Abstract

A bidirectional DC–DC converter is required for an energy storage system. High efficiency and a high step-up and step-down conversion ratio are the development trends. In this research, a series of bidirectional high-gain Cuk circuits was derived by combining tapped inductors and bidirectional Cuk. After analyzing and comparing the characteristics of each circuit, a bidirectional high-gain Cuk circuit with a tapped-inductor (reverse coupling) was proposed. The proposed converter has a simple structure and a high voltage gain in both the step-down (Buck) and step-up (Boost) operation modes. The voltage stress of S2 was low. The voltage stress of S1 was high, however, and this is a disadvantage of the proposed converter. The proposed circuit’s characteristics were thoroughly examined, including the voltage gain characteristics and the design of the main parameters. We established a power loss model of the new topology, and the tapped-inductor turn ratio was optimized for high efficiency. Finally, a 400 W experimental implementation of the converter was shown to achieve efficiencies of 93.5% and 92.4% in the step-up and step-down modes, respectively. These findings verified the validity of the proposed circuit’s theoretical analysis.

Similar content being viewed by others

Introduction

Because of the scarcity of fossil fuels and serious environmental issues in recent years, significant effort has been focused on the development of environmentally friendly distributed generation (DG) technologies1. Renewable energy, however, does not produce consistent energy because of weather conditions. Energy storage is required to provide stable power2. Furthermore, the voltage of a storage battery is typically low, in the 12–48 V range, whereas the voltage of a DC bus is 400 V or higher to meet the requirements of an inverter or AC grid3. As a result, for energy storage systems to connect a low-voltage battery to a high-voltage DC bus, a bidirectional DC–DC converter with a high step-up/step-down voltage conversion ratio is required4. Furthermore, these converters have been researched extensively for a wide range of industrial applications, including uninterruptible power supply systems, electric vehicles, and aviation power supplies5. The traditional buck-boost converter can provide a high voltage gain with a large duty ratio, which will cause considerable conduction losses because of the large current ripples. Additionally, several bidirectional DC–DC converters based on isolated topologies have been presented in the literature. These topologies require a transformer and a high number of switching devices, which increases the cost and the switching losses, in addition to requiring more complicated control schemes.

Many bidirectional DC–DC converters with a high step-up/step-down conversion ratio have been proposed to improve the voltage gain and efficiency of a converter. The cascade method was used in reference 6 to broaden the ratio range of a bidirectional converter whose gain was calculated by multiplying the gains of each level converter. The efficiency was low, however, because of the cascade, and there was an issue of instability. The proposed converter in reference 7 improved a bidirectional DC-DC converter’s conversion ratio by connecting the low-voltage side in parallel and the high-voltage side in a series, but the structure of the converter was complex. Some appealing solutions, such as switched capacitors8,9, switched inductors10, and coupled inductors11, have been introduced for a basic bidirectional DC/DC converter to increase the voltage conversion ratio. The proposed bidirectional bridge modular switched-capacitor-based resonant DC–DC converter achieved a high step-up/step-down conversion ratio through a switched capacitor unit8. However, it employed a large number of switches, and the voltage and current stresses on the switches were high due to resonance. As a result, although the circuit proposed in 9 reduced the number of switches, its conversion ratio range was limited. Reference 10 employed the coupled-inductor technique to build a bidirectional DC–DC converter with a high step-up/step-down voltage gain. The current ripple was large because the current waveform on the low-voltage side of the topology was a square wave. In addition, reference 11 discussed nonisolated bidirectional DC–DC converters based on dual-coupled inductors, which could achieve a high voltage gain and reduced switch voltage stresses by connecting the secondary windings of two coupled inductors in series. However, it necessitated a complex control.

In summary, these isolated converter structures usually have too many switches, so the conduction losses of the switches were very high. Additionally, the practical implementation is complicated and expensive. The existing nonisolated high-gain circuits are mainly switch capacitor converters and coupled inductor converters. The drawbacks of a switch capacitor converter include the switching loss and the current stress. The drawbacks of a coupled inductor converter include the complex circuit structure and the leakage inductance that results in spikes that need to be suppressed using snubber circuits.

