Abstract

Bayesian inference and ultrasonic velocity have been used to estimate the self-association concentration of the asphaltenes in toluene using a changepoint regression model. The estimated values agree with the literature information and indicate that a lower abundance of the longer side-chains can cause an earlier onset of asphaltene self-association. Asphaltenes constitute the heaviest and most complicated fraction of crude petroleum and include a surface-active sub-fraction. When present above a critical concentration in pure solvent, asphaltene “monomers” self-associate and form nanoaggregates. Asphaltene nanoaggregates are thought to play a significant role during the remediation of petroleum spills and seeps. When mixed with water, petroleum becomes expensive to remove from the water column by conventional methods. The main reason of this difficulty is the presence of highly surface-active asphaltenes in petroleum. The nanoaggregates are thought to surround the water droplets, making the water-in-oil emulsions extremely stable. Due to their molecular complexity, modelling the self-association of the asphaltenes can be a very computationally-intensive task and has mostly been approached by molecular dynamic simulations. Our approach allows the use of literature and experimental data to estimate the nanoaggregation and its credible intervals. It has a low computational cost and can also be used for other analytical/experimental methods probing a changepoint in the molecular association behaviour.

Similar content being viewed by others

Introduction

Petroleum spills occur due to anthropogenic (as well as natural) phenomena, such as petroleum exploration, transportation and refining1,2,3. The long-term impacts to the ecosystem by oil spills are reviewed elsewhere4,5,6. Water-in-oil emulsions (WOE) form during petroleum spills as a result of petroleum mixing with sea water, whereby very little energy is required for emulsification to occur7. Such emulsions are very stable and problematic to remove due to their high viscosity and stability8, 9. The efficient removal of WOEs thus requires phase separation into water and oil phases. The WOE stability is a function of factors that include a high water content (30–90%)10, 11, water salinity12, 13 and pH14, 15.

Asphaltenes, and specifically the natural interfacially-active emulsifiers within them16, 17, have been extensively reported to be the main cause of the high WOE stability. The importance of waxes and the water droplet size distribution in increasing the viscosity of WOEs has also been reported numerously11, 18. Asphaltenes is a class of compounds that is operationally defined as soluble in toluene and insoluble in n-pentane or n-heptane19,20,21. The features of an asphaltene fraction, therefore, are defined by the precipitating solvent and can comprise a vast structural polydispersity19, 21, 22. A subfraction of the asphaltenes23, 24, that is reported to be more polar25, stabilises the WOEs by adsorbing at the water/oil interface forming rigid films resisting droplet coalescence12, 26, 27.

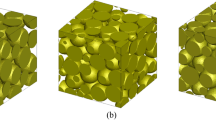

In understanding the asphaltene phase properties, the Yen-Mullins model20 is one of the most widely-accepted. It suggests that in low concentrations, asphaltenes in petroleum exist as monomers. As their concentration increases to the critical nanoaggregate concentration (CNAC) of 50–150 mg/L asphaltenes self-associate into nanoaggregates. Further, as their concentration reaches 2–3 g/L asphaltenes start forming clusters20. The surface-active asphaltenes self-associate at the nanoscale28 forming nanoaggregates, the latter were reported to form films that stabilise WOEs29,30,31. The nanoaggregates are ca. 3–10 nm in size, have an ellipsoidal shape and can entrap solvent within the aggregate interior32, 33. There are two primary forces governing nanoaggregation, attraction between the aromatic cores and repulsion from the aliphatic appendages20. We have previously suggested that the abundance of longer side-chains (\(\hbox {C}_{\ge 19}\)) contributes to a later onset of nanoaggregation34. Asphaltene nanoaggregates have been suggested to contribute to the stability of water-in-oil emulsions20, 35, 36. The asphaltenes’ nanoaggregate state at the water-oil interface has also been debated, proposing that molecules are in a monomeric37, 38 state or the observed film density is grater than that of the nanoaggregate (although the nanoaggregate thickness is preserved)16. A discussion about this and further literature review of asphaltene nanoaggregation is presented in Svalova et al.34. In what follows it is assumed that asphaltene nanoaggregates contribute to the WOE stability.

Asphaltene nanoaggregation is assumed to be the first stage of their self-association, which occurs at concentrations of ca. 100 mg/L (\(\pm 50\ \hbox {mg}/\hbox {L}\)) in toluene20, 39, 40, corresponding to the critical nanoaggregate concentration (CNAC)39. This concentration can be determined using conductivity41, centrifugation42, nuclear magnetic resonance43 and high-Q ultrasonic measurements39. We have used the latter technique to test the CNAC of four asphaltene samples34. At higher concentrations (g/L) asphaltene nanoaggregates start forming clusters corresponding to the critical cluster concentration.

The question of asphaltene self-association and aggregation has been approached by modelling methods mainly using molecular dynamics. Jiménez-Serratos et al.44 used coarse-grained molecular simulations and the statistical associating fluid theory equation of state45 to investigate the impact of asphaltene concentration, solvent composition and temperature on aggregation. Coarse-grained molecular simulations46 indicated an agreement with the Yen–Mullins hierarchy20 detecting nanoaggregation and clustering, whereby asphaltene nanoaggregates with long aliphatic appendages could not form clusters. The characterisation of different stages of asphaltene aggregation in heptane were studied by umbrella sampling of the potential mean force47. The results suggested that in small-scale systems the formation of nanoaggregates occurs in less than 10 ns, with 4–12 monomers per nanoaggregate. Nanoaggregate formation was also observed in a large-scale system47. In contrast, Headen et al.48 used molecular dynamics to suggest that the distribution of asphaltene aggregates is continuous in character.

