Abstract

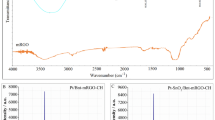

A novel environmental nano-catalyst based on zeolite (ZE) adjusted with carbon nanotube/silver nanoparticles (Ag/CNT) ornamented carbon paste electrode (CPE) is used for electrochemical oxidation of propylene glycol (PG) in 0.5 M H2SO4 solution. The techniques like cyclic voltammetry (CV), chronoamperometry (CA) and electrochemical impedance spectroscopy (EIS) are utilized to achieve the catalytic activity performance. Surface characteristics are achieved by means of scanning electron microscope (SEM) and Energy dispersive X-ray analysis (EDX) techniques. Enhancing the loading magnitude of CNT into catalyst's ingredient can meaningfully develop the catalytic activity of the electrocatalyst towards propylene oxidation. The impact of altering the concentration of propylene glycol and the scanning rate on the resulting electrocatalyst performance during the oxidation cycle is considered. Chronoamperograms present an amplify of the steady state oxidation current density values after addition of these nano-catalysts. A promising catalytic stability of nano-catalyst has been achieved in electing its use for propylene glycol electro-oxidation in fuel cells applications.

Similar content being viewed by others

Introduction

The world has faced energy shock because fossil fuel reserves are rapidly exhausted. Also, the utilization of fossil fuels is being perceived for its harmful influences that may cause a natural and social crisis1,2. Thus, it is important to look for a practical alternate fuel and make new energy conversion instruments to resolve these energy cohort difficulties3,4. Direct alcohol fuel cells dependent on small organic molecules have great consideration as probable power devices, mainly for portable electronic devices and electric vehicles in view of their high energy density, efficiency, low ecological contamination and low working temperature5,6. The electrocatalytic oxidations of different small organic molecules on various edited electrodes have been examined for application in fuel cells7,8,9,10,11,12,13. Most of recent reports, polyalcohol such as ethylene glycol, propylene glycol and glycerol, are a good choice in fuel cells due to its high reactivity in electro-oxidation, inflammability, lower toxicity and high boiling point that allows tranquil handling and storage14,15. Polyalcohol fuels are valuable due to they can be produced from renewable sources16,17. Furthermore, to improve the efficacy of fuel employment, active catalysts, having enough ability to break strong C–C bond in polyalcohol are highly wanted18,19,20.The electrochemical oxidation of polyalcohol on noble metals such as platinum, palladium, and gold has been demonstrated in several recent investigations. Sadiki et al.21 have studied the polyalcohol oxidation in alkaline media by improving the efficacy of the palladium catalysts edited by several adatoms (antimony, tin, lead). The existence of bimetallic surface leads to enhance the oxidation rate of these alcohols. Munoz et al.22 presented that a carbon-supported Pd-Cu nanocatalyst can increase the polyalcohol oxidation rate in alkaline medium. The developments have been accredited to both electronic and bifunctional effects. Furthermore; the Cu/Pd ratio seems to have a noteworthy impression on the rate of oxidation23,24. To make the electro-oxidation of polyalcohol practically valuable, novel inexpensive and selective catalysts are required. Catalyst plays a crucial role in electrochemical energy conversion in fuel cell. Carbon paste electrode (CPE) is the most popular catalytic support material due to their strong electronic conductivity, comparative stability in different media and high effective surface area25,26,27.The nano-modified electrodes are substantial to improve the catalytic activity in order to reduce production costs.

Recently, silver nano particles (AgNPs) have potentially demonstrated in electrocatalysis applications. AgNPs can act as a conduction center to improve the transmission of electrons and deliver exceptional catalytic activity28,29. Carbon nanotubes (CNTs) are porous constituents with special characteristics, high efficiency, high surface area, strong conductivity, and chemical stability30. Carbon nanotube has high electrocatalytic activity in numerous substances and therefore suitable for building various electrocatalyst with high efficiency31,32,33,34. Zeolites are known as microporous crystalline aluminosilicate materials with high surface area, adsorptive and molecular sieving materials. Zeolites are unique materials, which can be exploited in the development of modified electrodes with high chemical and thermal stability35,36,37,38. Nevertheless, the propylene glycol oxidation in acidic media is quiet not fully revealed and requires to be studied. It is well recognized that carbon paste electrode with nano-material showed electrocatalytic act towards propylene glycol oxidation in acidic medium due to strong adsorbability of PG molecules on the nano-material surface.

