Abstract

Tunnel oxide passivated contacts (TOPCon) embedding a thin oxide layer between polysilicon and base crystalline silicon have shown great potential in the development of solar cells with high conversion efficiency. In this study, we investigate the formation mechanism of hole-carrier selective contacts with TOPCon structure on n-type crystalline silicon wafers. We explore the thermal annealing effects on the passivation properties in terms of the stability of the thermally-formed silicon oxide layer and the deposition conditions of boron-doped polysilicon. To understand the underlying principle of the passivation properties, the active dopant in-diffusion profiles following the thermal annealing are investigated, combined with an analysis of the microscopic structure. Based on PC1D simulation, we find that shallow in-diffusion of boron across a robust tunnel oxide forms a p–n junction and improves the passivation properties. Our findings can provide a pathway to understanding and designing high-quality hole-selective contacts based on the TOPCon structure for the development of highly efficient crystalline silicon solar cells.

Similar content being viewed by others

Introduction

To achieve high conversion efficiency in crystalline silicon (c-Si) solar cells, the carrier selective contacts are of considerable importance in suppressing the recombination current (J0) of the minority carriers and gaining a high open-circuit voltage (VOC)1,2,3,4,5,6,7,8. Among a wide range of approaches, the tunnel oxide passivated contacts (TOPCon) are promising candidates because of their low recombination loss and high carrier selectivity with a high conversion efficiency of 25.7%5. The TOPCon structure, which introduces a buffer layer of tunnel oxide between heavily-doped polysilicon (poly-Si) and the base wafer, exhibits high-quality passivation owing to an indirect metal contact with the c-Si wafer, one-dimensional current flow, and tunneling-based carrier selectivity2,3,4,5,6,7,8.

In the case of the electron-selective TOPCon, it was proposed that the different band offsets between Si and SiO2 (4.7 eV for the valence band and 3.2 eV for the conduction band) offer asymmetric tunnel barriers for the electrons and holes, which provide effective electron-selective contacts9,10. However, it has been reported that the tunnel mechanism is not the only working principle in the TOPCon structure; conduction via pinholes or/and nanopits within the oxide layer must also be considered10,11,12,13. Furthermore, for better carrier transport, post-deposition annealing at an optimal temperature is required to promote the moderate pinhole/nanopit density and to reduce the interface state density induced by the saturation of SiOx6,11,12,13,14,15,16. If the annealing temperature is excessively high, the tunnel oxide is no longer stable because of the formation of highly dense pinholes/nanopits11,12,13,14,15,16 and introduction of redundant dopant in-diffusion into the c-Si substrate3,4,17,18. The latter increases the recombination loss of the minority carriers owing to the Auger recombination rate and deficient electronic band bending3,4,17,18.

In contrast to the electron-selective TOPCon, studies on hole-selective contacts are limited, and the passivation quality is relatively poorer than that of the electron counterpart due to the recombination loss via B-O complex defects2,19,20,21,22,23,24,25,26,27,28,29,30,31. Although the traditional tunneling-based interpretation indicates that the hole-selective contacts seem to be inefficient, studies have reported on their high implied VOC (iVOC) of approximately 720 mV and low recombination current that is less than 10 fA cm-221,23,25. For example, the replacement of B-doped poly-Si with Ga-doped poly-Si prevents the formation of the B-O complex defects with the achievement of a high iVOC of 731 mV21. The substitution of AlOx to SiOx achieved an iVOC of 723 mV and J0 of 6.6 fA cm−2 due to the high negative space charge density of AlOx25. Similar to the electron-selective contacts, the hole-selective contacts require the stability of the tunnel oxide layer for chemical passivation and shallow in-diffusion for field-effect passivation30,31. However, the underlying formation mechanism of the hole-carrier selectivity via thermal annealing and the microscopic structure have not yet been satisfactorily explained. In these regard, we investigated the passivation properties of the hole-selective contacts based on the TOPCon structure under thermal annealing. We examined the microstructural evolution to directly observe the annealing effect on the tunnel oxide and passivation under different deposition conditions of the B-doped poly-Si. Active boron in-diffusion profiles were studied to understand the influence on the electronic band structure under thermal annealing combined with PC1D simulation. Our studies reveal that the structural stability of the tunnel oxide and the p–n junction formed across the tunnel oxide are essential to improve the passivation properties.