Cuk converters are gaining popularity because the input and output inductors reduce electromagnetic interference problems and the output ripple is small12. In this research, tapped inductance and bidirectional Cuk are combined to create a series of bidirectional high-gain Cuk circuits. After analyzing and comparing the characteristics of each circuit, a bidirectional high-gain Cuk circuit with a tapped-inductor (reverse coupling) is proposed. The proposed converter has a simple structure and high voltage gain in both the step-down (Buck) and step-up (Boost) operation modes. The proposed circuit’s characteristics, including the voltage gain characteristics and the design of the main parameters, are thoroughly examined. Based on this examination, we established a power loss model of the new topology, and the tapped-inductor turn ratio was optimized for high efficiency. Finally, a 400 W 48 V/400 V prototype was created to verify the validity of the proposed circuit’s theoretical analysis.

A tapped-inductor bidirectional Cuk

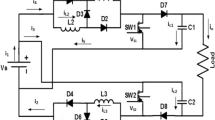

The bidirectional Cuk circuit features low input and output ripple and low EMI interference, and the circuit diagram is shown in Fig. 1. Because of the influence of the parasitic parameters, the voltage gain of this circuit is limited, and it is not suitable for occasions with a large voltage transformation ratio. Therefore, a series of bidirectional high-gain Cuk circuits is created by combining tapped inductance and bidirectional Cuk to increase the voltage gain of bidirectional Cuk.

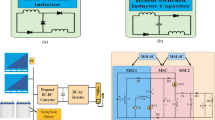

The proposed series of circuits use coupled inductors to replace the inductors L1 or L2 in Fig. 1. Because of the different connection methods of the coupled inductor, four different circuits can be derived. Additionally, because the coupled inductor has two coupling modes (i.e., same-direction coupling and reverse-direction coupling), a total of eight circuits can be derived, as shown in Figs. 2 and 3. These converters with tapped inductors are formed by the same-direction coupling shown in Fig. 2. The reverse-direction coupling is shown in Fig. 3. The tapped inductor is composed of L1 with the number of turns N1 and L2 with the number of turns N2, where the tap ratio is n = N2: N1. Furthermore, D1 is the parasitic body diode of S1 and D2 is the parasitic body diode of S2. The same-direction coupling means that the currents all flow from the same-named end of the inductor and vice versa.

The voltage gain M of these converters versus the duty ratio D and the turn ratio n is obtained for the continuous current mode (CCM) mode by analyzing the working principles of the previously noted circuits, as shown in Table 1. S1-tap means that the inductor L1 of the bidirectional Cuk circuit is replaced by the tap inductor Lt, and the common terminal of the tapped inductor is connected to S1, as shown in Fig. 2a and Fig. 3a. S2-tap means that the inductor L2 of the bidirectional Cuk circuit is replaced by the tap inductor Lt, and the common terminal of the tapped inductor is connected to S2, as shown in Figs. 2b and 3b. CB-tap 1 means that the inductor L1 of the bidirectional Cuk circuit is replaced by the tap inductor Lt, and the common terminal of the tapped inductor is connected to CB, as shown in Figs. 2c and 3c. CB-tap 2 means that the inductor L2 of the bidirectional Cuk circuit is replaced by the tap inductor Lt, and the common terminal of the tapped inductor is connected to CB, as shown in Figs. 2d and 3d.

The corresponding curve can be drawn using the data from Table 1, as shown in Fig. 4. The voltage-gain characteristic curve of the circuits formed by same-direction coupling is shown in Fig. 4a. The curves of the S1-tap circuit and capacitor-tap circuit 2 are overlapped, and the curves of the S2-tap circuit and capacitor-tap circuit 1 are overlapped. As shown in Fig. 4a, the bidirectional Cuk circuit with the tapped inductor derived from S2-tap and capacitor-tap circuit 1 can achieve a high voltage gain. The voltage conversion ratio characteristic curve of the circuits formed by the reverse-direction coupling is shown in Fig. 4b. The curves of the S1-tap circuit and capacitor-tap circuit 2 are overlapped, and the curves of the S2-tap circuit and capacitor-tap circuit 1 are overlapped. As shown in Fig. 4b, the bidirectional Cuk circuit with the tapped inductor derived from S1-tap and capacitor-tap circuit 2 can achieve a high voltage gain.

The voltage conversion ratio characteristic curves of the circuits in Figs. 3d and 2b are plotted, as shown in Fig. 5, to obtain the circuit with a larger step-up ratio from the previously noted circuits. As a result, it is determined that the circuit in Fig. 3d is the best of the previously noted circuits.

