Abstract

Biopolymer-based soil treatments have shown effectiveness in soil improvement, with successful field-scale implementation. In this study, we explored the effect of cyclic wetting–drying (W–D) and freezing–thawing (F–T) on the strength durability of biopolymer-treated soils. The results indicate that cyclic W–D and F–T gradually degrade soil strength owing to water adsorption and local biopolymer dilution. Poorly graded sand was highly vulnerable to these weathering effects; however, this problem was mitigated when the soil contained a fines content of 15–25%. These biopolymer-treated soils effectively resisted numerous cycles of both W–D and F–T, indicating that biopolymer-treated soils are suitable for earthen slope reinforcement.

Similar content being viewed by others

Introduction

Recently, geotechnical engineers have attempted to develop biological soil treatment and ground improvement methods to alleviate environmental concerns related to high CO2 emitting cement in geotechnical engineering practices1. Among the sustainable approaches for soil treatment and ground improvement, biopolymer-based soil treatment (BPST) has shown sufficient enhancement of geotechnical engineering properties (e.g., strength, permeability control, and erosion reduction) of soil and successful field-scale implementation2,3,4,5,6. Furthermore, BPST promotes the seed germination, growth, and drought resistance of vegetation due to the high water retention characteristic and organic origin of biopolymers7,8.

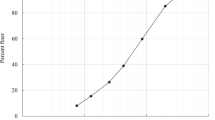

Improved geotechnical engineering properties allow BPST to be an environmentally friendly ground improvement method for soil erosion/scouring prevention and slope surface protection9,10. However, climate-related weathering processes such as cyclic wetting–drying (W–D) and freezing–thawing (F–T) are suspected to reduce the strength of BPST-reinforced soils11. Furthermore, these repetitive weathering conditions can frequently accelerate particle erosion and surface layer detachment, resulting in an unstable vegetative environment. In particular, the heavy rainfall in summer (June to August) and sub-zero temperatures in surface soil during winter (January to February) (Fig. 1) render slope surface reinforcing materials to be inevitably more vulnerable to degradation in South Korea12. To assure the reliability of BPST field application, it is necessary to assess the durability of BPST against fluctuating atmospheric weathering conditions.

Average air and surface temperatures and frequency of rainfall in South Korea (Seoul) from 1981 to 2010. Data from Korea Meteorological Administration (https://www.weather.go.kr).

The ASTM D559 and D560 standard test methods specify the durability assessment methods for soil–cement mixtures exposed to weathering processes, where both standards propose to monitor the mass loss of engineered soil samples after being exposed to 12 cycles of either W–D or F–T13,14. However, sample brushing is vulnerable to the diversity of experimental data acquired by different operators15. In response, the durability of engineered soil mixtures has been assessed by measuring the unconfined compressive strength (qu) to improve accuracy by reducing experimenter errors16,17,18,19,20,21.

Although some research has evaluated the durability of biopolymer-treated soils by measuring qu after exposure to cyclic weathering conditions, previous studies mainly focused on W–D weathering21,22,23,24,25. However, surface soils usually experience repetitive frosting and thawing, severely impacting the stability and erodibility of soil along slopes during winter seasons in the mid-latitude regions of the northern hemisphere26,27. In particular, it has been reported that erosion poses a major risk during the thawing period, where surface runoff can detach particles from the loosened ground surface28. Thus, F–T durability analysis should be assessed for BPST. Furthermore, although the soil composition in BPST enhances strength and workability, these responses have not been sufficiently investigated yet.

Therefore, the main objectives of this study were to investigate whether BPST is affected by cyclic W–D and F–T weathering conditions and suggest a more effective BPST composition as a slope reinforcement material. In detail, this study assessed the durability of xanthan gum (XG) and xanthan gum-starch (XS) biopolymer-treated soils, which were applied via wet spraying to embankment slope construction with different fines contents9. The durability of XG and XS BPST samples exposed to repetitive W–D and F–T cycles was assessed based on qu, weight loss. The effect of soil composition (i.e., fines content) was analyzed under comprehensive accelerated weathering conditions (i.e., cyclic W–D and F–T) to provide a competitive mixing recipe for field applications.

Materials and methods

Materials

Soil binders: biopolymers and cement

This study focused on compounds of two gel-type polysaccharide biopolymers; xanthan gum (XG) and starch (ST). Specifically, XG and ST compounds (XS) are a 3:7 mixture of XG and ST, and this formulation has suggested and verified as a slope-soil reinforcing material in the previous studies8,9,10,29, considering their soil strengthening, vegetation promotion, and cost-effectiveness9. Combining XG (strengthening purpose) with ST (economic feasibility purpose), this recipe addresses field-applicability enhancement of XG-based soil treatment. In this study, we focused on evaluating the strength durability of XS-treated soil in various soil compositions. In addition, the durability of cement treatment, the most widely commercialized soil improvement method, and pure XG treatment condition were compared with that of XS-treated soils. The detail of individual materials is described below.