Results and discussion

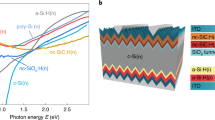

Effect of thermal annealing on passivation

We prepared the tunnel oxide passivated hole contacts as a symmetric structure on an n-type c-Si, as shown in Fig. 1a. The thermal oxidation process was used to induce a silicon oxide (SiOx) layer as a nominal tunneling barrier. Subsequently, B-doped poly-Si was deposited using the low-pressure chemical vapor deposition (LPCVD) method to ensure a blister-free contact32,33,34. The detailed sample preparation procedures are illustrated in Fig. 1b and described in the section “Methods”.

To assess the thermal stability of the tunnel oxide, we prepared two groups of samples with 1.2-nm-thick and 1.5-nm-thick SiOx layers while the p-type poly-Si was deposited at a temperature of 510 °C and gas flow rate ratio (R) of 0.5 (where R ≡ [B2H6]/[SiH4] in a mixture of diborane (B2H6) and silane (SiH4) precursor gases). Subsequently, the samples were annealed at various temperatures in the range of 750–1000 °C under a nitrogen ambient environment for 30 min. To examine the passivation properties, we extracted iVOC and J0 using the quasi-steady-state photoconductance (QSSPC) method.

Figure 2a shows the variation of iVOC with respect to the post-deposition annealing temperatures (TPDA) for different thicknesses of the SiOx layers. Compared to the as-deposited samples, the passivation characteristics under the thermal annealing process showed an improvement in iVOC for all samples. This is attributed to the enhanced crystallinity of the poly-Si layer and field-effect passivation by the dopant in-diffusion and activation as well as the reduced interface state density2,14,17,18,30,31. For both groups of samples, as TPDA was increased, iVOC increased and reached the maximum; subsequently, iVOC decreased for higher TPDA. The maximum iVOC was obtained at 800 °C for the samples with the 1.2-nm-thick SiOx layer and at 950 °C for the samples with the 1.5-nm-thick SiOx layer. The relevant opposite trends could be observed for J0 for both samples. For the samples with the 1.2-nm-thick SiOx, J0 was higher for TPDA ≥ 800 °C whereas, for the samples with the 1.5-nm-thick SiOx, the J0 was minimum at TPDA = 950 °C and increased slightly at TPDA = 1000 °C. We could not obtain J0 for TPDA < 800 °C due to high fitting errors by low lifetime of the minority carriers (Fig. S1).

Thermal stability of tunnel oxide

To correlate the observed passivation properties to the microstructure of the SiOx layers, we obtained cross-sectional transmission electron microscope (TEM) images of the interfacial regions of the poly-Si and c-Si, as shown in Fig. 3. The top and bottom sides of each image correspond to the poly-Si layer and c-Si wafer region, respectively, and the thin bright layer between the poly-Si and wafer corresponds to the thermally grown SiOx layer. In the as-deposited samples, the SiOx layers had a nearly uniform interface with approximately homogeneous thicknesses; thus, the thicknesses of the SiOx layers could be estimated. The normally indicated ‘poly-Si layer’ appeared to be in amorphous phase, as confirmed in a fast Fourier transformed (FFT) image of the red-boxed area in the inset of Fig. 3a. After the thermal annealing, the poly-Si layers showed better crystallinity, as confirmed with the clear diffraction patterns in the FFT image of Fig. 3b, which would improve the passivation properties compared to that of the as-deposited states.

TEM images of the cross-sectional structures around the SiOx layers in as-deposited states, annealed at 850 °C, 900 °C, 950 °C, and 1000 °C for the samples with (a)–(e) 1.2-nm-thick SiOx layers and (f)–(j) 1.5-nm-thick SiOx layers. The FFT images in (a) and (b) were obtained from the red-boxed regions.

Notably, the degradation of the oxide layer was clearly observable for the sample with the 1.2-nm-thick SiOx layer, where the bright oxide layer modulated, and was disrupted for the samples annealed at TPDA = 900 °C. For the sample annealed at TPDA ≥ 950 °C, the oxide layer had severe damages and an irregular morphology. Meanwhile, a uniform and robust 1.5-nm-thick SiOx layer was observed except at TPDA ≥ 950 °C, where the thickness of the SiOx layer was partially reduced and inhomogeneous in accordance with our previous study15. Thickness reduction can be ascribed to the production of a volatile SiO phase through the annealing process at high temperature in a nitrogen environment produced by the reaction process of SiO2 (s) + Si (s) → 2 SiO (g), where s and g denote the solid and gaseous phases, respectively35,36. In addition, the growth of the voids/pinholes formed and epitaxial recrystallization of the poly-Si induce the modulation of morphology with the increase of interface defect density by the direct contacts between poly-Si and c-Si37,38. Considering the different thicknesses and expected higher oxygen stoichiometry for the thicker SiOx layers, a relatively robust SiOx layer could be observed for the 1.5-nm-thick layer since the nascent void formation rate for the 1.5-nm-thick SiOx layer was slower than that of the 1.2-nm-thick layer. Further studies will be required to quantify the void/pinhole/nanopit density.