Because the analysis of these converters in the step-down mode is similar to the analysis in the step-up mode, it is not repeated here.

The feasibility analysis of the topologies’ large ratio is shown in Table 2 based on the preceding analysis. In the table, the term “inapplicable” means that the conversion ratio of this circuit is less than that of the bidirectional Cuk circuit, and the term “available” means that the conversion ratio of this circuit is greater than that of the bidirectional Cuk circuit.

A tapped-inductor bidirectional high gain Cuk converter

The circuit topology

According to this analysis, we proposed a tapped-inductor bidirectional Cuk converter with a high step-up/step-down conversion ratio, as shown in Fig. 6. The proposed converter is made up of the following components: the low-side voltage V2, the high-side voltage V1, the inductor L3, the tapped inductor Lt, the capacitor CB, and the two switches S1–S2. The tapped inductor Lt is composed of L1 and L2 coupled in the opposite direction, and the turns of the inductor are N1 and N2(N1 > N2). The equivalent circuits of these stages are shown in Fig. 7.

The effective turn ratio of the tapped inductor is expressed as follows.

The coupling coefficient of the tapped inductor is:

where Lm is the equivalent magnetizing inductance on the N2 side; and Lk is the leakage inductance on the N2 side.

Operational principles

When using the proposed circuit in energy storage systems, the battery voltage V2 is on the low-voltage side and the DC-bus voltage V1 is on the high-voltage side. The proposed converter can operate in both step-up mode and step-down mode with bidirectional power flow. Reference 13 contains the operating principles and steady-state analysis. Hence, the simple results are discussed in the following, but the detailed analysis is not repeated.

As shown in Fig. 8, one switching period of the step-up mode has two switching stages. In Fig. 8, vgs2 is the driving signal of S2, the currents flowing through the L1, L2, and L3 inductors are iLs, iLp, and iL3, and iD1, iS2, and iCB are the currents flowing through D1, S2, and CB. The equivalent circuits of these stages are shown in Fig. 9.

The gain of the proposed circuit in the step-up mode can be derived as follows.

Ideally, the leakage inductor can be ignored, and the Mup can be derived as follows.

where Mup is the step-up conversion ratio of the proposed converter and D is the duty cycle of S2.

As shown in Fig. 10, one switching period of the step-down mode has two switching stages. In Fig. 10, vgs1 is the driving signal of S1, the currents flowing through the L1, L2, and L3 inductors are iL1, iL2, and iL3, and iD2, iS1, and iCB are the currents flowing through D2, S1, and CB. The equivalent circuits of these stages are shown in Fig. 11.

The gain of the proposed circuit in the step-down mode can be derived as follows.

Ideally, the leakage inductor can be ignored, and Mdown can be derived as follows.

where Mdown is the step-down conversion ratio of the proposed converter and D is the duty cycle of S1.

Comparison analysis of the proposed converter

The characteristic comparison of the proposed converter with the counterparts is shown in Table 3 (NS is the number of power switches, NCI is the number of coupled inductors, NI is the number of inductors, and NC is the number of capacitors). The conventional buck/boost converter can achieve bidirectional power flows while employing the fewest number of power switches, but the converter’s conversion ratio range is limited. The converter in reference 14 has a high step-up/step-down conversion ratio, but it is complex and inefficient. Compared with the converters in reference 14, the converter’s efficiency in reference 15 has been improved by using soft switching technology, but the circuit structure is still complex. It can be seen that the proposed converter achieves a high and wide voltage-gain range by employing two power switches. Additionally, it has a simple structure.

The feasibly control strategy for the proposed converter

To improve the dynamic performance and antidisturbance ability of the proposed converter, we proposed an improved fuzzy control strategy based on the Takagi–Sugeno-Kang fuzzy control technique, as shown in Fig. 12. The operating principle and a detailed analysis of the control strategy can be obtained from reference 13. Therefore, the detailed analysis is not repeated in this paper.

Analysis and design of the key parameters

Optimized design of turn ratio

Power loss model

A power loss model of the new topology is established in the step-up mode. The loss of the proposed converter is composed of the losses of S2, Lt, L3, and D1. The specific analysis is given as follows.