XG (CAS: 11138-66-2; Sigma-Aldrich), produced by Xanthomonas campestris, is a commonly applied polysaccharide biopolymer in current geotechnical engineering research. XG structure consists of a repeating backbone of 1,4-linked β-d-glucose with side chains composed of two mannose molecules and one glucuronic acid molecule30. XG wells form a viscous hydrogel when dissolved in water due to the negative charge of pyruvic and glucuronic acid groups on the side chains contributing to the binding of water molecules31. XG is commonly used as a thickener in the food, cosmetics, and petroleum industries and as a soil strengthening agent in geotechnical engineering32,33,34.

ST (CAS No. 9005-25-8, Sigma Aldrich), one of the most commercialized biopolymers, consists of amylose and amylopectin. When dissolved in heated (> 90 °C) water, amylose can induce gelation, forming a firm gel when cooled, whereas amylopectin forms swollen granules that increase the fluid’s viscosity35. Several types of ST exist depending on the originated plants (e.g., corn, potato, casaba) and the corresponding ratios of amylose to amylopectin. Because of its cost-effectiveness, combinations of ST and other biopolymers are being investigated for use as soil binding materials36. For example, this study used corn ST, which has approximately 25% amylose, to prepare XG and ST compounds (XS) as strengthening materials for levee slope surfaces9.

Ordinary Portland cement (manufacturer: Eugene Koryeo Cement Co.) was used in this study for comparison with BPST cases. The cement used had a specific gravity of 3.1, an average grain diameter of 14 μm, and a specific surface area of 2800 cm2/g.

Sand and Korean residual soil

Jumunjin sand is a standard sand material in Korea. The sand, which is classified as a poorly graded sand (SP) according to Unified Soil Classification System (USCS) criteria, has a mean particle size (D50) of 0.51 mm and specific gravity (Gs) of 2.65. It has a coefficient of uniformity (Cu) of 1.12, a coefficient of curvature (Cc) of 0.98, and maximum and minimum void ratios (emax and emin) of 0.89 and 0.64, respectively. The particle size distribution is shown in Fig. 2.

Korean residual soil (KRS), also called hwangtoh (in Korean) or red yellow soil, was used to analyze the effect of fines content and simulate in situ soil conditions. KRS is mainly composed of silt with clay and has a Gs of 2.7. KRS is classified as clayey sand (SC) based on its particle size distribution (D50 of 0.07 mm), as shown in Fig. 2. The Atterberg limits of KRS (i.e., liquid limit = 31% and plasticity index = 15) were obtained according to ASTM D4318, as shown in Table 137.

Before specimen preparation, clean sand and KRS were dried in an oven at 110 °C for 24 h. In this study, jumunjin sand and KRS were mixed with XG- and XS biopolymers. By mixing jumunjin sand and KRS with different mass ratios, four soil compositions were prepared according to riverine embankment design standards (Table 1)38. The liquid limit of the prepared sand-KRS mixtures (excluding pure sand) was determined by a fall cone test using a British cone (tip angle 30°, mass 80 g)39,40.

Experimental procedure

Preparation of stabilized soil samples

Dry XS compounds were dissolved in deionized water to obtain mb/mw = 8% (mb/mw = biopolymer-to-water mass ratio) biopolymer hydrogels. Subsequently, the dried soil was uniformly mixed with the biopolymer solution at mw/ms (mass ratio of water to soil) = 25%, resulting in biopolymer to soil contents in mass (mb/ms) of 2% with an initial water content of 25%. This initial water content (i.e., water mixing ratio to soil) is the same for all biopolymer-treated soil samples in this study, based on previous research regarding the compaction test of KRS soil and a case study of field application for XS-treated soil9,41. In the same way, pure XG-treated soil samples were prepared at mb/ms of 1% and 2% for sand. In addition, dry cement was dissolved in deionized water at a water-cement ratio of 2.5:1 and then mixed with sand to achieve a cement content of 10% at an initial water content of 25%, representing a typical soil–cement mixture20. All binder-soil mixtures prepared in this study are summarized in Table 2.

The prepared binder-soil mixtures were poured and tamped into a standard cylindrical PVC mold with an inner diameter of 50 mm and a height of 100 mm (i.e., a length-to-diameter aspect ratio of 2). When biopolymer-treated soil is implemented in a field slope as surface protection layer (i.e., 5–10 mm thickness), it is typically exposed to air and dried out via evaporation. To focus on how cyclic weathering environments degrade the dry strength of biopolymer-treated soil after the biopolymer treatment has provided sufficient strengthening effects through air drying; all specimens were equivalently dried at room temperature (23 °C) for 28 days until the soil sample weight was no longer changed9. The PVC mold was removed after 7 days to ensure adequate drying in all directions. The average initial dry density and water content after 28 days of drying are listed in Table 2. All samples were prepared in triplicate to obtain reliable average strength values.

Cyclic W–D and F–T programs in the laboratory

All samples dried for 28 days were exposed to facilitated weathering conditions: cyclic W–D and F–T processes according to the methods suggested in ASTM D559 and ASTM D560. However, the cycle durations specified in the standards were not rigorously followed, as they were considered too short for the biopolymer-treated soil13,14 (Fig. 3). ASTM D559 defines one W–D cycle as 5 h of sample immersion followed by a sufficient drying process and suggests at least 12 repeated cycles, equivalent to 60 h of cumulative soaking time13. In contrast, this study conducted a W–D cycle of submerging samples in distilled water for 24 h (Fig. 4a), followed by a minimum of 48 h of oven drying at 35 °C until water content reached the previous water content value before immersion, thus simulating a more severe weathering condition. This wetting–drying process was repeated six times, which is equivalent to a total of 144 h of cumulative soaking time.