The aim of this work is to produce a novel environmental nano-catalyst created from modified carbon paste electrode with zeolite, carbon nanotube and silver nanoparticles to have the collective characteristics of the three modifiers together. After analysis of the electrochemical response of this novel catalyst using various techniques, it was found to give high electrocatalytic activity towards electrooxidation of propylene glygol. A different percentages of the catalyst with large surface area, simple and low cost construction are recommended for propylene glycol oxidation in acidic medium.

Experimental

Materials and reagents

The chemicals are graphite, multi walled carbon nanotube, zeolite Y-type (SiO2/Al2O3- ≥ 5.1) and silver nanoparticles (AgNPs) powder (dispersion nanoparticles, < 100 nm), propylene glycol (99. 8%), Sigma–Aldrich (USA) and were used without further purifications. All solutions are prepared utilizing triple distilled water. All experiments were achieved at room temperature. The solution pH for propylene glycol is 3.9 before adding the acid. After adding the sulphuric acid, the pH value for different concentrations of acid is in the range of 0.1–0.4.

SMWZCPE modified electrode preparation

In order to develop the catalytic activity of (CPE) electrode different weights of zeolite and silver nanoparticles were investigated with no significant change in current. However, the loading of CNT into the catalyst (10–40 mg) gives a significant change in current and was considered in Table 1.

The best modification for carbon paste (CPE) electrode was made by mixing 5 g of graphite powder with drops of paraffin oil on a glassy mortar, then 40 mg of carbon nanotube, 5 mg of silver nanoparticles and 0.1 g of zeolite were added to set up the catalyst (Ecat-1) (SMWZCPE), which was utilized in all experiments. The carbon paste was packed in a Teflon tube with pressing to acquire a smooth surface.

Cell and apparatus

A three-electrode cell enclosing a platinum rode as a counter electrode (CE), saturated calomel electrode (SCE) as a reference electrode (RE) and (SMWZCPE) as the working electrode (WE) was used. Cyclic voltammetry (CV), Chronoamperometry (CA) and Electrochemical impedance spectroscopic (EIS) measurements are achieved by EC-Lab SP 150 Potentiostat electrochemical workstation. EIS are done at 10 mV ac amplitude at frequency of 1.0 mHz to 100 kHz. EC-Lab software is operated for demonstrating. The electrochemical measurements were performed at room temperature. Scanning electron microscopic (SEM) measurements were performed by SEM Model Quanta 250 FEG (Field Emission Gun) related with EDX Unit (Energy Dispersive X-ray Analyses) (FEI company, Netherlands). To determine the sample's specific surface area and pore-size distributions, the Brunauer–Emmett–Teller (BET) and Barrett-Joyner-Halenda (BJH) procedures were utilised.

Results and discussion

Characterization of SMWZCPE modified electrode

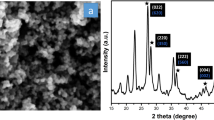

Figure 1A shows the SEM images of the SMWZCPE modified electrode which reveals that silver nanoparticles, CNT and zeolite are dispersed well in a uniform distribution with the graphite paste. The rough surface with vertically arranged nanoarrays can be detected in Fig. 1A. Thus, the structural advantages of nanomaterial as being near ideal candidates to be significant catalyst with low electron affinity, high electron mobility, and outstanding chemical and physical stability and highly conductive. It can be applicable in nanoscale molecular electronics, sensing and actuating devices, or as reinforcing additive fibers in functional composite materials39. Generally, constructing nanostructured cartalysts play a substantial role in exploiting promising supercapacitors with satisfactory electrochemical performance40. Figure 1B demonstrates well the EDX spectrum of SMWZCPE which approves the existence of C, O, Ag, Al and Si by a good percentage in the formed electrocatalyst. The uniform spreading of the elements along the entire catalyst surface offered an opportunity to improve the active electrochemical surface area and increasing the elecrocatalytic efficiency.