-

(1)

The loss of S2.

The conduction loss is expressed as follows

$$ P_{con\_S} = I_{rms\_S}^{2} \cdot R_{ds(on)\_S} $$(7)where Irms_S2 is the effective value of the current across S2, and Rds(on) is the forward conduction resistance of S2 at a certain temperature, which can be estimated from the datasheet and the ambient temperature.

The switching loss is found as follows

$$ P_{sw} = \frac{1}{2} \cdot f_{s} V_{ds} \cdot \left[ \begin{gathered} I_{d01} \cdot (t_{ri} + t_{fv} ) \hfill \\ { + }I_{d02} \cdot (t_{rv} + t_{fi} ) \hfill \\ \end{gathered} \right] $$(8)where tri, tfv, tr, and tfi are the equivalent times of the four phases with the loss during the switching process, which can be calculated from the datasheet.

The loss of the equivalent output capacitance of S2 is found as follows:

$$ P_{{{\text{Co}} \_S}} = \frac{1}{2} \cdot C_{oss} \cdot V_{ds\_S2}^{2} \cdot f_{S} $$(9)Therefore, the overall loss of S2 is given by the following:

$$ P_{s} = P_{con\_S} + P_{sw} + P_{{{\text{Co}} \_S}} $$(10) -

(2)

The loss of D1

$$ P_{D} = V_{F} \cdot I_{D} + V_{off\_D} \cdot Q_{rr} \cdot f_{S} $$(11)where VF is the forward voltage drop of D1, ID is the average value of the current across D1, Voff_D is the reverse voltage of D1, and Qrr is the reverse recovery charge of D1.

-

(3)

The loss of the inductor

The core loss is found as follows:

$$ P_{core} = f_{s} \cdot Kf_{eq}^{{{{\alpha - 1}}}} B^{\beta } \left( {C_{0} + C_{1} T + C_{2} T^{2} } \right) $$(12)$$ f_{eq} (D) = \frac{2}{{B^{2} \pi^{2} }}\int\limits_{0}^{T} {(\frac{dB}{{dt}})^{2} dt = } \frac{{2f_{s} }}{{\pi^{2} D(1 - D)}} $$(13)

The winding loss is found as follows

Therefore, the overall loss of inductor is given by the following:

where the parameters K, α, β, C0, C1, and C2 can be obtained from the datasheet provided by the core manufacturer; T is the operating temperature of the magnetic core; Vcore is the volume of the magnetic core; IL_rms is the effective value of the current through the inductor; and Rdc is the equivalent resistance of the inductor.

The power loss models of Lt and L3 are similar to each other. Therefore, the description of the power loss model of Lt is not repeated here.

To summarize, the overall loss of the proposed converter in the step-up mode is given by the following:

Hence, the efficiency of the proposed converter in the step-up mode is given as follows

Similarly, the overall loss of the proposed converter in the step-down mode is given by the following:

Hence, the efficiency of the proposed converter in the step-down mode is given as follows

The optimization selection of turn ratio

The loss characteristics of the proposed circuit are analyzed using Mathcad and the power loss model from the previous section. The following are the converter’s main simulation parameters: V2 = 48 V, V1 = 400 V, Po = 400 W, L3 = 1.5 mH, L1 = 0.9 mH, switching frequency: fs = 50 kHz.

According to Formula (16), the curves for the loss of the proposed circuit and the turn ratio under different loads can be drawn using Mathcad, as shown in Fig. 13.

From Fig. 13, when the output power is constant, the total loss of the circuit decreases at first and then increases as the turn ratio increases. As a result, a minimum loss point serves as the foundation for selecting the appropriate turn ratio in this research.

The calculation curve for the efficiency of the proposed circuit in the step-up mode can be drawn using Formula (17), as shown in Fig. 14a. Figure 14b depicts the calculation curve for the efficiency of the proposed circuit in the step-down mode, according to Formula (19).

As shown in Fig. 14, the circuit’s efficiency increases at first and then decreases as the turn ratio increases. There is a maximum level of efficiency. As a result, to achieve the expected output and high efficiency, an appropriate turn ratio and steady-state duty ratio should be chosen. The turn ratio should be around 0.4, and the duty cycle should be around 0.75, according to Fig. 14.