The results of the microstructural analysis were consistent with macroscopic passivation properties observed in Fig. 2, which led us to the conclusion that the structural instability deteriorated the passivation characteristics showing the increase of J0 and decrease of iVOC. Therefore, optimal thickness is required considering thermal stability and carrier transport through oxide layers14.

Effect of thermal annealing on passivation under different poly-Si growth conditions

In order to optimize the hole-selective contacts and investigate the effects of thermal annealing, we explored the passivation properties with respect to the deposition conditions while maintaining the thickness of the SiOx layers at 1.5 nm. We first modulated the gas flow rate ratio (R) to fabricate the poly-Si layers at a growth temperature (TG) of 530 °C using the LPCVD method and annealed the samples at a temperature range of 750–1000 °C. Because a higher R corresponds to a higher amount of boron involved during the deposition, higher boron concentration in the poly-Si was expected and reflected in the decrease of sheet resistance (Fig. S2). Subsequently, we extracted the iVOC to test the passivation quality of each sample.

Figure 4a shows the extracted iVOC for the samples with different R. As discussed before, thermal annealing improved the passivation quality for all samples. For TPDA < 950 °C, the annealed samples grown under higher R had higher passivation properties. Meanwhile, the improvement of passivation by the higher R slowed down as TPDA was further increased. Furthermore, at TPDA = 950 °C, iVOC of all the samples had marginal differences with the highest value at R = 0.5 rather than at R = 0.6. At TPDA = 1000 °C, the reduction of iVOC and a different tendency with respect to R were observed. The reduced passivation is associated with the damaged tunnel oxide layer, as observed in Fig. 3. The dependency to R may be related to the enhanced built-in electric field generated by the high doping ratio around the tunnel barrier. Strong built-in fields improve passivation properties and the transport of carriers across the tunnel oxide.

Next, we explored the passivation properties with respect to TG at R = 0.5, as shown in Fig. 4b. The thermal treatment improved the passivation as before and a lower TG offered a better passivation effect for TPDA < 950 °C. The improvement at low growth temperature can be ascribed to the lower activation energy of the B2H6 decomposition than that of SiH4, resulting in a reduced boron concentration during the high temperature deposition39,40. As in the case of R dependence, the effect of TG gradually decreased as TPDA was increased, and iVOC of the annealed samples at TPDA = 950 °C became minimal. At TPDA = 1000 °C, the instability of the tunnel oxide layer deteriorated the passivation property and dropped the iVOC.

Overall, we observed that the growing conditions with respect to R and TG resulted in different passivation properties at low TPDA, and the differences became negligible at an optimal TPDA, which indicated that the crystallization and dopant in-diffusion were more critical to determining the passivation effects within our explored ranges.

Active boron diffusion and resultant band structures

To determine the correlation between the boron in-diffusion and tunnel oxide, we performed the electrochemical capacitance–voltage (ECV) measurements for the samples with the 1.5-nm-thick oxide layer. The prepared samples were grown at a flow rate of R = 0.5 and growth temperature of TG = 530 °C, but at different annealing temperatures (TPDA) in the range of 850–1000 °C. Figure 5a shows the active boron profiles following the thermal annealing. As TPDA was increased, the distribution of the boron dopant became more dispersive causing deeper in-diffusion into the c-Si. The enhanced diffusion originated from the enhanced diffusivity caused by the thermal energy and the reduced diffusion barrier owing to the degradation of the oxide layer18,31. The passivation property of the selective contact deteriorates at high TPDA because of the following three reasons: First, the excessive in-diffusion of boron atoms into the silicon substrate forms an extended p-type region in the n-type substrate, following which the p-type flat-band region across the oxide greatly suppresses the field-effect passivation at the oxide region30,31. Second, the high concentration of the diffused boron atoms introduces an elevated Auger recombination rate17,18. Third, the increase of the aforementioned unpassivated surface area of the c-Si caused by the damage in SiOx also deteriorates the passivation.