The adsorption–desorption isotherms and pore size distribution of the nano-catalyst based on zeolite (ZE) adjusted with Ag/CNT ornamented carbon paste electrode are displayed in Fig. 2A and B, respectively.

Under relatively low pressure (P/Po < 0.01), the adsorbed amount of N2 presented a vertical rise for all materials, signifying the existence of a signicant amount of micropores. Also, it is clear from increasing the mesoporous structure that there is accessible pathways for the diffusion and absorption of ions. Generally, the measured specific surface area using BET is found to be 139 m2 g-1 with an average pore size of 7 nm indicating the existence of a signicant amount of micropores. The higher specifc surface area measured in is attributed to the proper proportion of the micropore volume and mesopore volume41.

Electrocatalytic properties of SMWZCPE modified electrode

Figure 3 presents the CVs obtained at the bare carbon paste electrode in 0.5 M H2SO4 of pH 0.3 and modified electrode SMWZCPE in 0.5 M H2SO4 with and without 0.5 M propylene glycol at a scan rate of 100 mV·s-1. CV verified at the bare electrode seemed unremarkable indicated catalytic inactivity. However, the CVs of the modified electrode offered a developed electro-catalytic activity towards propylene oxidation. The oxidation of propylene at modified electrode reveals a reversible oxidation peak at 0.7 V and 0.38 V with a peak current ~ 50 times more than the bare one. This indicated that the electrocatalytic activity of the modified electrode surface can be improved upon addition of zeolite, silver nanoparticles to the carbon nanotube matrix where a large effective surface area was obtained inducing higher adsorptivity of propylene through active hydroxyl function group to the modified electrode surface.

The propylene glycol oxidation is suggested in Scheme 1 to be as follows:

As shown in Scheme 1, propylene glycol is simply oxidized to pyruvic acid (2-oxopropanoic acid) containing carbonyl and carboxylic groups. This acid is highly applicable for producing fine chemicals and pharmaceuticals, which can be acquired by propylene glycol oxidation42.

Electrochemical impedance spectroscopy technique is applied to examine the conductivity (catalytic activity) of the modified electrode towards propylene oxidation which is inversely proportional to the impedance. EIS scans distinguished at the peak potential 0.7 V for bare in 0.5 M H2SO4 and SMWZCPE electrode in 0.5 M H2SO4 with and without 0.5 M propylene glycol. Figure 4 as Nyquist plots showed a semi-circle links to a charge transfer resistance and a line links to a diffusion process at both high and low frequencies, respectively. The experimental results were fitted with one-time constant model (Fig. 4 inset) including Rs (solution resistance), R1 (charge transfer resistance), W (Warburg impedance linked to diffuesion prcess) and Q1 (constant phase element of capacitance). Constant phase element was attributed to microscopic roughness and surface heterogeneity43,44. Bare electrode show a large semicircle diameter than that of modified SMWZCPE electrode signifing that impedance reduced and conductivity upsurges. These results support well the high oxidation peak current acquired from CVs response for modified SMWZCPE electrode.

The impedance (ZCPE) of a constant phase element is:

where α is an exponent account for surface heterogeneity, 0 ≤ α ≤ 1, j is the imaginary number (j = (− 1)1/2), ω = 2πf is the angular frequency in rad/s, f is the frequency in Hz = S-145,46,47. The EIS outcomes have confirmed the conclusions drawn from the above cyclic voltammetry experiments. The outcomes of EIS analysis are listed in Table 2. The outecomes certified well CV data, where SMWZCPE electrode have the highest current and lowest impedance values.