To our knowledge, however, there has been little effort yet to address the uncertainty associated with asphaltene nanoaggregation concentration in a probabilistic manner. As experiments are often costly and/or time-consuming, replication is not possible which makes statistical inference difficult. The latter is, however, possible when a Bayesian approach is deployed which makes use of expert/literature information as well as experimental data. This study focuses on a novel application of Bayesian inference better estimating the CNAC nanoaggregation concentration and its credible region using ultrasonic characterisation39. Ultrasonic chracterisation data of four asphaltene samples E1–E434 will be used in this work.

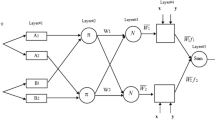

In what follows we model the asphaltene nanoaggregation concentration assuming a piecewise regression with a single changepoint. The latter is equivalent to the model by Zielinski et al.49 used in earlier studies34, 39 and the changepoint (further denoted \(\gamma\)) is equivalent to the CNAC. Bayesian inference will be used to estimate the \(\gamma\) mean and range as well as other model parameters using Markov chain Monte Carlo (MCMC) sampling. To avoid confusion, the asphaltene samples E1–E4 will be referred to as specimens and numerical values drawn by the MCMC algorithm will be referred to as samples. The Methods section describes our proposed model and the details of the sampling scheme. The section also refers to a synthetic study that we performed to verify the reliability of our sampler. The Results section illustrates illustrate the MCMC sampling outputs, including estimation of the posterior distribution of \(\gamma\). The Discussion section further explores the results and compares them with the structural properties of the asphaltenes34. The combination of the asphaltene structural properties and a probabilistic estimation of nanoaggregation could be very useful in petroleum spill remediation strategies. Finally, in the Conclusions section we summarise the study and outline further directions.

Methods

Specimen information and preparation

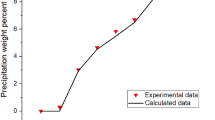

The asphaltenes were precipitated from four petroleum samples: E1 with E2 and E3 with E4 are from two different source rocks respectively and all are from different reservoirs. E1 and E2 are from South America and E3 with E4 are from North America. The asphaltene preparation procedures, including precipitation and purification, geochemical description of the samples and ultrasonic methodology can be found in our earlier study34. The Resoscan50 ultrasonic instrument was used for the asphaltenes’ characterisation, the measurements are illustrated in Fig. 134. Parent petroleum specimens were selected such that there are two specimens per source rock of difference degree of biodegradation. The specimens E1 (mildly biodegraded) with E2 (mildly-moderately biodegraded) and from E3 (highly biodegraded) with E4 (mildly-moderately biodegraded) are from two different source rocks respectively and all are from different reservoirs34. Noteworthy, there was significant noise in the data which we removed before modelling the data by analysing the outliers in the ultrasonic trace versus time. However diversions from the two-line model remain e.g. in the high-concentration tail of E3. These diversions may have been caused by the high molecular heterogeneity of the asphaltenes51, micro air bubbles52 or trace impurities. This is illustrated numerically in our synthetic data study where we emulate one of our specimens and a specimen from Andreatta et al.39 to validate our MCMC scheme. Bayesian inference can serve to remediate this as it combines expert opinion40 and experimental data to estimate the aggregation point. The synthetic data study also illustrates this as the aggregation point is recovered for both data sets.

Bayesian inference using Markov chain Monte Carlo sampling

This subsection provides an introduction to Bayesian inference and Markov chain Monte Carlo simulation which the familiar reader should feel free to skip.

In statistical modelling, we assume a process/experiment Y generating an outcome y that is governed by a model M and controlled by a collection of parameters (vector) \(\varvec{\theta }\). Statistical inference is carried out to infer/estimate \(\varvec{\theta }\), of which there are two main approaches: frequentist and Bayesian. The frequentist/classical approach is based on how the process would behave given a high number of repetitions n, and has been used in our previous analysis34. Often, however, experiments and/or events cannot be repeated (a meaningful number of times). The Bayesian approach53 is extremely useful in conditions of low/noisy data availability and will be used here.

Required in both approaches is the likelihood. To formulate the likelihood, it is assumed that Y follows some probability distribution (e.g. Gaussian) with a probability density function f, and the probability of \(Y=y\) under the model M controlled by \(\varvec{\theta }\) is expressed by \(f(y|\varvec{\theta })\) (M suppressed in notation). The likelihood function of \(\varvec{\theta }\) given data \(y=(y_1,y_2,\ldots ,y_n)\) is defined as the product of f over all data values of y, \(L(\varvec{\theta }|y)=\prod _{i=1}^nf(y_i|\varvec{\theta })\).

In the likelihood approach, L is maximised to obtain the maximum likelihood estimate (MLE) of \(\varvec{\theta }\) assuming M. This implies that the likelihood alone can be used to draw inference about \(\varvec{\theta }\) and whether M is suitable to model y. However, when n is small then the uncertainty around the MLE will be high. The Bayesian approach, on the other hand, allows the incorporation of expert/literature knowledge about \(\varvec{\theta }\), expressed in a probability distribution \(\pi (\varvec{\theta })\), called the prior belief/distribution. The goal of inference is then to obtain the conditional probability distribution of \(\varvec{\theta }\) given y. This distribution is also known as the posterior distribution, which is denoted by \(\pi (\varvec{\theta }|y)\) and obtained through the Bayes’ rule53:

Formalism (1) can also be interpreted as the combination of the likelihood \(L(\varvec{\theta }|y)\) and the expert knowledge \(\pi (\varvec{\theta })\). Except for the simplest statistical models, the integral \(\int \pi (\varvec{\theta } L(\varvec{\theta }|y)dy\) is usually analytically unavailable, thus making \(\pi (\varvec{\theta }|y)\) analytically unavailable too. Therefore, Bayesian inference usually resorts to computational methods, among which Markov chain Monte Carlo (MCMC)54 is the most popular.