The F–T cycle consisted of freezing samples at − 23 °C (250.15 K) for 24 h (Fig. 4b) using a laboratory freezing chamber (FMG-300, JEIO Tech.), then thawing for 23 h at 23 °C (room temperature according to ASTM D56014. Both the W–D and F–T processes were repeated six times, and the durability of soils was analyzed in terms of qu and soil weight variation after completing each cycle (Fig. 4c).

Unconfined compression test

Unconfined compression tests were performed to assess the qu and stiffness (E50) after the number of cycles using a universal loading apparatus (HM-5030.3F, Humboldt). The loading rate of the compression tests was set to 1% strain (1 mm) per minute. Before loading onto the machine, all samples were trimmed to flatten the top and bottom surfaces. The samples were then compressed until failure, and the axial load was obtained automatically every 1 s. The qu values were obtained using the maximum axial stress represented in the stress–strain curves. The secant modulus of elasticity (E50) was obtained by measuring the slope between the origin and half of the peak strength (1/2 qu) coordinates for all stress–strain curves.

Scanning electron microscope observation

The microstructures of biopolymer-treated soil were observed using scanning electron microscope (SEM) equipment (JSM-IT800, JEOR, Japan). The crushed samples obtained after unconfined compressive test at each cycle were attached to a 50-mm-diameter SEM mount with carbon conductive tabs. The specimens were coated with osmium (OsO4) for 10 s under vacuum condition using a plasma coater (OPC-60A).

Results and analysis

Strength of unexposed biopolymer-treated soil after 28 days of drying

Figure 5A,B show the stress–strain development, unconfined compressive strength (qu), and secant modulus (E50) of the seven BPST samples dried for 28 days before exposure to the weathering cycle (Table 3). After 28 days of dehydration, the residual water content of all sample cases was less than 2%.

For pure jumunjin sand, X2 (2095 kPa) had the highest initial qu, followed by C10 (1938 kPa), XS2 (1546 kPa), and X1 (1436 kPa) (Fig. 5a). When the XG and XS solution were added to sandy soil, the viscous XG and XS solution contacts the coarse grain surface. They coat the sand particles and form a viscous film that creates bridges between particles34. Afterwards, by permitting water evaporation over the curing period, the air dehydration renders XG and XS hydrogels into condensed and stiff films than can provide higher bonding strength6 (Fig. 6a). The formation of intergranular matrices amongst sand grains dominantly contributed to the increase in the overall qu and E50 of the biopolymer-treated soil. Therefore, the dried biopolymer-treated soil exhibited strength comparable to cement-treated soil, even in cohesionless soil. Furthermore, when dehydrated, a higher XG content was accompanied by a more extensive and thicker XG matrix, causing higher qu and E50 values. Even though X2 treatment of sand results in higher qu than cement treatment, it shows higher ductility with lower stiffness with regard to C10.

The soil composition also affects qu, as it is evident that soil with a higher fines content has higher qu than pure sand with the same XS content. For example, when 15%, 25%, and 50% fines were included in the soil, qu increased by 1.1, 1.2, and 2.3 times, and E50 increased by 1.3, 1.7, and 2.4 times for XS2(15), XS2(25), and XS2(50), respectively (Fig. 5b). It is because XS biopolymer can interact directly with clay particles via electrostatic interactions, hydrogen bonding, and ionic bonds owing to the electrical charges on clay surfaces34. In other words, biopolymer monomers and fine particles combine to form interparticular bridge resulting a formation of dense and tightly-bonded biopolymer-clay matrices, accompanied by conglomeration effect which biopolymer-clay matrices agglomerating sand grains and behaves like secondary grains between sand particles3 (Fig. 6b). Consequently, based on the fact that high dry strength and stiffness are obtained by fine addition at initial state (in an unexposed state), we can anticipate that the fine addition will have a similarly positive effect on the resistance to repeated weathering conditions.

Cyclic W–D responses of biopolymer-treated soil

The responses of the BPST samples exposed to cyclic W–D are presented in Fig. 6. Although XG- and XS-treated pure sands (i.e., X1, X2, and XS2) showed competitive strength compared to cement-treated sands (i.e., C10) before exposure to wetting, the X1, X2, and XS2 cases instantly collapsed during the first submerging process owing to their self-weight (Fig. 7a). Thus, the X1, X2, and XS2 conditions were inappropriate for evaluation in the following W–D cycles. When biopolymer-treated pure sand was dehydrated, biopolymers as gel phase filling the pores shrunk and shifted to tensile biofilm, resulting in an interconnected grain structure with voids34. Water permeates into the pores when the dried samples are immersed, causing the biopolymer to swell (i.e., a phase shift to a viscous hydrogel state occurs)42. The significant swelling caused by the rehydration process, which is mainly induced by the hydrophilicity of the biopolymer, deteriorates the bonding strength, causing samples to collapse under their self-weight.