Effect of carbon nanotube content

The loading of CNT into the catalyst ingredients has a substantial influence on the catalytic activity of the modified electerode towards propylene oxidation due to growth of surface area. Figure 5 displays the CVs respone for propylene oxidation on modified electrode SMWZCPE with various loading of CNT (10–40 mg) in 0.5 M H2SO4 at scan rate of 100 mV·s-1. The propylene oxidation is reliant on the loading amount of CNT and anodic peak current increase with the increase in CNT loading in the synthesized electrocatalyst (direct relationship). Also, the onset potential shifts to more negative values for the best performing. As clearly interpreted, the increase in anodic peak currents indicates a corresponding increase in avaliable active sites with higher adsorption extent for hydroxyl group, which required for propylene oxidation31,32,33.

Effect of scan rate

Effect of varying the potential scan rate (ν ranging from 10 to 400 mV·s-1) was performed on modified SMWZCPE electrode in 0.5 M H2SO4 in absence of propylene glycol to confirm the electrochemical activity of the catalyst in aqueous solution (Fig. 6). Increasing the scan rate resulted in higher anodic peak current density and positive shift occurs in the forward peak potential. A linear relationship between the anodic peak current and square root of the scan rate was gotten as shown in the inset of the figure, with the following equation:

The impact of the potential scan rate (ν ranging from 10 to 500 mV s−1) on the electrocatalytic anodic peak current of modified electrode SMWZCPE was also achieved in 0.5 M H2SO4 with 0.5 M propylene glycol and established in (Fig. 7). As the scan rate increases (10-500 mV s−1), the oxidation peak current amplified constantly and the peak potential moved positively. The plot of anodic peak current and square root of the scan rate (Inset B) leads to a linear relation: Ip (μA) = 91.22 + 2.77 ν 1/2 (mV s−1) (r2 = 0.9466), which approves that the oxidation process of propylene glycol is diffusion controlled mechanism with some adsorption phenomena48,49.

Effect of propylene glycol concentration

The synthesized electrode was applied to distinguish the impact of propylene concentration for fuel cells application. The oxidation of propylene in the range of 0.01 to 0.5 mol/L was considered on this electrode. Figure 8 shows the conductivity of this modified electrode for various propylene concentration from 0.01 to 0.5 mol/L by CVs at the scan rate of 50 mV s −1.

The propylene oxidation curves expose that anodic current peaks increase with expanding propylene concentration50,51. These obtained results confirm that our modified electrode SMWZCPE acts as an effective catalyst for the oxidation of propylene in 0.5 M H2SO4. Figure 8 inset demonstrates a linearity by:

It's suggested that the above relationship between Ip and [propylene] is owing to a diffusion-controlled mechanism.

Stability of SMWZCPE electrocatalyst

The stability of an electrocatalyst is an essential and evaluated by chronoamperomety. The chronoamperometric curves were obtained in the solution of 0.5 mol/L H2SO4 containing (0.01—0.5 mol/L ) propylene for 20 min at constant potential 0.7 V. Figure 9 demonstrates current—time relation for different concentrations of propylene glycol, in the first the modified electrode SMWZCPE reveals continous decay of anodic oxidation current and after ~ 2.5 min reached relatively stable value until the end of experiment (~ 20 min). This denotes good mechanical and electrocatalytic constancy of the modified electrode toward PG oxidation.

The comparison of current density for the electrochemical oxidation of different alcohols is given in Table 3 and it was found that our catalyst in this work gives the highest current density value in comparison to others as seen in the Table reaching to 0.135 mA cm2.

Finally, based on the obtained outcomes its confirm that SMWZCPE modified electrode shows good promises to improve the activity of oxidation reaction of propylene glycol in acidic medium fuel cells.

Conclusion

-

1.

A novel environmental nano-catalyst successfully constructed by modified carbon paste electrode with zeolite, carbon nanotube and silver nanoparticles .

-

2.

The characterization of the electrode SEM and EDX analysis shows that a well dispersed zeolite, CNT with the existence of silver nanoparticles occurs with a good percentage on the surface.

-

3.

Electrochemical measurements discovered the exceptional electrocatalytic activity of nano-catalyst for oxidizing propylene.

-

4.

Propylene oxidation progression was following diffusion – controlled process at electrocatalyst surface.

-

5.

Enhancing CNT content developed the attained anodic peak current until greatest performance at the electrocatalyst comprising 40 mg of CNT.