(a) ECV profiles of the active boron concentration annealed at 850 °C, 900 °C, 950 °C, and 1000 °C for the samples with 1.5-nm-thick SiOx layers and (b) simulated band diagrams based on the PC1D simulation. Schematic of the band structures corresponding to (c) the shallow in-diffusion and (d) deep in-diffusion of the boron dopants.

To determine the resultant band structure from the dopant profiles, we performed PC1D simulation based on our experimental ECV data (see Fig. S3). Figure 5b shows the TPDA dependent real-space dispersion of the electronic band structure. Because our hole-selective contacts were p–n junctions, clear band bending was observable regardless of the TPDA. The higher TPDA pushed away the position of depletion region from the tunnel oxide layer and broadened the p–n junction. This effect reduces the electric fields across the tunnel barrier, and the trapezoidal shape of the tunnel barrier is changed to nearly rectangular by the absence (or weakness) of the electric fields (Fig. 5c,d). As the built-in electric field is expected to support the hole carriers in crossing the tunnel barrier via the direct- or/and defect-assisted tunneling as well as thermionic emission, the carrier selectivity is improved41. Therefore, the optimal thermal annealing plays an important role in enhancing the passivation of the hole-selective contacts through the formation of the electric fields across the tunnel barrier and high-quality chemical passivation from the robust tunnel oxide layer.

Conclusion

In this study, we investigated the effects of thermal annealing on the passivation properties of tunnel oxide passivated hole-selective contacts grown on an n-type c-Si. The samples with 1.5-nm-thick oxide layers showed a higher onset temperature of oxide degradation compared to samples with 1.2-nm-thick oxide layers, which was reflected in the passivation properties and microstructures of the oxide layers. We explored the effects of thermal annealing under different growth conditions of the poly-Si. We observed that the dopant in-diffusion and damage of the oxide layer were the two dominant factors influencing the passivation quality, whereas the growth temperatures of the poly-Si and gas flow rate ratios of the precursor and dopant gases had a relatively weaker impact on the formation of hole-selective contacts. Active boron dopant concentration and the corresponding band structure formed were also investigated, which revealed that the position and gradient of the depletion region played an important role in gaining high carrier selectivity. These findings offer useful information to understand the formation mechanism of hole-selective contacts under thermal annealing and may have potential implications in the designing of crystalline silicon solar cells with high-conversion efficiency.

Methods

The c-Si wafers used in this study were n-type Czochralski (100)-oriented c-Si wafers. We used 200-μm-thick c-Si with a resistivity of 1.2–1.3 Ω cm and size of 156.7 × 156.7 mm2. All wafers were cleaned using deionized (DI) water + H2O2 + HCl (RCA2) at 85 °C and chemically polished using 10% KOH solution at 80 °C. The wafer surfaces were etched to approximately 10 μm. The wafers were immersed into 10% HF solution for 10 s to remove the native silicon oxide from the wafers.

The cleaned wafers were loaded into the LPCVD chamber and purged using N2 gas for 45 min at a temperature of 530 °C. Then, the SiOx layers were grown by dry thermal oxidation at a temperature of 630 °C and oxygen flow rate of 3 SLM to form 1.2-nm-thick (1.5-nm-thick) layers under a pressure of 0.3 Torr (760 Torr) for 15 min. The hole-selective layers were grown using the LPCVD method. We fabricated 200-nm-thick B-doped polysilicon on the oxidized wafers with the gas flow ratio, R ≡ [B2H6]/[SiH4], in a mixture of B2H6 and SiH4 precursor gases while fixing the flow rate of the SiH4 gases at 100 SCCM and a temperature range of 500–550 °C. After the deposition, the samples were exposed to post-deposition annealing at a temperature range of 750–1000 °C using a tube furnace under a nitrogen atmosphere.

After the sample preparation, the iVOC values were determined by the QSSPC method (WCT-120, Sinton Instruments). The microstructural images were obtained using TEM (JEOL, JEM-ARM300F) operated at 200 keV. The TEM samples were prepared using a focused-ion beam. Active boron-concentration profiles were obtained using the ECV profiling technique (WEB Wafer Profile CVP21), and a PC1D simulation was performed to describe the band diagrams based on the experimental results.

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Würfel, U., Cuevas, A. & Würfel, P. Charge carrier separation in solar cells. IEEE J. Photovolt. 5, 461–469 (2015).

Feldmann, F. et al. Efficient carrier-selective p- and n-contacts for Si solar cells. Sol. Energy Mater. Sol. Cells 131, 100–104 (2014).