Given the possibility of errors during the design and winding processes, the best turn ratio is \({\lambda }_{opt}\) = 0.375–0.412. The efficiency calculation curves are shown in Fig. 15. When the proposed converter operates under rated conditions, the best turn ratio is \({\lambda }_{opt}\) = 0.394. Figure 15a depicts the efficiency curve in the step-up mode, and Fig. 15b shows the efficiency curve in the step-down mode.

Other parameters design

The selection of the inductor

To ensure that the circuit works in CCM mode, the values of L1, L2, and L3 must be greater than the inductance value with critical continuity. These values are given as follows:

The selection of capacitor

The selection of the capacitor mainly includes consideration of the voltage stress and the voltage ripple within a certain range. The value of CB is found as follows:

Simulation and experimental verification

Simulation results

We performed detailed simulations in Matlab/Simulink to verify the correctness of the aforementioned theoretical analysis. The proposed converter operation is verified at V2 = 48 V, V1 = 400 V, Po = 400 W, L3 = 1.5 mH, L1 = 0.9 mH, L2 = 0.33 mH, Lk = 0.92 uH, CB = 2.2 uF, Co1 = 47 uF, Co2 = 47 uF, and the switching frequency fs = 50 kHz.

The simulation results in the step-up mode at full load are shown in Fig. 16. In Fig. 16, vgs2 is the driving signal for S2, the currents flowing through the L1, L2, and L3 inductors are iLs, iLp, and iL3, and iD1, iS2, and iCB are the currents flowing through D1, S2, and CB, respectively.

The simulation results in the step-down mode at full load are shown in Fig. 17. vgs1 is the driving signal for S1, the currents flowing through the L1, L2, and L3 inductors are iLs, iLp, and iL3, and iD2, iS1, and iCB are the currents flowing through D2, S1, and CB separately.

In the step-up mode, the output voltage is stable at 400 V, as shown in Fig. 16. The duty cycle of S2 is 0.74. The voltage stresses of S2 and D1 are 457 V and 472 V. Similarly, Fig. 17 shows that the output voltage is stable at 48 V in the step-down mode. The duty cycle of S1 is 0.26. The voltage stresses of S1 and D2 are 987 V and 180 V. The voltage and current spikes of S1, S2, and the inductor are caused by the leakage inductance of the coupled inductor. Thus, the results in Figs. 16 and 17 show that the simulation results closely match the theoretical analysis.

Experimental results

To validate the theoretical analysis, we built a laboratory prototype of the proposed converter. First, based on typical applications, we selected the operating conditions of the proposed converter as V2 = 48 V, V1 = 400 V, and Po = 400 W. Second, according to Formulas (20)–(23), L3 = 1.5 mH, L1 = 0.9 mH, L2 = 0.33 mH, CB = 2.2 uF, Co1 = 100 uF, and Co2 = 100 uF. Then the voltage-current stress of the semiconductor device can be obtained by analyzing the specific operating principle of the converter. The voltage-current stress of S1 is as follows:

The voltage-current stress of S2 is as follows:

where I1 is the average value of the high-voltage side current and I2 is the average value of the low-voltage side current.

The maximum voltage and the current stress values of S1 and S2 are obtained by incorporating the corresponding parameters. Then, based on a certain margin, the specific type of switching tube that is required can be selected. The specific parameters of the proposed converter are listed in Table 4, and the prototype is shown in Fig. 18.

When v2 = 48 V, we obtain the experimental results in the step-up mode at a full load as shown in Fig. 19. Figure 19a shows the waveforms of vgs2, vds2, and ids2, and the duty cycle of S2 is 0.75. The voltage stress of S2 is 325 V. Figure 19b shows the waveforms of vgs2, vD1, and iD1, and the voltage stress of D1 is 675 V. Figure 19c shows the waveforms of vgs2, v1, iL1, and iL3, and the output voltage of the proposed converter in step-up mode is 400.8 V.

When v2 = 36 V, we obtain the experimental results in the step-up mode at full load as shown in Fig. 20. As illustrated in Fig. 20, the duty cycle of S2 is 0.81, and the output voltage of the proposed converter in the step-up mode is 400.4 V. The voltage stresses of S2 and D1 are 362 V and 669 V.