-

6.

The proposed SMWZCPE modified electrode shows acceptable stability towards propylene glycol oxidation.

References

Lin, Q., Wei, Y., Liu, W., Yu, Y. & Hu, J. Electrocatalytic oxidation of ethylene glycol and glycerol on nickel ion implanted-modified indium tin oxide electrode. Int. J. Hydrog. Energy 42, 1403–1411 (2017).

Stradiotto, N. R., Toghill, K. E., Xiao, L., Moshar, A. & Compton, R. G. The fabrication and characterization of a nickel nanoparticle modified boron doped diamond electrode for electrocatalysis of primary alcohol oxidation. Electroanal. Int. J. Devoted Fundam. Pract. Aspects Electroanal. 21, 2627–2633 (2009).

Wang, F. et al. Lignocellulosic biomass as sustainable feedstock and materials for power generation and energy storage. J. Energy Chem. 57, 247–280 (2021).

Boekaerts, B. & Sels, B. F. Catalytic advancements in carboxylic acid ketonization and its perspectives on biomass valorisation. Appl. Catal. B Environ. 283, 119607 (2021).

Tarrús, X., Montiel, M., Vallés, E. & Gómez, E. Electrocatalytic oxidation of methanol on CoNi electrodeposited materials. Int. J. Hydrog. Energy 39, 6705–6713 (2014).

Jung, H. J. et al. Enhanced catalytic dechlorination of 1, 2-dichlorobenzene using Ni/Pd bimetallic nanoparticles prepared by a pulsed laser ablation in liquid. Catalysts 8, 390 (2018).

Yu, Y., Wang, T., Fu, Y., Su, W. & Hu, J. Platinum nanoparticles ion-implanted-modified indium tin oxide electrode for electrocatalytic oxidation of formaldehyde. Int. J. Hydrog. Energy 39, 17617–17621 (2014).

Yu, Y., Jia, M., Tian, H. & Hu, J. The fabrication of silver ion implantation-modified electrode and its application in electrocatalytic oxidation of formaldehyde. J. Power Sources 267, 123–127 (2014).

Joo, J., Uchida, T., Cuesta, A., Koper, M. T. & Osawa, M. Importance of acid–base equilibrium in electrocatalytic oxidation of formic acid on platinum. J. Am. Chem. Soc. 135, 9991–9994 (2013).

Lamy, C., Belgsir, E. & Leger, J. Electrocatalytic oxidation of aliphatic alcohols: application to the direct alcohol fuel cell (DAFC). J. Appl. Electrochem. 31, 799–809 (2001).

Macak, J. et al. Self-organized nanotubular TiO2 matrix as support for dispersed Pt/Ru nanoparticles: Enhancement of the electrocatalytic oxidation of methanol. Electrochem. Commun. 7, 1417–1422 (2005).

Gao, G.-Y., Guo, D.-J. & Li, H.-L. Electrocatalytic oxidation of formaldehyde on palladium nanoparticles supported on multi-walled carbon nanotubes. J. Power Sources 162, 1094–1098 (2006).

Cao, H., Fan, Z., Hou, G., Tang, Y. & Zheng, G. Ball-flower-shaped Ni nanoparticles on Cu modified TiO2 nanotube arrays for electrocatalytic oxidation of methanol. Electrochim. Acta 125, 275–281 (2014).

Ramulifho, T., Ozoemena, K. I., Modibedi, R. M., Jafta, C. J. & Mathe, M. K. Electrocatalytic oxidation of ethylene glycol at palladium-bimetallic nanocatalysts (PdSn and PdNi) supported on sulfonate-functionalised multi-walled carbon nanotubes. J. Electroanal. Chem. 692, 26–30 (2013).

Xiong, W. et al. Fine cubic Cu2O nanocrystals as highly selective catalyst for propylene epoxidation with molecular oxygen. Nat. Commun. 12, 1–8 (2021).

Fernández, P. S., Martins, M. E. & Camara, G. A. New insights about the electro-oxidation of glycerol on platinum nanoparticles supported on multi-walled carbon nanotubes. Electrochim. Acta 66, 180–187 (2012).