The principle of MCMC is to provide random samples which represent/approximate the posterior distribution \(\pi (\varvec{\theta }|y)\), through an iterative algorithm54. Specifically, the random samples are generated according to a Markov chain, which is a stochastic process whereby the value (of \(\varvec{\theta })\) at state i only depends on the value at state \(i-1\). The burn-in54 is the initial period of the chain whereby extreme/implausible values are likely to be accepted, thus the burn-in is typically discarded from the posterior analysis. The algorithm should be run long enough to achieve convergence, i.e. the distribution \(\pi (\varvec{\theta }|y)\) approximated by the samples does not change with the new samples54. To find a reliable posterior estimate of \(\varvec{\theta }\) it is essential that the Markov chain explores the space of \(\varvec{\theta }\) efficiently. Posterior trace plots e.g. Fig. 2, where the samples are well-spread and appear uncorrelated with past values are an indication of high sampling efficiency. The effective sample size (ESS)55, e.g. Table 2, can also be used as a diagnostic whereby an ESS that is as high as the number of iterations imply maximum efficiency and an absence of autocorrelation between the samples.

The density plots e.g. Fig. 3 and scatter plots e.g. Fig. 4 of the sampled values illustrate the posterior distribution \(\pi (\varvec{\theta }|y)\), as well as how it differs to the prior beliefs. Using the MCMC samples that represent \(\pi (\varvec{\theta }|y)\), we can obtain the posterior predictive distribution56 of a quantity of interest \(\tilde{y}\):

This is how the posterior predictive intervals in Fig. 5 are obtained.

In the next section, we will specify \(\varvec{\theta }\) and y in the context of a single changepoint model for the nanoaggregation of the asphaltenes. In the Prior elicitation and posterior inference section, we will elicit the prior distributions \(\pi (\varvec{\theta })\) and specify the details of MCMC, when inferring the parameters of the changepoint model using the Bayesian approach.

Single changepoint model

Nanoaggregation of the asphaltenes may be detected by ultrasonic velocity measurements using theory of surface-active compound (surfactant) aggregation39, 49. Within a uniform liquid, the ultrasonic velocity u is related to density \(\rho\) and adiabatic compressibility \(\beta\) of the medium according to the Urick equation57

For multi-phase fluids which are well-dispersed, and ignoring the effects of sound scattering (valid for sufficiently low concentration of scatterers and away from scattering resonances)52, Equation (3) can be applied with density and compressibility represented by weighted averages of the mixture components. An extension of Equation (3) allows to detect the onset of surfactant aggregation into micelles to detect the critical micelle concentration, as proposed by Zielinski et al.49, where the full model derivation is given. Without loss of generality, we present the Zielinski et al.49 model in the context of the asphaltene critical nanoaggregation concentration (CNAC) only. In particular, the sound velocity u is related to apparent molar solution quantities following the relation

where v denotes specific volume, c- weight concentration, tilde- apparent quantities and subscripts refer to solvent (0), monomer (1) and aggregated (a) quantities. Also,

The model (4) implies that pre- and post-aggregation, sonic velocity is related to surfactant concentration as a combination of two linear behaviours whose intersection estimates the CNAC.

Formalism (4) can be estimated by a single-changepoint linear regression model, where the speed of sound y varies with asphaltene concentration x as follows.

where \(i=1,2,\ldots ,n\) denotes the sample index, n denotes the total number of measurements, \(\varepsilon _{j,i},\, j=1,2\) refers to random errors that follow a Normal distribution with mean 0 and precision \(\tau _j\), subscripts refer to the monomeric (\(j=1\)) and aggregated (\(j=2\)) concentrations respectively. Given that Model (M0) requires that the two regression lines intersect at \(x=\gamma\), there is an identifiability issue with the quintuplet \(\{\alpha _1,\alpha _2,\beta _1,\beta _2,\gamma \}\) as any of the parameters can be defined as a combination of the remaining four. We set \(\alpha _2=\alpha + (\beta _1-\beta _2)\gamma\), \(\alpha =\alpha _1\) and further use the formalism

In M1, \(\gamma\) denotes the changepoint (equivalent to CNAC). Note that \(\alpha\) corresponds to the speed of sound in pure solvent (toluene). Let \(\theta =(\alpha ,\beta _1,\beta _2,\gamma , \sigma _1,\sigma _2)\) and the likelihood for M1 is as follows:

In the above, \(n_1\) denotes the size of \(\{x \ni x_i <\gamma ,i=1,2,\ldots n_1 \}\) and n is the total number of measurements (sample size).

Prior elicitation and posterior inference

The prior distributions \(\pi (\theta )\) for the model parameters \(\theta\) were elicited using the information in39 summarised in Table 1. This data can be used to define prior distribution means.