Zhou, J., Huang, Q., Ding, Y., Hou, G. & Zhao, Y. Passivating contacts for high-efficiency silicon-based solar cells: From single-junction to tandem architecture. Nano Energy 92, 106712 (2022).

Allen, T. G., Bullock, J., Yang, X., Javey, A. & De Wolf, S. Passivating contacts for crystalline silicon solar cells. Nat. Energy 4, 914–928 (2019).

Richter, A. et al. n-Type Si solar cells with passivating electron contact: Identifying sources for efficiency limitations by wafer thickness and resistivity variation. Sol. Energy Mater. Sol. Cells 173, 96–105 (2017).

Peibst, R. et al. Towards 28%-efficient Si single-junction solar cells with better passivating POLO junctions and photonic crystals. Sol. Energy Mater. Sol. Cells 238, 111560 (2022).

Richter, A. et al. Design rules for high-efficiency both-sides-contacted silicon solar cells with balanced charge carrier transport and recombination losses. Nat. Energy 6, 429–438 (2021).

Yan, D. et al. Polysilicon passivated junctions: The next technology for silicon solar cells?. Joule 5, 811–828 (2021).

Williams, R. Photoemission of electrons from silicon into silicon dioxide. Phys. Rev. 140, A569–A575 (1965).

Peibst, R. et al. Working principle of carrier selective poly-Si/c-Si junctions: Is tunnelling the whole story?. Sol. Energy Mater. Sol. Cells 158, 60–67 (2016).

Tetzlaf, D. et al. A simple method for pinhole detection in carrier selective POLO-junctions for high efficiency silicon solar cells. Sol. Energy Mater. Sol. Cells 173, 106–110 (2017).

Feldmann, F. et al. Charge carrier transport mechanisms of passivating contacts studied by temperature-dependent J–V measurements. Sol. Energy Mater. Sol. Cells 178, 15–19 (2018).

Galleni, L. et al. Mechanisms of charge carrier transport in polycrystalline silicon passivating contacts. Sol. Energy Mater. Sol. Cells 232, 111359 (2021).

Liu, W. et al. Polysilicon passivating contacts for silicon solar cells: Interface passivation and carrier transport mechanism. ACS Appl. Energy Mater. 2, 4609–4617 (2019).

Choi, S. et al. Structural evolution of tunneling oxide passivating contact upon thermal annealing. Sci. Rep. 7, 12853 (2017).

Moldovan, A. et al. Tunnel oxide passivated carrier-selective contacts based on ultra-thin SiO2 layers. Sol. Energy Mater. Sol. Cells 142, 123–127 (2015).

Morisset, A. et al. Evolution of the surface passivation mechanism during the fabrication of ex-situ doped poly-Si(B)/SiOx passivating contacts for high-efficiency c-Si solar cells. Sol. Energy Mater. Sol. Cells 221, 110899 (2021).

Yang, G., Ingenito, A., Isabella, O. & Zeman, M. IBC c-Si solar cells based on ion-implanted poly-silicon passivating contacts. Sol. Energy Mater. Sol. Cells 158, 84–90 (2016).

Feldmann, F. et al. Tunnel oxide passivated contacts as an alternative to partial rear contacts. Sol. Energy Mater. Sol. Cells 131, 46–50 (2014).

Nogay, G. et al. Interplay of annealing temperature and doping in hole selective rear contacts based on silicon-rich silicon-carbide thin flms. Sol. Energy Mater. Sol. Cells 173, 18–24 (2017).

Young, D. L. et al. Gallium-doped poly-Si:Ga/SiO2 passivated emitters to n-Cz wafers with iVoc > 730 mV. IEEE J. Photovolt. 7, 1640–1645 (2017).

Schnabel, M. et al. Hydrogen passivation of poly-Si/SiOx contacts for Si solar cells using Al2O3 studied with deuterium. Appl. Phys. Lett. 112, 203901 (2018).

Stodolny M. K. et al. Novel schemes of p+ poly-Si hydrogenation implemented in industrial 6" bifacial front-and-rear passivating contacts solar cells, In Proc. 35th European Photovoltaic Solar Energy Conference and Exhibition, Brussels, Belgium, 414–417 (2018).

Mack, S., Lenes, M., Luchies, J.-M. & Wolf, A. P-Type silicon solar cells with passivating rear contact formed by LPCVD p+ polysilicon and screen printed Ag metallization. Phys. Status Solidi RRL 13, 201900064 (2019).