When v2 = 60 V, we obtain the experimental results in the step-up mode at full load as shown in Fig. 21. As illustrated in Fig. 21, the duty cycle of S2 is 0.69, and the output voltage of the proposed converter in the step-up mode is 400.1 V. The voltage stresses of S2 and D1 are 315 V and 725 V.

Compare with the simulation results in Fig. 16, the experimental results in the step-up mode are consistent with it. Both of them are then consistent with the theoretical analysis. The voltage and current spikes are caused by the leakage inductance.

When v1 = 400 V, we obtain the experimental results in the step-up mode at full load as shown in Fig. 22. Figure 22a shows the waveforms of vgs1, vds1, and ids1, and the voltage stress of S1 is 731 V. Figure 22b shows the waveforms of vgs1, vD2, and iD2, and the voltage stress of D2 is 225 V. Figure 22c shows the waveforms of vgs2, vo, iL1, and iL3, and the output voltage of the proposed converter is 47.9 V.

When v1 = 250 V, we obtain the experimental results in the step-down mode at full load as shown in Fig. 23. As illustrated in Fig. 23, the duty cycle of S1 is 0.4, and the output voltage of the proposed converter in the step-up mode is 47.9 V. The voltage stresses of S1 and D2 are 640 V and 173 V.

When v1 = 250 V, we obtain the experimental results in the step-down mode at full load as shown in Fig. 24. As illustrated in Fig. 24, the duty cycle of S1 is 0.253 and the output voltage of the proposed converter in the step-up mode is 47.9 V. The voltage stresses of S1 and D2 are 785.5 V and 245 V.

Similarly, compare with the simulation results in Fig. 17, the experimental results in the step-down mode are consistent with it. Both of them are then consistent with the theoretical analysis.

We obtain the input and output current waveforms in the step-up/step-down mode at full load as shown in Fig. 25. Figure 25a shows the current waveforms in the step-up mode, and Fig. 25b shows the current waveforms in the step-down mode. As illustrated in Fig. 25, the input and output current ripple of the proposed converter is low.

The measured efficiency curve of the experimental circuit in the step-up mode is shown in Fig. 26a. Figure 26b shows the measured efficiency curve of the experimental circuit in the step-down mode. Compare with Fig. 14, it can be seen that the proposed circuit’s measured efficiency curve agrees with the calculation curve. The trends of the curves are increased firstly and then decreased. Furthermore, because the actual total loss is not taken into account in the calculation, the maximum measured efficiency is less than the theoretical calculation value.

When the proposed converter operates under rated conditions and the best turn ratio is \({\lambda }_{opt}\) = 0.394, we obtain the experimental loss of the proposed converter as shown in Fig. 27. As illustrated in Fig. 27, the loss is mainly concentrated on the switching and the coupled inductor in the step-up/step-down mode.

The conversion efficiency versus the output power in the step-up mode and step-down mode is plotted in Fig. 28.In the step-up mode, the maximum efficiency of the proposed converter is 93.5%. In the step-down mode, the proposed converter has a maximum efficiency of 92.2%.

Comparing Figs. 28 and 15, we found that the trends of the measured efficiency curve and the calculation curve ere consistent in the step-up/step-down mode. The trends increased at first and then decreased as the output power increased. Similarly, because the actual total loss was not taken into account, the maximum measured efficiency was less than the theoretical calculation value.

Conclusion

The use of a tapped inductor in this research improved the bidirectional DC-DC converter’s conversion ratio and overcame the shortcomings of the nonisolated bidirectional DC–DC converter’s low conversion ratio. Furthermore, a series of bidirectional high-gain Cuk circuits was derived by summarizing and analyzing the various forms of the proposed coupled inductor. The best circuit was obtained by analyzing and comparing the characteristics of each circuit, and we proposed a bidirectional high-gain Cuk circuit with a capacitor-tapped inductor (reverse coupling). In both the step-down and step-up operation modes, this converter had a simple structure and a high voltage gain. Following this, the proposed circuit’s operational principles and characteristics were thoroughly examined. In addition, the efficiency of the proposed converter was improved further after the optimal selection of the coupled inductor’s turn ratio. Finally, we created a 400 W 48 V/400 V prototype to verify the validity of the proposed circuit’s theoretical analysis.

Data availability

The datasets of this study are available from the corresponding author on reasonable request.

