface analysis, and theoretical studies. J. Mol. Struct. 1240, 130611 (2021).

Caldona, E. B. et al. Corrosion inhibition of mild steel in acidic medium by simple azole-based aromatic compounds. J. Electroanal. Chem. 880, 114858 (2021).

Muthukrishnan, P., Jeyaprabha, B. & Prakash, P. Mild steel corrosion inhibition by aqueous extract of Hyptis suaveolens leaves. Int. J. Ind. Chem. 5, 1–11 (2014).

Wang, D., Li, Y., Chen, B. & Zhang, L. Novel surfactants as green corrosion inhibitors for mild steel in 15% HCl: Experimental and theoretical studies. Chem. Eng. J. 402, 126219 (2020).

Tabatabaei Majd, M., Akbarzadeh, S., Ramezanzadeh, M., Bahlakeh, G. & Ramezanzadeh, B. A detailed investigation of the chloride-induced corrosion of mild steel in the presence of combined green organic molecules of Primrose flower and zinc cations. J. Mol. Liq. 297, 111862 (2020).

Bahlakeh, G., Dehghani, A., Ramezanzadeh, B. & Ramezanzadeh, M. Highly effective mild steel corrosion inhibition in 1 M HCl solution by novel green aqueous mustard seed extract: Experimental, electronic-scale DFT and atomic-scale MC/MD explorations. J. Mol. Liq. 293, 111559 (2019).

Ostovari, A., Hoseinieh, S. M., Peikari, M., Shadizadeh, S. R. & Hashemi, S. J. Corrosion inhibition of mild steel in 1 M HCl solution by henna extract: A comparative study of the inhibition by henna and its constituents (lawsone, gallic acid, α-d-glucose and tannic acid). Corros. Sci. 51, 1935–1949 (2009).

Kohsari, I. et al. In vitro antibacterial property assessment of silver nanoparticles synthesized by Falcaria vulgaris aqueous extract against MDR bacteria. J. Sol-Gel Sci. Technol. 90, 380–389 (2019).

Li, X.-H., Deng, S.-D. & Fu, H. Inhibition by Jasminum nudiflorum Lindl. leaves extract of the corrosion of cold rolled steel in hydrochloric acid solution. J. Appl. Electrochem. 40, 1641–1649 (2010).

Zangeneh, M. M., Zangeneh, A., Pirabbasi, E., Moradi, R. & Almasi, M. Falcaria vulgaris leaf aqueous extract mediated synthesis of iron nanoparticles and their therapeutic potentials under in vitro and in vivo condition. Appl. Organomet. Chem. 33, e5246 (2019).

Majd, M. T., Ramezanzadeh, M., Bahlakeh, G. & Ramezanzadeh, B. Probing molecular adsorption/interactions and anti-corrosion performance of poppy extract in acidic environments. J. Mol. Liq. 304, 112750 (2020).

Li, H., Qiang, Y., Zhao, W. & Zhang, S. A green Brassica oleracea L. extract as a novel corrosion inhibitor for Q235 steel in two typical acid media. Colloids Surf. A Physicochem. Eng. Asp. 616, 126077 (2021).

Haldhar, R. et al. Investigation of plant waste as a renewable biomass source to develop efficient, economical and eco-friendly corrosion inhibitor. J. Mol. Liq. 335, 116184 (2021).

Haddadi, S. A., Ramazani, S. A. A., Mahdavian, M. & Arjmand, M. Epoxy nanocomposite coatings with enhanced dual active/barrier behavior containing graphene-based carbon hollow spheres as corrosion inhibitor nanoreservoirs. Corros. Sci. 185, 109528 (2021).

Keshmiri, N., Najmi, P., Ramezanzadeh, M. & Ramezanzadeh, B. Designing an eco-friendly lanthanide-based metal organic framework (MOF) assembled graphene-oxide with superior active anti-corrosion performance in epoxy composite. J. Clean. Prod. 319, 128732 (2021).

Wan, S. et al. Soybean extract firstly used as a green corrosion inhibitor with high efficacy and yield for carbon steel in acidic medium. Ind. Crops Prod. 187, 115354 (2022).

Kaya, F., Solmaz, R. & Geçibesler, İH. Adsorption and corrosion inhibition capability of Rheum ribes root extract (Işgın) for mild steel protection in acidic medium: A comprehensive electrochemical, surface characterization, synergistic inhibition effect, and stability study. J. Mol. Liq. 372, 121219 (2023).

Berrissoul, A. et al. Assessment of corrosion inhibition performance of Origanum compactum extract for mild steel in 1 M HCl: Weight loss, electrochemical, SEM/EDX, XPS, DFT and molecular dynamic simulation. Ind. Crops Prod. 187, 115310 (2022).

Ghahremani, P., Tehrani, M. E. H. N., Ramezanzadeh, M. & Ramezanzadeh, B. Golpar leaves extract application for construction of an effective anti-corrosion film for superior mild-steel acidic-induced corrosion mitigation at different temperatures. Colloids Surf. A Physicochem. Eng. Asp. 629, 127488 (2021).

Rathod, M. R., Rajappa, S. K. & Kittur, A. A. Garcinia livingstonei leaves extract influenced as a mild steel efficient green corrosion inhibitor in 1 M HCl solution. Mater. Today Proc. 54, 786–796 (2022).

Yee, Y. P., Saud, S. N. & Hamzah, E. Pomelo peel extract as corrosion inhibitor for steel in simulated seawater and acidic mediums. J. Mater. Eng. Perform. 29, 2202–2215 (2020).

Hynes, N. R. J. et al. Aerva lanata flowers extract as green corrosion inhibitor of low-carbon steel in HCl solution: An in vitro study. Chem. Pap. 75, 1165–1174 (2021).

Haque, J., Verma, C., Srivastava, V. & Nik, W. B. W. Corrosion inhibition of mild steel in 1M HCl using environmentally benign Thevetia peruviana flower extracts. Sustain. Chem. Pharm. 19, 100354 (2021).

Rathod, M. R., Rajappa, S. K., Praveen, B. M. & Bharath, D. K. Investigation of Dolichandra unguis-cati leaves extract as a corrosion inhibitor for mild steel in acid medium. Curr. Res. Green Sustain. Chem. 4, 100113 (2021).

Author information

Authors and Affiliations

Contributions

M.A.: Data Curation, Writing-Original Draft (Surface Characterization Sections), Conceptualization. M.G.: Writing-Original Draft (Electrochemical Sections), Writing-Review & Editing, Methodology. A.R. S.A.: Writing-Review & Editing, Supervision, Resources. M.M.: Writing-Review & Editing, Validation, Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Alimohammadi, M., Ghaderi, M., Ramazani S.A., A. et al. Falcaria vulgaris leaves extract as an eco-friendly corrosion inhibitor for mild steel in hydrochloric acid media. Sci Rep 13, 3737 (2023). https://doi.org/10.1038/s41598-023-30571-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-30571-6

This article is cited by

-

Corrosion protection of mild steel in corrosive media, a shift from synthetic to natural corrosion inhibitors: a review

Bulletin of the National Research Centre (2024)

-

Hexane extract of Persea schiedeana Ness as green corrosion inhibitor for the brass immersed in 0.5 M HCl

Scientific Reports (2024)

-

Evaluation of Glebionis coronaria L. flower extract as a novel green inhibitor for mild steel corrosion in acidic environment

Biomass Conversion and Biorefinery (2024)

-

Recycling of expired ciprofloxacin in synthetic acid rain (SAR) solution as a green corrosion inhibitor for copper: a theoretical and experimental evaluation

Journal of Applied Electrochemistry (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.