Response to exposure under W–D cycles. (a) The collapse of XS2 samples at the first wetting. (b) Crack development in XS2(50) after the second W–D cycle. (c) XS2(50) splitting into fragments after repetitive swelling and shrinkage (after the sixth cycle). Stress–strain curves after cyclic W–D (1–6 cycles) of (d) XS2(15), (e) XS2(25), (f) XS2(50), and (g) C10.

After repeated W–D cycles, the maximum axial stress values decreased, and the strain corresponding to the maximum axial stress value increased in the other BPST and cement treatment cases (Fig. 7d–g). Specifically, XS2(15) and XS2(25) exhibited higher ductility with increased failure strain (i.e., more than 1% strain) (Fig. 7d,e), which implies that the cyclic disturbances of the biopolymer film increase the possibility of high ductility and strain softening of biopolymer-treated soil23. Similar to XS2(15) and XS2(25), XS2(50) showed a rapid reduction in peak stress, whereas the failure strain decreased, implying lower ductility (Fig. 7f). This happened due to the cracks observed after repeated cycles (Fig. 7b,c). In contrast to the biopolymer-treated soils, C10 maintained relatively brittle behavior after cyclic W–D, with failure occurring at approximately 1% strain (Fig. 7g).

Figure 8 presents the qu and E50 after the first to sixth W–D cycles. The qu values of all specimens gradually decreased with the number of W–D cycles (Fig. 8a). In particular, XS2(50), which maintained the highest qu (2765 kPa) up to the first cycle, exhibited a sharp decrease after the second cycle. Meanwhile, the qu values of C10, XS2(15), and XS2(25) gradually decreased up to the sixth cycle, whereas these samples maintained a higher qu than that of XS2(50) after the second cycle. After the sixth W–D cycle, the qu was the highest in C10, followed by XS2(15), XS2(25), and XS2(50). The qu values of XS2(15) and XS2(25) satisfied the strength requirement (above 490 kPa) for maintaining vegetation on slope surfaces recommended by the Ministry of Land, Infrastructure, and Transport (MOLIT) of South Korea, even after six cycles43. Furthermore, the E50 deterioration of XS2(15) and XS2(25) mainly occurred during the first cycle and became constant after the first cycle (Fig. 8b). In contrast, the E50 value of XS2(50) showed a continuous decrease with W–D cycles, showing a tendency similar to the qu results.

As previously shown in Fig. 7b,c, a rapid qu deterioration of XS2(50) was observed due to cracks developed on the surface of the samples despite their high initial strength. During the drying process, cracks are generated on the surface of XS2(50) owing to the extreme shrinkage and swelling caused by moisture loss and absorption. The XG biopolymer has a natural affinity toward the water, originating from the anionic side chains in its molecular structure30. Thus, biopolymer-treated soils, especially those that include fines, would attract and retain more moisture within the soil matrix through synergetic effects with clay activity44. This characteristic was expected to contribute to more shrinkage, especially in XS2(50), with more fines content. Once a crack occurs on the surface, swelling and shrinkage could be accelerated because water could easily penetrate the samples and react with a larger specific surface than before. With the growth of surface cracks, the XS2(50) samples were eventually split into several fragments, resulting in a qu less than 1/36 times (after the fourth cycle) the initial strength.

Figure 9 presents the cumulative soil loss with respect to the initial weight of each sample during the repetition of the W–D process. By the end of the sixth W–D cycle, the XS2(25) samples showed the least weight loss of 1.5%, whereas XS2(15) and XS2(50) showed losses of 4% and 4.5%, respectively. XS2(15) and XS2(50) exhibited detachment of coarse particles at the surface during the submerging process, which indicates that the biopolymer film diluted by repeated exposure to moisture gradually lost its soil binding capabilities. The soil loss that occurred in XS2(50) originated from the detachment at the periphery of the cracks rather than the overall surface. However, all XS-treated soils demonstrated allowable soil loss based on criteria from the Portland Cement Association (i.e., maximum allowable mass loss of 14% for SP, SC soils) and the United States Army Corps of Engineers (i.e., loss less than 8% for granular soil with a plasticity index above 10)45,46.

Figure 10 shows the correlation between the cumulative soil loss amount and qu of the biopolymer-treated soil after each cycle. The qu—soil loss showed an exponential correlation with high R2 values, which aligns with the observations of Baghadadi and Shihata15. However, it was demonstrated that biopolymer-treated soil, including soils with large fines (e.g., XS2(50)), can present a biased correlation due to the severe damage through crack generation after six cycles. Thus, the conventional W–D durability evaluation methodologies for soil–cement could be appropriate for biopolymer-treated soil, which includes a 15–25% fraction of fines.