Noteworthy, the values of \(\beta _1\) and \(\beta _2\) are multiplied by a factor of \(10^{-3}\) as our concentration values are in mg/L rather than in g/L as in39. Also note that \(\alpha\) is equivalent to the speed of sound in pure toluene/solvent measured by a specific instrument. We suggest that if the information on the speed of sound in toluene is available for a given instrument then that information is used for the prior mean of \(\alpha\) is used instead of that in Table 1.

Prior/expert distributions are chosen to allow conditional posterior distributions to be analytically available where possible:

where N and Ga denote normal and Gamma distributions respectively. The prior mean and standard deviation of \(\gamma\) (equivalent to the CNAC) are elicited from literature20. The mean of the \(\alpha\) is set at the mean speed of sound in toluene by using our ultrasonic instrument34. All the parameters apart from \(\gamma\) can be sampled from their conditional posterior distributions using a Gibbs step54, details of which can be found in the Supplementary Information (Equations (S1–S5)). The conditional posterior distribution of \(\gamma\) is not analytically available thus will be sampled using a Metropolis54 update. The MCMC sampler was written in R statistical software58 and C++ through the Rcpp package59.

We carried out a study (Supplementary Information) on synthetic data designed to emulate the UG8 asphaltene by Andreatta et al.39 and our E2 specimen. Noteworthy, the precision value to emulate the E2 specimen was found to be two orders of magnitude lower than that of UG8, Figure S1. In other words, the synthetic data study illustrated that there is significant noise in our data compared to that of39. The synthetic study included testing the impact of prior mean misspecification on the posterior estimation of \(\alpha\). We used the mean speed of sound in toluene for our samples (1304.6 m/s) as the prior mean, which is 2.5 m/s different do that in UG8. As asphaltene ultrasonic characterisation within a concentration range of 0–2000 mg/L corresponds to a velocity range size of less than 0.1 m/s, the said difference of 2.5 m/s is twenty-five times a typical velocity measurement range. Despite this, our sampling scheme correctly recovered the true value of \(\alpha\) for both data sets.

The chain mixing was very efficient for all parameters (Figure S2), and all posterior densities illustrate a single mode (Figure S3). The only exception is the posterior distribution of the synthetic E2 for \(\gamma\) which has a number of closely-distributed local peaks. This might be related to the compartmentalisation of the model posterior mode around specimen data in conditions of noise, Figure S4. As the amount of prior information for the regression coefficients is low, we chose very flat (high variance) prior distributions of monomeric and aggregated regression precisions. The synthetic study illustrated that this prior distribution allows to recover true precision values with a difference of two orders of magnitude. The posterior predictive regions for both specimens are illustrated in Figure S5 where the 95% regions reflect the magnitude of noise/uncertainty associated with each of the specimens.

Results

A Metropolis-within-Gibbs MCMC scheme54 based on Equations (S1)–(S5) was used to sample the joint posterior distribution of the regression coefficients and the changepoint \(\gamma\). The scheme was run for a burn-in period of \(10^{6}\) iterations54, after which \(4\times 10^{4}\) samples were obtained after thinning by 100. An exception is the E4 specimen which was thinned by 1000 due to extremely poor mixing and high autocorrelation. In particular, the effective sample size (ESS)55, 60, 61 of \(\alpha\) was c.a. 150. In comparison, given totally uncorrelated sample the ESS should be very close to the MCMC chain length. Figure 2 illustrates the mixing for the changepoint \(\gamma\) for all specimens. Good mixing can be observed in all cases and the sample space is sufficiently explored. Mixing plots for the remaining parameters can be found in Supplementary Information (Figure S6), where mixing is good in all cases except for \(\tau _1\) of E3. In the latter, the sampler is exploring the extreme range of \(\tau _1\) potentially caused by the high noise in the monomeric regression region. The ESS of the thinned MCMC runs is greater than 1300 for all parameters which is also satisfactory, as in Table 2. The largest ESS can are observed for \(\beta _2\), \(\tau _1\) and \(\tau _2\) which indicates that these parameters have the lowest posterior autocorrelation and most efficient exploration of the sample space. The specimen E4 appears to have the lowest ESS for most parameters even after thinning by 1000. This reflects a very high autocorrelation and potentially a substantial uncertainty in the estimation of \(\gamma\).

Figure 3 illustrates the density plots of parameter posterior distributions. In regards to the model parameters other than \(\gamma\), the specimens E1 and E3 have unimodal posterior distributions for most of the parameters. Conversely, E2 and E4 illustrate posterior multimodality for most parameters although their global posterior modes are still well-defined. The posterior distributions for \(\tau _1\) are extremely heavy-tailed, their separate density plots are in Supplementary Information Figure S7. Despite having the smallest posterior mean, E3 has the longest tail of \(\tau _1\) posterior in relation to other specimens perhaps indicating that the presence of noisy measurements led to the acceptance of extreme proposed \(\tau _1\) values. The specimen E4 has a multimodal distribution of \(\tau _1\) with the global mode of ca. \(6\times 10^{4}\) which is similar to E1 and E2. The posterior variance is much smaller than that of the prior for \(\alpha ,\beta _1\) and \(\beta _2\) and is somewhat smaller for \(\tau _1\) and \(\tau _2\) across all of the specimens.