References

Lai C.M., Lin, Y.C., & Lin, Y.J. Newly-constructed bidirectional DC/DC converter topology with high voltage conversion ratio for vehicle to DC-microgrid (V2DCG) system. in 2015 IEEE 2nd International Future Energy Electronics Conference (IFEEC). (IEEE, 2015).

Yamamoto, Y., Takiguchi, T., & Sato, T. et al. Two-phase interleaved bidirectional converter input-parallel output-series connection. in (Lee, W.-C., Hyun, D.-S., Lee, T.-K. eds.) A novel control method for three-phase PWM rectifiers using a single current sensor (ISPE 2015). IEEE Trans. Power Electron. 15(5), 861–870 (2000).

Hongfei, Wu. et al. High step-up-step-down non-isolated BDC with built-in DC-transformer for energy storage systems. IET Power Electron. 7(13), 2571–2579 (2016).

Wu, H. et al. High step-up/step-down soft-switching bidirectional DC–DC converter with coupled-inductor and voltage matching control for energy storage systems. IEEE Trans. Indus. Electron. 63(5), 2892–2903 (2016).

Liu, H. et al. A novel reversal coupled inductor high-conversion-ratio bidirectional DC–DC converter. IEEE Trans. Power Electron. 2017, 1–1 (2017).

Ardi, H., Reza Ahrabi, R. & Ravadanegh, S. N. Non-isolated bidirectional DC–DC converter analysis and implementation. IET Power Electron. 7(12), 3033–3044 (2014).

Zhang, Y. et al. Interleaved switched-capacitor bidirectional DC-DC converter with wide voltage-gain range for energy storage systems. IEEE Trans. Power Electron. 33(5), 3852–3869 (2018).

Ding, Y., He, L., Liu, Z. Bi-directional bridge modular switched-capacitor-based DC-DC converter with phase-shift control. in 2016 IEEE Energy Conversion Congress and Exposition. Milwaukee, USA. (IEEE, 2016).

Cornea, O. et al. Bidirectional power flow control in a DC microgrid through a switched-capacitor cell hybrid DC-DC converter. IEEE Trans. Indus. Electron. 64(4), 3012–3022 (2017).

Hong, C.-M. et al. Novel bidirectional DC–DC converter with high step-up/down voltage gain. 2009 Energy Conversion Congress and Exposition (IEEE, 2009).

Zhang, M., Xing, Y., Wu, H. et al. A dual coupled inductors-based high step-up/step-down bidirectional dc–dc converter for energy storage system. in 2017 IEEE Applied Power Electronics Conference and Exposition(APEC). Tampa, USA. (IEEE, 2017).

Hongxing, C. H. E. N., Weiming, L. I. N. & Tao, Z. E. N. G. A high gain step-up Cuk circuit with scalable cell. Proc. CSEE 39(23), 7013–7022 (2019).

Hongxing, C., Weiming, L. & Tao, Z. A novel high gain bidirectional DC–DC Cuk converter and its improved fuzzy control. Proc. Chin. Soc. Electr. Eng. 41(17), 6025–6039 (2021).

Akhormeh, A. et al. High gain bidirectional quadratic DC–DC converter based on coupled inductor with current ripple reduction capability. IEEE Trans. Indus. Electron. 68(9), 7826–7837 (2021).

Zhang, Y., Liu, H. & Li, J. A low-current ripple and wide voltage-gain range bidirectional DC–DC converter with coupled inductor. IEEE Trans. Power Electron. 35(2), 1525–1535 (2019).

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China(No: 52172327) and the Fujian Province Natural Science Foundation(Nos.: 2021J011028, 2020J01860) and the Fuzhou Science and Technology Plan Project (No. 2021-S-236). And we thank LetPub (https://www.letpub.com) for its linguistic assistance during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

H.X. contributed to the laboratory prototype experiments, study design, interpretation, analyses, and manuscript preparation. W.M. proposed the main idea and contributed to the study design and manuscript revision. W.R. contributed to the laboratory prototype experiments and manuscript preparation. W.H. contributed to the manuscript revision. All authors contributed to and have approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chen, H., Lin, Wm., Liu, Wr. et al. Tapped-inductor bi-directional Cuk converter with high step-up/down conversion ratio and its optimum design. Sci Rep 12, 13745 (2022). https://doi.org/10.1038/s41598-022-17801-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-17801-z

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.