Cyclic F–T responses of biopolymer-treated soil

Figure 11 presents the axial stress–strain curve of all stabilized soils after the repetitive F–T process. As the number of F–T cycles increased, the maximum axial stress values decreased, and the strain corresponding to the maximum axial stress increased (i.e., strain softening) in all stabilized soils (Fig. 11a–g). Although biopolymer-treated pure sands (i.e., X1, X2, and XS2) experienced severe disturbance at the beginning of the W–D process, they exhibited higher resistance against the F–T process without any disturbance compared to the corresponding samples under the W–D weathering condition (Fig. 11a–c). The BPST samples with higher XG content showed more brittle behavior than those with lower XG content at the initial stage, whereas the failure strain increased to over 2% after F–T cycles in both X1 and X2, demonstrating increased ductility as the number of F–T cycles increased. On the other hand, all XS-treated soils presented a strain-softening tendency similar to the others, but the degree of failure strain change between 0 and 6 cycles decreased under higher fines content conditions (Fig. 11c–f). C10 still showed less strain-softening behavior with a smaller failure strain (i.e., approximately 1% of strain) than the biopolymer-treated soils, similar to the W–D result (Fig. 11g). However, the variation in peak stress by the F–T cycle was within the range corresponding to that of biopolymer-treated soils, indicating that the biopolymer-treated soil is competitive with cement-treated soil in terms of F–T resistance performance.

The qu and E50 after each F–T cycle, as shown in Fig. 12, decreased linearly as the number of F–T cycles increased. XS2(50), X2, and XS2(25) maintained higher qu (3203, 1728, and 1507 kPa) than C10 (1400 kPa) after six cycles, in contrast to the W–D responses. The other biopolymer-treated soils (XS2(15), XS2, and X1) also satisfied the strength requirement (above 490 kPa) recommended for slope stabilization in Korea43. Furthermore, the stiffness of the biopolymer-treated soil showed a slight decrease in the same manner as qu. The residual E50 of the biopolymer-treated soil after the F–T process had a range smaller than that of the cement-treated soil, except for XS2(50).

The cumulative weight loss trends of the XS-treated soils are shown in Fig. 13. The cumulative soil loss was less than 0.5%, which was less significant than the W–D results, reaching 5% mass loss. A small amount of weight loss occurred in every XS-treated soil after the first and second cycles, but the sample weights slightly increased as the number of F–T cycles increased after the third cycle. This marginal increase in weight could be due to the moisture condensation that occurred on the surface of the samples during freezing. Thus, a correlation between the residual strength and cumulative loss was not observed in the F–T process.

Discussion

The durability index (DI) and strength reduction ratio (SRR) (i.e., SRR = 1 − DI) were considered to analyze the effect of W–D and F–T cycles on the strength characteristics and durability of biopolymer-treated soils. The durability index (DI) is the percentage determined by dividing the qu that remained after the desired number of W–D or F–T cycles by that of an identical specimen subjected to only 28 days of curing47;

where qu,N = UCS after N times of cycles; and qu,0 = UCS before exposure to cycles.

Figure 14a,b present the DI and SRR of XS2 treated soils under W–D, respectively. As mentioned above, the X1, X2, and XS2 samples were excluded because of bulk collapse in the early W–D stages (Fig. 7a). Under W–D weathering conditions, the biopolymer-treated soil generally exhibited unsatisfactory durability performance compared to cement-treated soil. In particular, it showed larger vulnerability in pure sand, and pure KRS which has 50% of clay fraction. Those results is deeply related to the hydrophilic nature of the biopolymer itself, accompanied with high moisture absorption capacity (i.e., higher moisture buffering values) compared to cement48.

In pure sand, moisture attraction results in strength deterioration via swelling and local dilution at outermost of biopolymer layer, hindering the viscous biopolymer gel from binding soil particles23. Especially, since the electrostatic interaction between sand particles and biopolymer is small, it can be expected that strength degradation is mainly induced by particle detachment at the interface with water (outermost part) when implementing XS biopolymer treatment with poorly graded sand for slope protection.

In pure KRS soil (XS2(50)), although it had the highest initial qu, cracks gradually emerged and showed a significantly low DI of approximately 2%. This deterioration behavior is mainly caused by severe swelling and shrinkage induced by synergetic water absorption of both biopolymer and clay activity33,49. Therefore, when we implemented slope protection layer using XS biopolymer treatment with fine-rich soil, there is a potential of bulk cracking in layer or the detachment and sliding failure of layer itself to occur at the field.

Meanwhile, it confirmed that those vulnerability can be mitigated at soil with 15% and 25% of fine fraction. XS2(15) and XS2(25) showed 37% and 34% DI values after six W–D cycles, and the SRR decreased from 100% (in pure sand) to less than 18% and 13%, respectively, after the first cycle (Fig. 14a,b). Although repeated W–D process induces outward weathering on XS-clay matrices partially, it can be seen that conglomeration with sand grains is maintained after W–D cycles, showing a durability index of about 35% (Fig. 15a).

In the F–T process, the DI of all biopolymer-treated soils showed a gradual decrease, maintaining a range of 72–90% after six cycles (Fig. 14c). Compared to the cement-treated soil retaining 80% DI, the biopolymer-treated soils exhibited competitive durability under F–T weathering conditions. In particular, the addition of fines content remarkably improved F–T durability by reducing the SRR from 28% (in pure sand) to 10% (in XS2(50)) after six F–T cycles (Fig. 14d).