Khatib, S. J. & Oyama, S. Direct oxidation of propylene to propylene oxide with molecular oxygen: a review. Catal. Rev. 57, 306–344 (2015).

Gomes, J. F., De Paula, F. B. C., Gasparotto, L. H. S. & Tremiliosi-Filho, G. The influence of the Pt crystalline surface orientation on the glycerol electro-oxidation in acidic media. Electrochim. Acta 76, 88–93 (2012).

Shelley, S. A renewable route to propylene glycol. Chem. Eng. Prog 103, 6–9 (2007).

Jeffery, D. Z. & Camara, G. A. The formation of carbon dioxide during glycerol electrooxidation in alkaline media: first spectroscopic evidences. Electrochem. Commun. 12, 1129–1132 (2010).

Sadiki, A. et al. Increased electrochemical oxidation rate of alcohols in alkaline media on palladium surfaces electrochemically modified by antimony, lead, and tin. Electrochim. Acta 139, 302–307 (2014).

Munoz, F. et al. Palladium–copper electrocatalyst for the promotion of the electrochemical oxidation of polyalcohol fuels in the alkaline direct alcohol fuel cell. Appl. Catal. B Environ. 174, 323–328 (2015).

Muneeb, O. et al. Electrochemical oxidation of polyalcohols in alkaline media on palladium catalysts promoted by the addition of copper. Electrochim. Acta 218, 133–139 (2016).

Muneeb, O. et al. Improved electrochemical oxidation of polyalcohols in alkaline media on palladium-nickel catalysts. Chem. 2, 9261–9266 (2017).

Gao, H., He, J.-B., Wang, Y. & Deng, N. Advantageous combination of solid carbon paste and a conducting polymer film as a support of platinum electrocatalyst for methanol fuel cell. J. Power Sources 205, 164–172 (2012).

Mikhailov, S. Physics and applications of graphene: Experiments, BoD–Books on Demand, (2011).

Guzsvány, V., Vajdle, O., Gurdeljević, M. & Kónya, Z. Ag or Au Nanoparticles decorated multiwalled carbon nanotubes coated carbon paste electrodes for amperometric determination of H 2 O 2. Top. Catal. 61, 1350–1361 (2018).

Xie, C., Upputuri, P. K., Zhen, X., Pramanik, M. & Pu, K. Self-quenched semiconducting polymer nanoparticles for amplified in vivo photoacoustic imaging. Biomaterials 119, 1–8 (2017).

Bedolla-Pantoja, M. Investigation of silver catalyst for propylene epoxidation: promotion and reaction mechanism, in University of Delaware (2010).

Pal, S. et al. Covalently connected carbon nanotubes as electrocatalysts for hydrogen evolution reaction through band engineering. ACS Catal. 7, 2676–2684 (2017).

Ali, A., Akyüz, D., Asghar, M. A., Koca, A. & Keskin, B. Free-standing carbon nanotubes as non-metal electrocatalyst for oxygen evolution reaction in water splitting. Int. J. Hydrog. Energy 43, 1123–1128 (2018).

Geng, X., Jing, J., Cen, Y., Datta, R., Liang, J. In situ synthesis and characterization of polyethyleneimine-modified carbon nanotubes supported PtRu electrocatalyst for methanol oxidation, J. Nanomater. 2015 (2015).

Ouyang, J. Applications of carbon nanotubes and graphene for third-generation solar cells and fuel cells, Nano. Mater. Sci. 1, 77–90 (2019).

Barakat, N., Alajami, M., Ghouri, Z. K., Al-Meer, S., CoNi nanoparticles/CNT composite as effective anode for direct urea fuel cells (2018).

Daas, B. M. & Ghosh, S. Fuel cell applications of chemically synthesized zeolite modified electrode (ZME) as catalyst for alcohol electro-oxidation-a review. J. Electroanal. Chem. 783, 308–315 (2016).