The specimen split between posterior uni-/bimodality of the regression parameters is likely to be related to the accepted values of \(\gamma\). Plot (f) illustrates that E1 and E3 have very strongly-defined posterior modes of \(\gamma\) with smaller local modes around the lower end of the concentration range. The posterior \(\gamma\) density of E2 has a strong global mode, however the mode around 50 mg/L also has a high proportion of posterior density. Similarly, the posterior \(\gamma\) density of E4 has a global mode around 45 mg/L with strong peaks around 120 and 150 mg/L. The latter phenomenon can be attributed to the compartmentalisation of the posterior density around the specimen data which results in one/several regions where an intersection of two regressions is likely. This gives rise in bimodality of the posterior distributions of the remaining regression parameters. To illustrate this, Fig. 4 shows the sampled posterior log-density, \(\log \pi (\theta |y)\), versus the sampled values of \(\gamma\). For E1 and E3 \(\log \pi (\theta |y)\) peaks around the posterior mean of \(\gamma\). For E2, the \(\log \pi (\theta |y)\) is near the posterior mean, however for E4 it does not correspond to a global peak but rather is a ‘weighted average’ of the local peaks corresponding to density peaks in Fig. 3(f). It might be advantageous to retake the E4 specimen measurement in order to obtain a more conclusive estimate of \(\gamma\), which would be a focus of a follow-up investigation.

Discussion

Bayesian inference and MCMC sampling of the posterior distribution can be very useful in the conditions of sparse and noisy data. Figure 5 illustrates the posterior estimation of the changepoint \(\gamma\) of the four asphaltene specimens, as well as Bayesian credible intervals61. It is clear that our measurements have a greater noise that those reported by e.g. Andreatta et al.39 and the use of Bayesian inference has allowed us to estimate the \(\gamma\) value as well as the uncertainty region for the entire changepoint model. Note that every data point in Fig. 1 is an average over up to 100 measurements over time. The variation of the ultrasound speed across these measurements is small relative to the overall trend. In our previous study34 we have illustrated using pure surfactant solutions that the Resoscan instrument can detect molecular self-association at a similar scale to the asphaltenes. Thus, we infer that the fluctuations in the ultrasound velocity versus concentration for asphaltenes are mainly caused by the physico-chemical properties of the sample.

The changepoint \(\gamma\) posterior mean values for E2 and E3 are close to the prior means of 100 mg/L. In contrast, E1 and E4 have posterior means at 78 and 73 mg/L respectively. Also, E4 has the widest 95% confidence interval for \(\gamma\) which illustrates the impact of \(\log \pi (\theta |y)\) multimodality (Fig. 4). The shaded confidence regions reflect the estimation of the posterior mean of the regression parameters \(\alpha , \beta _1\) and \(\beta _2\). For E3, the velocity range spans ca. 0.5 m/s which is the largest interval of all the specimens, reflecting the largest posterior variance (Fig. 3a–c). The obtained confidence intervals are consistent with the previous literature findings20. For all of the specimens, one point or less lie outside the credible intervals which is consistent with a 5% outlier rate.

Noteworthy, the behaviour of E1 is different to the remaining samples in that the velocity gradient is increasing in the monomeric region as opposed to vice versa in the remaining samples. The gradients in Fig. 5 are controlled by a complex relation between apparent molar quantities, including compressibility and volume (Eq. 3). For example, one of the reasons of the ultrasonic gradient on the monomeric region to be negative is for the apparent compressibility of the monomeric asphaltene to be more than twice that of the solvent. Understanding the cause for this phenomenon is beyond the scope of this work and should be addressed in future studies.

The estimated changepoint values are similar to those we reported using non-Bayesian methods34. In the latter study, the architecture of the asphaltenes was linked to their aggregation behaviour by considering the abundance of the long side-chains (\(\hbox {C}_{\ge 19}\)). As steric repulsion is assumed to arise from the n-alkane appendages20, it is reasonable to suggest that the longer moieties complicate/delay nanoaggregation more than the shorter ones. The relation between the abundance of side-chains and complexity in aggregation has been studied earlier in e.g. Wang et al.62. In our earlier study, side-chains have been obtained by mineralising the aromatic cores and releasing the aliphatic appendages using ruthenium ion catalysed oxidation (RICO)63, 64. Asphaltene side-chains are released as n-alkanoic fatty acid methyl esters which are the dominant products, and are also extremely volatile. Also, the reaction produces a significant amount of di-alkanoic fatty acid di-methyl esters and other products which can interfere with the main peaks of interest63, 65. Therefore, the results of RICO should be used as indicative. The specimens E1–E4 were reported to have 14%, 21%, 18% and 11% of long n-alkanoic side-chains respectively.

Comparing to the present study, the the relative abundance of the long side-chains is linearly related to \(\gamma\). In particular, E2 has the largest posterior \(\gamma\) mean as well as the greatest abundance of the long side-chains, followed by E3, E1 and E4. This in turn would support the steric hindrance argument. Although this relation is reasonable and exciting, we have illustrated the difficulties in estimating the posterior \(\gamma\) for E4. Therefore, the link between the changepoint concentration and the abundance of long side-chains should serve as an an indication of a relation and be tested in subsequent studies. Nonetheless, the combined use of the asphaltene structural properties and the probabilistic modelling of their changepoint have the potential to be powerful in oil spill remediation strategies.