Typically F–T durability of stabilized soil (engineered soil) is dominantly affected by the moisture state (i.e., free water in pores), which is related to volume expansion due to ice formation28,50. When freezing occurs, the remaining water in the stabilized soil increases in volume by approximately 9%51. When the frozen fluids in the pore space expand and reach the available free space in the pore, hydraulic pressure is applied to the stabilized soil matrix, accompanied by a gradual increase in pore size and bond breakage between the binding agent and soil particles50,51,52. However, the biopolymer-treated soils evaluated in this study, dehydrated over 28 days, lost most of the free water occupying the pores through evaporation, resulting in residual water content retention in the range of 0.6–1.7%, as shown in Table 2 (i.e., reduced by 93–98% from the initial water content of 25%). Therefore, disturbance of the soil matrix owing to expanding ice formation in the pore space is tenuous in dried samples. Instead, abrasion on the XS biopolymer-clay matrices could occur the gradual degradation of strength and stiffness. The strength reduction and ductility change under F–T could be attributed to the cumulative abrasion and weakening at biopolymer-clay matrices, which associated by condensed water (i.e., fresh moisture) during each freezing period at surface of the sample (Fig. 15b).

From the comprehensive results of W–D and F–T in this study, it can be noted that SC (clayey sand according to the Unified Soil Classification System) soil containing 15–25% fines content is advantageous for the long-term durability of biopolymer-treated soil. In addition, river design standards in Korea classify soil composition for embankment construction into three grades (I, II, and III), considering leakage resistance and crack prevention. The standards stipulate that a grade I or II soil composition should be utilized for embankment construction38. The suggested soil composition from this study satisfied the grade II specification (i.e., well-graded soil with a plasticity index in the range of 7–15), as shown in Table 1. Therefore, it is expected that the slope protection method using biopolymer-treated soil will be sufficiently competitive in terms of strength and durability performance when using SC soil.

However, although the strength and soil loss evaluated in this study are general indicators for assessing the durability of stabilized soil, this controlled environment has not fully demonstrated an in situ climatically degrading environments. Thus, further studies on real weathering effects should be conducted to predict the performance and stability of biopolymer-treated soil in the field. In addition, natural environments contain many microorganisms that may affect the biological stability of biopolymer-treated soil. Therefore, biological degradation due to microbial activity requires further study.

Conclusion

In this study, the comprehensive strength durability of xanthan gum-based biopolymer-treated soils under cyclic W–D and F–T cycles was evaluated via a series of laboratory experiments. Cyclic W–D of biopolymer-treated soils gradually degrades the strength and stiffness of the soils owing to a high degree of swelling resulting from hydrophilicity during W–D conditions. The vulnerability was very high, particularly in poorly graded sand. However, the resistance to strength deterioration was effectively enhanced when the soil had a certain fines content (15–25%). Meanwhile, strength degradation and soil loss caused by cyclic F–T in a sufficiently dehydrated state were less severe than those caused by W–D, demonstrating competitive performance compared to cement-treated soil. Because 15–25% fine-containing soil shows sufficiently positive effects in both W–D and F–T, satisfying the soil properties in the design criteria for the earthen levee, it is suitable to use biopolymer-treated soil as an earthen slope reinforcement material. However, further studies on durability under natural climate weathering conditions should be conducted to predict long-term performance based on these laboratory results.

Data availability

All the experimental data that support the findings of this study are available from the corresponding author upon reasonable request through email.

References

Chang, I., Im, J. & Cho, G. C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 8, 251. https://doi.org/10.3390/su8030251 (2016).

Chang, I., Im, J. & Cho, G.-C. Geotechnical engineering behaviors of gellan gum biopolymer treated sand. Can. Geotech. J. 53, 1658–1670. https://doi.org/10.1139/cgj-2015-0475 (2016).

Chang, I. & Cho, G.-C. Shear strength behavior and parameters of microbial gellan gum-treated soils: From sand to clay. Acta Geotech. 14, 361–375. https://doi.org/10.1007/s11440-018-0641-x (2019).

Lee, M., Im, J., Chang, I. & Cho, G.-C. Evaluation of injection capabilities of a biopolymer-based grout material. Geomech. Eng. 25, 31–40. https://doi.org/10.12989/gae.2021.25.1.031 (2021).

Kwon, Y.-M., Ham, S.-M., Kwon, T.-H., Cho, G.-C. & Chang, I. Surface-erosion behaviour of biopolymer-treated soils assessed by EFA. Geotech. Lett. 10, 1–7. https://doi.org/10.1680/jgele.19.00106 (2020).

Chang, I. et al. Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Trans. Geotech. 24, 100385. https://doi.org/10.1016/j.trgeo.2020.100385 (2020).

Chang, I., Prasidhi, A. K., Im, J., Shin, H.-D. & Cho, G.-C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 253–254, 39–47. https://doi.org/10.1016/j.geoderma.2015.04.006 (2015).

Tran, A. T. P., Chang, I. & Cho, G.-C. Soil water retention and vegetation survivabiity improvement using microbial biopolymers in drylands. Geomech. Eng. 17, 475–483. https://doi.org/10.12989/gae.2019.17.5.475 (2019).