Xin, Z. et al. Ultra-thin atomic layer deposited aluminium oxide tunnel layer passivated hole-selective contacts for silicon solar cells. Sol. Energy Mater. Sol. Cells 191, 164–174 (2019).

Winter, M., Bordihn, S., Peibst, R., Brendel, R. & Schmidt, J. Degradation and regeneration of n+-doped poly-Si surface passivation on p-type and n-type Cz-Si under illumination and dark annealing. IEEE J. Photovolt. 10, 423–430 (2020).

Padhamnath, P., Khanna, A., Nandakumar, N., Aberle, A. G. & Duttagupta, S. Impact of firing temperature on fire-through metal contacts to P-doped (n+) and B-doped (p+) poly-Si. Sol. Energy Mater. Sol. Cells 230, 111217 (2021).

Bothe, K. & Schmidt, J. Electronically activated boron-oxygen-related recombination centers in crystalline silicon. J. Appl. Phys. 99, 013701 (2006).

Schmidt, J. Light-induced degradation in crystalline silicon solar cells. Solid State Phenom. 95–96, 187–196 (2004).

Ingenito, A. et al. A passivating contact for silicon solar cells formed during a single firing thermal annealing. Nat. Energy 3, 800–808 (2018).

Yan, D., Cuevas, A., Phang, S. P., Wan, Y. & Macdonald, D. 23% efficient p-type crystalline silicon solar cells with hole-selective passivating contacts based on physical vapor deposition of doped silicon films. Appl. Phys. Lett. 113, 061603 (2018).

Morisset, A. et al. Conductivity and surface passivation properties of boron-doped poly-silicon passivated contacts for c-Si solar cells. Phys. Status Solidi A 216, 1800603 (2018).

Nemeth, B. et al. Polycrystalline silicon passivated tunneling contacts for high efficiency silicon solar cells. J. Mater. Res. 31, 671–681 (2016).

Choi, S. et al. Formation and suppression of hydrogen blisters in tunnelling oxide passivating contact for crystalline silicon solar cells. Sci. Rep. 10, 9672 (2020).

Devine, R. A. B., Mathiot, D., Warren, W. L. & Aspar, B. O interstitial generation and diffusion in high temperature annealed Si/SiO2/Si structures. J. Appl. Phys. 79, 2302–2308 (1996).

Stuckelberger, J. et al. Passivating electron contact based on highly crystalline nanostructured silicon oxide layers for silicon solar cells. Sol. Energy Mater. Sol. Cells 158, 2–10 (2016).

Moldovan, A. et al. Simple cleaning and conditioning of silicon surfaces with UV/ozone sources. Energy Procedia 55, 834–844 (2014).

Kim, H. et al. Passivation properties of tunnel oxide layer in passivated contact silicon solar cells. Appl. Surf. Sci. 409, 140–148 (2017).

Bragg, J. K., McCarty, L. V. & Norton, F. J. Kinetics of pyrolysis of diborane. J. Am. Chem. Soc. 73, 2134–2140 (1951).

Gordon, M. S., Gano, D. R., Binkley, J. S. & Frisch, M. J. Thermal decomposition of silane. J. Am. Chem. Soc. 108, 2191–2195 (1986).

Chiu, F.-C. A review on conduction mechanisms in dielectric films. Adv. Mater. Sci. Eng. 2014, 1–18 (2014).

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Plannig (KETEP, Grant Nos. 20213030010240) funded by the Ministry of Trade, Industry and Energy (MOTIE) and the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2020R1A2C1099974). This work was conducted under the framework of the Research and Development of the Korea Institute of Energy Research (C2-2402) and the New and Renewable Energy Technology Development Program of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) through a grant funded by the Ministry of Knowledge Economy, Korea (Project No. 20203030010300).

Author information

Authors and Affiliations

Contributions

M.G.K and K.-H.K. conceived the project. I.S.K., K.H.M., S.H.L., S.C., and K.T.J. performed the experiments. S.P., H.S., M.G.K., and K.-H.K. supervised the studies. Y.J.K. and I.S.K. carried out the PC1D simulation. Y.J.K., I.S.K., M.G.K., and K.-H.K. led the manuscript preparation with contributions from other authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kim, YJ., Kweon, I.S., Min, K.H. et al. Thermal annealing effects on tunnel oxide passivated hole contacts for high-efficiency crystalline silicon solar cells. Sci Rep 12, 15024 (2022). https://doi.org/10.1038/s41598-022-18910-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-18910-5

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.