Conclusions

Asphaltene nanoaggregation ultrasonic characterisation data has been studied using Bayesian inference to produce an estimation of the critical nanoaggregation concentration20, 39, herein referred to the changepoint \(\gamma\). This is a novel application in the field of the asphaltenes and is superior to the frequentist methods as the uncertainty associated with the aggregation concentration, as well as model parameters, can be quantified. The use of Bayesian inference has allowed to incorporate the literature information about asphaltene \(\gamma\), thus helping to navigate through the noise in the measurements. The \(\gamma\) estimation of the four samples indicated values consistent with literature, although an earlier onset of aggregation has also been suggested linked to a lower abundance of the longer aliphatic appendages. Despite the noise in the data, the Bayesian sampling scheme was able to recover the regression behaviour and estimate the \(\gamma\) and it’s confidence intervals for all of the specimens. This illustrates that the combined of prior information and experimental data likelihood is extremely useful in conditions of data sparsity and noise.

Given an appropriate prior distribution specification our model can be applied to any asphaltene characterisation data that is assumed to follow a changepoint regression behaviour and has uncertainty, such as calorimetry19, 66 and nuclear magnetic resonance67. The computational burden of the proposed sampling scheme is very low and can be run within minutes.

Further developments of this work include a hierarchical Bayesian structure of the single-changepoint model that would allow to estimate the regression coefficients by borrowing strength from all of the specimens/pooling the data. A two-changepoint model may also be proposed to estimate the \(\gamma\) whereby the region of aggregation is modelled by an appropriate stochastic process. The latter which would allow a more flexible structure for a process combining monomeric and aggregated behaviours if the complexity of the asphaltene monomers22 is too high for the model by Zielinski et al. to be appropriate. Additional geochemical investigations can also complement the current study, for example further understanding the composition and architecture of the aliphatic moieties of the asphaltenes through elemental analysis.

Data availability

The data sets used in this study are available from Newcastle University Research Data Repository https://doi.org/10.25405/data.ncl.14206862.v1. Computer algorithms and further information can be obtained from the corresponding author on reasonable request.

References

Zhang, Z. et al. Degradation of n-alkanes and polycyclic aromatic hydrocarbons in petroleum by a newly isolated Pseudomonas aeruginosa DQ8. Biores. Technol. 102, 4111–4116 (2011).

Sobrinho, H. B., Luna, J. M., Rufino, R. D., Porto, A. F. & Sarubbo, L. A. Biosurfactants: classification, properties and environmental applications. Recent Dev. Biotechnol. 11, 1–29 (2013).

Souza, E. C., Vessoni-Penna, T. C. & Souza Oliveira, R. P. Biosurfactant-enhanced hydrocarbon bioremediation: an overview. Int. Biodeterior. Biodegrad. 89, 88–94 (2014).

Piatt, J. F., Lensink, C. J., Butler, W., Kendziorek, M. & Nysewander, D. R. Immediate impact of the ‘Exxon Valdez’ oil spill on marine birds. Auk 107, 387–397 (1990).

Peterson, C. H. et al. Long-term ecosystem response to the Exxon Valdez Oil Spill. Science 302, 2082–2086 (2003).

Loughlin, T. R. Marine mammals and the Exxon Valdez (Academic Press, Cambridge, 2013).

Berridge, S. A., Thew, M. T. & Loriston-Clarke, A. G. The formation and stability of emulsions of water in crude petroleum and similar stocks. J. Inst. Pet. 54, 333–357 (1968).

Sjoblom, J. et al. Our current understanding of water-in-crude oil emulsions. Recent characterization techniques and high pressure performance. Adv. Colloid Interface Sci. 100–102, 399–473 (2003).

Dicharry, C., Arla, D., Sinquin, A., Gracia, A. & Bouriat, P. Stability of water/crude oil emulsions based on interfacial dilatational rheology. J. Colloid Interface Sci. 297, 785–791 (2006).

Bridie, A. J., Wanders, T. H. W., Zegveld, W. & Van Der Heijde, H. B. Formation, prevention and breaking of sea water in crude oil emulsions chocolate mousses. Mar. Pollut. Bull. 11, 343–348 (1980).

Lee, R. F. Agents which promote and stabilize water-in-oil emulsions. Spill Sci. Technol. Bull. 5, 117–126 (1999).

Gafonova, O. V. & Yarranton, H. W. The stabilization of water-in-hydrocarbon emulsions by asphaltenes and resins. J. Colloid Interface Sci. 241, 469–478 (2001).

Alves, D. R. et al. Influence of the salinity on the interfacial properties of a Brazilian crude oil-brine systems. Fuel 118, 21–26 (2014).

Kokal, S. Crude-oil emulsions: a state-of-the-art review. SPE Prod. Facil. 20, 5–13 (2005).

Elsharkawy, A. M., Yarranton, H. W., Al-sahhaf, T. & Fahim, M. Water in crude oil emulsions in the Burgan oilfield: effects of oil aromaticity, resins to asphaltenes content (R/(R+A)), and water pH. J. Dispers. Sci. Technol. 29, 224–229 (2008).

Kilpatrick, P. K. Water-in-crude oil emulsion stabilization: review and unanswered questions. Energy Fuels 26, 4017–4026 (2012).

Rocha, J. A. et al. Role of aqueous phase chemistry, interfacial film properties, and surface coverage in stabilizing water-in-bitumen emulsions. Energy Fuels 30, 5240–5252 (2016).

Thompson, D. G., Taylor, A. S. & Graham, D. E. Emulsification and demulsification related to crude oil production. Colloids Surf. 15, 175–189 (1985).

Andersen, S. I. & Birdi, K. S. Aggregation of asphaltenes as determined by calorimetry. J. Colloid Interface Sci. 142, 497–502 (1991).

Mullins, O. C. The asphaltenes. Ann. Rev. Anal. Chem. 4, 393–418 (2011).