Seo, S. et al. Site application of biopolymer-based soil treatment (BPST) for slope surface protection: In-situ wet-spraying method and strengthening effect verification. Const. Build. Mater. 307, 124983. https://doi.org/10.1016/j.conbuildmat.2021.124983 (2021).

Ko, D. & Kang, J. Experimental studies on the stability assessment of a levee using reinforced soil based on a biopolymer. Water 10, 1059. https://doi.org/10.3390/w10081059 (2018).

Khoury, N. & Zaman, M. Environmental effects on durability of aggregates stabilized with cementitious materials. J. Mater. Civ. Eng. 19, 41–48. https://doi.org/10.1061/(ASCE)0899-1561(2007)19:1(41) (2007).

Kim, J., Jeong, S. & Regueiro, R. A. Instability of partially saturated soil slopes due to alteration of rainfall pattern. Eng. Geol. 147, 28–36. https://doi.org/10.1016/j.enggeo.2012.07.005 (2012).

ASTM. D559/D559M-15 Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures (ASTM International, 2015).

ASTM. D560/D560M-16 Standard Test Methods for Freezing and Thawing Compacted Soil-Cement Mixtures (ASTM International, 2016).

Shihata, S. & Baghdadi, Z. Long-term strength and durability of soil cement. J. Mater. Civ. Eng. 13, 161–165. https://doi.org/10.1061/(ASCE)0899-1561(2001)13:3(161) (2001).

Dempsey, B. J. & Thompson, M. R. Vacuum saturation method for predicting freeze-thaw durability of stabilized materials. Highway Res. Rec. 442, 44–57 (1973).

Baghdadi, Z. & Shihata, S. On the durability and strength of soil–cement. Proc. Inst. Civ. Eng. Ground Improv. 3, 1–6. https://doi.org/10.1680/gi.1999.030101 (1999).

Kamei, T., Ahmed, A. & Shibi, T. Effect of freeze–thaw cycles on durability and strength of very soft clay soil stabilised with recycled Bassanite. Cold Reg. Sci. Technol. 82, 124–129. https://doi.org/10.1016/j.coldregions.2012.05.016 (2012).

Sahoo, J. P. & Pradhan, P. K. Effect of lime stabilized soil cushion on strength behaviour of expansive soil. Geotech. Geol. Eng. 28, 889–897. https://doi.org/10.1007/s10706-010-9332-6 (2010).

Neramitkornburi, A. et al. Durability against wetting–drying cycles of sustainable lightweight cellular cemented construction material comprising clay and fly ash wastes. Constr. Build. Mater. 77, 41–49. https://doi.org/10.1016/j.conbuildmat.2014.12.025 (2015).

Soldo, A., Miletić, M. & Auad, M. L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 10, 267. https://doi.org/10.1038/s41598-019-57135-x (2020).

Wen, K. et al. Mechanical behaviors of hydrogel-impregnated sand. Constr. Build. Mater. 207, 174–180. https://doi.org/10.1016/j.conbuildmat.2019.02.141 (2019).

Chang, I., Im, J., Lee, S.-W. & Cho, G.-C. Strength durability of gellan gum biopolymer-treated Korean sand with cyclic wetting and drying. Constr. Build. Mater. 143, 210–221. https://doi.org/10.1016/j.conbuildmat.2017.02.061 (2017).

Im, J., Chang, I. & Cho, G.-C. Effects of malonic acid crosslinked starch for soil strength improvement. Trans. Geotech. 31, 100653. https://doi.org/10.1016/j.trgeo.2021.100653 (2021).

Reddy, J. J. & Varaprasad, B. Long-term and durability properties of xanthan gum treated dispersive soils—An eco-friendly material. Mater. Today Proc. 44, 309–314. https://doi.org/10.1016/j.matpr.2020.09.472 (2021).

Cohen, J. et al. Recent Arctic amplification and extreme mid-latitude weather. Nat. Geosci. 7, 627–637. https://doi.org/10.1038/ngeo2234 (2014).

Ferrick, M. & Gatto, L. W. Quantifying the effect of a freeze–thaw cycle on soil erosion: Laboratory experiments. Earth Surf. Process. Landf. 30, 1305–1326. https://doi.org/10.1002/esp.1209 (2005).

Kværnø, S. H. & Øygarden, L. The influence of freeze–thaw cycles and soil moisture on aggregate stability of three soils in Norway. CATENA 67, 175–182. https://doi.org/10.1016/j.catena.2006.03.011 (2006).

Kang, W., Ko, D. & Kang, J. Erosion resistance performance of surface-reinforced levees using novel biopolymers investigated via real-scale overtopping experiments. Water 13, 2482 (2021).

García-Ochoa, F., Santos, V., Casas, J. & Gomez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 18, 549–579. https://doi.org/10.1016/S0734-9750(00)00050-1 (2000).

Casas, J. A., Mohedano, A. F. & García-Ochoa, F. Viscosity of guar gum and xanthan/guar gum mixture solutions. J. Sci. Food Agric. 80, 1722–1727. https://doi.org/10.1002/1097-0010(20000915)80:12%3c1722::AID-JSFA708%3e3.0.CO;2-X (2000).

Imeson, A. Thickening and Gelling Agents for Food 1st edn. (Springer, 1992).