Vinodh, R. et al. Polyaniline–13X zeolite composite-supported platinum electrocatalysts for direct methanol fuel cell applications. Polym. Int. 68, 929–935 (2019).

Yao, J., Yao, Y., Mirzaii, H. Proton modified Pt zeolite fuel cell electrocatalysts, in Renewable Energy in the Service of Mankind Vol I, 173–182 (Springer, 2015).

Makertihartha, I., Zunita, M., Rizki, Z., Dharmawijaya, P. Recent advances on zeolite modification for direct alcohol fuel cells (DAFCs), in AIP Conference Proceedings, 020030 (AIP Publishing LLC, 2017).

Xiao, J. et al. Stable field emission from vertically oriented SiC nanoarrays. Nanomaterials 11, 3025 (2021).

Qi, J., Yan, Y., Cai, Y., Cao, J. & Feng, J. Nanoarchitectured design of vertical-standing arrays for supercapacitors: progress challenges, and perspectives. Adv. Funct. Mater. 31, 2006030 (2021).

Wang, Q., Qin, B., Zhang, X., Xie, X. & Cao, Q. Synthesis of N-doped carbon nanosheets with controllable porosity derived from bio-oil for high-performance supercapacitors. J. Mater. Chem. A 6, 19653–19663 (2018).

Torbina, V. V., Ivanchikova, I. D., Kholdeeva, O. A., Skobelev, I. Y. & Vodyankina, O. V. Propylene glycol oxidation with tert-butyl hydroperoxide over Cr-containing metal-organic frameworks MIL-101 and MIL-100. Catal. Today 278, 97–103 (2016).

Fekry, A. The influence of chloride and sulphate ions on the corrosion behavior of Ti and Ti-6Al-4V alloy in oxalic acid. Electrochim. Acta 54, 3480–3489 (2009).

Francis, A., Abdel-Gawad, S., Shoeib, M., Toward CNT-reinforced chitosan-based ceramic composite coatings on biodegradable magnesium for surgical implants, J. Coat. Technol. Res. 1–18 (2021).

Macdonald, D. D. Reflections on the history of electrochemical impedance spectroscopy. Electrochim. Acta 51, 1376–1388 (2006).

Fekry, A. Impedance and hydrogen evolution studies on magnesium alloy in oxalic acid solution containing different anions. Int. J. Hydrog. Energy 35, 12945–12951 (2010).

Gawad, S. A., Nasr, A., Fekry, A. M. & Filippov, L. O. Electrochemical and hydrogen evolution behaviour of a novel nano-cobalt/nano-chitosan composite coating on a surgical 316L stainless steel alloy as an implant. Int. J. Hydrog. Energy 46, 18233–18241 (2021).

Zhou, W., Du, Y., Zhang, H., Xu, J. & Yang, P. High efficient electrocatalytic oxidation of formic acid on Pt/polyindoles composite catalysts. Electrochim. Acta 55, 2911–2917 (2010).

Zhao, Y., Yang, X., Tian, J., Wang, F. & Zhan, L. Methanol electro-oxidation on Ni@ Pd core-shell nanoparticles supported on multi-walled carbon nanotubes in alkaline media. Int. J. Hydrog. Energy 35, 3249–3257 (2010).

Tammam, R., Fekry, A. & Saleh, M. Electrocatalytic oxidation of methanol on ordered binary catalyst of manganese and nickel oxide nanoparticles. Int. J. Hydrog. Energy 40, 275–283 (2015).

Tammam, R. H., Fekry, A. M. & Saleh, M. M. Enhanced oxygen evolution reaction over glassy carbon electrode modified with NiO x and Fe 3 O 4. Korean J. Chem. Eng. 36, 1932–1939 (2019).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

S.A.A.G. corresponding author, writing and reviewing A.M.F. Idea, practical work and reviewing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdel-Gawad, S.A., Fekry, A.M. A novel environmental nano-catalyst of zeolite amended with carbon nanotube/silver nanoparticles decorated carbon paste electrode for electro-oxidation of propylene glycol. Sci Rep 12, 9136 (2022). https://doi.org/10.1038/s41598-022-12268-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-12268-4

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.