Sjoblom, J., Simon, S. & Xu, Z. Model molecules mimicking asphaltenes. Adv. Colloid Interface Sci. 218, 1–16 (2015).

Schuler, B. et al. Heavy oil based mixtures of different origins and treatments studied by atomic force microscopy. Energy Fuels 31, 6856–6861 (2017).

Stanford, L. A., Rodgers, R. P., Marshall, A. G., Czarnecki, J. & Wu, X. A. Compositional characterization of bitumen/water emulsion films by negative- and positive-ion electrospray ionization and fielddesorption/ionization Fourier transform ion cyclotron resonance mass spectrometry. Energy Fuels 21, 963–972 (2007).

Czarnecki, J. Stabilization of water in crude oil emulsions. Part 2. Energy Fuels 23, 1253–1257 (2009).

Gawrys, K. L., Blankenship, G. A. & Kilpatrick, P. K. On the distribution of chemical properties and aggregation of solubility fractions in asphaltenes. Energy Fuels 20, 705–714 (2005).

McLean, J. D. & Kilpatrick, P. K. Effects of asphaltene aggregation in model heptane-toluene mixtures on stability of water-in-oil emulsions. J. Colloid Interface Sci. 196, 56–59 (1997).

Pauchard, V., Rane, J. P. & Banerjee, S. Asphaltene-laden interfaces form soft glassy layers in contraction experiments: a mechanism for coalescence blocking. Langmuir 30, 12795–12803 (2014).

Barre, L., Jestin, J., Morisset, A., Palermo, T. & Simon, S. Relation between nanoscale structure of asphaltene aggregates and their macroscopic solution properties. Oil Gas Sci. Technol. 64, 617–628 (2009).

Jestin, J., Simon, S., Zupancic, L. & Barre, L. A small angle neutron scattering study of the adsorbed asphaltene layer in water-inhydrocarbon emulsions: structural description related to stability. Langmuir 23, 10471–10478 (2007).

Verruto, V. & Kilpatrick, P. K. Water-in-model oil emulsions studied by small-angle neutron scattering: interfacial thickness and composition. Langmuir 24, 12807–12822 (2008).

Alvarez, G., Jestin, J., Argillier, J. F. & Langevin, D. Small-angle neuron scattering study of crude oil emulsions: structure of the oil-water interface. Langmuir 25, 3985–3990 (2009).

Sirota, E. B. & Lin, M. Y. Physical behavior of asphaltenes. Energy Fuels 21, 2809–2815 (2007).

Eyssautier, J. et al. Insight into asphaltene nanoaggregate structure inferred by small angle neutron and X-ray scattering. J. Phys. Chem. 115, 6827–6837 (2011).

Svalova, A., Parker, N. G., Povey, M. J. W. & Abbott, G. D. Determination of asphaltene critical nanoaggregate concentration region using ultrasound velocity measurements. Scientific Reports 7, 1–11 (2017).

Fan, Y., Simon, S. & Sjöblom, J. Interfacial shear rheology of asphaltenes at oil-water interface and its relation to emulsion stability: influence of concentration, solvent aromaticity and nonionic surfactants. Colloids Surf. A 366, 120–128 (2010).

Masliyah, J. H., Xu, Z. & Czarnecki, J. A. Handbook on Theory and Practice of Bitumen Recovery from Anthabasca Oil Sands. Theoretical Basis Vol. 1 (Kingsley Knowledge Publications, Cochrane, 2011).

Rane, J. P., Pauchard, V., Couzis, A. & Banjaree, S. Interfacial rheology of asphaltenes at oil-water interface and interpretation of the equation of state. Langmuir 29, 4750–4759 (2013).

Rane, J. P. et al. Applicability of the Langmuir equation of state for asphaltene adsorption at the oil-water interface: coal-derived, petroleum, and synthetic asphaltenes. Energy Fuels 29, 3584–3590 (2015).

Andreatta, G., Bostrom, N. & Mullins, O. C. High-Q ultrasonic determination of the critical nanoaggregate concentration of asphaltenes and the critical micelle concentration of standard surfactants. Langmuir 21, 2728–2736 (2005).

Mullins, O. C. et al. Advances in asphaltene science and the Yen–Mullins model. Energy Fuel 26, 3986–4003 (2012).

Zeng, H., Song, Y. Q., Johnson, D. L. & Mullins, O. C. Critical nanoaggregate concentration of asphaltenes by low frequency conductivity. Energy Fuels 23, 1201–1208 (2009).

Mostowfi, F., Indo, K., Mullins, O. C. & McFarlane, R. Asphaltene nanoaggregates studied by centrifugation. Energy Fuels 23, 1194–1200 (2009).

Freed, D. E., Lisitza, N. V., Sen, P. N. & Song, Y. Q. A study of asphaltene nanoaggregation by NMR. Energy Fuels 23, 1189–1193 (2009).

Giménez-Serratos, G., Totton, T. S., Jackson, G. & Müller, E. A. Aggregaton behaviour of model asphaltenes revealed from large-scale coarse-grained molecular simulations. J. Phys. Chem. B 123, 2380–2396 (2019).

Müller, E. A. & Mejía, A. Extension of the saft-vr mie eos to model homonuclear rings and its parametrization based on the principle of corresponding states. Langmuir 33, 11518–11529 (2017).

Wang, J. & Ferguson, A. L. Mesoscale simulation of asphaltene aggregation. J. Phys. Chem. B 120, 8016–8035 (2016).