Cabalar, A., Wiszniewski, M. & Skutnik, Z. Effects of xanthan gum biopolymer on the permeability, odometer, unconfined compressive and triaxial shear behavior of a sand. Soil Mech. Found. Eng. 54, 356–361. https://doi.org/10.1007/s11204-017-9481-1 (2017).

Chang, I., Im, J., Prasidhi, A. K. & Cho, G.-C. Effects of xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 74, 65–72. https://doi.org/10.1016/j.conbuildmat.2014.10.026 (2015).

Eliasson, A.-C. Starch in Food: Structure, Function and Applications (CRC Press, 2004).

Kulshreshtha, Y., Schlangen, E., Jonkers, H., Vardon, P. & Van Paassen, L. Corncrete: A corn starch based building material. Constr. Build. Mater. 154, 411–423. https://doi.org/10.1016/j.conbuildmat.2017.07.184 (2017).

ASTM. D4318-05 Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils (ASTM International, 2007).

Ministry of Land Transportation and Maritime Affairs (MLTM). River Design Criteria South Korea (MLTM, 2009).

BSI. EN ISO 17892–1: Geotechnical Investigation and Testing—Laboratory Testing of Soil. Determination of Water Content (British Standard Institute, 2014).

Budhu, M. The effect of clay content on liquid limit from a fall cone and the british cup device. Geotech. Test. J. 8, 91–95. https://doi.org/10.1520/GTJ10515J (1985).

Chang, I. & Cho, G.-C. Geotechnical behavior of a beta-1,3/1,6-glucan biopolymer-treated residual soil. Geomech. Eng. 7, 633–647. https://doi.org/10.12989/gae.2014.7.6.633 (2014).

Lee, S., Chang, I., Chung, M.-K., Kim, Y. & Kee, J. Geotechnical shear behavior of xanthan gum biopolymer treated sand from direct shear testing. Geomech. Eng. 12, 831–847. https://doi.org/10.12989/gae.2017.12.5.831 (2017).

Ministry of Land Infrastructure and Transport (MOLIT). Greening Construction on Road Slope: Design and Construction Guideline, South Korea (2009).

Bai, Y. et al. Mechanical behavior of polymer stabilized sand under different temperatures. Constr. Build. Mater. 290, 123237. https://doi.org/10.1016/j.conbuildmat.2021.123237 (2021).

Portland Cement Association (PCA). Soil-Cement Laboratory Handbook (PCA, 1992).

Naval Facilities Engineering Systems Command (NAVFAC). Design Manual DM7-02: Foundation and Earth Structures (Department of the Navy (US), 1986).

Kamei, T., Ahmed, A. & Ugai, K. Durability of soft clay soil stabilized with recycled Bassanite and furnace cement mixtures. Soils Found. 53, 155–165. https://doi.org/10.1016/j.sandf.2012.12.011 (2013).

Muguda, S. et al. Durability and hygroscopic behaviour of biopolymer stabilised earthen construction materials. Constr. Build. Mater. 259, 119725. https://doi.org/10.1016/j.conbuildmat.2020.119725 (2020).

Kwon, Y.-M., Chang, I., Lee, M. & Cho, G.-C. Geotechnical engineering behaviors of biopolymer-treated soft marine soil. Geomech. Eng. 17, 453–464. https://doi.org/10.12989/GAE.2019.17.5.453 (2019).

Pilehvar, S. et al. Effect of freeze–thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 200, 94–103. https://doi.org/10.1016/j.conbuildmat.2018.12.057 (2019).

Gowthaman, S., Nakashima, K. & Kawasaki, S. Freeze–thaw durability and shear responses of cemented slope soil treated by microbial induced carbonate precipitation. Soils Found. 60, 840–855. https://doi.org/10.1016/j.sandf.2020.05.012 (2020).

Aygörmez, Y., Canpolat, O., Al-mashhadani, M. M. & Uysal, M. Elevated temperature, freezing–thawing and wetting–drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 235, 117502. https://doi.org/10.1016/j.conbuildmat.2019.117502 (2020).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) Grants funded by the Korean government (MSIT) (No. 2022R1A2C2091517 and 2017R1A5A1014883), and the first author is supported by Innovative Talent Education Program for Smart City funded by the Ministry of Land, Infrastructure and Transport (MOLIT) of the Korean government.

Author information

Authors and Affiliations

Contributions

M.L. contributed to methodology, validation, investigation, data curation, visualization and writing the original draft. Y.M.K. contributed to investigation, review and editing the draft. D.Y.P. contributed to investigation and data curation. I.C. contributed to conceptualization, validation, review and editing, and supervision. G.C.C. contributed conceptualization, resources, supervision, and project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, M., Kwon, YM., Park, DY. et al. Durability and strength degradation of xanthan gum based biopolymer treated soil subjected to severe weathering cycles. Sci Rep 12, 19453 (2022). https://doi.org/10.1038/s41598-022-23823-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-23823-4

This article is cited by

-

Xanthan biopolymer-based soil treatment effect on kaolinite clay fabric and structure using XRD analysis

Scientific Reports (2023)

-

A review of the use of bio-based substances in soil stabilization

Environment, Development and Sustainability (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.