Aminzadeh, R., Nikazar, M. & Dabir, B. Determining the occurrence time of different stages of asphaltene aggregation using molecular dynamic simulations. Pet. Sci. Technol. 37, 2101–2107 (2019).

Headen, T. F., Boek, E. S., Jackson, G., Totton, T. S. & Müller, E. A. Simulation of asphaltene aggregation through molecular dynamics: insights and limitations. Energy Fuels 31, 1108–1125 (2017).

Zielinski, R., Ikeda, S., Nomura, H. & Kato, S. Adiabatic compressibility of alkyltrimethylammonium bromides in aqueous solutions. J. Colloid Interface Sci. 119, 398–408 (1986).

TF Instruments. \(\mathit{Resoscan}^{{\rm TM}}\)- System Operations Manual. TF Instruments GmbH (2007).

Schuler, B. et al. Supplementary information: heavy oil based mixtures of different origins and treatments studied by afm. Energy Fuels 31, S1–S25 (2017).

Povey, M. J. W. Ultrasonic Techniques for Fluids Characterisation, Water 11–45 (Academic Press, Berkeley, 1997).

Lee, P. M. Bayesian Statistics: An Introduction 4th edn. (Wiley, Chichester, 2012).

Brooks, S., Gelman, A., Jones, G. L. & Meng, X.-L. Handbook of Markov Chain Monte Carlo (Chapman & Hall/CRC, Boston, 2010).

Martino, L., Elvira, V. & Louzada, F. Effective sample size for importance sampling based on discrepancy measures. Signal Process. 131, 386–401 (2017).

Farah, M. & Kottas, A. Bayesian inference for sensitivity analysis of computer simulations, with an application to radiative transfer models. Technometrics 56, 159–173 (2014).

Urick, J. R. A sound velocity method for determining the compressibility of finely divided substances. J. Appl. Phys. 18, 983–987 (1947).

R Core Team. R: A Language and Environment for Statistical Computing (R Foundation for Statistical Computing, Vienna, 2019).

Eddelbuttel, D. & Francois, R. Rcpp: seamless R and C\(++\) integration. J. Stat. Comput. 40, 1–18 (2011).

Priestley, M. B. M. B. Spectral Analysis and Time Series. Probability and Mathematical Statistics (Academic Press, London, 1981).

Gamerman, D. & Lopes, H. F. Gibbs Sampling 2nd edn. (Taylor & Francis, Boca Raton, 2006).

Wang, W. et al. Nanoaggregates of diverse asphaltenes by mass spectrometry and molecular dynamics. Energy Fuels 31, 9140–9151 (2017).

Peng, P., Fu, J. & Sheng, G. Ruthenium-ions-catalyzed oxidation of an immature asphaltene: structural features and biomarker distribution. Energy Fuels 13, 266–277 (1999).

Alboudwarej, H., Beck, J., Svrcek, W. & Yarranton, H. Sensitivity of asphaltene properties to separation techniques. Energy Fuels 16, 462–469 (2002).

Ma, A., Shuichang, Z. & Zhang, D. Ruthenium-ion-catalyzed oxidation of asphaltenes of heavy oils in Lunnan and Tahe oilfields in Tarim Basin, NW China. Org. Geochem. 39, 1502–1511 (2008).

Andersen, S. I. & Christensen, S. D. The critical micelle concentration of asphaltenes as measured by calorimetry. Energy Fuels 14, 38–42 (2000).

Lisitza, N. V., Freed, D. E., Sen, P. N. & Song, Y.-Q. Study of asphaltene nanoaggregation by nuclear magnetic resonance (NMR). Energy Fuels 23, 1189–1193 (2009).

Acknowledgements

The study in this manuscript contains work conducted during a PhD study undertaken as part of the Natural Environment Research Council (NERC) Centre for Doctoral Training (CDT) in Oil and Gas (Grant Number NE/M00578X/1), the British Geological Survey (BGS) via the British University Funding Initiative (BUFI) and Newcastle University whose support is gratefully acknowledged. The authors acknowledge support from EPSRC grant “Ultrasonic propagation in complex media: correlated spatial distributions and multiple dispersed phases” (University of Leeds EPSRC EP/M026310/1) which supported the Resoscan and associated laboratory infrastructure. The authors thank Melvin Holmes (University of Leeds) and David Earley, Paul Donohoe and Berni Bowler (Newcastle University) who provided technical support during experimental work involved in this study.

Author information

Authors and Affiliations

Contributions

A.S. performed the geochemical and ultrasonic asphaltene experiments, developed the initial versions of the statistical algorithms and wrote the manuscript. D.W. assisted with inference of the statistical algorithms and interpretation of the results. C.L. developed the later and final versions of the statistical algorithms and assisted with statistical inference and interpretation of the results. V.D. conceived the idea of a Bayesian version of the changepoint model and assisted with statistical inference and interpretation of the results. N.G.P. assisted with the planning of the ultrasonic experiments and interpretation of their results. M.J.P. provided access to the ultrasonic analytical facilities and assisted with the interpretation of the related results. G.D.A. assisted with planning and interpretation of the ultrasonic and geochemical experiments. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Svalova, A., Walshaw, D., Lee, C. et al. Estimating the asphaltene critical nanoaggregation concentration region using ultrasonic measurements and Bayesian inference. Sci Rep 11, 6698 (2021). https://doi.org/10.1038/s41598-021-85926-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-85926-8

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.